CN102706407A - Microwave transmission device and fill level measuring device - Google Patents

Microwave transmission device and fill level measuring deviceDownload PDFInfo

- Publication number

- CN102706407A CN102706407ACN2012100968507ACN201210096850ACN102706407ACN 102706407 ACN102706407 ACN 102706407ACN 2012100968507 ACN2012100968507 ACN 2012100968507ACN 201210096850 ACN201210096850 ACN 201210096850ACN 102706407 ACN102706407 ACN 102706407A

- Authority

- CN

- China

- Prior art keywords

- microwave

- waveguide

- measuring device

- potting

- microwave transmitter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000005540biological transmissionEffects0.000titleclaimsdescription6

- 238000004382pottingMethods0.000claimsabstractdescription49

- 238000005538encapsulationMethods0.000claimsabstractdescription11

- 238000000034methodMethods0.000claimsdescription22

- 239000011521glassSubstances0.000claimsdescription15

- 239000000463materialSubstances0.000claimsdescription15

- 238000005266castingMethods0.000claimsdescription7

- 239000002184metalSubstances0.000claimsdescription6

- 229910052751metalInorganic materials0.000claimsdescription6

- 239000006060molten glassSubstances0.000claims1

- 150000001875compoundsChemical class0.000abstractdescription15

- 230000005855radiationEffects0.000description14

- 238000004880explosionMethods0.000description7

- 238000012545processingMethods0.000description6

- 239000002360explosiveSubstances0.000description5

- 238000011161developmentMethods0.000description4

- 229920001343polytetrafluoroethylenePolymers0.000description4

- 239000004810polytetrafluoroethyleneSubstances0.000description4

- 239000004020conductorSubstances0.000description3

- 238000010276constructionMethods0.000description3

- 230000000694effectsEffects0.000description3

- 238000011156evaluationMethods0.000description3

- 238000004519manufacturing processMethods0.000description3

- 238000005259measurementMethods0.000description3

- 238000001228spectrumMethods0.000description3

- RTZKZFJDLAIYFH-UHFFFAOYSA-NDiethyl etherChemical compoundCCOCCRTZKZFJDLAIYFH-UHFFFAOYSA-N0.000description2

- 230000001070adhesive effectEffects0.000description2

- 238000004458analytical methodMethods0.000description2

- 230000015572biosynthetic processEffects0.000description2

- 238000004891communicationMethods0.000description2

- 238000013461designMethods0.000description2

- 230000005670electromagnetic radiationEffects0.000description2

- 239000007789gasSubstances0.000description2

- 238000009434installationMethods0.000description2

- 238000000691measurement methodMethods0.000description2

- 230000010355oscillationEffects0.000description2

- -1polytetrafluoroethylenePolymers0.000description2

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description1

- 239000004696Poly ether ether ketoneSubstances0.000description1

- 239000004721Polyphenylene oxideSubstances0.000description1

- 239000000654additiveSubstances0.000description1

- 230000003466anti-cipated effectEffects0.000description1

- JUPQTSLXMOCDHR-UHFFFAOYSA-Nbenzene-1,4-diol;bis(4-fluorophenyl)methanoneChemical compoundOC1=CC=C(O)C=C1.C1=CC(F)=CC=C1C(=O)C1=CC=C(F)C=C1JUPQTSLXMOCDHR-UHFFFAOYSA-N0.000description1

- 238000006243chemical reactionMethods0.000description1

- 238000011109contaminationMethods0.000description1

- 229910052802copperInorganic materials0.000description1

- 239000010949copperSubstances0.000description1

- 230000003247decreasing effectEffects0.000description1

- 238000005516engineering processMethods0.000description1

- 231100001261hazardousToxicity0.000description1

- 238000010438heat treatmentMethods0.000description1

- 230000001939inductive effectEffects0.000description1

- 238000007689inspectionMethods0.000description1

- 239000007788liquidSubstances0.000description1

- 229910052756noble gasInorganic materials0.000description1

- 150000002835noble gasesChemical class0.000description1

- 230000003287optical effectEffects0.000description1

- 229920000570polyetherPolymers0.000description1

- 229920002530polyetherether ketonePolymers0.000description1

- 230000035939shockEffects0.000description1

- 229920002379silicone rubberPolymers0.000description1

- 239000004945silicone rubberSubstances0.000description1

- 239000012780transparent materialSubstances0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F23/00—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm

- G01F23/22—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm by measuring physical variables, other than linear dimensions, pressure or weight, dependent on the level to be measured, e.g. by difference of heat transfer of steam or water

- G01F23/28—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm by measuring physical variables, other than linear dimensions, pressure or weight, dependent on the level to be measured, e.g. by difference of heat transfer of steam or water by measuring the variations of parameters of electromagnetic or acoustic waves applied directly to the liquid or fluent solid material

- G01F23/284—Electromagnetic waves

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01P—WAVEGUIDES; RESONATORS, LINES, OR OTHER DEVICES OF THE WAVEGUIDE TYPE

- H01P3/00—Waveguides; Transmission lines of the waveguide type

- H01P3/02—Waveguides; Transmission lines of the waveguide type with two longitudinal conductors

- H01P3/08—Microstrips; Strip lines

- H01P3/081—Microstriplines

- H01P3/082—Multilayer dielectric

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01P—WAVEGUIDES; RESONATORS, LINES, OR OTHER DEVICES OF THE WAVEGUIDE TYPE

- H01P3/00—Waveguides; Transmission lines of the waveguide type

- H01P3/12—Hollow waveguides

- H01P3/122—Dielectric loaded (not air)

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01P—WAVEGUIDES; RESONATORS, LINES, OR OTHER DEVICES OF THE WAVEGUIDE TYPE

- H01P3/00—Waveguides; Transmission lines of the waveguide type

- H01P3/16—Dielectric waveguides, i.e. without a longitudinal conductor

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Thermal Sciences (AREA)

- Fluid Mechanics (AREA)

- General Physics & Mathematics (AREA)

- Measurement Of Levels Of Liquids Or Fluent Solid Materials (AREA)

- Geophysics And Detection Of Objects (AREA)

- Transmitters (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及用于填充程度测量设备的微波发送装置,具有电子装置、微波发送器和波导管,其中波导管内部空间用浇注材料浇注。此外本发明涉及具有这样的微波发送装置的填充程度测量设备。The invention relates to a microwave transmitter for a filling level measuring device, having an electronics unit, a microwave transmitter and a waveguide, wherein the interior of the waveguide is cast with a potting compound. Furthermore, the invention relates to a filling level measuring device with such a microwave transmitter.

背景技术Background technique

填充程度测量设备通常用于监视容器中的液体或者松散材料的填充程度。为此采用的测量方法是多种多样的,并且包括例如机械的测量方法,例如浮子或者振动传感器,但是也包括电容式、电感式和光学的测量方法。所采用的测量方法被区分为接触式和无接触式测量方法。在无接触式测量方法中特别经常使用微波范围和相邻的频率范围中的雷达技术工作。本发明从这样一种填充程度测量设备和一种在该填充程度测量设备中采用的微波发送装置出发。Fill level measuring devices are commonly used to monitor the fill level of liquids or bulk materials in containers. The measuring methods used for this are various and include, for example, mechanical measuring methods, such as floats or vibration sensors, but also capacitive, inductive and optical measuring methods. The measurement methods employed are differentiated into contact and non-contact measurement methods. Radar technology in the microwave range and the adjacent frequency range is particularly frequently used in non-contact measuring methods. The invention starts from such a filling level measuring device and a microwave transmitter used in the filling level measuring device.

不言而喻,使用按照雷达原理工作的填充程度测量设备和相应的微波发送装置不仅能够确定介质在容器中的填充程度,而且更确切地也能够确定从如下表面到“填充程度测量设备”或者微波发送装置的任意的距离:该表面反射从测量设备或者从发送装置发出的微波;尽管如此,填充程度测量设备或者用于这样的填充程度测量设备的微波发送装置仍然继续被讨论。It is self-evident that with a filling level measuring device operating on the radar principle and corresponding microwave transmitters it is possible not only to determine the filling level of the medium in the container, but also to determine from the following surface to the "filling level measuring device" or Any distance from the microwave transmitter: the surface reflects the microwaves emitted by the measuring device or from the transmitter; nevertheless, a filling level measuring device or a microwave transmitter for such a filling level measuring device continues to be discussed.

这类填充程度测量设备具有微波发送装置,其中微波发送装置包括用于产生微波信号的电子装置、用于传导微波信号的波导管、以及微波发送器,其中微波发送器把微波信号输入耦合到波导管中。该微波信号由波导管传导,辐射到介质所在的、要确定该介质的填充程度的容器中。该微波信号由容器中的介质反射,并且进入波导管返回到微波发送器,该微波发送器通常也同时充当微波接收器。Filling level measuring devices of this type have a microwave transmission device, wherein the microwave transmission device comprises electronics for generating microwave signals, a waveguide for conducting the microwave signal, and a microwave transmitter, wherein the microwave transmitter couples the microwave signal input into the waveguide tube. The microwave signal is conducted by the waveguide and radiates into the container in which the medium is located, the filling level of which is to be determined. The microwave signal is reflected by the medium in the vessel and enters the waveguide back to the microwave transmitter, which usually also acts as a microwave receiver at the same time.

从WO 02/16889 A1得知一种用于确定容器中的填充材料的填充程度的设备,该设备具有产生电磁测量信号的信号发生单元并且具有发送/接收单元,该发送/接收单元通过天线在填充材料的表面的方向上发送测量信号并且接收在填充材料的表面反射的回波信号,其中天线由波导组成,波导在辐射方向上在定义形状的空腔中扩张,并且所述设备具有分析单元,该分析单元根据测量信号的运行时间确定容器中的填充程度。该填充程度测量设备减少沉淀物形成,也就是说通过提供介电的填充材料,介质在设备上的附着几乎被排除,其中所述介电的填充材料至少部分填满波导并且几乎完全填满天线的扩张的空腔。From WO 02/16889 A1 is known a device for determining the filling level of a filling material in a container, which device has a signal-generating unit generating an electromagnetic measurement signal and has a transmitting/receiving unit, which transmits/receives via an antenna at The measurement signal is transmitted in the direction of the surface of the filling material and the echo signal reflected at the surface of the filling material is received, wherein the antenna consists of a waveguide which expands in the direction of radiation in a cavity of defined shape, and the device has an evaluation unit , the evaluation unit determines the fill level in the container from the runtime of the measurement signal. The filling degree measuring device reduces the formation of deposits, that is to say, the adhesion of the medium to the device is virtually ruled out by providing a dielectric filling material which at least partially fills the waveguide and almost completely fills the antenna. dilated cavity.

US 6,987,481 B2公开了一种雷达填充程度测量设备,该雷达填充程度测量设备能够用定向耦合器产生并且接收椭圆极化的波。此外,该雷达填充程度测量设备具有单侧封闭的波导管,该波导管被用浇注材料浇注。US 6,987,481 B2 discloses a radar filling level measuring device which is able to generate and receive elliptically polarized waves with a directional coupler. Furthermore, the radar filling level measuring device has a waveguide closed on one side, which is cast with a casting compound.

从现有技术中得知的填充程度测量设备具有不利的结构尺寸,特别当在测量设备的安装地点缺乏位置,到安装地点的通路狭窄或者要测量的波导管自身具有小的尺寸时。该结构尺寸尤其是通过下述事实向下限制,即在所使用的微波辐射的频率预先规定的情况下,为传导或者引导所使用的微波射束通常采用的带状导体和/或波导管部件必须具有最小尺寸,以便该带状导体或者波导管部件完全能够损耗很小地传导微波辐射。Filling level measuring devices known from the prior art have unfavorable structural dimensions, in particular when there is a lack of space at the installation site of the measuring device, the access to the installation site is narrow or the waveguide to be measured itself has small dimensions. The structural size is limited in particular by the fact that, given the predetermined frequency of the microwave radiation used, strip conductors and/or waveguide parts are usually used for conducting or guiding the microwave radiation used. Minimum dimensions are necessary in order for the strip conductor or waveguide part to be able to conduct the microwave radiation with very little loss.

发明内容Contents of the invention

因此本发明的任务在于,说明一种微波发送装置和使用这种微波发送装置的填充程度测量设备,所述微波发送装置和填充程度测量设备是特别紧凑的并且是成本有利的。It is therefore the object of the present invention to specify a microwave transmitter and a filling level measuring device using such a microwave transmitter which are particularly compact and cost-effective.

上面导出并且指出的任务从开头描述的微波发送装置出发通过如下方式解决,即微波发送器和电子装置具有浇注体(Verguss)。The object derived and indicated above is achieved starting from the microwave transmitter device described at the outset in that the microwave transmitter and the electronics have an encapsulation.

通过微波发送器和电子装置具有浇注体,产生一种惊人的优点,即微波发送装置能够以紧凑的结构方式实现,因为由于该浇注体为传导所使用的微波辐射所采用的部件的最小尺寸在所使用的微波辐射的预先规定的频率下减小。这种效果虽然在带状导体的情况下也可以察觉,但是尤其在波导的情况下产生特别大的作用。对此效果负责的是,在浇注体中使用的浇注材料与在现有技术中包围电子装置的空气相比具有更大的介电常数也称电容率根据波导的几何结构,每个波导具有所谓的边界频率。较大的波导管具有较小的边界频率。具有低于边界频率的频率的信号被强烈抑制,并且在波导管中实际上不能传播。如果提高波导的填充介质的介电常数,则其边界频率降低。因此在给定微波发送装置的工作频率的情况下,在使用具有提高的介电常数的浇注材料时能够减小导波部件的结构尺寸。By having the potting body for the microwave transmitter and the electronics, the surprising advantage arises that the microwave transmitter device can be realized in a compact construction, since the smallest dimensions of the components used for the conduction of the microwave radiation used by the potting body are in the The pre-specified frequency of the microwave radiation used is reduced. Although this effect is also perceptible in the case of strip conductors, it has a particularly large effect especially in the case of waveguides. This effect is responsible for the fact that the potting compound used in the potting has a greater dielectric constant than the air surrounding the electronics in the prior art also known as permittivity Depending on the waveguide geometry, each waveguide has a so-called boundary frequency. Larger waveguides have smaller boundary frequencies. Signals with frequencies below the boundary frequency are strongly suppressed and practically cannot propagate in the waveguide. If the dielectric constant of the filling medium of the waveguide is increased, its boundary frequency is decreased. For a given operating frequency of the microwave transmitting device, the structural size of the waveguide component can thus be reduced when using a potting compound with an increased dielectric constant.

波导的最小尺寸的减小这里作为示例,该示例表示用与空气或者其他通常包围电子装置的介质相比具有较高介电常数的浇注材料制造的浇注体怎样减小电子装置的组件的最小尺寸。在直径为31mm的用空气填充的圆的波导管的情况下例如产生约5.7GHz的边界频率。一种被表明为特别合适的浇注材料是在频率在5.7GHz到约26GHz的范围中时具有约2.3的介电常数的透明的硅橡胶。如果用该浇注材料浇注圆的波导管,则该圆的波导管的直径为约21mm就已经足以获得5.7GHz的边界频率。缩放因子是浇注材料的介电常数的方根的倒数。由于浇注体所产生的最小尺寸的可比较的减小也可以在电子装置和微波发送器的其他组件上发生,本发明正是利用这点。The reduction in the minimum size of the waveguide is presented here as an example of how a potting made of a potting material with a higher dielectric constant than air or other medium that typically surrounds an electronic device can reduce the minimum size of a component of an electronic device . In the case of an air-filled circular waveguide with a diameter of 31 mm, for example, a boundary frequency of approximately 5.7 GHz results. A potting material which has been found to be particularly suitable is transparent silicone rubber which has a dielectric constant of approximately 2.3 at frequencies in the range from 5.7 GHz to approximately 26 GHz. If a round waveguide is cast with this potting compound, a diameter of the round waveguide of about 21 mm is already sufficient to obtain a boundary frequency of 5.7 GHz. The scaling factor is the inverse of the square root of the dielectric constant of the casting material. A comparable reduction in the minimum dimensions due to the potting can also take place at other components of the electronics and microwave transmitter, and it is precisely this that is exploited by the invention.

根据本发明的一种有利的扩展,微波发送器和电子装置设置在共同的印刷电路板上,并且具有共同的浇注体。According to an advantageous development of the invention, the microwave transmitter and the electronics are arranged on a common printed circuit board and have a common encapsulation.

通过微波发送器和电子装置设置在共同的印刷电路板上,并且它们被共同的浇注体包围,本发明的微波发送装置获得特别紧凑的结构形式。电子装置和微波发送器之间的必要的电连接在这种构型中能够特别短而且节省位置地实现。在制造填充程度测量设备时也得出优点。尤其是仅需制作一个印刷电路板并且装备组件,由此减少了制造时必要的工作步骤的数量。取代一个共同的印刷电路板,微波发送器和电子装置也可以设置在两个或者多个印刷电路板上,这些印刷电路板直接紧邻设置并且此外具有共同的浇注体;在该模块化的变型中也获得基本的优点。Because the microwave transmitter and the electronics are arranged on a common printed circuit board and they are surrounded by a common potting body, a particularly compact design of the microwave transmitter according to the invention is achieved. The necessary electrical connections between the electronics unit and the microwave transmitter can be realized in a particularly short and space-saving manner in this configuration. Advantages also result when producing the filling level measuring device. In particular, only one printed circuit board has to be produced and equipped with components, thereby reducing the number of work steps necessary for production. Instead of a common printed circuit board, the microwave transmitter and the electronics can also be arranged on two or more printed circuit boards, which are arranged directly next to each other and also have a common encapsulation; in this modular variant Basic advantages are also obtained.

本发明的一种有利的构型的特点在于,波导管、微波发送器和电子装置具有共同的浇注体。通过波导管、微波发送器和电子装置的该共同的浇注体尤其是在制造微波发送装置时得出这样的优点:所有三个组件能够在一个唯一的共同的工作步骤中浇注。此外,共同的浇注体提高了整个微波发送装置的稳定性,由此微波发送装置对于例如震荡和振动的机械负荷不那么敏感。An advantageous embodiment of the invention is characterized in that the waveguide, the microwave transmitter and the electronics have a common potting body. The common potting body of waveguide, microwave transmitter and electronics yields the advantage, in particular when producing microwave transmitters, that all three components can be cast in a single common working step. Furthermore, the common encapsulation increases the stability of the entire microwave transmitter, so that the microwave transmitter is less sensitive to mechanical loads such as oscillations and vibrations.

根据本发明的一种特别有利的扩展设置,波导管具有终端。该终端在处理侧封闭波导管并且保证位于容器中的介质不与微波发送装置的部分——从终端看——接触。因为该终端表示波导管和位于容器中的介质之间的接口,所以该终端由对于由电子装置产生的辐射可透过的材料组成。例如PTFE(聚四氟乙烯)对此适合。According to a particularly advantageous embodiment of the invention, the waveguide has an end. The termination closes the waveguide on the processing side and ensures that the medium located in the container does not come into contact with parts of the microwave transmitter as viewed from the termination. Since this termination represents the interface between the waveguide and the medium located in the container, it consists of a material which is transparent to the radiation generated by the electronic device. For example PTFE (polytetrafluoroethylene) is suitable for this.

此外有利的是,浇注材料的介电常数与终端的介电常数一致。由此避免了微波辐射在扩张方向上的介电常数的跳跃,否则所述跳跃将导致不希望的反射。该一致不必一定是精确的。通常近似一致也已经足以充分良好地避免介电常数跳跃处的反射。It is also advantageous if the dielectric constant of the potting compound corresponds to the dielectric constant of the terminal. Jumps in the dielectric constant of the microwave radiation in the direction of expansion are thereby avoided, which would otherwise lead to undesired reflections. This agreement does not have to be exact. Usually approximately uniformity is also good enough to avoid reflections at jumps in the dielectric constant.

优选设置,所使用的微波信号的中心频率在1GHz到100GHz的范围内。在本发明的一种特别优选的构型中,所使用的微波信号的中心频率在4GHz到6GHz的范围内,特别在5GHz。Preferably, the central frequency of the microwave signal used is in the range of 1 GHz to 100 GHz. In a particularly preferred embodiment of the invention, the center frequency of the microwave signal used is in the range from 4 GHz to 6 GHz, in particular 5 GHz.

一种特别的优点通过如下方式实现:浇注体作为用于实现防爆、例如用于实现自保护的措施使用,如果应用需要这点的话。因为基于雷达的填充程度测量设备——和与其一起还有微波发送装置——在完全不同的处理环境中采用,所以它们必须在各种应用场合具有协调一致的安全技术特性,例如必须以防爆方式实施,也就是说在可爆炸的气氛存在的情况下不允许是任何点火源。自保护的点火保护类型涉及暴露于可爆炸气氛的操作装置和连接线路内的电能被限制到这样的水平之下,在该水平时通过火花形成或者通过加热能引起点火。对于构造和检验为在气体爆炸危险区域中的使用所确定的自保护操作装置以及为与引入这样的区域中的自保护电路连接考虑的有关操作装置的确定,由标准EN60079-11-Teil 11:durch Eigensicherheit“i””进行规定。该标准也适用于如下电气操作装置或者电气操作装置的部分,所述电气操作装置位于有气体爆炸危险的区域之外,或者通过根据EN 60079-0的另外的点火保护方式得到保护,只要在有气体爆炸危险的区域中的电气电路的自保护可以取决于该电气操作装置的设计和结构方式或者取决于该电气操作装置的部分。A particular advantage is achieved in that the potting body is used as a measure for explosion protection, for example for self-protection, if the application requires this. Since radar-based filling level measuring devices - and together with them microwave transmitters - are used in completely different processing environments, they must have harmonized safety-technical properties for the various applications, e.g. must be installed in an explosion-proof manner implementation, that is to say the presence of an explosive atmosphere must not be any source of ignition. The self-protected ignition protection type involves that the electrical energy in operating devices and connecting lines exposed to an explosive atmosphere is limited below the level at which ignition can be caused by spark formation or by heating. For the construction and inspection of self-protective operating devices determined for use in gas explosion hazardous areas and for the determination of relevant operating devices to be considered in connection with self-protective circuits introduced into such areas, by standard EN60079-11 -Teil 11: durch Eigensicherheit "i"". This standard also applies to electrical operating devices or parts of electrical operating Ignition protection is protected as long as the self-protection of electrical circuits in areas at risk of gas explosion can depend on the design and construction of the electrical operating device or on parts of the electrical operating device.

在另一个实施例中,浇注体实现点火保护意义上的浇注封装。浇注封装的点火保护方式也称为“Ex-m”点火保护方式。在点火保护意义上的浇注封装的情况下,把可能表示潜在的点火源的组件用对于该应用目的合适的浇注材料覆盖。通过该措施保证,周围的可爆炸的气氛不与这些组件接触。在浇注封装的点火保护方式情况下,浇注封装的表面温度在发生预料的错误时不允许达到周围的可爆炸气氛的点火温度。标准EN 60079-18-Teil18:durch Vergusskapselung“m””规定了对该点火保护方式的要求。在最好的情况下这样提供浇注体,即使得能够满足多个点火保护标准的要求。In a further embodiment, the potting realizes potting in the sense of ignition protection. The ignition protection method of the casting package is also called "Ex-m" ignition protection method. In the case of potting encapsulation in the sense of ignition protection, components which may represent potential ignition sources are covered with a potting compound suitable for the purpose of the application. This measure ensures that the surrounding explosive atmosphere does not come into contact with the components. In the case of the ignition protection method of the potting, the surface temperature of the potting must not reach the ignition temperature of the surrounding explosive atmosphere in the event of an anticipated error. Standard EN 60079-18 -Teil18: The durch Vergusskapselung "m" specifies the requirements for this type of ignition protection. In the best case the casting body is provided in such a way that the requirements of several ignition protection standards can be met.

先前导出的和示出的任务从开头描述的填充程度测量设备出发还通过如下方式解决,即在填充程度测量设备中使用的微波发送装置如上述实施,这也允许以减小的尺寸和成本制造填充程度测量设备。The previously deduced and illustrated object starting from the filling level measuring device described at the outset is also solved in that the microwave transmitter used in the filling level measuring device is implemented as described above, which also allows production with reduced dimensions and costs Fill level measuring equipment.

根据本发明的一种有利的扩展设置,填充程度测量设备具有耐压外壳,微波发送装置设置在该耐压外壳内,耐压外壳具有辐射可透过的处理窗,并且波导管将微波发送器与该辐射可透过的处理窗连接。辐射可透过的处理窗可以尤其是也通过上述终端构造。According to an advantageous development of the invention, the filling degree measuring device has a pressure-resistant housing in which the microwave transmitter is arranged, the pressure-resistant housing has a radiation-permeable process window, and the waveguide connects the microwave transmitter Connected to the radiation transparent process window. A radiation-transmissive treatment window can in particular also be formed through the above-mentioned terminations.

所述耐压封装是另一种可能的点火保护方式。在这种也称为“Ex-d”的点火保护方式中,爆炸保护通过如下方式保证,即在外壳内可能发生的爆炸通过耐压封装被屏蔽为使得耐压外壳外的主导的能够爆炸的气氛不能被点燃。因此,外壳壁中的引路必须有防点火击穿的缝。外壳的表面温度在发生预期错误的情况下也不允许达到周围的能够爆炸的气氛的点火温度。标准EN60079-1-Teil 1:durch druckfesteKapselung“d””规定了对于该点火保护方式的操作装置的要求。The pressure-resistant encapsulation is another possible ignition protection. In this type of ignition protection, also known as "Ex-d", explosion protection is ensured in that possible explosions inside the enclosure are shielded by the pressure-resistant encapsulation so that the dominant explosion-capable The atmosphere cannot be ignited. Therefore, the lead-through in the housing wall must have ignition breakdown-proof slots. The surface temperature of the housing must also not reach the ignition temperature of the surrounding explosive atmosphere in the event of an anticipation error. Standard EN60079-1 -Teil 1: The durch druckfesteKapselung "d" specifies the requirements for the operating device of this ignition protection method.

从微波发送器输入耦合到波导管中的微波信号从波导管直到辐射可透过的处理窗引导,并且通过该辐射可透过的处理窗辐射到要确定其填充程度的介质所在的容器中。为使微波信号能够辐射到容器中,辐射可透过的处理窗对于电磁谱的至少确定的范围是可透过的,所述电磁谱能够由填充程度测量设备用微波发送器发送。该微波信号被容器中的介质反射,并且通过辐射可透过的处理窗和波导管返回到微波发送器,该微波发送器通常同时也充当微波接收器。The microwave signal input coupled into the waveguide from the microwave transmitter is guided from the waveguide up to the radiation-transparent processing window and radiates through the radiation-transparent processing window into the container in which the medium whose filling level is to be determined is located. In order to be able to radiate microwave signals into the container, the radiation-permeable treatment window is transparent to at least a defined range of the electromagnetic spectrum, which can be transmitted by the filling level measuring device with a microwave transmitter. The microwave signal is reflected by the medium in the vessel and returns through the radiation transparent process window and waveguide to the microwave transmitter, which typically also acts as a microwave receiver at the same time.

辐射可透过的处理窗不一定设置在波导管的处理侧末端,而是可以在波导管中在波导管的两个末端之间的任何位置处采用。这里,波导管尤其是可以以多部分构造。例如波导管可以具有设备侧的部分,其用浇注材料浇注并且由辐射可透过的处理窗在处理侧封闭。在该辐射可透过的处理窗处,在该构型中连接波导管的处理侧部分,该处理侧部分同样可以被浇注。The radiation transparent treatment window need not be provided at the treatment-side end of the waveguide, but may be employed anywhere in the waveguide between the two ends of the waveguide. Here, in particular, the waveguide can be constructed in multiple parts. For example, the waveguide can have a device-side part which is cast with a potting compound and closed on the process side by a radiation-transmissive process window. At the radiation-transparent process window, the process-side part of the waveguide is connected in this configuration, which process-side part can likewise be cast.

因为无论是电子装置还是微波发送器都设置在耐压外壳中,所以不需要穿过耐压外壳的花费大的线路引路来连接电子装置与微波发送器。Since both the electronics and the microwave transmitter are arranged in the pressure-resistant housing, no complex wiring through the pressure-resistant housing is required to connect the electronics to the microwave transmitter.

本发明的一种有利的构型的特定在于,浇注体完全填满耐压外壳的内部空间。用浇注材料完全填充耐压外壳的内部空间提高整个填充程度测量设备的稳定性。尤其是,填充程度测量设备的设置在耐压外壳的内部中的组件由此被特别保护不会由于震荡等松脱。An advantageous embodiment of the invention is characterized in that the potting body completely fills the interior of the pressure housing. The complete filling of the interior space of the pressure-resistant housing with the potting compound increases the stability of the entire filling degree measuring device. In particular, the components of the filling level measuring device which are arranged in the interior of the pressure-resistant housing are thus particularly protected against detachment due to shocks or the like.

根据本发明的一种特别有利的扩展设置,辐射可透过的处理窗是玻璃窗。玻璃材料特别适合用于本发明的防爆设备的辐射可透过的处理窗。玻璃不仅在电磁辐射谱的宽范围内是可透过的,而且也可以通过相应的附加剂着色,也就是说使电磁辐射谱的快不可用范围成为不可透过的,使得辐射可透过的处理窗的特性能够特定于应用地匹配,这样尤其是能够实现不同的折射率。此外能够从多种多样已知的玻璃中选择具有希望的特性的玻璃。另外通过为辐射可透过的处理窗使用玻璃可以得出合理的材料成本。According to a particularly advantageous development of the invention, the radiation-transmissive treatment window is a glass window. Glass materials are particularly suitable for use in the radiation-transparent process window of the explosion-proof device of the invention. Glass is not only transparent in a wide range of the electromagnetic radiation spectrum, but can also be colored by corresponding additives, that is to say, the fast unusable range of the electromagnetic radiation spectrum is made impermeable and the radiation is transparent. The properties of the processing window can be adapted in an application-specific manner, so that in particular different refractive indices can be realized. Furthermore, a glass having the desired properties can be selected from a wide variety of known glasses. In addition, reasonable material costs can be achieved by using glass for the radiation-transparent treatment window.

被表明为特别有利的是,玻璃窗具有金属熔融玻璃。金属熔融玻璃是用于观察处理的热预应力特殊玻璃。在制造时把玻璃片熔融到金属环中并且与该金属环持久地连接。玻璃和金属的不同的热膨胀系数引起整个玻璃体的均匀的压应力状态。从为辐射可透过的处理窗使用金属熔融玻璃得出的优点是,金属熔融玻璃在损坏的情况下仅在表面显示出裂缝,但是通常不会出现完全损坏。It has been found to be particularly advantageous if the glazing comprises metallic fused glass. Metal Fused Glass is a thermally prestressed special glass for observation processing. During production, the glass sheet is fused into the metal ring and permanently connected to it. The different thermal expansion coefficients of glass and metal induce a uniform compressive stress state throughout the glass body. The advantage derived from the use of molten metal glass for radiation-transparent treatment windows is that in the event of damage the molten metal glass only shows cracks on the surface, but as a rule complete damage does not occur.

根据本发明的另一种优选的扩展设置,填充程度测量设备具有输出装置,该输出装置例如通过总线接口构建。通过总线接口、显示器或者无线电连接形式的输出装置,由本发明的防爆设备收集的数据或者——在所进行的分析或者预分析之后的——信息能够便利地并且可靠地输出。According to a further preferred development of the invention, the filling level measuring device has an output device, which is formed, for example, via a bus interface. Via an output device in the form of a bus interface, a display or a radio link, the data collected by the explosion protection device according to the invention or—after the analysis or pre-analysis carried out—information can be output conveniently and reliably.

附图说明Description of drawings

详细地,现在有多种可能来构造和扩展本发明的填充程度测量设备。为此参阅排在权利要求1后的权利要求以及参阅下面参照附图对于优选的实施例的详细的描述。在附图中,In detail, there are now various possibilities to construct and expand the filling level measuring device according to the invention. For this purpose reference is made to the claims following claim 1 and to the following detailed description of preferred exemplary embodiments with reference to the drawings. In the attached picture,

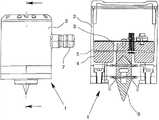

图1示出沿本发明的填充程度测量设备的纵轴线的剖面图,和Figure 1 shows a sectional view along the longitudinal axis of the filling degree measuring device of the present invention, and

图2示出本发明的填充程度测量设备的不同视图。FIG. 2 shows different views of the filling level measuring device of the invention.

具体实施方式Detailed ways

图1的剖面图公开了具有本发明微波发送装置的本发明填充程度测量设备1的一个实施例的内部结构。该填充程度测量设备具有耐压的外壳2,该外壳2能够屏蔽在耐压外壳2内发生的环境气氛的爆炸。在耐压外壳2内设置用于引导微波信号的波导管3。波导管3由浇注体4填满并且包围。印刷电路板5同样由浇注体4包围。在印刷电路板5上设置微波发送器和电子装置。通过波导管3把由电子装置产生的微波信号导向终端6。终端6用于在要观察的过程的方向上有针对性地辐射微波信号。终端6由辐射可透过的材料组成,在本例中是PTFE(聚四氟乙烯),其他未在此处示出的终端例如用PEEK(聚醚醚铜)组成。The sectional view in FIG. 1 discloses the internal structure of an exemplary embodiment of a filling level measuring device 1 according to the invention with a microwave transmission device according to the invention. The filling level measuring device has a pressure-

微波发送装置构造为自保护的,也就是其满足点火保护方式的有关标准。The microwave transmitter is designed to be self-protecting, ie it meets the relevant standards for ignition protection methods.

从该过程中发出的微波辐射能够从终端6通过波导管3到达微波发送器。这里微波发送器也充当接收装置。为与未示出的外部的控制和分析装置交换数据,本发明的填充程度测量设备1具有输出装置7。The microwave radiation emitted from this process can pass from the

从图1的剖面图可以看出,填充程度测量设备1的耐压外壳2未完全用浇注体4填满。由此在耐压外壳2内部在浇注体4上面产生未用浇注材料填满的空间。根据本发明的填充程度测量设备1的另一种构型,耐压外壳2也可以用浇注材料完全填满。同样,该空间也可以取代浇注材料而用其他介质填充或者抽成真空。为填充该空间提供特别是化学上惰性的介质,因为由此能够有效避免填充介质与耐压外壳2的材料和耐压外壳2的其余的内容进行化学反应。为此非放射性的惰性气体特别合适。It can be seen from the sectional view in FIG. 1 that the

通过上面设置有微波发送器和电子装置的印刷电路板5具有如下浇注体4,即使得上述组件满足点火保护方式“EX-i”并且印刷电路板5与波导管3一起完全被浇注并且设置在耐压外壳2内部,则波导管3、印刷电路板5、微波发送器和电子装置既满足点火保护方式“EX-d”也满足点火保护方式“EX-i”。The printed

浇注体4被构造为使得其完全包围上面设置有组件和波导管3的印刷电路板5并且机械上使它们彼此连接。另外,浇注体4将波导管3和印刷电路板5与耐压外壳2连接。通过由浇注体4连接印刷电路板5、波导管3和耐压外壳2,本发明的填充程度测量设备1的上述组件在机械上被稳定并且由此在很大程度上防止振动和震荡。The potting body 4 is designed such that it completely surrounds the printed

浇注体4由极其均匀的浇注材料组成,该浇注材料尤其是不具有气泡和污染物。浇注体4的浇注材料不仅具有特别好的赋予其特别的稳定性的内聚性,而且具有突出的粘附特性。浇注体4的粘附特性保证了在浇注体4和与浇注材料接触的组件的表面之间的可靠的和几乎无缝的连接。重要的还有,浇注体4实际上无缝地填满了波导管3内的空腔和邻接的表面,因为这种缝会导致微波信号在波导管3内部的不希望的反射。The potting body 4 consists of an extremely homogeneous potting material which is in particular free of air bubbles and contamination. The casting compound of the casting body 4 not only has a particularly good cohesion which gives it a particular stability, but also has outstanding adhesive properties. The adhesive properties of the potting body 4 ensure a reliable and almost seamless connection between the potting body 4 and the surface of the component which is in contact with the potting compound. It is also important that the potting body 4 fills the cavity in the

图2在四个不同的视图中示出本发明的填充程度测量设备1。这里特别可以看到电缆引路7的侧面设置。在填充程度测量设备1的朝向处理的一侧处可以看到圆锥形延伸的终端6。这里该填充程度测量设备具有满足通信标准PROFIBUS-PA的数据接口,其他的通信标准同样可以实现。FIG. 2 shows the filling level measuring device 1 according to the invention in four different views. Here in particular the lateral arrangement of the

Claims (13)

Translated fromChineseApplications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102011010801.7 | 2011-02-09 | ||

| DE102011010801.7ADE102011010801B4 (en) | 2011-02-09 | 2011-02-09 | Microwave transmitter and level gauge |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102706407Atrue CN102706407A (en) | 2012-10-03 |

| CN102706407B CN102706407B (en) | 2017-06-13 |

Family

ID=45654875

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210096850.7AExpired - Fee RelatedCN102706407B (en) | 2011-02-09 | 2012-02-09 | Microwave dispensing device and filling extent measuring apparatus |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9109941B2 (en) |

| EP (1) | EP2487472A3 (en) |

| CN (1) | CN102706407B (en) |

| DE (1) | DE102011010801B4 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112867294A (en)* | 2019-11-12 | 2021-05-28 | 西门子股份公司 | Explosion-proof pressure-resistant shell |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011112045A1 (en) | 2011-09-01 | 2013-03-07 | Krohne Messtechnik Gmbh | Microwave transmitter with potting |

| DE102015100414A1 (en)* | 2015-01-13 | 2016-07-14 | Krohne Messtechnik Gmbh | Device for determining the level of a medium in a container |

| DE102015113955A1 (en)* | 2015-08-24 | 2017-03-02 | Endress+Hauser Gmbh+Co. Kg | Level gauge for measuring a level |

| EP3176547B1 (en)* | 2015-12-02 | 2018-09-19 | Siemens Aktiengesellschaft | Housing part for a measurement device having a microwave-permeable glass or ceramic window |

| US10378947B2 (en) | 2016-07-07 | 2019-08-13 | Rosemount Tank Radar Ab | Radar level gauge system with feeding comprising an electrical filter |

| US10480985B2 (en) | 2017-09-29 | 2019-11-19 | Rosemount Tank Radar Ab | Explosion proof radar level gauge |

| FR3073828B1 (en)* | 2017-11-21 | 2020-11-13 | Total Marketing Services | CLOSING DEVICE FOR A CONTAINER INCLUDING AN ELEMENT FOR MEASURING THE CONTENT LEVEL OF THE CONTAINER |

| DE102018132285A1 (en)* | 2018-12-14 | 2020-06-18 | Endress+Hauser SE+Co. KG | Level meter |

| DE102020133194A1 (en)* | 2020-12-11 | 2022-06-15 | Endress+Hauser SE+Co. KG | level gauge |

| DE102020133198B4 (en)* | 2020-12-11 | 2023-10-05 | Endress+Hauser SE+Co. KG | High-frequency module for a level measuring device and level measuring device |

| US20250185179A1 (en)* | 2023-12-04 | 2025-06-05 | Blackberry Limited | Intrisically safe designed devices and methods therefor |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3593224A (en)* | 1969-02-04 | 1971-07-13 | Teledyne Inc | Microwave tube transformer-window assembly having a window thickness equivalent to one-quarter wavelength and metallic step members to transform impedance |

| US5070730A (en)* | 1989-04-10 | 1991-12-10 | Saab Marine Electronics Aktiebolag | Device for level gauging with microwaves |

| DE19800306A1 (en)* | 1998-01-07 | 1999-07-15 | Grieshaber Vega Kg | Aerial unit for filling level measuring radar unit for radiating microwaves along main radiating direction in container |

| US5954526A (en)* | 1996-10-04 | 1999-09-21 | Rosemount Inc. | Process control transmitter with electrical feedthrough assembly |

| CN1447909A (en)* | 2000-08-21 | 2003-10-08 | 恩德莱斯和豪瑟尔两合公司 | Device for determining level of filler material in container |

| CN1498347A (en)* | 2000-11-23 | 2004-05-19 | VEGA����ɳ�����Ϲ�˾ | Feedback device for electric high frequency signal and level measuring device provided with said device |

| CN1802554A (en)* | 2003-04-25 | 2006-07-12 | Vega格里沙贝两合公司 | Radar filling level measurement using circularly polarized waves |

| CN101317102A (en)* | 2005-11-29 | 2008-12-03 | 罗伯特·博世有限公司 | Modular unit for a radar antenna array with integrated HF chip |

| DE102007042043A1 (en)* | 2007-09-05 | 2009-03-12 | Endress + Hauser Gmbh + Co. Kg | Level measuring instrument for determining and monitoring level of filling material provided in container with run time measuring method of sent signals, has transducer unit and sensor unit having ultrasonic sensor |

| DE102007057211A1 (en)* | 2007-11-26 | 2009-05-28 | Martin Meyer | Monitor for a tank filling level has a sensor with an evaluation unit and a transmitter, integrated into the tank closure |

| CN101640320A (en)* | 2008-02-20 | 2010-02-03 | Vega格里沙贝两合公司 | Conductor leadthrough, housing device, field apparatus and method for producing a conductor leadthrough |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4016506A (en)* | 1975-12-24 | 1977-04-05 | Honeywell Inc. | Dielectric waveguide oscillator |

| US5495218A (en)* | 1994-04-20 | 1996-02-27 | Thermo Instrument Controls Inc. | Microwave waveguide seal assembly |

| EP0943902B1 (en)* | 1998-03-18 | 2004-07-14 | VEGA Grieshaber KG | Microwave level gauge capable of operation at high temperatures and/or high pressures and/or in a chemically agressive environment |

| US6295018B1 (en)* | 1999-09-27 | 2001-09-25 | Rosemount Inc. | Low power radar level instrument with enhanced diagnostics |

| DE10023497A1 (en)* | 2000-05-13 | 2001-11-15 | Endress Hauser Gmbh Co | Microwave-type level gauge for industrial applications, is equipped with a plate for positioning the microwave generator |

| DE10057441B4 (en)* | 2000-11-20 | 2014-02-13 | Vega Grieshaber Kg | Horn antenna for a radar device |

| US6750657B2 (en)* | 2000-11-23 | 2004-06-15 | Vega Grieshaber Kg | Combination of a feedthrough element for an electric high-frequency signal and a probe, and a level meter metering device including a combination of this type |

| DE10060069C1 (en)* | 2000-12-01 | 2002-04-25 | Krohne Messtechnik Kg | Stress-free microwave window mounting, comprises outer clamped flange, into which window is adhered or welded by its thermoplastic dielectric coating |

| US20060144800A1 (en)* | 2002-11-27 | 2006-07-06 | Barreras Francisco J Sr | Sewage treatment system for use in marine toilet and other remote toilets |

| DE102005054233A1 (en)* | 2005-11-14 | 2007-05-16 | Grieshaber Vega Kg | Waveguide junction for level radar, has decoupling unit with coupling unit and resonating cavity for decoupling of electromagnetic waves into waveguide, where resonating cavity is integrated in printed circuit board |

| US7265558B1 (en)* | 2006-10-05 | 2007-09-04 | Rosemount Tank Radar Ab | Radar level gauge using elliptically or circularly polarized waves |

| DE102008016829A1 (en)* | 2008-04-01 | 2009-10-08 | KROHNE Meßtechnik GmbH & Co. KG | Level switch and sensor element for a level switch |

- 2011

- 2011-02-09DEDE102011010801.7Apatent/DE102011010801B4/ennot_activeExpired - Fee Related

- 2012

- 2012-02-07EPEP12000779.4Apatent/EP2487472A3/ennot_activeWithdrawn

- 2012-02-09USUS13/369,714patent/US9109941B2/enactiveActive

- 2012-02-09CNCN201210096850.7Apatent/CN102706407B/ennot_activeExpired - Fee Related

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3593224A (en)* | 1969-02-04 | 1971-07-13 | Teledyne Inc | Microwave tube transformer-window assembly having a window thickness equivalent to one-quarter wavelength and metallic step members to transform impedance |

| US5070730A (en)* | 1989-04-10 | 1991-12-10 | Saab Marine Electronics Aktiebolag | Device for level gauging with microwaves |

| US5954526A (en)* | 1996-10-04 | 1999-09-21 | Rosemount Inc. | Process control transmitter with electrical feedthrough assembly |

| DE19800306A1 (en)* | 1998-01-07 | 1999-07-15 | Grieshaber Vega Kg | Aerial unit for filling level measuring radar unit for radiating microwaves along main radiating direction in container |

| CN1447909A (en)* | 2000-08-21 | 2003-10-08 | 恩德莱斯和豪瑟尔两合公司 | Device for determining level of filler material in container |

| CN1498347A (en)* | 2000-11-23 | 2004-05-19 | VEGA����ɳ�����Ϲ�˾ | Feedback device for electric high frequency signal and level measuring device provided with said device |

| CN1802554A (en)* | 2003-04-25 | 2006-07-12 | Vega格里沙贝两合公司 | Radar filling level measurement using circularly polarized waves |

| CN101317102A (en)* | 2005-11-29 | 2008-12-03 | 罗伯特·博世有限公司 | Modular unit for a radar antenna array with integrated HF chip |

| DE102007042043A1 (en)* | 2007-09-05 | 2009-03-12 | Endress + Hauser Gmbh + Co. Kg | Level measuring instrument for determining and monitoring level of filling material provided in container with run time measuring method of sent signals, has transducer unit and sensor unit having ultrasonic sensor |

| DE102007057211A1 (en)* | 2007-11-26 | 2009-05-28 | Martin Meyer | Monitor for a tank filling level has a sensor with an evaluation unit and a transmitter, integrated into the tank closure |

| CN101640320A (en)* | 2008-02-20 | 2010-02-03 | Vega格里沙贝两合公司 | Conductor leadthrough, housing device, field apparatus and method for producing a conductor leadthrough |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112867294A (en)* | 2019-11-12 | 2021-05-28 | 西门子股份公司 | Explosion-proof pressure-resistant shell |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2487472A2 (en) | 2012-08-15 |

| DE102011010801A1 (en) | 2012-08-09 |

| US20120206290A1 (en) | 2012-08-16 |

| US9109941B2 (en) | 2015-08-18 |

| EP2487472A3 (en) | 2015-05-27 |

| CN102706407B (en) | 2017-06-13 |

| DE102011010801B4 (en) | 2016-01-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102706407B (en) | Microwave dispensing device and filling extent measuring apparatus | |

| US9091584B2 (en) | Microwave window and level-measuring system that works according to the radar principle | |

| US9110165B2 (en) | Measuring device of process automation technology for ascertaining and monitoring a chemical or physical process variable in a high temperature process in a container | |

| US9212942B2 (en) | Waveguide coupling, high-frequency module, fill-level radar and use | |

| US7952035B2 (en) | Conductor leadthrough, housing device, field apparatus and method for producing a conductor leadthrough | |

| CN101233393B (en) | Potential separation for fill level radar | |

| JP4980306B2 (en) | Wireless communication device | |

| US9086311B2 (en) | Microwave-sending device | |

| CN110006504B (en) | Circuit board for a radar level gauge having a waveguide coupling device | |

| US10234321B2 (en) | Radar level gauge system with single propagation mode feed-through | |

| CN207456563U (en) | For the radar levelmeter of the high-frequency model and application of the level gauging high-frequency model | |

| CN109428142B (en) | Waveguide coupling structure, high-frequency radar module and filling level radar | |

| CN107677340A (en) | High-frequency model, radar levelmeter and its manufacture method for level gauging | |

| CN103245395B (en) | Level measurement system that works on the radar principle | |

| US20210305672A1 (en) | High-frequency component | |

| US20160262254A1 (en) | Intrinsically safe radio frequency (rf) adapter | |

| CN114729905A (en) | Antenna assembly for transmitting microwaves and measuring assembly having at least one such antenna assembly | |

| CN101027815B (en) | Device for transmitting broadband high-frequency signals | |

| US7227495B2 (en) | Radar fill-level sensing device | |

| US20220228900A1 (en) | Waveguide for a radar level gauge | |

| US20250004097A1 (en) | Radar measuring device for determining fill levels and/or distances | |

| RU2780644C1 (en) | Dual-edge radar module | |

| JP2001183312A (en) | Densitometer | |

| CN113137998A (en) | Fill level sensor for detecting the fill level of a fill medium in a container | |

| US20070103361A1 (en) | Shielded compartment for mounting a high frequency radar component on a printed circuit board |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20170613 |