CN102353913A - Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic field - Google Patents

Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic fieldDownload PDFInfo

- Publication number

- CN102353913A CN102353913ACN2011101960870ACN201110196087ACN102353913ACN 102353913 ACN102353913 ACN 102353913ACN 2011101960870 ACN2011101960870 ACN 2011101960870ACN 201110196087 ACN201110196087 ACN 201110196087ACN 102353913 ACN102353913 ACN 102353913A

- Authority

- CN

- China

- Prior art keywords

- cantilever

- sensitive element

- base

- gmr sensitive

- gmr

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Hall/Mr Elements (AREA)

- Measuring Magnetic Variables (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及传感器技术领域,特别是用于微弱信号的传感器,具体地说,涉及一种用于测量微弱磁场的单轴磁传感器。The invention relates to the technical field of sensors, in particular to sensors for weak signals, and in particular to a single-axis magnetic sensor for measuring weak magnetic fields.

背景技术Background technique

微弱磁场测量在地磁导航、目标探测、地质勘探、生物医学等领域都有广泛应用。现阶段用于微弱磁场测量的传感器类型较多,主要包括磁通门传感器、光泵式磁传感器、质子式磁传感器、光纤磁传感器、巨磁阻抗磁传感器、GMR(Giant Magnetoresistive,巨磁阻)磁传感器等,其中GMR磁传感器是基于微电子工艺制成的,相比其他类型的磁传感器明显具有体积小、功耗低、易批量生产等特点。Weak magnetic field measurement is widely used in geomagnetic navigation, target detection, geological exploration, biomedicine and other fields. At this stage, there are many types of sensors used for weak magnetic field measurement, mainly including fluxgate sensors, optical pump magnetic sensors, proton magnetic sensors, optical fiber magnetic sensors, giant magnetoresistive magnetic sensors, and GMR (Giant Magnetoresistive, giant magnetoresistance) Magnetic sensors, etc. Among them, the GMR magnetic sensor is made based on microelectronics technology. Compared with other types of magnetic sensors, it has the characteristics of small size, low power consumption, and easy mass production.

1988年,法国科学家Albert Fert和德国科学家Peter Grunberg各自领导的实验小组先后独立发现了GMR效应,其中Albert Fert实验小组研究发现在微弱磁场中铁-铬多层薄膜的电阻值急剧变化,并将该现象命名为“GMR效应”,而PeterGrunberg小组在铁-铬-铁三层反铁磁薄膜结构中也发现了类似的实验现象。此后针对GMR效应的研究便如火如荼地展开了,具有GMR效应的新结构不断呈现,而对具有GMR效应的结构也称之为GMR敏感元件。随着研究的不断深入,人们发现GMR敏感元件的磁场灵敏度越高,其噪声特别是1/f噪声也越大,而且其中取决于内部磁结构的1/f磁噪声无法通过常规的电调制方法予以抑制,正是这一点限制了GMR磁传感器分辨力的进一步提高。In 1988, the experimental groups led by French scientist Albert Fert and German scientist Peter Grunberg independently discovered the GMR effect successively. Among them, the experimental group of Albert Fert found that the resistance value of the iron-chromium multilayer film changed sharply in a weak magnetic field, and described this phenomenon Named "GMR effect", and Peter Grunberg's group also found a similar experimental phenomenon in the iron-chromium-iron three-layer antiferromagnetic thin film structure. Since then, the research on the GMR effect has been carried out in full swing, and new structures with the GMR effect have emerged continuously, and the structure with the GMR effect is also called a GMR sensitive element. With the deepening of research, it is found that the higher the magnetic field sensitivity of the GMR sensitive element, the greater the noise, especially the 1/f noise, and the 1/f magnetic noise which depends on the internal magnetic structure cannot pass the conventional electrical modulation method It is precisely this that limits the further improvement of the resolution of the GMR magnetic sensor.

近年国外对于如何有效抑制GMR敏感元件的1/f噪声的问题开展了大量研究,其中运用微机械结构驱动磁性薄膜调制被测低频微弱磁场来抑制GMR敏感元件1/f噪声的技术方案最为可行。美国陆军实验室的Alan S.Edelstein等在2003至2007之间陆续取得了4项相关的美国国家专利(专利号:US6670809、US7046002、US7185541、US7195945),这些专利中所述技术方案的共同特点是:首先将磁力线聚集器制备在微机械结构上,然后利用静电驱动方式驱动微机械结构和磁力线聚集器共同高频振动,磁力线聚集器的磁场放大倍数随之周期性地变化,此时处于磁力线聚集器间隙内的GMR敏感元件可探测到一个高频调制后的被测磁场。此类技术方案虽可有效抑制GMR敏感元件的1/f噪声,并明显提高GMR磁传感器的低频磁场分辨力,但目前尚存在一些问题:In recent years, a lot of research has been carried out abroad on how to effectively suppress the 1/f noise of GMR sensitive elements. Among them, the technical solution to suppress the 1/f noise of GMR sensitive elements by using micromechanical structures to drive magnetic thin films to modulate the measured low-frequency weak magnetic field is the most feasible. Alan S.Edelstein of U.S. Army Laboratory, etc. successively obtained 4 related U.S. national patents (patent numbers: US6670809, US7046002, US7185541, US7195945) between 2003 and 2007. The common features of the technical solutions described in these patents are : Firstly, the magnetic field line concentrator is prepared on the micro-mechanical structure, and then the micro-mechanical structure and the magnetic field line concentrator are driven to vibrate at high frequency together by means of electrostatic drive, and the magnetic field magnification of the magnetic field line concentrator changes periodically accordingly. At this time, it is in the magnetic field line concentrator The GMR sensitive element in the sensor gap can detect a high-frequency modulated magnetic field to be measured. Although such technical solutions can effectively suppress the 1/f noise of GMR sensitive elements and significantly improve the low-frequency magnetic field resolution of GMR magnetic sensors, there are still some problems:

(1)调制深度较低,只有14%左右,因此磁场分辨力较低;(1) The modulation depth is low, only about 14%, so the magnetic field resolution is low;

(2)结构相对复杂,工艺涉及深度反应离子刻蚀技术及绝缘硅技术,耗时耗力,成本很高;(2) The structure is relatively complex, and the process involves deep reactive ion etching technology and insulating silicon technology, which is time-consuming and labor-intensive, and the cost is high;

(3)实现调制所需的静电驱动电压明显高于常用集成电路供电电压,达50V以上,给实际使用带来不便。(3) The electrostatic driving voltage required to realize the modulation is significantly higher than the power supply voltage of commonly used integrated circuits, reaching more than 50V, which brings inconvenience to actual use.

发明内容Contents of the invention

本发明将提供一种调制深度较大,分辨力较高,结构工艺简单,驱动电压较低的弱磁场测量传感器。The invention will provide a weak magnetic field measurement sensor with large modulation depth, high resolution, simple structure and process, and low driving voltage.

本发明的技术方案是:一种单轴压电驱动的弱磁场测量传感器,包括绝缘基底、三对电极、GMR敏感元件、两个相同的磁力线聚集器、调制膜、微悬臂梁和压电陶瓷薄片。所述绝缘基底采用表面抛光的玻璃片,在绝缘基底表面上镀有三对电极;所述GMR敏感元件呈细条状,其中央位置有一横向的间隙,GMR敏感元件固定在绝缘基底表面上。每个磁力线聚集器较窄一端开有“凹”形槽,“凹”形槽宽度比GMR敏感元件略宽;两个磁力线聚集器分别固定在GMR敏感元件两端的绝缘基底表面上,GMR敏感元件两端分别位于磁力线聚集器的“凹”形槽内,GMR敏感元件和两个磁力线聚集器三者中轴线成一直线。第二对和第三对电极分别与GMR敏感元件的两对输入输出电极连接。所述微悬臂梁包括基座、悬臂。基座固定在绝缘基底上,基座连接悬臂,基座上表面与悬臂上表面共平面,悬臂厚度小于基座厚度。悬臂的自由端开有两个对准孔,紧靠对准孔且沿悬臂的中轴线向基座方向依次开有若干个阻尼孔;悬臂下表面两个对准孔之间制备有高磁导率软磁材料的调制膜,调制膜正对GMR敏感元件的间隙,调制膜的形状与间隙的表面形状相同,调制膜与GMR敏感元件垂直距离根据需要确定,通常为8~15微米。所述压电陶瓷薄片表面为长方形,其宽度与悬臂宽度一致,厚度方向为极化方向,压电陶瓷薄片粘在悬臂上,沿压电陶瓷薄片长度方向一端延伸至基座,并与第一对电极电连接,另一端延伸靠近阻尼孔。The technical solution of the present invention is: a uniaxial piezoelectric driven weak magnetic field measurement sensor, including an insulating substrate, three pairs of electrodes, a GMR sensitive element, two identical magnetic field line concentrators, a modulation film, a micro-cantilever beam and piezoelectric ceramics Flakes. The insulating base adopts a polished glass sheet, and three pairs of electrodes are plated on the surface of the insulating base; the GMR sensitive element is in the shape of a thin strip with a transverse gap in the center, and the GMR sensitive element is fixed on the surface of the insulating base. The narrower end of each magnetic force line concentrator has a "concave" groove, and the width of the "concave" groove is slightly wider than the GMR sensitive element; the two magnetic force line concentrators are respectively fixed on the surface of the insulating substrate at both ends of the GMR sensitive element, and the GMR sensitive element The two ends are respectively located in the "concave" groove of the magnetic force line concentrator, and the central axes of the GMR sensitive element and the two magnetic force line concentrators are in a straight line. The second pair and the third pair of electrodes are respectively connected to the two pairs of input and output electrodes of the GMR sensitive element. The micro-cantilever includes a base and a cantilever. The base is fixed on the insulating base, the base is connected with the cantilever, the upper surface of the base is coplanar with the upper surface of the cantilever, and the thickness of the cantilever is smaller than that of the base. There are two alignment holes on the free end of the cantilever, and several damping holes are opened close to the alignment holes and along the central axis of the cantilever toward the base; a high magnetic permeability is prepared between the two alignment holes on the lower surface of the cantilever. Modulation film of soft magnetic material, the modulation film is facing the gap of the GMR sensitive element, the shape of the modulation film is the same as the surface shape of the gap, the vertical distance between the modulation film and the GMR sensitive element is determined according to the need, usually 8-15 microns. The surface of the piezoelectric ceramic sheet is rectangular, its width is consistent with the width of the cantilever, and the thickness direction is the polarization direction. The piezoelectric ceramic sheet is glued to the cantilever, and one end of the piezoelectric ceramic sheet extends to the base along the length direction of the piezoelectric ceramic sheet, and is connected to the first The opposite electrode is electrically connected, and the other end extends close to the damping hole.

本发明的有益效果是:采用压电驱动微悬臂梁作为调制动力源,调制膜振动幅度和调制深度较大(仿真实验证明大于40%),通过调制膜的调制使微弱直流磁场在GMR敏感元件处为高频交变磁场,抑制了GMR元件的1/f噪声,通过采用磁力线聚集器使微弱磁场在GMR敏感元件处得到了放大,从而磁传感器测量分辨力得到大幅度提高(仿真实验证明提高了两个数量级);因微悬臂梁结构简单,制造方便,有效降低了传感器的制作成本;压电陶瓷薄片的驱动力较大,只需较小的驱动电压(小于15V)即可获得足够的振动幅度。The beneficial effects of the present invention are: the piezoelectrically driven micro-cantilever beam is used as the modulation power source, the vibration amplitude and the modulation depth of the modulation film are relatively large (the simulation experiment proves that it is greater than 40%), and the modulation of the modulation film makes the weak DC magnetic field in the GMR sensitive element The place is a high-frequency alternating magnetic field, which suppresses the 1/f noise of the GMR element, and the weak magnetic field is amplified at the GMR sensitive element by using a magnetic force line concentrator, so that the measurement resolution of the magnetic sensor is greatly improved (simulation experiments prove that the improvement two orders of magnitude); due to the simple structure of the micro-cantilever beam, it is easy to manufacture, which effectively reduces the production cost of the sensor; the driving force of the piezoelectric ceramic sheet is relatively large, and only a small driving voltage (less than 15V) can obtain sufficient Vibration amplitude.

附图说明Description of drawings

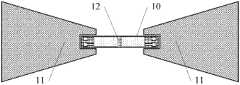

图1是本发明某一具体实施方式提供的单轴压电驱动弱磁场测量传感器的结构示意图;Fig. 1 is a schematic structural view of a uniaxial piezoelectric-driven weak magnetic field measurement sensor provided by a specific embodiment of the present invention;

图2是本发明某一具体实施方式中的磁力线聚集器与GMR敏感元件的结构示意图;Fig. 2 is a schematic structural view of a magnetic flux concentrator and a GMR sensitive element in a specific embodiment of the present invention;

图3(a)是本发明某一具体实施方式中微悬臂梁的俯视图;Fig. 3 (a) is the top view of the micro-cantilever beam in a certain embodiment of the present invention;

图3(b)是本发明某一具体实施方式中微悬臂梁的仰视图。Fig. 3(b) is a bottom view of the micro-cantilever in a specific embodiment of the present invention.

1-基座,2-悬臂,3-对准孔,4-阻尼孔,5-压电陶瓷薄片,6-绝缘基底,7-第一对电极,8-第二对电极,9-第三对电极,10-GMR敏感元件,11-磁力线聚集器,12-间隙,13-微悬臂梁,14-调制膜,15-台阶。1-base, 2-cantilever, 3-alignment hole, 4-damping hole, 5-piezoelectric ceramic sheet, 6-insulating substrate, 7-first pair of electrodes, 8-second pair of electrodes, 9-third Counter electrode, 10-GMR sensitive element, 11-magnetic field line concentrator, 12-gap, 13-microcantilever beam, 14-modulation film, 15-step.

具体实施方式Detailed ways

下面结合附图对本发明作进一步说明。The present invention will be further described below in conjunction with accompanying drawing.

图1是本发明某一具体实施方式提供的单轴压电驱动弱磁场测量传感器的结构示意图。如图所示:包括绝缘基底6、电极对7、电极对8、电极对9、基座1、悬臂2、对准孔3、阻尼孔4、压电陶瓷薄片5、GMR敏感元件10及磁力线聚集器11。绝缘基底6采用表面抛光的玻璃片,形状不限于本实施方式中的长方形,还可以是圆形等。电极对7、8、9是通过先在绝缘基底6上溅射(或真空蒸镀、电镀等)导电金属膜(金、铝、铜等),然后再光刻腐蚀成型。电极对7连接压电陶瓷薄片5上面的电极;电极对8连接GMR敏感元件10上自带的一对电极;电极对9连接GMR敏感元件10上自带的另一对电极。电极对7、8、9的形状和位置无特殊要求,以方便引线连接为准,图1所示的电极对7、8、9的形状和位置仅是其中一种较好的选择。基座1与悬臂2相连,基座1的形状不限于图1所示的“凹”形,在保证不影响电极对7和为悬臂2提供稳定固定、支撑的前提下可设计成多种形状。悬臂2一端与基座1相连,另一段为自由端,向前伸出,悬臂2的形状并不限于图1所示形状(还可以是矩形、梯形、锤头型等)。悬臂2的自由端开有2个对准孔3(见图3(a))。靠近对准孔3,沿悬臂2中轴线向内依次开有若干个阻尼孔4。压电陶瓷片5的宽度与悬臂2相同,用胶粘在悬臂2的上表面,沿压电陶瓷片5长度方向一端靠近阻尼孔4,另一端延伸至基座1,并与电极对7电连接。基座1通过低温键合工艺或直接粘胶的方法固定于绝缘基底6上,使调制膜14正对GMR敏感元件10的间隙12,调制膜14与GMR敏感元件10垂直距离根据需要确定,通常为8~15微米。Fig. 1 is a schematic structural diagram of a uniaxial piezoelectric-driven weak magnetic field measurement sensor provided by a specific embodiment of the present invention. As shown in the figure: including

图2是本发明本发明某一具体实施方式中的GMR敏感元件10和磁力线聚集器11的结构示意图。如图所示:磁力线聚集器11由高磁导率软磁材料制成(如NiFe、CoZrNb等),形状为梯形(也可为长方形),其一端开有“凹”形槽,“凹”形槽的宽度比GMR敏感元件10的宽度略宽,可以通过光刻腐蚀工艺制造磁力线聚集器11。GMR敏感元件10为市售元件(如美国NVE公司的AA002-02等),呈细条状,中间有一条横向的间隙12,其两端分别位于一个磁力线聚集器11的“凹”形槽内,GMR敏感元件10和两个磁力线聚集器11这三者中轴线成一直线,采用环氧树脂胶粘接固定在绝缘基底上。Fig. 2 is a schematic structural diagram of the GMR

图3(a)与图3(b)是本发明某一具体实施方式中微悬臂梁13的俯视图和仰视图。如图所示:微悬臂梁13采用微硅工艺制成的,包括基座1、悬臂2。基座1的形状不限于图1所示的“凹”形,在保证不影响电极对7和为悬臂2提供稳定支撑的前提下可设计成多种形状。基座1与悬臂2相连,基座1上表面与悬臂2上表面共平面,悬臂2厚度小于基座1厚度,因此两者连接处存在一个台阶15。悬臂2的自由端开有两个对准孔3,紧靠对准孔3向内沿悬臂2中轴线依次开有若干阻尼孔4,阻尼孔数目可为3~5个。在悬臂2下表面两个对准孔13之间有调制膜14。调制膜14正对GMR敏感元件的间隙12,调制膜14的形状与间隙12的表面形状相同,调制膜14的制备方法是在悬臂2的下表面上电镀(或真空蒸镀、溅射等)制备一定厚度的高磁导率软磁材料膜(如NiFe、CoZrNb等),然后再用光刻腐蚀方法成型。Fig. 3(a) and Fig. 3(b) are the top view and bottom view of the

使用时,将第一对电极与外部的激励电路相连接,压电陶瓷薄片振动带动悬臂梁工作在谐振状态;第二对电极与外部恒定电压源(或电流源)连接,第三对电极与外部检测电路连接,根据外部检测电路的测量值可以得到弱磁场的大小。When in use, the first pair of electrodes is connected to an external excitation circuit, and the vibration of the piezoelectric ceramic sheet drives the cantilever beam to work in a resonant state; the second pair of electrodes is connected to an external constant voltage source (or current source), and the third pair of electrodes is connected to the external constant voltage source (or current source). The external detection circuit is connected, and the magnitude of the weak magnetic field can be obtained according to the measured value of the external detection circuit.

Claims (2)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201110196087CN102353913B (en) | 2011-07-13 | 2011-07-13 | Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic field |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201110196087CN102353913B (en) | 2011-07-13 | 2011-07-13 | Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic field |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102353913Atrue CN102353913A (en) | 2012-02-15 |

| CN102353913B CN102353913B (en) | 2013-06-12 |

Family

ID=45577511

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201110196087Expired - Fee RelatedCN102353913B (en) | 2011-07-13 | 2011-07-13 | Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic field |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102353913B (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103116144A (en)* | 2013-01-22 | 2013-05-22 | 中国人民解放军国防科学技术大学 | Z-direction magnetic field sensor with magnetic orbit structure |

| CN103116143A (en)* | 2013-01-22 | 2013-05-22 | 中国人民解放军国防科学技术大学 | Integrated high-accuracy triaxial magnetic sensor |

| CN103323794A (en)* | 2013-06-21 | 2013-09-25 | 中国人民解放军国防科学技术大学 | GMR-MEMS integrated weak magnetic sensor adopting plane micro-coil |

| CN103323795A (en)* | 2013-06-21 | 2013-09-25 | 中国人民解放军国防科学技术大学 | Integrated three-axis magnetic sensor |

| CN103323796A (en)* | 2013-06-21 | 2013-09-25 | 中国人民解放军国防科学技术大学 | MTJ magnetic field sensor using graphene as barrier layer |

| CN103706128A (en)* | 2013-02-01 | 2014-04-09 | 万代股份有限公司 | Magnetic response toy, main toy body and auxiliary toy body employed by magnetic response toy |

| CN106646278A (en)* | 2016-12-09 | 2017-05-10 | 中国人民解放军国防科学技术大学 | Low-noise MEMS pre-amplification device utilizing high-resolution magnetic field detection |

| CN107894577A (en)* | 2017-10-27 | 2018-04-10 | 中国人民解放军国防科技大学 | Weak magnetic sensor for inhibiting 1/f noise by regulating and controlling magnetic moment by electric field and application method thereof |

| CN109556647A (en)* | 2018-11-30 | 2019-04-02 | 苏州大学 | A kind of low-frequency noise inhibition device and method of tunnel magneto-resistance effect sensor |

| CN110286338A (en)* | 2019-06-13 | 2019-09-27 | 中国人民解放军国防科技大学 | Magnetic field modulation structure suitable for integral type triaxial magnetic sensor |

| CN113126012A (en)* | 2019-12-30 | 2021-07-16 | 创领心律管理医疗器械(上海)有限公司 | Active implanted medical instrument and magnetic induction mechanism thereof |

| CN113562687A (en)* | 2021-07-23 | 2021-10-29 | 中国科学院空天信息创新研究院 | A low-frequency MEMS magnetoresistive sensor fabrication method with magnetoresistive motion modulation |

| CN114415086A (en)* | 2022-01-06 | 2022-04-29 | 中国科学院空天信息创新研究院 | Two-stage amplification low-frequency magnetoresistive sensor and preparation method thereof |

| CN115248403A (en)* | 2022-06-27 | 2022-10-28 | 上海阿芮斯智能科技有限公司 | MEMS fluxgate sensor based on conical magnetic gathering device and manufacturing method thereof |

| CN115856725A (en)* | 2022-11-25 | 2023-03-28 | 南方电网数字电网研究院有限公司 | magnetic sensor |

| CN119619924A (en)* | 2024-12-09 | 2025-03-14 | 深圳技术大学 | A weak magnetic field measuring device and a measuring method thereof |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6670809B1 (en)* | 2000-08-18 | 2003-12-30 | The United States Of America As Represented By The Secretary Of The Army | Magnetic sensor with modulating flux concentrator having minimized air resistance for 1/f noise reduction |

| US7046002B1 (en)* | 2004-11-26 | 2006-05-16 | The United States Of America As Represented By The Secretary Of The Army | Magnetic sensor with variable sensitivity |

| US7185541B1 (en)* | 2005-02-03 | 2007-03-06 | The United States Of America As Represented By The Secretary Of The Army | MEMS magnetic device and method |

| US7195945B1 (en)* | 2004-09-15 | 2007-03-27 | United States Of America As Represented By The Secretary Of The Army | Minimizing the effect of 1/ƒ noise with a MEMS flux concentrator |

| EP2017619A1 (en)* | 2007-07-20 | 2009-01-21 | Koninklijke Philips Electronics N.V. | Magnetic sensor device |

| CN101545957A (en)* | 2009-04-24 | 2009-09-30 | 江苏大学 | Gate-structure magnetoelectric magnetic filed sensor and manufacturing method thereof |

- 2011

- 2011-07-13CNCN 201110196087patent/CN102353913B/ennot_activeExpired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6670809B1 (en)* | 2000-08-18 | 2003-12-30 | The United States Of America As Represented By The Secretary Of The Army | Magnetic sensor with modulating flux concentrator having minimized air resistance for 1/f noise reduction |

| US7195945B1 (en)* | 2004-09-15 | 2007-03-27 | United States Of America As Represented By The Secretary Of The Army | Minimizing the effect of 1/ƒ noise with a MEMS flux concentrator |

| US7046002B1 (en)* | 2004-11-26 | 2006-05-16 | The United States Of America As Represented By The Secretary Of The Army | Magnetic sensor with variable sensitivity |

| US7185541B1 (en)* | 2005-02-03 | 2007-03-06 | The United States Of America As Represented By The Secretary Of The Army | MEMS magnetic device and method |

| EP2017619A1 (en)* | 2007-07-20 | 2009-01-21 | Koninklijke Philips Electronics N.V. | Magnetic sensor device |

| CN101545957A (en)* | 2009-04-24 | 2009-09-30 | 江苏大学 | Gate-structure magnetoelectric magnetic filed sensor and manufacturing method thereof |

Cited By (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103116143A (en)* | 2013-01-22 | 2013-05-22 | 中国人民解放军国防科学技术大学 | Integrated high-accuracy triaxial magnetic sensor |

| CN103116144A (en)* | 2013-01-22 | 2013-05-22 | 中国人民解放军国防科学技术大学 | Z-direction magnetic field sensor with magnetic orbit structure |

| CN103116144B (en)* | 2013-01-22 | 2015-01-14 | 中国人民解放军国防科学技术大学 | Z-direction magnetic field sensor with magnetic orbit structure |

| CN103116143B (en)* | 2013-01-22 | 2015-01-14 | 中国人民解放军国防科学技术大学 | Integrated high-accuracy triaxial magnetic sensor |

| CN103706128A (en)* | 2013-02-01 | 2014-04-09 | 万代股份有限公司 | Magnetic response toy, main toy body and auxiliary toy body employed by magnetic response toy |

| CN103323795A (en)* | 2013-06-21 | 2013-09-25 | 中国人民解放军国防科学技术大学 | Integrated three-axis magnetic sensor |

| CN103323796A (en)* | 2013-06-21 | 2013-09-25 | 中国人民解放军国防科学技术大学 | MTJ magnetic field sensor using graphene as barrier layer |

| CN103323795B (en)* | 2013-06-21 | 2015-04-08 | 中国人民解放军国防科学技术大学 | Integrated three-axis magnetic sensor |

| CN103323794B (en)* | 2013-06-21 | 2015-07-15 | 中国人民解放军国防科学技术大学 | GMR-MEMS integrated weak magnetic sensor adopting plane micro-coil |

| CN103323796B (en)* | 2013-06-21 | 2015-07-29 | 中国人民解放军国防科学技术大学 | A kind of MTJ magnetic field sensor using Graphene as barrier layer |

| CN103323794A (en)* | 2013-06-21 | 2013-09-25 | 中国人民解放军国防科学技术大学 | GMR-MEMS integrated weak magnetic sensor adopting plane micro-coil |

| CN106646278B (en)* | 2016-12-09 | 2019-05-24 | 中国人民解放军国防科学技术大学 | A kind of low noise MEMS preamplifier part using high resolution detection of magnetic field |

| CN106646278A (en)* | 2016-12-09 | 2017-05-10 | 中国人民解放军国防科学技术大学 | Low-noise MEMS pre-amplification device utilizing high-resolution magnetic field detection |

| CN107894577A (en)* | 2017-10-27 | 2018-04-10 | 中国人民解放军国防科技大学 | Weak magnetic sensor for inhibiting 1/f noise by regulating and controlling magnetic moment by electric field and application method thereof |

| CN107894577B (en)* | 2017-10-27 | 2019-11-29 | 中国人民解放军国防科技大学 | Weak magnetic sensor for inhibiting 1/f noise by regulating and controlling magnetic moment by electric field and application method thereof |

| CN109556647A (en)* | 2018-11-30 | 2019-04-02 | 苏州大学 | A kind of low-frequency noise inhibition device and method of tunnel magneto-resistance effect sensor |

| CN110286338A (en)* | 2019-06-13 | 2019-09-27 | 中国人民解放军国防科技大学 | Magnetic field modulation structure suitable for integral type triaxial magnetic sensor |

| CN110286338B (en)* | 2019-06-13 | 2021-04-02 | 中国人民解放军国防科技大学 | A magnetic field modulation structure suitable for an integrated three-axis magnetic sensor |

| CN113126012A (en)* | 2019-12-30 | 2021-07-16 | 创领心律管理医疗器械(上海)有限公司 | Active implanted medical instrument and magnetic induction mechanism thereof |

| CN113562687B (en)* | 2021-07-23 | 2024-04-09 | 中国科学院空天信息创新研究院 | Manufacturing method of low-frequency MEMS (micro-electromechanical systems) magneto-resistive sensor modulated by magneto-resistive motion |

| CN113562687A (en)* | 2021-07-23 | 2021-10-29 | 中国科学院空天信息创新研究院 | A low-frequency MEMS magnetoresistive sensor fabrication method with magnetoresistive motion modulation |

| CN114415086A (en)* | 2022-01-06 | 2022-04-29 | 中国科学院空天信息创新研究院 | Two-stage amplification low-frequency magnetoresistive sensor and preparation method thereof |

| CN114415086B (en)* | 2022-01-06 | 2025-02-18 | 中国科学院空天信息创新研究院 | A two-stage amplified low-frequency magnetoresistive sensor and its preparation method |

| CN115248403A (en)* | 2022-06-27 | 2022-10-28 | 上海阿芮斯智能科技有限公司 | MEMS fluxgate sensor based on conical magnetic gathering device and manufacturing method thereof |

| CN115856725A (en)* | 2022-11-25 | 2023-03-28 | 南方电网数字电网研究院有限公司 | magnetic sensor |

| CN115856725B (en)* | 2022-11-25 | 2023-12-12 | 南方电网数字电网研究院有限公司 | magnetic sensor |

| CN119619924A (en)* | 2024-12-09 | 2025-03-14 | 深圳技术大学 | A weak magnetic field measuring device and a measuring method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102353913B (en) | 2013-06-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102353913A (en) | Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic field | |

| CN103323794B (en) | GMR-MEMS integrated weak magnetic sensor adopting plane micro-coil | |

| CN101430369B (en) | Self-generating broadband laminated magneto-inducible piezoelectric effect AC magnetic field sensor and manufacturing method | |

| CN109307850B (en) | Magnetic sensor for suppressing low-frequency noise by utilizing magnetic flux electric control and application method thereof | |

| CN111624525B (en) | An Integrated Triaxial Magnetic Sensor Using Magnetic Stress Control to Suppress Magnetic Noise | |

| CN107894576B (en) | Integrated low-power-consumption three-axis magnetic field sensor with high Z-direction resolution | |

| Bennett et al. | Magnetic field response of doubly clamped magnetoelectric microelectromechanical AlN-FeCo resonators | |

| CN103116144B (en) | Z-direction magnetic field sensor with magnetic orbit structure | |

| CN101294824B (en) | Electromagnetic micro-torsional pendulum resonant vibration type sensor based on micro-electronic mechanical skill | |

| CN101533075A (en) | MEMS horizontal resonant mode gauss meter | |

| CN102914394A (en) | MEMS (Micro Electro Mechanical System) giant magneto-resistance type high pressure sensor | |

| CN107894577A (en) | Weak magnetic sensor for inhibiting 1/f noise by regulating and controlling magnetic moment by electric field and application method thereof | |

| CN107449410A (en) | Microthrust test device is detected in electromagnetic drive type tunnel magnetoresistive face | |

| CN108039404B (en) | Cantilever beam type magnetic sensor, preparation method and use method thereof | |

| CN103033770A (en) | Giant magneto-impedance effect two-dimensional magnetic field sensor | |

| CN101515026A (en) | Resonance micro electromechanical system magnetic field sensor and measuring method thereof | |

| CN102427111A (en) | Flexible layered magnetoelectric element | |

| CN102279373B (en) | Uniaxially electrostatic-driven sensor for weak magnetic field measurement | |

| CN103278148B (en) | Two-axis microgyroscope of magnetostrictive solid oscillator | |

| CN110068318A (en) | A kind of tunnel magnetoresistive microthrust test device based on snakelike hot-wire coil | |

| CN206178120U (en) | Reduce magnetism electric sensor sensing element of vibration noise | |

| CN105988090A (en) | Micro-machine magnetic field senor and application thereof | |

| CN106291406A (en) | A coilless magnetic sensor | |

| CN111521842A (en) | Z-axis resonant micro-accelerometer with electrostatic stiffness adjustment based on tunnel magnetoresistance detection | |

| CN106199462A (en) | A kind of magnetoelectric transducer sensing element reducing vibration noise |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20130612 | |

| CF01 | Termination of patent right due to non-payment of annual fee |