CN102539188A - Test device for continuous lifting system of large-tonnage topside module - Google Patents

Test device for continuous lifting system of large-tonnage topside moduleDownload PDFInfo

- Publication number

- CN102539188A CN102539188ACN2011104467531ACN201110446753ACN102539188ACN 102539188 ACN102539188 ACN 102539188ACN 2011104467531 ACN2011104467531 ACN 2011104467531ACN 201110446753 ACN201110446753 ACN 201110446753ACN 102539188 ACN102539188 ACN 102539188A

- Authority

- CN

- China

- Prior art keywords

- lifting system

- tower

- cable

- test device

- upper block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000012360testing methodMethods0.000titleclaimsabstractdescription24

- 229910000831SteelInorganic materials0.000claimsabstractdescription11

- 239000010959steelSubstances0.000claimsabstractdescription11

- 230000003068static effectEffects0.000claimsdescription7

- 230000001360synchronised effectEffects0.000abstractdescription4

- 238000011160researchMethods0.000abstractdescription3

- 238000010586diagramMethods0.000description6

- 238000007667floatingMethods0.000description6

- 238000004364calculation methodMethods0.000description5

- 238000000034methodMethods0.000description5

- 238000010276constructionMethods0.000description3

- 238000005259measurementMethods0.000description3

- 238000013461designMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000004088simulationMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 238000011161developmentMethods0.000description1

- 238000005516engineering processMethods0.000description1

- 238000009434installationMethods0.000description1

- 238000012545processingMethods0.000description1

Images

Landscapes

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及试验装置,尤其涉及一种用于大吨位上部组块连续提升系统的试验装置。属于海洋工程技术领域。The invention relates to a test device, in particular to a test device for a large-tonnage upper block continuous lifting system. It belongs to the field of marine engineering technology.

背景技术Background technique

海洋油气资源的开发需在海上布置一定数量的海洋石油平台。海洋石油平台主要有两种类型:固定平台、浮式平台。The development of offshore oil and gas resources requires a certain number of offshore oil platforms. There are two main types of offshore oil platforms: fixed platforms and floating platforms.

海洋石油固定平台一般包括:上部组块和水下固定支撑结构。此类海洋石油平台一般是将上部组块和水下固定支撑结构在陆地单独建造,并采用浮托法进行海上安装作业。在大型上部组块的船运过程中通常需要在其下部和船舶甲板之间布置下部支撑结构。对于浮式平台,其一般由上部组块和下部浮体组成,在其下水之前,通常需在场地或船坞完成其上部组块和下部浮体的组对工作。A fixed offshore oil platform generally includes: an upper module and an underwater fixed support structure. This type of offshore oil platform is generally built separately on land with the upper module and the underwater fixed support structure, and adopts the float-over method for offshore installation operations. During the shipping of large topside modules it is often necessary to arrange a substructure between its lower part and the deck of the ship. For a floating platform, it generally consists of an upper block and a lower floating body. Before launching, it is usually necessary to complete the assembly of the upper block and the lower floating body at the site or dock.

对于海洋石油平台的建造,传统工艺一般是先将下部支撑结构、下部浮体等下部结构预制完成,然后,再继续进行上部组块的建造。建造过程中,上部组块需要先提升一定的高度,以便使下部支撑结构、下部浮体等下部结构能够顺利的插入或运输至上部组块的底部。因此,上部组块的提升是整个海洋石油平台组装过程中的重要一环,直接影响到海洋石油平台的建造周期及生产成本。For the construction of offshore oil platforms, the traditional process is generally to prefabricate the lower structures such as the lower support structure and the lower floating body first, and then continue to construct the upper modules. During the construction process, the upper block needs to be raised to a certain height first, so that the lower supporting structure, the lower floating body and other substructures can be smoothly inserted or transported to the bottom of the upper block. Therefore, the lifting of the upper block is an important part of the assembly process of the entire offshore oil platform, which directly affects the construction period and production cost of the offshore oil platform.

目前,大吨位上部组块连续提升系统的提升能力已达到35000吨,提升高度为60米。由于上部组块的吨位较大,提升高度较高,作业时间较长,因此对上部组块提升系统的工作性能可靠性要求极高。如果直接进行提升作业,提升系统作业的存在潜在的风险不易发现,这就要求在提升系统实际作业之前,需对其工作性能进行检验,以测试其工作指标是否达到要求。At present, the lifting capacity of the large-tonnage upper block continuous lifting system has reached 35,000 tons, and the lifting height is 60 meters. Due to the large tonnage of the upper block, high lifting height and long operating time, the requirements for the reliability of the working performance of the upper block lifting system are extremely high. If the lifting operation is carried out directly, the potential risks of the lifting system operation are not easy to find. This requires that before the actual operation of the lifting system, its working performance needs to be inspected to test whether its working indicators meet the requirements.

发明内容Contents of the invention

本发明的主要目的在于克服现有技术存在的上述缺点,而提供一种大吨位上部组块连续提升系统的试验装置,其可以检验提升系统的多吊点同步提升性能;并根据试验装置各部件的受力测量值与理论计算值的比较结果,修正有限元计算模型,从而更好地指导实际提升系统的设计;同时,通过模拟试验能够充分反映提升系统在各种情况下的运动响应,解决了利用一套试验装置完全模拟提升系统提升上部组块的问题;为提升系统的功能可行性及其自身的安全性提供了依据,降低了提升系统作业的潜在风险,对提升系统的进一步深入研究具有指导意义。The main purpose of the present invention is to overcome the above-mentioned shortcomings existing in the prior art, and to provide a test device for a large-tonnage upper block continuous lifting system, which can test the multi-lifting point synchronous lifting performance of the lifting system; and according to the components of the test device The comparison results of the force measurement value and the theoretical calculation value can revise the finite element calculation model, so as to better guide the design of the actual lifting system; at the same time, the simulation test can fully reflect the motion response of the lifting system in various situations, and solve the problem of The use of a set of test equipment to completely simulate the problem of lifting the upper block of the lifting system; provide a basis for the functional feasibility of the lifting system and its own safety, reduce the potential risk of the lifting system operation, further in-depth research on the lifting system Instructive.

本发明的目的是由以下技术方案实现的:The purpose of the present invention is achieved by the following technical solutions:

一种大吨位上部组块连续提升系统的试验装置,其特征在于:包括两个底座、塔架、斜拉支撑、塔顶梁、液压提升器、中间组块、配重,其中,两个底座呈对称式布置安放于地基上;底座上分别安装有塔架与斜拉支撑,而塔架又与斜拉支撑连接为一体,塔架的顶部安装有塔顶梁,塔顶梁上设有数个凸台;凸台上安装有液压提升器,液压提升器与计算机相连;位于液压提升器下端的钢绞线固定在中间组块上,中间组块上面安放有不同重量的配重块。A test device for a large-tonnage upper block continuous lifting system, which is characterized in that it includes two bases, a tower, a cable-stayed support, a tower top beam, a hydraulic lifter, an intermediate block, and a counterweight, wherein the two bases It is arranged symmetrically on the foundation; the base is respectively installed with a tower and a cable-stayed support, and the tower is connected with the cable-stayed support as a whole. The top of the tower is equipped with a tower top beam, and several A boss; a hydraulic lifter is installed on the boss, and the hydraulic lifter is connected with the computer; the steel strand at the lower end of the hydraulic lifter is fixed on the middle block, and counterweights of different weights are placed on the middle block.

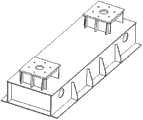

所述底座钢结构箱形体。The base steel structure box-shaped body.

所述斜拉支撑为桁架式结构。The cable-stayed support is a truss structure.

所述塔顶梁为钢结构箱形体。The tower top beam is a box-shaped steel structure.

所述计算机与动静态应变测试仪相连,动静态应变测试仪与应变片相连,应变片预先贴在提升系统测点处。The computer is connected with the dynamic and static strain tester, the dynamic and static strain tester is connected with the strain gauge, and the strain gauge is pre-attached to the measuring point of the lifting system.

本发明的有益效果:本发明可以检验提升系统的多吊点同步提升性能;并根据试验装置各部件的受力测量值与理论计算值的比较结果,修正有限元计算模型,从而更好地指导实际提升系统的设计;同时,通过模拟实验能够充分反映提升系统在各种工况下的运动响应,解决了利用一套试验装置完全模拟提升系统提升上部组块的问题;为提升系统的功能可行性及其自身的安全性提供了依据,降低了提升系统作业的潜在风险,对提升系统的进一步深入研究具有指导意义。Beneficial effects of the present invention: the present invention can test the synchronous lifting performance of multiple lifting points of the lifting system; and according to the comparison results of the force measurement value and the theoretical calculation value of each part of the test device, the finite element calculation model is corrected, so as to better guide The design of the actual lifting system; at the same time, the motion response of the lifting system under various working conditions can be fully reflected through the simulation experiment, and the problem of using a set of test equipment to completely simulate the lifting system to lift the upper block is solved; the function of the lifting system is feasible It provides a basis for the safety and its own safety, reduces the potential risk of the lifting system operation, and has guiding significance for further in-depth research on the lifting system.

附图说明:Description of drawings:

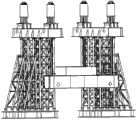

图1为本发明整体结构主视示意图。Fig. 1 is a schematic front view of the overall structure of the present invention.

图2为本发明整体结构立体示意图。Fig. 2 is a three-dimensional schematic diagram of the overall structure of the present invention.

图3为本发明液压提升器示意图。Fig. 3 is a schematic diagram of the hydraulic lifter of the present invention.

图4为本发明底座示意图。Fig. 4 is a schematic diagram of the base of the present invention.

图5为本发明塔架及斜拉支撑示意图。Fig. 5 is a schematic diagram of the tower and cable-stayed supports of the present invention.

图6为本发明塔顶梁示意图。Fig. 6 is a schematic diagram of the tower top beam of the present invention.

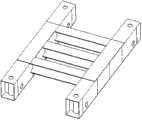

图7为本发明中间组块示意图。FIG. 7 is a schematic diagram of an intermediate block of the present invention.

图中主要标号说明:Explanation of main symbols in the figure:

1底座、2塔架、3斜拉支撑、4塔顶梁、41凸台、5液压提升器、51钢绞线、52构件夹持器、6中间组块、7配重块。1 base, 2 tower, 3 cable-stayed support, 4 tower top beam, 41 boss, 5 hydraulic lifter, 51 steel strand, 52 component holder, 6 middle block, 7 counterweight.

具体实施方式Detailed ways

如图1-图7所示,本发明主要包括:底座1、塔架2、斜拉支撑3、塔顶梁4、液压提升器5、中间组块6、配重7。其中,底座1为两个钢结构箱形体,呈对称式布置安放于地基上;底座1上分别安装有塔架2与斜拉支撑3,塔架2与斜拉支撑3之间是通过法兰连接方式构成一整体,斜拉支撑3为桁架式结构;每个塔架2的顶部通过法兰与塔顶梁4进行连接,塔顶梁4为钢结构箱形体,箱形体上设有数个凸台41;塔顶梁4上分别安装有一组液压提升器5,液压提升器5与计算机相连,由计算机同步控制。本实施例:每一组液压提升器5为两个,但不限于两个,根据需要可以为数个。液压提升器5安放于塔顶梁的凸台41上,两者之间采用螺栓连接;位于液压提升器5下端的钢绞线51,通过构件夹持器52固定在中间组块6上,根据试验需要,中间组块6上面安放有不同重量的配重块7。As shown in FIGS. 1-7 , the present invention mainly includes: a

考虑加工生产及运输等因素,实际提升系统中的塔架2设计成标准节式。为反映这一特征,本发明中的塔架2亦做成标准节式,每节塔架2高为两米,一组塔架2由两个标准节构成,中间采用法兰连接。Considering factors such as processing, production and transportation, the

提升系统测点处预先贴有应变片,用于测量试验过程中各部件的应力值,以便与有限元计算结果进行比较。应变片通过导线与动静态应变测试仪连接,可以实时测试结构件关键部位的应力值,动静态应变测试仪与计算机相连,以显示测点处的测量曲线,并将测试到的数据保存到计算机上。试验过程中记录液压提升器5的提升速度及同步控制精度,检验其是否达到指标要求。The measuring points of the lifting system are pre-attached with strain gauges, which are used to measure the stress value of each component during the test, so as to compare with the finite element calculation results. The strain gauge is connected with the dynamic and static strain tester through the wire, which can test the stress value of the key parts of the structure in real time. The dynamic and static strain tester is connected with the computer to display the measurement curve at the measuring point and save the tested data to the computer. superior. During the test, record the lifting speed and synchronous control accuracy of the

上述液压提升器、应变片、构件夹持器、动静态应变测试仪、计算机为已有技术。The above-mentioned hydraulic lifter, strain gauge, component holder, dynamic and static strain tester, and computer are prior art.

以上所述,仅是本发明的较佳实施例而已,并非对本发明作任何形式上的限制,凡是依据本发明的技术实质对以上实施例所作的任何简单修改、等同变化与修饰,均仍属于本发明技术方案的范围内。The above are only preferred embodiments of the present invention, and are not intended to limit the present invention in any form. Any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention still belong to within the scope of the technical solutions of the present invention.

Claims (5)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011104467531ACN102539188A (en) | 2011-12-28 | 2011-12-28 | Test device for continuous lifting system of large-tonnage topside module |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011104467531ACN102539188A (en) | 2011-12-28 | 2011-12-28 | Test device for continuous lifting system of large-tonnage topside module |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102539188Atrue CN102539188A (en) | 2012-07-04 |

Family

ID=46346626

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011104467531APendingCN102539188A (en) | 2011-12-28 | 2011-12-28 | Test device for continuous lifting system of large-tonnage topside module |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102539188A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102777044A (en)* | 2012-08-07 | 2012-11-14 | 中化二建集团有限公司 | Hoisting method of steel-structured spraying layer of urea prilling tower |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1306131A (en)* | 2001-02-28 | 2001-08-01 | 上海交通大学 | Platform for sinking combined simple turnnel pipe segments |

| CN1654306A (en)* | 2005-01-24 | 2005-08-17 | 史胜海 | Method for hoisting and loading giant-scale gantry crane by following-carrying method |

| US20090028647A1 (en)* | 2006-02-06 | 2009-01-29 | Ihc Engineering Business Limited | Installation Of Offshore Structures |

| CN102206938A (en)* | 2010-10-13 | 2011-10-05 | 天津市海王星海上工程技术有限公司 | Novel method for installing upper part block of offshore platform |

| CN102288420A (en)* | 2011-04-28 | 2011-12-21 | 中国海洋石油总公司 | Test device for deep water vertical pipe lifting system |

- 2011

- 2011-12-28CNCN2011104467531Apatent/CN102539188A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1306131A (en)* | 2001-02-28 | 2001-08-01 | 上海交通大学 | Platform for sinking combined simple turnnel pipe segments |

| CN1654306A (en)* | 2005-01-24 | 2005-08-17 | 史胜海 | Method for hoisting and loading giant-scale gantry crane by following-carrying method |

| US20090028647A1 (en)* | 2006-02-06 | 2009-01-29 | Ihc Engineering Business Limited | Installation Of Offshore Structures |

| CN102206938A (en)* | 2010-10-13 | 2011-10-05 | 天津市海王星海上工程技术有限公司 | Novel method for installing upper part block of offshore platform |

| CN102288420A (en)* | 2011-04-28 | 2011-12-21 | 中国海洋石油总公司 | Test device for deep water vertical pipe lifting system |

Non-Patent Citations (1)

| Title |

|---|

| 高杰,陈前银: "800t*185m门式起重机双直立门架整体吊装技术", 《工程建设与设计》* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102777044A (en)* | 2012-08-07 | 2012-11-14 | 中化二建集团有限公司 | Hoisting method of steel-structured spraying layer of urea prilling tower |

| CN102777044B (en)* | 2012-08-07 | 2015-05-27 | 中化二建集团有限公司 | Hoisting method of steel-structured spraying layer of urea prilling tower |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103617333B (en) | Ocean platform floating holder installation shock analog analysing method | |

| CN110095301A (en) | FPSO upper module model test method under a kind of simulation extreme sea condition | |

| CN105203301A (en) | Crown block active and passive combined heave compensation testing device | |

| CN102288420A (en) | Test device for deep water vertical pipe lifting system | |

| CN100487391C (en) | Weighting method of large cantilever structure | |

| CN103090945A (en) | Weighing method and independent weighing units of large ocean function module | |

| CN105043884A (en) | Testing device for carrying capacity of comprehensive pipe gallery and pipe joint and application method | |

| CN201897555U (en) | System for detecting plane internal deformation performance of building curtain wall | |

| CN201817802U (en) | Ocean platform hydraulic lifting device | |

| CN206223465U (en) | A kind of large scale structure fatigue test machine host | |

| CN108457261B (en) | A kind of self-elevating drilling platform cantilever beam rig floor experiment of weighing system and method | |

| US20230324268A1 (en) | Deepwater platform welded joint testing system | |

| CN102877412B (en) | Method of pre-assembly in integral erecting way of steel tower | |

| CN102539188A (en) | Test device for continuous lifting system of large-tonnage topside module | |

| Yu et al. | Hydrodynamic analysis of three-module semi-submersible platform and its mooring design | |

| CN110146246B (en) | An impact test test platform, test device and hoisting buffer test method | |

| CN202757788U (en) | Passive and follow-up loading structure experiment system | |

| CN202229837U (en) | Auxiliary calibrating device of fixed electronic weighing apparatus | |

| CN116256139A (en) | A test method for dynamic response of offshore structures under coupled wind-wave action | |

| CN203188123U (en) | Hydraulic jack device for lowering whole bridge anticollision steel cofferdam synchronously | |

| CN212391189U (en) | A loading device for seismic performance of reinforced concrete bridge piers | |

| CN203929187U (en) | Be applicable to the weighing system of semi-girder assembly | |

| CN2844867Y (en) | Calibrating device for super large railway scales | |

| CN114875875A (en) | Transformation and installation method of self-elevating platform pile fixing device | |

| CN109374170B (en) | Motion compensation platform base overturning force detection device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20120704 |