CN102324642A - electrical connector - Google Patents

electrical connectorDownload PDFInfo

- Publication number

- CN102324642A CN102324642ACN201110148229ACN201110148229ACN102324642ACN 102324642 ACN102324642 ACN 102324642ACN 201110148229 ACN201110148229 ACN 201110148229ACN 201110148229 ACN201110148229 ACN 201110148229ACN 102324642 ACN102324642 ACN 102324642A

- Authority

- CN

- China

- Prior art keywords

- electrical connector

- tongue plate

- terminal

- contact

- terminal group

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

- Connector Housings Or Holding Contact Members (AREA)

Abstract

Description

Translated fromChinese本发明为申请人在2007年8月10日申请的发明专利第200710025934.0号发明名称为电连接器的分案申请。The present invention is a divisional application of the invention patent No. 200710025934.0 filed by the applicant on August 10, 2007, and the title of the invention is an electrical connector.

【技术领域】【Technical field】

本发明涉及一种电连接器,尤其涉及一种用以与不同插头对接的电连接器。The present invention relates to an electrical connector, in particular to an electrical connector used for docking with different plugs.

【背景技术】【Background technique】

通用串行总线(Universal Serial Bus,USB)连接器广泛运用于各种电子设备上,例如电脑主机、移动硬盘、数码相机、打印机等,USB标准化团体(USBImplementers Forum,简称USBIF)先后公布了两个版本的USB标准:USB 1.1和与USB 1.1兼容的USB 2.0,USB 1.1的最高数据传输率为12Mbps(兆字节/秒),USB2.0则提高到480Mbps。USB 2.0标准定义了两种插座连接器:A型和B型,均设有四根端子。其中,A型插座连接器的四根端子成排设置,依次为电源端子、一对差分信号端子、接地端子。目前,USB 2.0A型插座连接器的相关专利,可参阅美国专利公告第5,779,489号、第5,725,386号及第6,139,350号。该等专利所揭示的USB 2.0A型插座连接器包括设有舌板的绝缘本体,安装在舌板上的四根端子及包覆在端子及绝缘本体外围的金属遮蔽壳体。然而,为了更快的在电子设备之间进行资料传输,仅仅安装四根端子的USB 2.0插座连接器无法满足用户的需求。Universal Serial Bus (USB) connectors are widely used in various electronic devices, such as computer hosts, mobile hard disks, digital cameras, printers, etc. Version of the USB standard: USB 1.1 and USB 2.0 compatible with USB 1.1, the highest data transfer rate of USB 1.1 is 12Mbps (megabytes per second), and USB2.0 is increased to 480Mbps. The USB 2.0 standard defines two socket connectors: Type A and Type B, each with four terminals. Among them, the four terminals of the A-type socket connector are arranged in a row, which are power terminals, a pair of differential signal terminals, and ground terminals in sequence. At present, for related patents of the USB 2.0A receptacle connector, please refer to US Patent No. 5,779,489, No. 5,725,386 and No. 6,139,350. The USB 2.0A receptacle connector disclosed in these patents includes an insulating body provided with a tongue plate, four terminals mounted on the tongue plate, and a metal shielding shell covering the periphery of the terminals and the insulating body. However, in order to transmit data between electronic devices faster, a USB 2.0 socket connector with only four terminals cannot meet the needs of users.

因此,为了提高信号传输的速度,现有的电连接器有必要进行改进以克服上述缺陷。Therefore, in order to increase the speed of signal transmission, it is necessary to improve the existing electrical connectors to overcome the above defects.

【发明内容】【Content of invention】

本发明的主要目的在于提供一种可以改善信号传输速度电连接器。The main purpose of the present invention is to provide an electrical connector capable of improving signal transmission speed.

为解决上述技术问题,本发明采用如下技术方案:一种电连接器,其设有可与电路板相配合的安装面以及可与对接插头相对接的对接面,所述电连接器包括绝缘本体、设于绝缘本体上的导电端子以及包覆绝缘本体的遮蔽壳体,所述遮蔽壳体设有收容空间,所述绝缘本体设有主体部以及延伸入收容空间内的舌板,所述导电端子包括第一端子组以及第二端子组,所述第一端子组中的端子包括电源端子、第一接地端子以及位于电源端子与第一接地端子之间的第一对差分信号端子,所述第一端子组中的端子包括设于舌板上的弹性第一接触部以及第一焊接部,所述第二端子组包括第二对差分信号端子、第三对差分信号端子以及位于第二对及第三对差分信号端子之间的第二接地端子,所述第二端子组中的端子包括设于舌板上的平板状第二接触部以及第二焊接部,所述第一接触部与第二接触部均位于舌板的同一侧,且所述第二接触部相较第一接触部更靠近电连接器的对接面。In order to solve the above technical problems, the present invention adopts the following technical solutions: an electrical connector, which is provided with a mounting surface that can be matched with a circuit board and a docking surface that can be connected with a docking plug, and the electrical connector includes an insulating body , a conductive terminal provided on the insulating body and a shielding case covering the insulating body, the shielding case is provided with a receiving space, the insulating body is provided with a main body and a tongue plate extending into the receiving space, the conductive The terminals include a first terminal group and a second terminal group, the terminals in the first terminal group include a power supply terminal, a first ground terminal, and a first pair of differential signal terminals located between the power supply terminal and the first ground terminal, the The terminals in the first terminal group include the elastic first contact portion and the first soldering portion on the tongue plate, and the second terminal group includes the second pair of differential signal terminals, the third pair of differential signal terminals and the second pair of differential signal terminals. and the second ground terminal between the third pair of differential signal terminals, the terminals in the second terminal group include a flat second contact portion and a second welding portion arranged on the tongue plate, the first contact portion and the second welding portion The second contact portions are all located on the same side of the tongue plate, and the second contact portions are closer to the mating surface of the electrical connector than the first contact portions.

相较于现有技术,本发明通过设置第一端子组及第二端子组,增加了信号传输的通道,提高了电连接器的信号传输速度。Compared with the prior art, the present invention increases signal transmission channels and increases the signal transmission speed of the electrical connector by arranging the first terminal group and the second terminal group.

【附图说明】【Description of drawings】

图1A是本发明第一实施方式中电连接器与电路板组合在一起的示意图。FIG. 1A is a schematic diagram of the combination of the electrical connector and the circuit board in the first embodiment of the present invention.

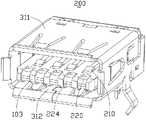

图1B是图1A中电连接器的立体组合图。FIG. 1B is a perspective assembled view of the electrical connector in FIG. 1A .

图2是图1B中电连接器的部分分解示意图。FIG. 2 is a partially exploded schematic diagram of the electrical connector in FIG. 1B .

图3是图2中电连接器的立体分解示意图。FIG. 3 is an exploded perspective view of the electrical connector in FIG. 2 .

图4是图2另一角度的部分分解示意图。FIG. 4 is a partially exploded schematic diagram of another angle of FIG. 2 .

图5是图3中电连接器另一角度的立体分解示意图。FIG. 5 is an exploded perspective view of the electrical connector in FIG. 3 from another angle.

图6是图5中电连接器另一角度的立体分解示意图。FIG. 6 is an exploded perspective view of the electrical connector in FIG. 5 from another angle.

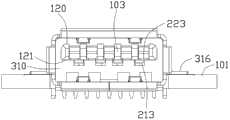

图7A是本发明第二实施方式中电连接器与电路板组合在一起的示意图。Fig. 7A is a schematic diagram of the combination of the electrical connector and the circuit board in the second embodiment of the present invention.

图7B是图7A中电连接器的立体组合图。FIG. 7B is a perspective assembled view of the electrical connector in FIG. 7A .

图8是图7B中电连接器的立体分解示意图。FIG. 8 is an exploded perspective view of the electrical connector in FIG. 7B .

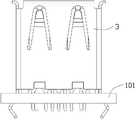

图9A是本发明第三实施方式中电连接器与电路板组合在一起的示意图。Fig. 9A is a schematic diagram of the combination of the electrical connector and the circuit board in the third embodiment of the present invention.

图9B是图9A另一角度的示意图。FIG. 9B is a schematic diagram of another angle of FIG. 9A .

图10是图9A中电连接器的立体分解示意图。FIG. 10 is an exploded perspective view of the electrical connector in FIG. 9A .

图11A是本发明第四实施方式中电连接器与电路板组合在一起的示意图。Fig. 11A is a schematic diagram of the combination of the electrical connector and the circuit board in the fourth embodiment of the present invention.

图11B是图11A中电连接器和电路板另一角度的部分分解示意图。FIG. 11B is a partial exploded view of the electrical connector and the circuit board in FIG. 11A from another angle.

图12是图11B电连接器的部分分解示意图。FIG. 12 is a partially exploded schematic view of the electrical connector of FIG. 11B .

图13是图12中电连接器的另一部分分解示意图。FIG. 13 is another partially exploded view of the electrical connector in FIG. 12 .

图14是图13另一角度的示意图。FIG. 14 is a schematic diagram of another angle of FIG. 13 .

图15是图11B中电连接器的立体分解示意图。FIG. 15 is an exploded perspective view of the electrical connector in FIG. 11B .

图16A是本发明第五实施方式中电连接器与电路板组合在一起的示意图。Fig. 16A is a schematic diagram of the combination of the electrical connector and the circuit board in the fifth embodiment of the present invention.

图16B是图16A另一角度的示意图。Fig. 16B is a schematic diagram of another angle of Fig. 16A.

图17是图16A中电连接器的部分分解示意图。FIG. 17 is a partially exploded schematic view of the electrical connector in FIG. 16A .

图18是图16A中电连接器的立体分解示意图。FIG. 18 is an exploded perspective view of the electrical connector in FIG. 16A .

图19A是本发明第六实施方式中电连接器与电路板组合在一起的示意图。Fig. 19A is a schematic diagram of the combination of the electrical connector and the circuit board in the sixth embodiment of the present invention.

图19B是图19A另一角度的示意图。Fig. 19B is a schematic diagram of another angle of Fig. 19A.

图20是图19A中电连接器的立体分解示意图。FIG. 20 is an exploded perspective view of the electrical connector in FIG. 19A .

图21是和本发明电连接器相对接的第二插头的示意图。Fig. 21 is a schematic diagram of a second plug mated with the electrical connector of the present invention.

图22是和本发明电连接器相对接的USB 2.0A型标准插头的示意图。Fig. 22 is a schematic diagram of a USB 2.0A standard plug docked with the electrical connector of the present invention.

【具体实施方式】【Detailed ways】

请参照图1A至图6所示,本发明第一实施方式中的电连接器100为安装于一电路板101上的USB插座连接器,可以和USB 2.0A型标准插头8对接,也可以和第二插头7对接。USB 2.0A型插头8舌片80前端仅仅设置有四个平板状接点81,第二插头7上绝缘舌片70的尺寸和USB 2.0A型标准插头8的舌片80相同,舌片70上也设有四个平板状接点71,另外还包括位于后排的具有弹性的五个附加接点72。电连接器100包括:绝缘本体1、固定于绝缘本体1上的导电端子2、安装于绝缘本体1外围的遮蔽壳体3,该遮蔽壳体3包括前遮蔽壳体31及后遮蔽壳体32。该电连接器100还设有与电路板101相配合的安装面102及与位于前端的对接面103。1A to 6, the

所述前遮蔽壳体31包括顶面311、底面312、连接顶面311和底面312的一对侧面313,顶面311和底面312以及侧面313之间形成一收容空间310,绝缘本体1包括有主体部11以及自主体部11向前延伸而成的相对较薄的舌板12,舌板12的尺寸和USB 2.0A型插座连接器的舌板尺寸相同,从而,制造本发明电连接器100时,可以重复利用USB 2.0A型插座连接器的部分模具,节省成本。舌板12位于收容空间310内,舌板12与前遮蔽壳体31的两侧面313、顶面311和底面312之间均相隔一定距离,本实施方式中,舌板12到前遮蔽壳体31顶面311比到底面312的距离更小。主体部11底部向下延伸形成有若干与电路板101抵接的垫脚13,所述安装面102为垫脚的底表面。The

所述导电端子2整体弯折成直角形状,包括有第一端子组21及第二端子组22,本实施方式中,第一端子组21和USB 2.0A型插座连接器的四根USB插座端子相同,即依次排列为电源端子217、第一对差分信号端子218(即负信号端子和正信号端子)、第一接地端子219。第一端子组21包括若干用以和USB 2.0A型插头8及第二插头7上的平板状接点81、71相接触的第一接触部210、与第一接触部210相连的用以与绝缘本体1固定的第一固持部211、自第一固持部211一端弯折延伸而成的用以与电路板101相连的第一焊接部212。其中,第一接触部210设置为圆弧状弹性结构。舌板12具有抵接面121及与抵接面121相对的配合面120,在本实施方式中,分别为舌板12下表面和上表面,第一接触部210向下延伸而凸伸出舌板12抵接面121,从而,第一接触部210与对接插头7、8相接触的第一接触点213位于舌板12抵接面121的下方。舌板12的抵接面121凹设有四个并排设置的用以收容第一端子组21的第一收容槽1211。所述第二焊接部212卡扣于绝缘本体1主体部11上设置的纵向延伸的第一固定槽111,并且向下延伸出主体部11,用以和电路板101连接。The

第二端子组22是在USB 2.0A型插座连接器的舌板上附加的五根端子,用以提高信号传输速度,包括第二对差分信号端子225及第三对差分信号端子227以及位于第二对及第三对差分信号端子之间的第二接地端子226,第二接地端子226用以降低第二对及第三对第二差分信号端子225、227之间的串绕。第二端子组22仅仅用以和第二插头7上位于平板状接点71后方的具有弹性的附加接点72接触。第二端子组22包括若干第二接触部220、与第二接触部220相连的用以与绝缘本体1固定的第二固持部221、自第二固持部221一端弯折延伸而成的用以与电路板101相连的第二焊接部222。其中,第二接触部220设置为平板状结构,第二接触部220上的与第二插头7接触的第二接触点223位于舌板12抵接面121的上方,第二接触点223和第一接触点213分别位于舌板12抵接面121的两侧。第一接触部210和第二接触部220沿舌板12的厚度方向位于不同高度上,USB 2.0A型插头8和第二插头7上的平板状接点81、71只能接触到与其对应的具有弹性的第一接触部210,而不会接触到收容于舌板12内的平板状第二接触部220,从而,避免产生混乱信号。The

舌板12的配合面120凹设有用以收容第二固持部221的五个第三收容槽1201。第二接触部220位于第二固持部221的下方,第二接触部220与第二固持部221之间连接有转接部224,第二接触部220和第二固持部221分别自转接部224的上下端向后延伸而成。舌板12抵接面121凹设有用以收容第二接触部220的第二收容槽1212,该第二收容槽1212并排设置而位于第一收容槽1211的前方。舌板12的前端向后凹设有上下贯通舌板12抵接面121和配合面120的用以收容转接部224的凹部122,凹部122连通第三收容槽1201及第二收容槽1212。第二焊接部222安装于绝缘本体1主体部11上,并且向下延伸出主体部11。第二固持部221位于舌板12的上半部分,第一接触部210和第二接触部220均位于舌板12的下半部分即位于舌板12的同一侧,第一接触部210位于第二接触部220的后方,充分利用了USB 2.0A型插座连接器中舌板的有限尺寸来安装第一端子组21及第二端子组22。The

前遮蔽壳体3顶面311、底面312及侧面313上设置有若干延伸入收容空间310的用以抵持对接插头的弹片315及位于最前端的朝外倾斜延伸的导引片314,该导引片314引导对接插头插入收容空间310内。前遮蔽壳体3侧面313向下延伸有固定于电路板101上的焊接脚316。前遮蔽壳体3顶面311后端设有固持孔317,用以和后遮蔽壳体32上端的固持片321相卡扣。后遮蔽壳体32两侧面上设有凸点322,用以和前遮蔽壳体31两侧面313上的凹孔318相扣持,从而将后遮蔽壳体32组装至前遮蔽壳体31上,并且包覆绝缘本体1和导电端子2。The

绝缘本体1主体部11后端向前凹设有一容置空间113,一定位板4组装至容置空间113内,设有五个上下贯通的定位孔41,第二焊接部222插入定位孔41内并且向下延伸出定位板4,从而,导电端子2第二焊接部222得到良好的定位。定位板4两侧设有一呈三角形的卡臂42,用以和容置空间113内设置的挡板114相扣持,从而将定位板4牢靠的固定在主体部11上。The rear end of the

请参阅图7A至图8所示,本发明第二实施方式中的电连接器200与第一实施方式中的电连接器100相似,其与第一实施方式不同之处在于:舌板12到前遮蔽壳体31的顶面311的距离比到底面312的距离更大,所述第一收容槽1211和第二收容槽1212设置于舌板12的上半部分,相应的,第三收容槽1201设置于舌板12的下半部分,舌板12抵接面121及与抵接面121相对的配合面120分别为舌板12上表面和下表面。第一接触部210和第二接触部220均位于舌板12的上半部分。Please refer to FIG. 7A to FIG. 8 , the

请参阅图9A至图10所示,本发明第三实施方式中的电连接器300与第一实施方式中的电连接器100相似,其与第一实施方式不同之处在于:电连接器300安装于前端具有开口104的电路板101上,前遮蔽壳体31的前端焊接脚316是自前遮蔽壳体31侧面313的中部朝外水平延伸而成。电连接器300的安装面102为前端焊接脚316的下表面,且位于前遮蔽壳体31底面312的上方。前遮蔽壳体31底面312及部分侧面313是收容于电路板101开口104内,如此设置,可以降低电连接器300和电路板101的整体高度。Please refer to FIG. 9A to FIG. 10 , the

主体部11的下端向前延伸形成有收容于电路板101开口104内的支撑板115,该支撑板115与舌板12大致平行,前遮蔽壳体31底面312向后延伸有卡扣部319,该卡扣部319固定于主体部11上,支撑板115支撑前遮蔽壳体31底面312的后部分。The lower end of the

请参阅图11A至图15所示,本发明第四实施方式中的电连接器400与第一实施方式中的电连接器100相似,其与第一实施方式不同之处在于:电连接器400的舌板12垂直于安装面102,舌板12抵接面121及与抵接面121相对的配合面120,在本实施方式中,分别为舌板12左侧面和右侧面,第一接触部210沿上下方向依次排列,且相互隔开。第二接触部220也沿上下方向依次排列,且相互隔开。第一端子组21和第二端子组22之间夹持有一固持板5。绝缘本体1后部还设有一开口朝后的凹室116,用以收容固持板5、第一端子组21和第二端子组22。该固持板5的两侧分别凸设有若干间隔设置的纵向凸条51,第一焊接部212及第二焊接部222均固定于相邻凸条51之间,第一端子组21的第一焊接部212与第一固持部211之间还设有向前延伸,然后横向延伸而成的弯折部214,该弯折部214后端抵靠在纵向凸条51的顶端,弯折部214横向部分贴靠在固持板5的前表面上。Please refer to FIG. 11A to FIG. 15 , the

请参阅图16A至图18所示,本发明第五实施方式中的电连接器500与第一实施方式中的电连接器100相似,其与第一实施方式不同之处在于:收容空间310的开口(即插接口)朝上,舌板12垂直于安装面102,第一接触部210及第二接触部220均位于舌板12的右侧。第一固持部211与第一焊接部212大致平行,中间连接有折弯部215。第二固持部221和第二焊接部222在竖直方向对齐。Please refer to FIG. 16A to FIG. 18 , the

请参阅图19A至图20所示,本发明第六实施方式中的电连接器600与第一实施方式中的电连接器100相似,其与第一实施方式不同之处在于:收容空间310的开口朝上,舌板12垂直于安装面102,第一接触部210及第二接触部220均位于舌板12的右侧。第一固持部211与第一焊接部212大致平行,中间连接有转折部216。第二焊接部222自第二固持部221末端倾斜延伸而成。安装面102和对接面103之间不垂直,也不平行,也就是说,安装面102倾斜于对接面103。Please refer to FIG. 19A to FIG. 20 , the

Claims (13)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201110148229CN102324642B (en) | 2007-08-10 | 2007-08-10 | Electric connector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201110148229CN102324642B (en) | 2007-08-10 | 2007-08-10 | Electric connector |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2007100259340ADivisionCN101364694B (en) | 2007-08-10 | 2007-08-10 | electrical connector |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102324642Atrue CN102324642A (en) | 2012-01-18 |

| CN102324642B CN102324642B (en) | 2013-05-08 |

Family

ID=45452339

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201110148229ActiveCN102324642B (en) | 2007-08-10 | 2007-08-10 | Electric connector |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102324642B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104733882A (en)* | 2015-03-09 | 2015-06-24 | 连展科技(深圳)有限公司 | Stand type socket electric connector |

| CN108232676A (en)* | 2016-12-21 | 2018-06-29 | 富士康(昆山)电脑接插件有限公司 | Electric connector |

| US10553994B2 (en) | 2016-12-21 | 2020-02-04 | Foxconn Interconnect Technology Limited | Electrical connector having separate front and rear shielding shells |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6554646B1 (en)* | 1998-12-14 | 2003-04-29 | Berg Electronics Group, Inc. | Electrical connector assembly |

| CN1421059A (en)* | 2000-03-31 | 2003-05-28 | 莫莱克斯公司 | Channel isolation shield |

| CN2587083Y (en)* | 2002-11-13 | 2003-11-19 | 富士康(昆山)电脑接插件有限公司 | Cable connector assembly |

| JP2005503656A (en)* | 2001-08-01 | 2005-02-03 | モレックス インコーポレーテッド | Impedance adjusted connector |

| US20050118876A1 (en)* | 2001-09-25 | 2005-06-02 | Toshihiro Niitsu | Connector for high-rate transmission |

- 2007

- 2007-08-10CNCN 201110148229patent/CN102324642B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6554646B1 (en)* | 1998-12-14 | 2003-04-29 | Berg Electronics Group, Inc. | Electrical connector assembly |

| CN1421059A (en)* | 2000-03-31 | 2003-05-28 | 莫莱克斯公司 | Channel isolation shield |

| JP2005503656A (en)* | 2001-08-01 | 2005-02-03 | モレックス インコーポレーテッド | Impedance adjusted connector |

| US20050118876A1 (en)* | 2001-09-25 | 2005-06-02 | Toshihiro Niitsu | Connector for high-rate transmission |

| CN2587083Y (en)* | 2002-11-13 | 2003-11-19 | 富士康(昆山)电脑接插件有限公司 | Cable connector assembly |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104733882A (en)* | 2015-03-09 | 2015-06-24 | 连展科技(深圳)有限公司 | Stand type socket electric connector |

| CN104733882B (en)* | 2015-03-09 | 2024-05-03 | 连展科技(深圳)有限公司 | Vertical socket electric connector |

| CN108232676A (en)* | 2016-12-21 | 2018-06-29 | 富士康(昆山)电脑接插件有限公司 | Electric connector |

| US10553994B2 (en) | 2016-12-21 | 2020-02-04 | Foxconn Interconnect Technology Limited | Electrical connector having separate front and rear shielding shells |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102324642B (en) | 2013-05-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101364694B (en) | electrical connector | |

| CN101562290B (en) | Flash memory device | |

| CN101453088B (en) | electrical connector | |

| CN102394408B (en) | Cable connecting assembly | |

| CN201113076Y (en) | socket electrical connector | |

| CN201097426Y (en) | socket electrical connector | |

| CN201204275Y (en) | electrical connector | |

| CN101364692B (en) | Electric connector for socket | |

| CN102437482B (en) | Electrical connector | |

| CN101740951B (en) | Electric connector | |

| CN201252288Y (en) | Electrical connector | |

| CN201430309Y (en) | Electric connector | |

| CN202150590U (en) | Cable plug connector | |

| CN201303172Y (en) | Electric connector | |

| CN101728663A (en) | Cable connector assembly | |

| CN101771226A (en) | electrical connector | |

| CN201097428Y (en) | Stacked electric connector | |

| CN202159800U (en) | Cable plug connector, board end socket connector and connector assembly | |

| CN201708308U (en) | Electric connector | |

| CN103972730B (en) | Electric connector | |

| CN201708312U (en) | Connector for electronic card | |

| CN102324642A (en) | electrical connector | |

| CN201097427Y (en) | electrical connector | |

| CN201774000U (en) | Terminal and electrical connector using the terminal | |

| CN101834357B (en) | Electrical connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |