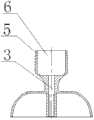

CN102620250B - Clamp for flaky light emitting diode (LED) lamp wick - Google Patents

Clamp for flaky light emitting diode (LED) lamp wickDownload PDFInfo

- Publication number

- CN102620250B CN102620250BCN201210066915.3ACN201210066915ACN102620250BCN 102620250 BCN102620250 BCN 102620250BCN 201210066915 ACN201210066915 ACN 201210066915ACN 102620250 BCN102620250 BCN 102620250B

- Authority

- CN

- China

- Prior art keywords

- led wick

- groove

- erecting bed

- draw

- installation portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 241000217776HolocentridaeSpecies0.000titleabstract7

- 238000009434installationMethods0.000claimsdescription32

- 239000000463materialSubstances0.000claimsdescription11

- 230000005855radiationEffects0.000claimsdescription7

- 239000003063flame retardantSubstances0.000claimsdescription4

- RNFJDJUURJAICM-UHFFFAOYSA-N2,2,4,4,6,6-hexaphenoxy-1,3,5-triaza-2$l^{5},4$l^{5},6$l^{5}-triphosphacyclohexa-1,3,5-trieneChemical compoundN=1P(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP(OC=2C=CC=CC=2)(OC=2C=CC=CC=2)=NP=1(OC=1C=CC=CC=1)OC1=CC=CC=C1RNFJDJUURJAICM-UHFFFAOYSA-N0.000claimsdescription3

- 239000007769metal materialSubstances0.000claimsdescription3

- 230000017525heat dissipationEffects0.000abstract1

- XEEYBQQBJWHFJM-UHFFFAOYSA-NIronChemical compound[Fe]XEEYBQQBJWHFJM-UHFFFAOYSA-N0.000description2

- 238000005516engineering processMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description1

- 239000000853adhesiveSubstances0.000description1

- 230000001070adhesive effectEffects0.000description1

- 230000032683agingEffects0.000description1

- 239000000956alloySubstances0.000description1

- 239000004411aluminiumSubstances0.000description1

- 229910052782aluminiumInorganic materials0.000description1

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000000052comparative effectEffects0.000description1

- 229910052802copperInorganic materials0.000description1

- 239000010949copperSubstances0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000007598dipping methodMethods0.000description1

- 230000000694effectsEffects0.000description1

- 229910052742ironInorganic materials0.000description1

- 230000001795light effectEffects0.000description1

- 238000012423maintenanceMethods0.000description1

- 238000000034methodMethods0.000description1

Images

Landscapes

- Arrangement Of Elements, Cooling, Sealing, Or The Like Of Lighting Devices (AREA)

- Fastening Of Light Sources Or Lamp Holders (AREA)

Abstract

Description

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210066915.3ACN102620250B (en) | 2012-03-14 | 2012-03-14 | Clamp for flaky light emitting diode (LED) lamp wick |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210066915.3ACN102620250B (en) | 2012-03-14 | 2012-03-14 | Clamp for flaky light emitting diode (LED) lamp wick |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102620250A CN102620250A (en) | 2012-08-01 |

| CN102620250Btrue CN102620250B (en) | 2014-07-02 |

Family

ID=46560348

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210066915.3AExpired - Fee RelatedCN102620250B (en) | 2012-03-14 | 2012-03-14 | Clamp for flaky light emitting diode (LED) lamp wick |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102620250B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103016983B (en)* | 2012-11-30 | 2015-09-02 | 马守峰 | A kind of LED |

| CN108982925A (en)* | 2018-05-28 | 2018-12-11 | 苏州诺纳可电子科技有限公司 | A kind of clamp for sheet type LED lamp wick |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201326984Y (en)* | 2008-11-28 | 2009-10-14 | 霍尼韦尔朗能电器系统技术(广东)有限公司 | Detachable LED lamp holder |

| CN101660670A (en)* | 2009-09-04 | 2010-03-03 | 山东魏仕照明科技有限公司 | LED illuminating lamp |

| CN101922625A (en)* | 2010-04-30 | 2010-12-22 | 苏州京东方茶谷电子有限公司 | LED bulb |

| CN202469904U (en)* | 2012-03-14 | 2012-10-03 | 苏州晶品光电科技有限公司 | Fixture for slice type LED (Light-Emitting Diode) lampwicks |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101085113B1 (en)* | 2009-04-20 | 2011-11-23 | 주식회사 케이티앤씨엔지니어링 | LED light fixture with socket and wall |

- 2012

- 2012-03-14CNCN201210066915.3Apatent/CN102620250B/ennot_activeExpired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201326984Y (en)* | 2008-11-28 | 2009-10-14 | 霍尼韦尔朗能电器系统技术(广东)有限公司 | Detachable LED lamp holder |

| CN101660670A (en)* | 2009-09-04 | 2010-03-03 | 山东魏仕照明科技有限公司 | LED illuminating lamp |

| CN101922625A (en)* | 2010-04-30 | 2010-12-22 | 苏州京东方茶谷电子有限公司 | LED bulb |

| CN202469904U (en)* | 2012-03-14 | 2012-10-03 | 苏州晶品光电科技有限公司 | Fixture for slice type LED (Light-Emitting Diode) lampwicks |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102620250A (en) | 2012-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201621507U (en) | Novel heat radiation structure of LED lamp | |

| CN201875471U (en) | LED (light-emitting diode) lamp tube | |

| CN102620250B (en) | Clamp for flaky light emitting diode (LED) lamp wick | |

| CN105090859A (en) | Novel anti-collision lamp light source for helicopter | |

| CN201582630U (en) | LED lighting bulb | |

| CN202469904U (en) | Fixture for slice type LED (Light-Emitting Diode) lampwicks | |

| CN204986704U (en) | Effective cooling type LED street lamp | |

| CN202733504U (en) | Insulated liner lamp | |

| CN201992446U (en) | High-efficiency LED bulbs | |

| CN202253041U (en) | Nanometer aluminum reflective layer plated LED bulb lamp | |

| CN202469908U (en) | Sheet-type LED lamp core used fixture | |

| CN102620252B (en) | Clamp for sheet type LED lamp wick | |

| CN201547725U (en) | Heat dissipation device of LED lamp | |

| CN202176956U (en) | Novel large-angle LED (Light Emitting Diode) bulb lamp | |

| CN205048181U (en) | LED drive power supply electricity -saving lamp | |

| CN205316202U (en) | Integration tee pipe highlight support LED lamp | |

| CN202065789U (en) | Light-emitting diode (LED) factory workshop lighting lamp | |

| CN203395853U (en) | Fixed mounting mechanism for COB (Chip On Board) light source | |

| CN202056829U (en) | Radiator for LED (Light Emitting Diode) energy-saving street lamp | |

| CN202469667U (en) | Novel induction-type LED lamp | |

| CN213177754U (en) | LED bulb power panel | |

| CN208222210U (en) | A kind of LED High Power Illuminator | |

| CN202501263U (en) | Light-emitting diode (LED) panel lamp | |

| CN203453878U (en) | LED (light-emitting diode) spotlight with convection heat radiation device | |

| CN202328098U (en) | Heat conducting structure of high-power LED (Light Emitting Diode) lamp |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C56 | Change in the name or address of the patentee | Owner name:SUZHOU JINGPIN ADVANCED MATERIALS CO., LTD. Free format text:FORMER NAME: SUZHOU JINGPIN PHOTOELECTRIC TECHNOLOGY CO., LTD. | |

| CP03 | Change of name, title or address | Address after:Wujiang District of Suzhou City, Jiangsu province 215200 Lili town FENHU Road No. 558 Patentee after:Suzhou Jing Pin new material limited company Address before:No. 3, building 2, building No. 558, Fen Hu Road, Fen Lake Economic Development Zone, Suzhou, Jiangsu, Wujiang Patentee before:Suzhou Jingpin Optical-Electronical Technology Co., Ltd. | |

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20180911 Address after:223600 No. 19 Xiaoshan Road, Shuyang County Economic Development Zone, Suqian, Jiangsu Patentee after:Jiangsu Eurasian lighting Limited by Share Ltd Address before:215200 558 FENHU Road, Wujiang District, Suzhou, Jiangsu Patentee before:Suzhou Jing Pin new material limited company | |

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20140702 Termination date:20190314 |