CN102514285A - Low-emissivity coated glass and manufacturing method thereof - Google Patents

Low-emissivity coated glass and manufacturing method thereofDownload PDFInfo

- Publication number

- CN102514285A CN102514285ACN2011104366494ACN201110436649ACN102514285ACN 102514285 ACN102514285 ACN 102514285ACN 2011104366494 ACN2011104366494 ACN 2011104366494ACN 201110436649 ACN201110436649 ACN 201110436649ACN 102514285 ACN102514285 ACN 102514285A

- Authority

- CN

- China

- Prior art keywords

- layer

- dielectric layer

- dielectric

- coated

- coated glass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000011521glassSubstances0.000titleclaimsabstractdescription81

- 238000004519manufacturing processMethods0.000titleclaimsabstractdescription6

- 239000010410layerSubstances0.000claimsabstractdescription215

- 239000002346layers by functionSubstances0.000claimsabstractdescription32

- 230000004888barrier functionEffects0.000claimsabstractdescription28

- 230000005855radiationEffects0.000claimsabstractdescription23

- 239000000758substrateSubstances0.000claimsabstractdescription16

- 229910007717ZnSnOInorganic materials0.000claimsdescription29

- XKRFYHLGVUSROY-UHFFFAOYSA-NArgonChemical compound[Ar]XKRFYHLGVUSROY-UHFFFAOYSA-N0.000claimsdescription23

- 229910001120nichromeInorganic materials0.000claimsdescription23

- VNNRSPGTAMTISX-UHFFFAOYSA-Nchromium nickelChemical compound[Cr].[Ni]VNNRSPGTAMTISX-UHFFFAOYSA-N0.000claimsdescription22

- 239000010949copperSubstances0.000claimsdescription17

- 238000004544sputter depositionMethods0.000claimsdescription15

- 229910052786argonInorganic materials0.000claimsdescription12

- 239000012300argon atmosphereSubstances0.000claimsdescription10

- 239000012298atmosphereSubstances0.000claimsdescription9

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000claimsdescription9

- 239000001301oxygenSubstances0.000claimsdescription9

- 229910052760oxygenInorganic materials0.000claimsdescription9

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000claimsdescription8

- 229910020286SiOxNyInorganic materials0.000claimsdescription8

- 229910010413TiO 2Inorganic materials0.000claimsdescription5

- 229910052757nitrogenInorganic materials0.000claimsdescription4

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000claimsdescription3

- 229910001128Sn alloyInorganic materials0.000claimsdescription3

- 229910000611Zinc aluminiumInorganic materials0.000claimsdescription3

- HXFVOUUOTHJFPX-UHFFFAOYSA-Nalumane;zincChemical compound[AlH3].[Zn]HXFVOUUOTHJFPX-UHFFFAOYSA-N0.000claimsdescription3

- 239000000919ceramicSubstances0.000claimsdescription3

- 229910052802copperInorganic materials0.000claimsdescription3

- GZCWPZJOEIAXRU-UHFFFAOYSA-Ntin zincChemical compound[Zn].[Sn]GZCWPZJOEIAXRU-UHFFFAOYSA-N0.000claimsdescription3

- 229910007694ZnSnO3Inorganic materials0.000claimsdescription2

- 239000012299nitrogen atmosphereSubstances0.000claimsdescription2

- 238000004062sedimentationMethods0.000claims7

- 230000009977dual effectEffects0.000claims4

- 238000002834transmittanceMethods0.000abstractdescription6

- 238000001755magnetron sputter depositionMethods0.000description14

- OLFCLHDBKGQITG-UHFFFAOYSA-Nchromium(3+) nickel(2+) oxygen(2-)Chemical compound[Ni+2].[O-2].[Cr+3]OLFCLHDBKGQITG-UHFFFAOYSA-N0.000description9

- 238000001228spectrumMethods0.000description8

- 238000007747platingMethods0.000description7

- 230000005540biological transmissionEffects0.000description5

- 229910052709silverInorganic materials0.000description5

- 239000004332silverSubstances0.000description5

- BQCADISMDOOEFD-UHFFFAOYSA-NSilverChemical compound[Ag]BQCADISMDOOEFD-UHFFFAOYSA-N0.000description4

- CSDREXVUYHZDNP-UHFFFAOYSA-NalumanylidynesiliconChemical compound[Al].[Si]CSDREXVUYHZDNP-UHFFFAOYSA-N0.000description4

- 238000000576coating methodMethods0.000description3

- 238000000034methodMethods0.000description3

- 230000004048modificationEffects0.000description3

- 238000012986modificationMethods0.000description3

- 239000011248coating agentSubstances0.000description2

- 230000007547defectEffects0.000description2

- 229910000623nickel–chromium alloyInorganic materials0.000description2

- 238000000985reflectance spectrumMethods0.000description2

- 229910052581Si3N4Inorganic materials0.000description1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000description1

- JYMITAMFTJDTAE-UHFFFAOYSA-Naluminum zinc oxygen(2-)Chemical compound[O-2].[Al+3].[Zn+2]JYMITAMFTJDTAE-UHFFFAOYSA-N0.000description1

- 239000007888film coatingSubstances0.000description1

- 238000009501film coatingMethods0.000description1

- 239000005344low-emissivity glassSubstances0.000description1

- KYKLWYKWCAYAJY-UHFFFAOYSA-Noxotin;zincChemical compound[Zn].[Sn]=OKYKLWYKWCAYAJY-UHFFFAOYSA-N0.000description1

- 229910052710siliconInorganic materials0.000description1

- 239000010703siliconSubstances0.000description1

- HQVNEWCFYHHQES-UHFFFAOYSA-Nsilicon nitrideChemical compoundN12[Si]34N5[Si]62N3[Si]51N64HQVNEWCFYHHQES-UHFFFAOYSA-N0.000description1

Images

Landscapes

- Surface Treatment Of Glass (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及玻璃深加工中的镀膜技术领域,具体是一种低辐射镀膜玻璃及其制造方法。The invention relates to the technical field of coating in glass deep processing, in particular to low-radiation coated glass and a manufacturing method thereof.

背景技术Background technique

传统的低辐射玻璃往往都是双银镀膜玻璃的结构,具体结构包括:玻璃基底和在玻璃基底上依次向上沉积的第一介电质层、银膜层、第一阻挡层、第二介电质层、银膜层、第二阻挡层,以及第三介电质层,按照所述结构生产的镀膜玻璃其透过色呈蓝绿色,此玻璃用于建筑后,透过此玻璃,从室内往室外看时,外界的物体也被增添了蓝绿色调,使得外界景物发生色变。Traditional low-emissivity glass often has a structure of double-silver coated glass. The specific structure includes: a glass substrate and a first dielectric layer, a silver film layer, a first barrier layer, and a second dielectric layer deposited sequentially upward on the glass substrate. quality layer, silver film layer, the second barrier layer, and the third dielectric layer, the coated glass produced according to the above structure has a blue-green transmission color, after the glass is used in the building, through this glass, from the indoor When looking outside, the external objects are also added with a blue-green tone, causing the external scenery to change color.

发明内容Contents of the invention

本发明的技术目的是克服现有技术存在的缺陷,提供一种新型的低辐射镀膜玻璃及其制造方法,使镀膜后的玻璃呈自然色。The technical purpose of the present invention is to overcome the defects of the prior art, provide a new type of low-emissivity coated glass and its manufacturing method, so that the coated glass has a natural color.

本发明的技术方案为:Technical scheme of the present invention is:

一种低辐射镀膜玻璃,包括玻璃基片和镀制在玻璃基片上的膜系,其特征在于,所述膜系自玻璃基片向外依次包括:A low-emissivity coated glass, comprising a glass substrate and a film system plated on the glass substrate, characterized in that the film system sequentially includes from the glass substrate outward:

第一电介质层、第二电介质层、第一功能层、第一阻挡层、中间电介质组合层、第三电介质层、第二功能层、第二阻挡层、顶层下电介质层、顶层上电介质层。First dielectric layer, second dielectric layer, first functional layer, first barrier layer, middle dielectric combination layer, third dielectric layer, second functional layer, second barrier layer, top lower dielectric layer, top upper dielectric layer.

作为优选的技术方案:As a preferred technical solution:

所述第一功能层为Cu层,所述第二功能层为Ag层;The first functional layer is a Cu layer, and the second functional layer is an Ag layer;

所述第一电介质层可设为Si3N4、ZnSnO3、TiO2或者SiOxNy膜层中的一种;The first dielectric layer can be set as one of Si3 N4 , ZnSnO3 , TiO2 or SiOxNy film layers;

所述第二电介质层、第三电介质层为ZnO层;The second dielectric layer and the third dielectric layer are ZnO layers;

所述第一阻挡层的为NiCr、AZO、Ti、Nb2O5或NiCrOx膜层中的一种;The first barrier layer is one of NiCr, AZO, Ti, Nb2 O5 or NiCrOx film layer;

所述中间电介质组合层为ZnSnO3、Si3N4膜层中的一种或者二者的组合层;The intermediate dielectric combination layer is one of ZnSnO3 , Si3 N4 film layers or a combination layer of both;

所述第二阻挡层设为NiCr、AZO、Ti、Nb2O5或NiCrOx膜层中的一种;The second barrier layer is set as one of NiCr, AZO, Ti, Nb2 O5 or NiCrOx film layer;

所述顶层下电介质层为ZnSnO3层;The dielectric layer under the top layer is a ZnSnO3 layer;

所述顶层上电介质层为Si3N4层。The dielectric layer on the top layer is a Si3 N4 layer.

一种用于制造上述低辐射镀膜玻璃的制造方法,其特征在于,包括以下步骤:A method for manufacturing the above-mentioned low-emissivity coated glass, characterized in that it comprises the following steps:

在所述玻璃基片上镀制Si3N4、ZnSnO3、TiO2或者SiOxNy膜层中的一种作为第一电介质层;Coating one of Si3 N4 , ZnSnO3 , TiO2 or SiOxNy film layers on the glass substrate as the first dielectric layer;

在所述第一电介质层上镀制作为第二电介质层的ZnO层;Plating a ZnO layer as a second dielectric layer on the first dielectric layer;

在所述第二电介质层上镀制作为第一功能层的Cu层;Plating a Cu layer as the first functional layer on the second dielectric layer;

在所述第一功能层上镀制NiCr、AZO、Ti、Nb2O5或NiCrOx膜层中的一种作为第一阻挡层;Plating one of NiCr, AZO, Ti, Nb2 O5 or NiCrOx film layer on the first functional layer as the first barrier layer;

在所述第一阻挡层上镀制ZnSnO3、Si3N4膜层中的一种或者二者的组合层层作为中间电介质组合层;Plating one of ZnSnO3 , Si3 N4 film layers or a combination layer of both on the first barrier layer as an intermediate dielectric combination layer;

在所述中间电介质组合层上镀制第三电介质层的ZnO层;Plating a ZnO layer of the third dielectric layer on the intermediate dielectric combination layer;

在所述第三电介质层上镀制第二功能层的Ag层;plating an Ag layer of the second functional layer on the third dielectric layer;

在所述第二功能层上镀制NiCr、AZO、Ti、Nb2O5或NiCrOx膜层中的一种作为第二阻挡层;One of NiCr, AZO, Ti, Nb2 O5 or NiCrOx film layer is plated on the second functional layer as the second barrier layer;

在所述第二阻挡层上镀制作为顶层下电介质层的ZnSnO3层;Plating a ZnSnO3 layer as the top lower dielectric layer on the second barrier layer;

在所述顶层下电介质层上镀制作为顶层上电介质层的Si3N4层;On the dielectric layer under the top layer, the Si3 N4 layer is plated as the dielectric layer on the top layer;

上述玻璃结构中,Si3N4层使用质量百分比为92:8的硅铝靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氮氛围中溅射沉积,功率为20-80kw,电源频率为20-40kHz;In the above-mentioned glass structure, the Si3 N4 layer uses a silicon-aluminum target with a mass percentage of 92:8, and is sputtered and deposited in an argon and nitrogen atmosphere by means of double rotating cathodes and intermediate frequency reactive magnetron sputtering, with a power of 20-80kw. The power frequency is 20-40kHz;

SiOxNy层使用质量百分比为92:8的硅铝靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氮、氧氛围中溅射沉积,功率为20-80kw,电源频率为20-40kHz;The SiOxNy layer uses a silicon-aluminum target with a mass percentage of 92:8, and is sputtered and deposited in an atmosphere of argon, nitrogen, and oxygen by means of double-rotating cathodes and intermediate-frequency reactive magnetron sputtering, with a power of 20-80kw and a power frequency of 20-40kHz ;

AZO层使用陶瓷锌铝靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氧氛围中溅射沉积,功率为5-15kw,电源频率为20-40kHz;The AZO layer uses a ceramic zinc-aluminum target, and is sputtered and deposited in an atmosphere of argon and oxygen by means of double-rotating cathodes and medium-frequency reactive magnetron sputtering, with a power of 5-15kw and a power frequency of 20-40kHz;

ZnSnO3层使用质量百分比为50:50的锌锡合金靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氧氛围中溅射沉积,功率为10-70kw,电源频率为20-40kHz;The ZnSnO3 layer uses a zinc-tin alloy target with a mass percentage of 50:50, and is sputtered and deposited in an atmosphere of argon and oxygen by means of double-rotating cathodes and medium-frequency reactive magnetron sputtering, with a power of 10-70kw and a power frequency of 20-40kHz;

NiCrOx层使用镍铬合金靶,采用平面阴极、直流磁控溅射方式在纯氩氛围中溅射沉积,功率为2-10kw;The NiCrOx layer uses a nickel-chromium alloy target, and is sputtered and deposited in a pure argon atmosphere by means of planar cathode and DC magnetron sputtering, with a power of 2-10kw;

功能层Ag层为使用银靶,采用平面阴极、直流磁控溅射方式在纯氩氛围中溅射沉积,功率为2-10kw;The Ag layer of the functional layer uses a silver target, and is sputtered and deposited in a pure argon atmosphere by means of planar cathode and DC magnetron sputtering, with a power of 2-10kw;

功能层Cu层为使用铜靶,采用平面阴极、直流磁控溅射方式在纯氩氛围中溅射沉积,功率为2-10kw。The Cu layer of the functional layer uses a copper target, and is sputtered and deposited in a pure argon atmosphere by means of planar cathode and DC magnetron sputtering, with a power of 2-10kw.

本发明的玻璃产品呈自然色,颜色均一,克服了现有产品的缺陷,并且在可见光区透过率高,在近红外区具有低辐射的优点。本发明的镀膜方法简单,容易实施,镀出的膜层均匀,产品质量好。The glass product of the invention has natural color and uniform color, overcomes the defects of existing products, has high transmittance in the visible light region, and has the advantages of low radiation in the near infrared region. The coating method of the invention is simple and easy to implement, the coated film layer is uniform and the product quality is good.

附图说明Description of drawings

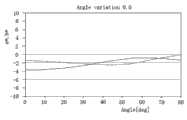

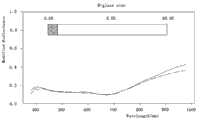

图1为实施例一低辐射镀膜玻璃的膜面反射光谱曲线;Fig. 1 is the film surface reflection spectrum curve of embodiment one low radiation coated glass;

图2为实施例一低辐射镀膜玻璃面的反射光谱曲线;Fig. 2 is the reflection spectrum curve of embodiment one low-emissivity coated glass surface;

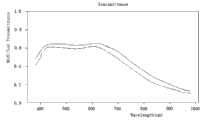

图3为实施例一低辐射镀膜玻璃的透射特性谱图;Fig. 3 is the transmission characteristic spectrogram of embodiment one low radiation coated glass;

图4为实施例一低辐射镀膜玻璃的单片色系坐标;Fig. 4 is the monolithic color system coordinate of embodiment one low-emissivity coated glass;

图5为实施例一低辐射镀膜玻璃构成的中空玻璃色系坐标;Fig. 5 is the color system coordinates of the insulating glass made of low-emissivity coated glass in embodiment one;

图6为实施例二低辐射镀膜玻璃的膜面反射光谱曲线;Fig. 6 is the film surface reflectance spectrum curve of embodiment two low radiation coated glass;

图7为实施例二低辐射镀膜玻璃的玻璃面反射光谱曲线;Fig. 7 is the glass surface reflection spectrum curve of embodiment two low radiation coated glass;

图8为实施例二低辐射镀膜玻璃的透射特性谱图;Fig. 8 is the transmission characteristic spectrogram of embodiment two low radiation coated glass;

图9为实施例二低辐射镀膜玻璃的单片色系坐标;Fig. 9 is the monolithic color coordinates of the low-emissivity coated glass of embodiment two;

图10为实施例二低辐射镀膜玻璃构成的中空玻璃色系坐标;Fig. 10 is the color system coordinates of the insulating glass made of the low-emissivity coated glass of embodiment two;

图11为本发明低辐射镀膜玻璃的结构示意图。Fig. 11 is a schematic structural view of the low-emissivity coated glass of the present invention.

具体实施方式Detailed ways

为详细说明本发明创造的技术方案、技术目的以及技术效果,下面结合实施例并配合附图予以详细说明。In order to describe the technical scheme, technical purpose and technical effect created by the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

如图11所示,本发明低辐射镀膜玻璃在玻璃基片10上向外依次镀有第一电介质层11、第二电介质层12、第一功能层13、第一阻挡层14、中间电介质组合层15、第三电介质层16、第二功能层17、第二阻挡层18、顶层下电介质层19以及顶层上电介质层20。As shown in Figure 11, the low-emissivity coated glass of the present invention is sequentially coated with a first

所述第一电介质层11可设为Si3N4、ZnSnO3、TiO2或者SiOxNy膜层中的一种;The first

所述第二电介质层12优选为ZnO层;The second

所述第一功能层13为Cu层;The first

所述第一阻挡层14为NiCr、AZO、Ti、Nb2O5或NiCrOx层;The

所述中间电介质组合层15为ZnSnO3或Si3N4层,或者是ZnSnO3和Si3N4的组合层;The intermediate

所述第三电介质层16为ZnO层;The third

所述第二功能层17为Ag层;The second

所述第二阻挡层18优选为为NiCr、ZnAlO、Ti、Nb2O5或NiCrOx层中的一种;The

所述顶层下电介质层19为ZnSnO3层;The

所述顶层上电介质层20为Si3N4层。The

上述结构中,所有氮化硅(Si3N4)层使用硅铝(质量百分比92:8)靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氮氛围中溅射沉积,功率为20-80kw,电源频率为20-40kHz;In the above structure, all silicon nitride (Si3 N4 ) layers use silicon aluminum (mass percentage 92:8) targets, and are sputtered and deposited in argon and nitrogen atmospheres by means of double rotating cathodes and intermediate frequency reactive magnetron sputtering. 20-80kw, power frequency 20-40kHz;

所有氮氧化硅(SiOxNy )层使用硅铝(质量百分比92:8)靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氮、氧氛围中溅射沉积,功率为20-80kw,电源频率为20-40kHz;All silicon oxynitride (SiOxNy) layers use silicon aluminum (mass percentage 92:8) targets, and are sputtered and deposited in an atmosphere of argon, nitrogen, and oxygen by means of double rotating cathodes and intermediate frequency reactive magnetron sputtering, with a power of 20-80kw. The power frequency is 20-40kHz;

锌铝氧化物(AZO)层使用陶瓷锌铝靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氧氛围中溅射沉积,功率为5-15kw,电源频率为20-40kHz;The zinc-aluminum oxide (AZO) layer uses a ceramic zinc-aluminum target, and is sputtered and deposited in an atmosphere of argon and oxygen by means of double-rotating cathodes and medium-frequency reactive magnetron sputtering, with a power of 5-15kw and a power frequency of 20-40kHz;

氧化锌锡(ZnSnOx)层,如ZnSnO3,使用锌锡合金(质量百分比50:50)靶,采用双旋转阴极、中频反应磁控溅射方式在氩、氧氛围中溅射沉积,功率为10-70kw,电源频率为20-40kHz;Zinc tin oxide (ZnSnOx) layer, such as ZnSnO3 , uses a zinc-tin alloy (mass percentage 50:50) target, adopts double rotating cathode, intermediate frequency reactive magnetron sputtering method to sputter deposition in argon and oxygen atmosphere, and the power is 10 -70kw, the power frequency is 20-40kHz;

所有氧化镍铬(NiCrOx)层使用镍铬合金靶,采用平面阴极、直流磁控溅射方式在纯氩氛围中溅射沉积,功率为2-10kw;All nickel-chromium oxide (NiCrOx) layers use nickel-chromium alloy targets, and are sputter-deposited in a pure argon atmosphere by planar cathode and DC magnetron sputtering, with a power of 2-10kw;

功能层Ag层为使用银靶,采用平面阴极、直流磁控溅射方式在纯氩氛围中溅射沉积,功率为2-10kw;The Ag layer of the functional layer uses a silver target, and is sputtered and deposited in a pure argon atmosphere by means of planar cathode and DC magnetron sputtering, with a power of 2-10kw;

功能层Cu层为使用铜靶,采用平面阴极、直流磁控溅射方式在纯氩氛围中溅射沉积,功率为2-10kw。The Cu layer of the functional layer uses a copper target, and is sputtered and deposited in a pure argon atmosphere by means of planar cathode and DC magnetron sputtering, with a power of 2-10kw.

实施例一:Embodiment one:

作为低辐射镀膜玻璃的一种优选结构,具体如下:As a preferred structure of low-emissivity coated glass, the details are as follows:

玻璃基片/Si3N4/ZnO/Cu/NiCr/ZnSnO3/ZnO/Ag/NiCr/ZnSnO3/Si3N4。Glass substrate/Si3 N4 /ZnO/Cu/NiCr/ZnSnO3 /ZnO/Ag/NiCr/ZnSnO3 /Si3 N4 .

其中,所述第一电介质层11为Si3N4层, Si3N4厚度为19.5nm;Wherein, the

所述第二电介质层12为ZnO层,ZnO厚度为10nm;The

所述第一功能层13为Cu层,Cu的厚度为7.5nm;The first

所述第一阻挡层14为NiCr层,NiCr的厚度为1.3nm;The

所述中间电介质组合层15为ZnSnO3层,ZnSnO3的厚度为68.9nm;The intermediate

所述第三电介质层16为ZnO层, ZnO的厚度为10nm;The

所述第二功能层17为Ag层,Ag的厚度为16.8nm;The second

所述第二阻挡层18为NiCr层,NiCr的厚度为0.6nm;The

所述顶层下电介质层19为ZnSnO3, ZnSnO3的厚度为20.4nm;The

所述顶层上电介质层20为Si3N4,Si3N4的厚度为15.6nm。The

玻璃膜层镀制完成后,产品参数如图所示:After the glass film coating is completed, the product parameters are as shown in the figure:

图1为实施例一低辐射镀膜玻璃的膜面反射光谱曲线;Fig. 1 is the film surface reflection spectrum curve of embodiment one low radiation coated glass;

图2为实施例一低辐射镀膜玻璃的玻璃面反射光谱曲线;Fig. 2 is the glass surface reflection spectrum curve of embodiment one low radiation coated glass;

图3为实施例一低辐射镀膜玻璃的透射特性谱图;Fig. 3 is the transmission characteristic spectrogram of embodiment one low radiation coated glass;

图4为实施例一低辐射镀膜玻璃的单片色系坐标;Fig. 4 is the monolithic color system coordinate of embodiment one low-emissivity coated glass;

图5为实施例一低辐射镀膜玻璃构成的中空玻璃色系坐标。Fig. 5 is the coordinates of the color system of the hollow glass made of low-emissivity coated glass in Embodiment 1.

图1-图3中,虚线曲线为标准参照产品的测试曲线,实线曲线为实施例一产品的测试参数曲线;图4-图5为色坐标的a*值、b*值与角度的变化曲线图谱,虚线曲线为随着角度的变化a*值(绿到红的变化)的变化参数曲线,实线曲线为b*值(蓝到黄的变化)的参数曲线。Among Fig. 1-Fig. 3, dotted line curve is the test curve of standard reference product, and solid line curve is the test parameter curve of embodiment 1 product; Fig. 4-Fig. 5 is the variation of a* value, b* value and angle of color coordinates Curve spectrum, the dotted curve is the parametric curve of a* value (change from green to red) with the change of angle, and the solid line curve is the parametric curve of b* value (change from blue to yellow).

由图1、图2可知具有实施例一结构的低辐射镀膜玻璃在可见光区具有高透过率,对近红外区具有低辐射率。图3说明所述低辐射镀膜玻璃在可见光区具有高阳光透过率。图4、图5说明所述低辐射镀膜玻璃呈自然色,且从各角度观察,颜色具有均一性。 SHAPE \* MERGEFORMAT It can be seen from Fig. 1 and Fig. 2 that the low-emissivity coated glass with the structure of the first embodiment has high transmittance in the visible light region and low emissivity in the near-infrared region. Figure 3 illustrates that the low-e coated glass has high sunlight transmittance in the visible light region. Fig. 4 and Fig. 5 illustrate that the low-emissivity coated glass has a natural color, and the color is uniform when observed from various angles. SHAPE \* MERGEFORMAT

实施例二:Embodiment two:

低辐射镀膜玻璃的另一种优选结构,具体为:Another preferred structure of low-emissivity coated glass, specifically:

玻璃基片/Si3N4/ZnO/Cu/NiCr/ZnSnO3/ZnO/Ag/NiCr/ZnSnO3/Si3N4。Glass substrate/Si3 N4 /ZnO/Cu/NiCr/ZnSnO3 /ZnO/Ag/NiCr/ZnSnO3 /Si3 N4 .

其中,所述第一电介质层11为Si3N4层,Si3N4的厚度为15.7nm;Wherein, the

第二电介质层12为ZnO层, ZnO的厚度为10nm;The

第一功能层13为Cu层, Cu的厚度为7.3nm;The first

第一阻挡层14为NiCr层,NiCr的厚度为0.6nm;The

中间电介质组合层15为ZnSnO3层, ZnSnO3的厚度为68.7nm;The intermediate

第三电介质层16为ZnO层, ZnO的厚度为10nm;The

第二功能层17为Ag层,Ag的厚度为15.6nm;The second

第二阻挡层18为NiCr层,NiCr的厚度为0.6nm;The

顶层下电介质层19为ZnSnO3层,ZnSnO3的厚度为20.6nm;The

顶层上电介质层20为Si3N4层,Si3N4的厚度为14nm。The

产品参数如图6-图10所示:The product parameters are shown in Figure 6-Figure 10:

图6为实施例二低辐射镀膜玻璃的膜面反射光谱曲线;Fig. 6 is the film surface reflectance spectrum curve of embodiment two low radiation coated glass;

图7为实施例二低辐射镀膜玻璃的玻璃面反射光谱曲线;Fig. 7 is the glass surface reflection spectrum curve of embodiment two low radiation coated glass;

图8为实施例二低辐射镀膜玻璃的透射特性谱图;Fig. 8 is the transmission characteristic spectrogram of embodiment two low radiation coated glass;

图9为实施例二低辐射镀膜玻璃的单片色系坐标;Fig. 9 is the monolithic color coordinates of the low-emissivity coated glass of embodiment two;

图10为实施例二低辐射镀膜玻璃构成的中空玻璃色系坐标。Fig. 10 is the coordinates of the color system of the insulating glass made of the low-emissivity coated glass of the second embodiment.

图6-图8中,虚线曲线为标准参照产品的测试曲线,实线曲线为实施例二产品的测试参数曲线;图9-图10为色坐标的a*值、b*值与角度的变化曲线图谱,虚线曲线为随着角度的变化a*值(绿到红的变化)的变化参数曲线,实线曲线为b*值(蓝到黄的变化)的参数曲线。Among Fig. 6-Fig. 8, dashed line curve is the test curve of standard reference product, and solid line curve is the test parameter curve of embodiment two products; Fig. 9-Fig. 10 is the variation of a* value, b* value and angle of color coordinates Curve spectrum, the dotted curve is the parameter curve of the change of a* value (change from green to red) with the change of angle, and the curve of solid line is the parameter curve of b* value (change from blue to yellow).

由图6、图7可知具有实施例一结构的低辐射镀膜玻璃在可见光区具有高透过率,对近红外区具有低辐射率。图8说明所述低辐射镀膜玻璃在可见光区具有高阳光透过率。图9、图10说明所述低辐射镀膜玻璃呈自然色,且从各角度观察,颜色具有均一性。It can be seen from Fig. 6 and Fig. 7 that the low-emissivity coated glass with the structure of the first embodiment has high transmittance in the visible light region and low emissivity in the near-infrared region. FIG. 8 illustrates that the low-E coated glass has high sunlight transmittance in the visible region. Figures 9 and 10 illustrate that the low-emissivity coated glass has a natural color, and the color is uniform when observed from various angles.

本领域技术人员均应了解,在不脱离本发明的精神或范围的情况下,可以对本发明进行各种修改和变型。因而,如果任何修改或变型落入所附权利要求书及等同物的保护范围内时,认为本发明涵盖这些修改和变型。Those skilled in the art will appreciate that various modifications and variations can be made in the present invention without departing from the spirit or scope of the invention. Therefore, if any modification or variation falls within the scope of protection of the appended claims and their equivalents, the present invention is deemed to cover such modification and variation.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011104366494ACN102514285A (en) | 2011-12-23 | 2011-12-23 | Low-emissivity coated glass and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011104366494ACN102514285A (en) | 2011-12-23 | 2011-12-23 | Low-emissivity coated glass and manufacturing method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN102514285Atrue CN102514285A (en) | 2012-06-27 |

Family

ID=46285483

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011104366494APendingCN102514285A (en) | 2011-12-23 | 2011-12-23 | Low-emissivity coated glass and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102514285A (en) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103448324A (en)* | 2013-08-16 | 2013-12-18 | 东莞南玻工程玻璃有限公司 | Rosy low-radiation coated glass and preparation method thereof |

| CN104290404A (en)* | 2014-10-30 | 2015-01-21 | 中山市亨立达机械有限公司 | Green double-silver LOW-E glass with special film system |

| CN104290403A (en)* | 2014-10-30 | 2015-01-21 | 中山市亨立达机械有限公司 | Green LOW-E glass with three Ag layers for special film system |

| CN106746730A (en)* | 2017-01-19 | 2017-05-31 | 吴江南玻华东工程玻璃有限公司 | A kind of method for strengthening the resistance to tempering performance of low radiation coated glass |

| CN108914077A (en)* | 2018-08-02 | 2018-11-30 | 南京邮电大学 | One kind being based on Nb2O5Transparent conductive oxide film and preparation method thereof |

| CN109809712A (en)* | 2019-03-27 | 2019-05-28 | 揭阳市宏光镀膜玻璃有限公司 | Asymmetric class double-silver LOW-E glass of phosphorus doping self-cleaning and preparation method thereof |

| CN112010567A (en)* | 2020-08-19 | 2020-12-01 | 江门耀皮工程玻璃有限公司 | Novel film system structure of large-angle non-color-cast double-layer silver-plated glass and processing technology thereof |

| CN112194383A (en)* | 2020-10-23 | 2021-01-08 | 浙江旗滨节能玻璃有限公司 | Low-emissivity glass and preparation method thereof |

| CN113173712A (en)* | 2021-05-25 | 2021-07-27 | 广东旗滨节能玻璃有限公司 | Low-emissivity coated glass and preparation method thereof |

| CN114853359A (en)* | 2022-04-26 | 2022-08-05 | 台玻天津玻璃有限公司 | Method for manufacturing double-sided mirror coated glass |

| CN115611526A (en)* | 2022-09-26 | 2023-01-17 | 吴江南玻华东工程玻璃有限公司 | A heat-processable low-emissivity glass and its preparation method |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6190776B1 (en)* | 1999-07-07 | 2001-02-20 | Turkiye Sise Cam | Heat treatable coated glass |

| CN101955324A (en)* | 2010-09-29 | 2011-01-26 | 吴江南玻华东工程玻璃有限公司 | Low emissivity coated glass |

| CN201809285U (en)* | 2010-09-29 | 2011-04-27 | 吴江南玻华东工程玻璃有限公司 | Single-silver coated glass |

| CN201817401U (en)* | 2010-07-26 | 2011-05-04 | 林嘉宏 | Double-silver low-emissivity coated glass capable of being processed in different places |

| CN201817404U (en)* | 2010-09-01 | 2011-05-04 | 林嘉宏 | Dual-silver low-radiation glass |

| CN201817402U (en)* | 2010-07-26 | 2011-05-04 | 林嘉宏 | Double-silver low-radiation glass capable of being processed at different place |

| CN201817403U (en)* | 2010-09-01 | 2011-05-04 | 林嘉宏 | Low emissivity glass capable of being processed in different places |

| CN201962204U (en)* | 2011-03-03 | 2011-09-07 | 林嘉宏 | Single-sliver and low-radiation coated glass capable of being machined at different place |

| CN202390316U (en)* | 2011-12-23 | 2012-08-22 | 林嘉宏 | Low-emissivity coated glass |

- 2011

- 2011-12-23CNCN2011104366494Apatent/CN102514285A/enactivePending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6190776B1 (en)* | 1999-07-07 | 2001-02-20 | Turkiye Sise Cam | Heat treatable coated glass |

| CN201817401U (en)* | 2010-07-26 | 2011-05-04 | 林嘉宏 | Double-silver low-emissivity coated glass capable of being processed in different places |

| CN201817402U (en)* | 2010-07-26 | 2011-05-04 | 林嘉宏 | Double-silver low-radiation glass capable of being processed at different place |

| CN201817404U (en)* | 2010-09-01 | 2011-05-04 | 林嘉宏 | Dual-silver low-radiation glass |

| CN201817403U (en)* | 2010-09-01 | 2011-05-04 | 林嘉宏 | Low emissivity glass capable of being processed in different places |

| CN101955324A (en)* | 2010-09-29 | 2011-01-26 | 吴江南玻华东工程玻璃有限公司 | Low emissivity coated glass |

| CN201809285U (en)* | 2010-09-29 | 2011-04-27 | 吴江南玻华东工程玻璃有限公司 | Single-silver coated glass |

| CN201962204U (en)* | 2011-03-03 | 2011-09-07 | 林嘉宏 | Single-sliver and low-radiation coated glass capable of being machined at different place |

| CN202390316U (en)* | 2011-12-23 | 2012-08-22 | 林嘉宏 | Low-emissivity coated glass |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103448324A (en)* | 2013-08-16 | 2013-12-18 | 东莞南玻工程玻璃有限公司 | Rosy low-radiation coated glass and preparation method thereof |

| CN103448324B (en)* | 2013-08-16 | 2015-06-24 | 东莞南玻工程玻璃有限公司 | Rosy low-radiation coated glass and preparation method thereof |

| CN104290404A (en)* | 2014-10-30 | 2015-01-21 | 中山市亨立达机械有限公司 | Green double-silver LOW-E glass with special film system |

| CN104290403A (en)* | 2014-10-30 | 2015-01-21 | 中山市亨立达机械有限公司 | Green LOW-E glass with three Ag layers for special film system |

| CN106746730A (en)* | 2017-01-19 | 2017-05-31 | 吴江南玻华东工程玻璃有限公司 | A kind of method for strengthening the resistance to tempering performance of low radiation coated glass |

| CN108914077A (en)* | 2018-08-02 | 2018-11-30 | 南京邮电大学 | One kind being based on Nb2O5Transparent conductive oxide film and preparation method thereof |

| CN109809712A (en)* | 2019-03-27 | 2019-05-28 | 揭阳市宏光镀膜玻璃有限公司 | Asymmetric class double-silver LOW-E glass of phosphorus doping self-cleaning and preparation method thereof |

| CN112010567A (en)* | 2020-08-19 | 2020-12-01 | 江门耀皮工程玻璃有限公司 | Novel film system structure of large-angle non-color-cast double-layer silver-plated glass and processing technology thereof |

| CN112194383A (en)* | 2020-10-23 | 2021-01-08 | 浙江旗滨节能玻璃有限公司 | Low-emissivity glass and preparation method thereof |

| CN113173712A (en)* | 2021-05-25 | 2021-07-27 | 广东旗滨节能玻璃有限公司 | Low-emissivity coated glass and preparation method thereof |

| CN114853359A (en)* | 2022-04-26 | 2022-08-05 | 台玻天津玻璃有限公司 | Method for manufacturing double-sided mirror coated glass |

| CN115611526A (en)* | 2022-09-26 | 2023-01-17 | 吴江南玻华东工程玻璃有限公司 | A heat-processable low-emissivity glass and its preparation method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102514285A (en) | Low-emissivity coated glass and manufacturing method thereof | |

| CN102555330A (en) | Low-emissivity coated glass with multiple functional layers | |

| CN202390316U (en) | Low-emissivity coated glass | |

| US20180065885A1 (en) | Coated article including low-emissivity coating, insulating glass unit including coated article, and/or methods of making the same | |

| CN101244898B (en) | Golden low-emissivity coated glass and manufacturing method thereof | |

| CN103753897B (en) | Wide-angle broadband anti-reflection coated glass | |

| CN105152549A (en) | Coated glass and preparation method thereof | |

| CN108975726B (en) | ultra-LOW reflection toughened LOW-E glass | |

| CN206553403U (en) | A kind of high infrared reflection coated glass | |

| CN105636919A (en) | Heat treatable coated glass pane | |

| TW201305078A (en) | Triple-silver low radiation coating glass and manufacturing method thereof | |

| CN114368919B (en) | Light-transmission-color heat-processable energy-saving LOW-E product | |

| CN114728841B (en) | Coated glass substrate | |

| CN111606578A (en) | A kind of temperable low-reflection double-silver low-emissivity coated glass and preparation method thereof | |

| TWI501931B (en) | Can strengthen the three silver low-emission coated glass | |

| CN102582167B (en) | Low-emission glass and manufacturing method for low-emission glass | |

| CN103879080A (en) | Three-silver-layer low-radiation glass and preparation method thereof | |

| CN209242941U (en) | double silver glass | |

| CN202448402U (en) | Low-E coated glass with multiple functional layers | |

| CN204160834U (en) | A kind of golden two silver low-radiation coated glass | |

| CN209242942U (en) | double silver glass | |

| CN209242940U (en) | double silver glass | |

| CN113614046B (en) | Low-E matchable coated articles with absorbent films and corresponding methods | |

| CN112777946A (en) | Three-silver glass | |

| CN111138089A (en) | Double silver glass |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C12 | Rejection of a patent application after its publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20120627 |