CN101944200A - Method and system for dispatching container trucks - Google Patents

Method and system for dispatching container trucksDownload PDFInfo

- Publication number

- CN101944200A CN101944200ACN201010231666XACN201010231666ACN101944200ACN 101944200 ACN101944200 ACN 101944200ACN 201010231666X ACN201010231666X ACN 201010231666XACN 201010231666 ACN201010231666 ACN 201010231666ACN 101944200 ACN101944200 ACN 101944200A

- Authority

- CN

- China

- Prior art keywords

- task

- time

- current

- executing

- card

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及集装箱卡车的调度领域,尤其涉及的是一种集装箱卡车的调度方法及系统。The invention relates to the dispatching field of container trucks, in particular to a dispatching method and system for container trucks.

背景技术Background technique

随着集装箱贸易量的增加及船舶大型化的发展使很多集装箱码头作业资源利用率达到或接近饱和,随着各码头吞吐量的不断增加,如何在尽量较少投入的同时保证停靠的船舶得到及时的服务成为集装箱码头所面临的一个重要问题。集装箱运输的增长,集装箱船舶的大型化、高速化趋势,要求码头不断提高装卸效率性,而集装箱码头的生产调度则是关键点。在港口竞争中,除了来自于港口的地理位置和腹地经济条件外,港口的技术条件、作业效率和管理水平也是体现其竞争力的重要因素。因此,要想在港口竞争中取得更大的利益,必须使作业系统化、合理化,而实现这一目标的有效途径就是优化港口资源的分配与调度,并且使其智能化。With the increase in container trade volume and the development of large-scale ships, the resource utilization rate of many container terminals has reached or is close to saturation. The quality of service has become an important issue faced by container terminals. The growth of container transportation and the trend of large-scale and high-speed container ships require terminals to continuously improve loading and unloading efficiency, and the production scheduling of container terminals is a key point. In port competition, in addition to the port's geographical location and hinterland economic conditions, the port's technical conditions, operating efficiency and management level are also important factors that reflect its competitiveness. Therefore, in order to obtain greater benefits in port competition, the operation must be systematized and rationalized, and the effective way to achieve this goal is to optimize the allocation and scheduling of port resources and make them intelligent.

传统的集卡调度是基于集卡绑定岸桥的规则下,采用计算机辅助调度的方式充分发挥操作人员的主观能动性完成堆场的操作。这种调度模式存在以下几个方面的问题:集卡将近50%的时间在空驶,利用率不高;为了保证岸桥的作业,在岸桥离相应集装箱堆场比较远的情况下,只能通过增加服务于岸桥的集卡来保证完成任务,而一旦船舶离相应的岸桥较近,则一部分集卡又被闲置,这就造成了资源和成本的极大浪费。因此集卡调度对于码头来说既有短期现实意义又有长远的意义,短期的意义是指集卡在满足岸桥服务要求的时候能够以较短的路径完成任务,节省油耗从而降低码头成本,长远的意义是指能够减少集卡的规模但又同时保证了岸桥的需要。The traditional truck scheduling is based on the rules that the trucks are bound to the quayside bridge, and the computer-aided scheduling method is used to give full play to the subjective initiative of the operators to complete the operation of the yard. This scheduling mode has the following problems: nearly 50% of the trucks are empty, and the utilization rate is not high; in order to ensure the operation of the quay crane, when the quay crane is far away from the corresponding container yard, only The completion of the task is ensured by increasing the collection trucks serving the quay cranes, and once the ship is close to the corresponding quay cranes, some collection trucks are idle again, which causes a great waste of resources and costs. Therefore, truck dispatching has both short-term practical and long-term significance for the terminal. The short-term meaning means that the truck can complete the task in a shorter path when meeting the service requirements of the quay crane, saving fuel consumption and reducing the cost of the terminal. The long-term meaning means that the size of the truck can be reduced while ensuring the needs of the quayside crane.

发明内容Contents of the invention

本发明的目的在于提供一种集装箱卡车的调度方法及系统,更好地实现集装箱码头的集卡调度,使集卡能够动态的服务于不同的岸桥和船舶,并为每辆集卡分配任务,决定每辆车完成任务的顺序、行驶路径,从而减少装卸桥(岸桥)的等待时间,节省车辆行驶的总路径,降低空载率,达到提高集装箱码头装卸效率的目的。The purpose of the present invention is to provide a scheduling method and system for container trucks to better realize the scheduling of container trucks at container terminals, so that the trucks can dynamically serve different quay cranes and ships, and assign tasks to each truck , to determine the order and driving path of each vehicle to complete the task, thereby reducing the waiting time of the loading and unloading bridge (quay bridge), saving the total path of the vehicle, reducing the empty-load rate, and achieving the purpose of improving the loading and unloading efficiency of the container terminal.

本发明的技术方案如下:Technical scheme of the present invention is as follows:

一种集装箱卡车的调度方法,其中,包括以下步骤:A method for dispatching container trucks, comprising the following steps:

S100:进行初始化操作;S100: perform an initialization operation;

S200:检测集卡i当前是否有任务,若没有任务则执行步骤S300;若有任务则执行S400;S200: Detect whether the collection card i currently has a task, if there is no task, execute step S300; if there is a task, execute S400;

S300:为集卡i分配新任务,然后执行步骤S400;S300: Assign a new task to the collection card i, and then perform step S400;

S400:运行集卡i的任务检测函数,检测集卡i当前任务的状态;S400: Run the task detection function of the collection card i to detect the status of the current task of the collection card i;

S500:令i=i+1,然后执行步骤S600;S500: set i=i+1, and then perform step S600;

S600:判断集卡i是否大于集卡总数,若否则执行S200;若是则执行S700;S600: Determine whether the collection card i is greater than the total number of collection cards, if not, execute S200; if so, execute S700;

S700:检测所有岸桥的任务运行状态,若有任何一个岸桥有任务未完成,则令总任务表的状态值=1;S700: Detect the task running status of all quay cranes, if any quay crane has a task that has not been completed, then make the status value of the total task table=1;

S800:检测所有堆场的任务运行状态,若有任何一个堆场有任务未完成,则令总任务表的状态值=1;S800: Detect the task running status of all storage yards, if there is any unfinished task in any storage yard, then make the status value of the total task table=1;

S900:令当前时间=当前时间+1;S900: Let current time=current time+1;

S1000:判断总任务表的状态值是否等于0,若是则结束;若否则返回步骤S100。S1000: Determine whether the state value of the total task table is equal to 0, if so, end; otherwise, return to step S100.

所述的集装箱卡车的调度方法,其中,所述步骤S100具体包括:The method for dispatching container trucks, wherein the step S100 specifically includes:

S110:令计时器的当前时间=0;S110: Let the current time of the timer=0;

S120:令总任务表的状态值=0;S120: Make the state value of the total task list=0;

S130:令i=0。S130: Let i=0.

所述的集装箱卡车的调度方法,其中,步骤S400具体包括:The method for dispatching container trucks, wherein step S400 specifically includes:

S410:判断集卡i的当前任务完成时间是否等于计时器的当前时间,若是则执行步骤S420;若否则执行步骤S440;S410: Determine whether the current task completion time of the collection card i is equal to the current time of the timer, if so, execute step S420; otherwise, execute step S440;

S420:给集卡的任务完成时间重新赋值使其小于所述当前时间;S420: Reassign the task completion time of the collection card to make it less than the current time;

S430:给相应的岸桥或堆场增加新的任务服务集卡,然后执行步骤S450;S430: Add a new task service set card to the corresponding quay crane or storage yard, and then perform step S450;

S440:判断集卡i是否有任务未完成,若是则执行步骤S450;若否则执行步骤S460;S440: Determine whether there is an unfinished task in the collection card i, if so, execute step S450; otherwise, execute step S460;

S450:令所述总任务表的状态值=1。S450: Make the state value of the total task table=1.

所述的集装箱卡车的调度方法,其中,步骤S700进一步包括:The method for dispatching container trucks, wherein step S700 further includes:

S710:判断岸桥的任务列表中是否有任务未完成,若是则执行步骤S720,若否则执行步骤S780;S710: Determine whether there are unfinished tasks in the task list of the quay crane, if so, execute step S720, otherwise execute step S780;

S720:判断岸桥的当前任务完成时间是否等于计时器的当前时间,若是则执行步骤S730;若否则执行步骤S770;S720: Determine whether the current task completion time of the quay crane is equal to the current time of the timer, if so, execute step S730; otherwise, execute step S770;

S730:调用岸桥服务的集卡的任务更新函数,更新集卡任务列表中的各项任务参数;S730: call the task update function of the collection card of the quay crane service, and update each task parameter in the collection card task list;

S740:将岸桥的当前任务移除,更新岸桥下一个任务的完成时间和净工作时间;S740: remove the current task of the quay crane, and update the completion time and net working time of the next task of the quay crane;

S750:判断岸桥的任务列表中是否有任务未完成,若是则执行步骤S770,若否则执行步骤S760;S750: Determine whether there is any unfinished task in the task list of the quay crane, if so, execute step S770, otherwise execute step S760;

S760:更新系统总的运行时间;S760: update the total running time of the system;

S770:令总任务表的状态值=1。S770: Let the state value of the total task table=1.

所述的集装箱卡车的调度方法,其中,步骤S730进一步包括:The method for dispatching container trucks, wherein step S730 further includes:

S731:调用任务移除函数将任务列表中的当前任务移除;S731: call the task removal function to remove the current task in the task list;

S732:判断集卡是否还有任务未完成,若是则执行步骤S733;若否则执行步骤S736;S732: Judging whether the collection card has unfinished tasks, if so, execute step S733; otherwise, execute step S736;

S733:更新集卡完成新任务的时间,并更新集卡总的运输时间;S733: Update the time when the collection truck completes the new task, and update the total transportation time of the collection truck;

S734:判断新任务的起点和终点是否为同一位置,若是则执行步骤S735;S734: Determine whether the starting point and the ending point of the new task are at the same location, if so, execute step S735;

S735:调用集卡的检测函数,对集卡的任务状态进行检测;S735: Call the detection function of the collection card to detect the task status of the collection card;

S736:调用集卡的任务分配函数,为集卡分配新的任务。S736: Call the task allocation function of the collection card to assign new tasks to the collection card.

所述的集装箱卡车的调度方法,其中,步骤S800进一步包括:The method for dispatching container trucks, wherein step S800 further includes:

S810:判断堆场的任务列表中是否有任务未完成,若是则执行步骤S820,若否则执行步骤S880;S810: Determine whether there is an unfinished task in the task list of the yard, if so, execute step S820, otherwise execute step S880;

S820:判断堆场的当前任务完成时间是否等于计时器的当前时间,若是则执行步骤S830;若否则执行步骤S870;S820: Determine whether the current task completion time of the yard is equal to the current time of the timer, if so, execute step S830; otherwise, execute step S870;

S830:调用堆场服务的集卡的任务更新函数,更新集卡任务列表中的各项任务参数;S830: call the task update function of the collection card of the yard service, and update each task parameter in the collection card task list;

S840:将堆场的当前任务移除,更新堆场下一个任务的完成时间和净工作时间;S840: remove the current task in the yard, and update the completion time and net working time of the next task in the yard;

S850:判断堆场的任务列表中是否有任务未完成,若是则执行步骤S870,若否则执行步骤S860;S850: Determine whether there is an unfinished task in the task list of the yard, if so, execute step S870, otherwise execute step S860;

S860:更新系统总的运行时间;S860: updating the total running time of the system;

S870:令总任务表状态值=1。S870: Make the state value of the total task table=1.

一种集装箱卡车的调度系统,包括集卡、岸桥和堆场,其中,还包括总计时器、总任务表、核心处理模块,以及分别与集卡、岸桥、堆场对应的功能模块,其中,A dispatching system for container trucks, including collection trucks, quayside cranes and storage yards, including a total timer, a total task table, a core processing module, and functional modules corresponding to collection trucks, quayside cranes, and storage yards, in,

所述总计时器用于记录码头调动系统的运行时间,所记录的时间为总计时器当前时间;总任务表用于储存码头所有的任务;所述核心处理模块用于控制整个系统的运行;The total timer is used to record the running time of the terminal mobilization system, and the recorded time is the current time of the total timer; the total task table is used to store all tasks of the terminal; the core processing module is used to control the operation of the entire system;

所述集卡对应的功能模块有:The functional modules corresponding to the collection card are:

集卡任务表,用于记录分配给该集卡的任务;Collecting card task table, used to record the tasks assigned to the collecting card;

集卡任务完成时间计算模块,用于记录当前作业完成时间;Collecting card task completion time calculation module, used to record the current job completion time;

集卡任务检测模块,用于检测集卡当前的任务状态;The collection card task detection module is used to detect the current task status of the collection card;

集卡任务更新模块,用于给集卡增加新的任务同时改变集卡任务表和集卡任务完成时间计算模块的状态;The collection card task update module is used to add new tasks to the collection card and change the state of the collection card task table and the collection card task completion time calculation module at the same time;

所述岸桥对应的功能模块有:The functional modules corresponding to the quay crane are:

岸桥任务表,用于记录分配给该岸桥的任务;Quay crane task table, used to record the tasks assigned to the quay crane;

岸桥任务完成时间计算模块,用于记录当前作业完成时间;The quay crane task completion time calculation module is used to record the current job completion time;

岸桥任务检测模块,用于检测岸桥当前的任务状态;The quay crane task detection module is used to detect the current task status of the quay crane;

岸桥任务更新模块,用于给岸桥添加新的任务;The quay crane task update module is used to add new tasks to the quay crane;

所述堆场对应的主要功能模块有:The main functional modules corresponding to the storage yard are:

堆场任务表,用于记录分配给该堆场的任务;The yard task table is used to record the tasks assigned to the yard;

堆场任务完成时间计算模块,用于记录当前作业完成时间;The yard task completion time calculation module is used to record the current job completion time;

堆场任务检测模块,用于检测堆场当前的任务状态;The yard task detection module is used to detect the current task status of the yard;

堆场任务更新模块,用于给堆场添加新的任务。The yard task update module is used to add new tasks to the yard.

本发明的有益效果:本发明的集装箱卡车的调度方法的计算量小,可实时得到集卡调度的优化结果,由于本发明方法只依据当前的码头状况对集卡调度做出优化,有利于处理突发的情况,更贴近于现实情况。该系统易于扩展,留有程序接口。易于进一步将堆场管理、岸桥管理融入到整个系统中,方便以后实现岸桥、集卡、堆场的整体优化的实现。可根据码头工作状态,动态调整集卡的使用数量。易于实现不同的优化目的。Beneficial effects of the present invention: The container truck dispatching method of the present invention has a small amount of calculation, and can obtain the optimization result of the collection truck dispatching in real time. Since the method of the present invention only optimizes the collection truck dispatching according to the current terminal conditions, it is beneficial to the processing The sudden situation is closer to the real situation. The system is easy to expand, leaving a program interface. It is easy to further integrate storage yard management and quay crane management into the whole system, and facilitate the realization of the overall optimization of quay crane, truck collection and storage yard in the future. According to the working status of the terminal, the number of trucks used can be dynamically adjusted. Easy to achieve different optimization purposes.

附图说明Description of drawings

图1为本发明实施例所提供的集装箱卡车的调度系统;Fig. 1 is the scheduling system of the container truck provided by the embodiment of the present invention;

图2为本发明实施例所提供的集装箱卡车的调度方法主流程图;Fig. 2 is the main flowchart of the dispatching method of the container truck provided by the embodiment of the present invention;

图3为本发明实施例提供的集卡任务检测流程图;Fig. 3 is the flow chart of task detection of collecting truck provided by the embodiment of the present invention;

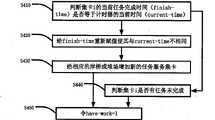

图4为本发明实施例提供的岸桥和堆场的任务检测流程图;Fig. 4 is the task detection flowchart of quay crane and storage yard provided by the embodiment of the present invention;

图5为本发明实施例提供的集卡任务更新流程图。Fig. 5 is a flow chart of updating a collection card task provided by an embodiment of the present invention.

具体实施方式Detailed ways

本发明的一种集装箱卡车的调度方法及系统,为使本发明的目的、技术方案及优点更加清楚、明确,以下参照附图并举实施例对本发明进一步详细说明。A method and system for dispatching container trucks of the present invention. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

英文解释一览表:List of explanations in English:

总任务表状态值 have_workTotal task table status value have_work

当前时间 current_timecurrent time current_time

任务完成时间 finish_timeTask completion time finish_time

任务移除函数 task_moveTask removal function task_move

系统总运行时间 all_timeThe total running time of the system all_time

检测 checkdetection check

任务增加函数 task_addTask addition function task_add

任务更新函数 renew_taskTask update function renew_task

下一任务的作业时间 tmp_timeThe job time of the next task tmp_time

工作时间 busy_timeWorking hours busy_time

参见图1为发明实施例所提供的集装箱卡车的调度系统。码头的调度主要包括集卡100、岸桥400、堆场300上任务的分配。集装箱卡车,简称集卡;所述集卡100用于运输货物;所述岸桥400用于将货物装上集卡运走;堆场300用于堆积货物的场所。所述调度系统200主要包括:总计时器201、总任务表202、核心处理模块220。其中,所述总计时器201用于记录码头调动系统的运行时间,所记时间即为current-time(当前时间);总任务表202用于储存码头所有的任务;所述核心处理模块220用于控制整个系统的运行。有一个总计时器201输入到集卡100、岸桥400、堆场300对应的所有对象中,所有对象根据这个计时器同步进行相应的操作。计时器每1秒钟记时一次,系统每1秒钟循环一次。然后在每次循环中判断集卡100、岸桥400和堆场300的对象检查计时变量(即总计时器的时间current-time)和自身正在执行的任务的完成时间(finish-time)是否相等,如果相等则采取相应操作(具体参见后文),否则继续执行当前的操作任务。Refer to Fig. 1 for the scheduling system of the container truck provided by the embodiment of the invention. The scheduling of the wharf mainly includes the assignment of tasks on the

所述系统200中还包括分别与集卡100、岸桥400、堆场300对应的功能模块。其中,The

集卡100对应的主要功能模块有:集卡任务表203用于记录分配给该集卡的任务;集卡任务完成时间计算模块204(集卡finish-time模块),用来记录当前作业完成时间;集卡任务检测模块205(集卡check模块),用于检测集卡当前的任务状态;集卡任务更新模块206(集卡renew-task模块),用于给集卡增加新的任务同时改变集卡任务表和集卡任务完成时间计算模块的状态。The main functional modules corresponding to the

岸桥400对应的主要功能模块有:岸桥任务表207用于记录分配给该岸桥的任务;岸桥任务完成时间计算模块208(岸桥finish-time模块),用来记录当前作业完成时间;岸桥任务检测模块209(岸桥check模块)用于检测岸桥当前的任务状态,若有新任务更新新任务的完成时间和岸桥的净工作时间等;岸桥任务更新模块210(岸桥task-add模块)用于给岸桥添加新的任务。The main functional modules corresponding to the

堆场300对应的主要功能模块有:堆场任务表211用于记录分配给该堆场的任务;堆场任务完成时间计算模块212(堆场finish-time模块),用来记录当前作业完成时间;堆场任务检测模块213(堆场check(检查)模块)用于检测堆场当前的任务状态,若有新任务更新新任务的完成时间和堆场的净工作时间等;堆场任务更新模块214(堆场task-add模块)用于给堆场添加新的任务。The main functional modules corresponding to the

在用仿真模型验证集装箱卡车的调度方法的结果的过程中发现以下情况:在每辆车分配的任务路径是相同的情况下,将每辆车的工作开始时间设定在不同的值(同在一个小的时间范围内20秒之内),最终得到的结果虽然满足集卡的空驶率保持不变,但是这个码头某个岸桥完成其所有任务的总时间的差异可以达到10%,即20秒的差异可以引起2000多秒的差异结果差异非常之大。由于在现实情况中,每辆车的开始工作时间、行驶速度、岸桥堆场的装卸时间都不是完全固定的一个值,有一定的随机性。这说明:仅根据初始状态分配每辆车的任务不是一个可行的方法,即使在理论上得到了最好的解,在实际情况中可能并不是一个好的解。所以车辆的任务分配必须是动态的分配,即每辆车在完成一个任务之后应根据码头的当时情况分配其下一个任务。In the process of verifying the results of the scheduling method of container trucks with the simulation model, the following situation is found: in the case that the assigned task path of each vehicle is the same, the work start time of each vehicle is set at a different value (same as in within a small time range of 20 seconds), although the final result satisfies that the empty driving rate of the trucks remains unchanged, the difference in the total time for a quay crane to complete all its tasks at this terminal can reach 10%, that is, 20 The difference in seconds can cause a difference of more than 2000 seconds, and the result difference is very large. Because in reality, the starting time, driving speed, and loading and unloading time of the quay crane yard of each vehicle are not a completely fixed value, and there is a certain degree of randomness. This shows that it is not a feasible method to assign the tasks of each vehicle only according to the initial state. Even if the best solution is obtained in theory, it may not be a good solution in practice. Therefore, the task allocation of vehicles must be a dynamic allocation, that is, after each vehicle completes a task, it should allocate its next task according to the current situation of the terminal.

在建立系统的基础上,本发明建立了集卡调度的动态优化方法,其详细过程如下:On the basis of establishing the system, the present invention establishes a dynamic optimization method for truck dispatching, and its detailed process is as follows:

(1)每一辆车在工作开始之初或完成一个作业任务之后就从码头的总任务表202中选择一个任务作为下一个任务。选择的任务满足以下条件:集卡的空驶时间+预计等待时间最小。由于一个码头的装卸任务一天不会超过1万个,而这1万个任务中许多任务都是从某一个堆场运送到某一个岸桥,或从某一个岸桥运送到某一堆场,本发明中可以根据以上特性将任务进行分类,这样得到的任务种类也就100个左右,于是用穷举的方法可以在很短的时间内找到一个使得集卡的空驶距离+预计等待时间最小的任务。(1) Each vehicle selects a task from the dock's general task table 202 as the next task at the beginning of work or after completing a task. The selected task satisfies the following conditions: the empty time of the truck + the expected waiting time is the smallest. Since the loading and unloading tasks of a terminal will not exceed 10,000 a day, and many of these 10,000 tasks are transported from a certain storage yard to a certain quay crane, or from a certain quay crane to a certain storage yard, In the present invention, tasks can be classified according to the above characteristics, so that there are only about 100 task types, so an exhaustive method can be used to find the one that minimizes the empty driving distance + expected waiting time of the collection truck in a very short time. Task.

其中预计等待时间是由集卡在堆场的等待时间和在岸桥的等待时间之和构成的。集卡在堆场的等待时间是指集卡到达堆场而堆场还有任务正在执行,集卡等待堆场执行完所有任务的时间。由于每一个集卡预定了任务之后,这个任务便进入了堆场的任务列表,通过检查堆场的现有任务列表,便可以求得堆场完成现有所有任务的时间t1,同样本发明也可以预计到集卡到达堆场的时间t2,若t1>t2,则集卡在堆场的等待时间=t1-t2,否则为0,同样可以计算得到集卡在岸桥的等待时间。The estimated waiting time is composed of the sum of the waiting time of the trucks in the storage yard and the waiting time of the quay crane. The waiting time of the collection trucks in the yard refers to the time when the collection trucks arrive at the yard and there are still tasks being executed in the yard, and the collection trucks wait for the yard to complete all tasks. After each collection card has scheduled a task, this task has just entered the task list of the stockyard, and by checking the existing task list of the stockyard, the time t1 for the stockyard to complete all existing tasks can be obtained, and the present invention also The time t2 when the trucks arrive at the storage yard can be estimated. If t1>t2, the waiting time of the trucks in the yard = t1-t2, otherwise it is 0, and the waiting time of the trucks on the quay can also be calculated.

(2)集卡选定任务之后将所选任务加入到集卡任务表203中,更新码头的总任务表(即将总任务表中的该任务移除)、岸桥和场桥的预定任务完成时间(即岸桥的finish-time和堆场的finish-time)、集卡的当前任务完成时间(即集卡的finish-time)。(2) After the collection card selects the task, the selected task is added to the collection card task table 203, the general task table of the terminal is updated (that is, the task in the general task table is removed), the scheduled tasks of the quay bridge and the yard bridge are completed Time (that is, the finish-time of the quay crane and the finish-time of the storage yard), and the current task completion time of the collection truck (that is, the finish-time of the collection truck).

参见图2为本发明实施例所提供的集装箱卡车的调度方法主流程图。所述的集装箱卡车的调度方法主要包括以下步骤:Referring to FIG. 2 , it is the main flow chart of the method for dispatching container trucks provided by the embodiment of the present invention. The dispatching method of described container truck mainly comprises the following steps:

S100:对系统进行初始化。S100: Initialize the system.

所述步骤S100进一步包括步骤:The step S100 further includes the steps of:

S110:令current-time=0,即初始化计时器的值。S110: set current-time=0, that is, initialize the value of the timer.

S120:令have-work=0,即假设码头总任务表中所有的任务已完成。S120: set have-work=0, that is, assume that all tasks in the dock general task table have been completed.

S130:令i=0,即从第一辆集卡开始运行检测。S130: Set i=0, that is, start to run detection from the first collection truck.

S200:检测集卡i当前是否有任务,若没有任务则执行步骤S300;若有任务则执行S400。S200: Detect whether the collection card i currently has a task, if there is no task, perform step S300; if there is a task, perform step S400.

S300:为集卡i分配新任务,然后执行步骤S400。S300: Assign a new task to the collection card i, and then perform step S400.

S400:运行集卡i的任务检测函数,检测集卡i当前任务的状态。S400: Run the task detection function of the collection card i to detect the status of the current task of the collection card i.

参见图3为本发明实施例提供的集卡任务检测流程图。所述任务检测函数的主要功能是:检查当前任务完成时间(finish-time)和总计时器时间(current-time)是否一致。若一致表示运输任务已完成,同时设置finish-time=-1(也可将其设置为其他值,只要满足finish-time小于current-time即可)。根据任务的目的地调用相应岸桥或堆场的任务增加函数,并令have-work=1(表示整个系统还有任务需要做,系统继续运行)。若不一致,检测任务表中是否有任务未完成。如果任务列表中还有未完成任务,令have-work=1(表示整个系统还有任务需要做,系统继续运行)。Referring to FIG. 3 , it is a flow chart of the card collection task detection provided by the embodiment of the present invention. The main function of the task detection function is to check whether the current task completion time (finish-time) is consistent with the total timer time (current-time). If it is consistent, it means that the transportation task has been completed, and set finish-time=-1 at the same time (it can also be set to other values, as long as finish-time is less than current-time). Call the task increase function of the corresponding quay crane or yard according to the destination of the task, and set have-work=1 (meaning that the whole system still has tasks to be done, and the system continues to run). If not, check whether there are unfinished tasks in the task list. If there are unfinished tasks in the task list, make have-work=1 (meaning that the entire system still has tasks to be done, and the system continues to run).

所述步骤S400进一步包括步骤:The step S400 further includes the steps of:

S410:判断集卡i的当前任务完成时间(finish-time)是否等于计时器的当前时间(current-time),若是则执行步骤S420;若否则执行步骤S440。S410: Determine whether the current task finish time (finish-time) of the collection card i is equal to the current time (current-time) of the timer, if so, execute step S420; otherwise, execute step S440.

S420:给finish-time重新赋值使其小于current-time。例如:令finish-time=-1。S420: Reassign a value to finish-time to make it smaller than current-time. For example: let finish-time=-1.

S430:给相应的岸桥或堆场增加新的任务服务集卡。然后执行步骤S450。S430: Add a new mission service collection card to the corresponding quay crane or storage yard. Then step S450 is executed.

具体操作为系统调用相应的岸桥或堆场任务增加函数给岸桥或堆场增加新的任务,服务当前已完成运输任务的集卡。The specific operation is that the system calls the corresponding quay crane or storage yard task adding function to add new tasks to the quay crane or storage yard, and serve the collection trucks that have currently completed the transportation task.

S440:判断集卡i是否有任务未完成,若是则执行步骤S450;若否则执行步骤S460。S440: Determine whether there is an unfinished task in the collection card i, if yes, execute step S450; otherwise, execute step S460.

S450:令have-work=1。S450: set have-work=1.

S460:返回调用点S460: Return to the calling point

S500:令i=i+1,然后执行步骤S600。S500: set i=i+1, and then perform step S600.

令i=i+1是循环检测每辆集卡;实现系统对每辆集卡的动态检测。Let i=i+1 be cyclic detection of each collection truck; realize the dynamic detection of each collection truck by the system.

S600:判断i是否大于集卡总数,若否则执行S200;若是则执行S700。S600: Determine whether i is greater than the total number of collection cards, if not, execute S200; if yes, execute S700.

否表示还有集卡没有检测到,需要继续检测;是则表示所以集卡都已经检测过一次,可以开始对岸桥或堆场进行检测。No means that there are still collection trucks that have not been detected and need to continue detection; yes means that all collection trucks have been detected once, and the detection of the quay crane or the storage yard can be started.

S700:检测所有岸桥的任务运行状态,若有任何一个岸桥有任务未完成,则令总任务表的状态值have-work=1;S700: Detect the task running status of all quay cranes, if any quay crane has unfinished tasks, make the status value of the total task table have-work=1;

参见图4为本发明实施例提供的岸桥和堆场的任务检测流程图。由于岸桥和堆场的作业方式几乎相同,只是平均起吊时间不同,所以岸桥和堆场定义了一个相同的check()函数。其主要功能如下:首先,检查岸桥或堆场的任务表是否有任务未完成,若否则返回程序调用点。检查当前任务完成时间finish-time和全局计时器时间current-time是否一致。Referring to FIG. 4, it is a flow chart of task detection of the quay crane and the storage yard provided by the embodiment of the present invention. Since the operation methods of the quay crane and the storage yard are almost the same, but the average lifting time is different, the quay crane and the storage yard define the same check() function. Its main functions are as follows: First, check whether there is any unfinished task in the task table of the quay crane or the storage yard, if not, return to the program call point. Check whether the finish-time of the current task is consistent with the current-time of the global timer.

如果一致,则:调用当前服务集卡的任务更新函数renew-task()。调用task-move()函数,将岸桥或堆场的当前任务移除,并得到下一任务的作业时间tmp-time。更新岸桥或堆场新增任务的完成时间:finish-time=current-time+tmp-time。更新整个岸桥或堆场在工作的时间:busy-time=tmp-time+busy-time。如果作业链为空更新all-time=current-time。If consistent, then: call the task update function renew-task() of the current service set card. Call the task-move() function to remove the current task of the quay crane or the storage yard, and get the operation time tmp-time of the next task. Update the completion time of the new task of the quay crane or the storage yard: finish-time=current-time+tmp-time. Update the working time of the whole quay crane or storage yard: busy-time=tmp-time+busy-time. If the job chain is empty update all-time=current-time.

若不一致,则令have-work=1。If not, set have-work=1.

所述步骤S700进一步包括步骤:The step S700 further includes the steps of:

S710:判断岸桥的任务列表中是否有任务未完成,若是则执行步骤S720,若否则执行步骤S780。S710: Determine whether there is any unfinished task in the task list of the quay crane, if yes, perform step S720, otherwise, perform step S780.

S720:判断岸桥的当前任务完成时间(finish-time)是否等于计时器的当前时间(current-time),若是则执行步骤S730;若否则执行步骤S770。S720: Determine whether the current task finish time (finish-time) of the quay crane is equal to the current time (current-time) of the timer, if yes, perform step S730; otherwise, perform step S770.

S730:调用其服务的集卡的任务更新函数,更新集卡任务列表中的各项任务参数。例如:移除原有的任务,计算新增任务的完成时间,统计集卡i总的运输时间等等。S730: Call the task update function of the collection card served by it, and update each task parameter in the collection card task list. For example: remove the original task, calculate the completion time of the new task, count the total transportation time of the collection card i, and so on.

参见图5为renew_task()函数的流程图,当岸桥或堆场完成对集卡的装卸任务后调用相应集卡的renew_task()函数,其主要功能是:调用task_move()将任务列表中的第一个任务(即当前任务)移除;如果任务列表中还有未完成任务,更新finish_time=当前任务的行驶距离/集卡行驶速度+当前时间。如果当前任务的起点和终点是同一个地点(表示不需要再行驶到下一目的地)调用check()函数。如果任务列表中没有未完成任务(任务为空),调用码头类的集卡任务分配函数。See Figure 5 for the flow chart of the renew_task() function. When the quay crane or the yard completes the task of loading and unloading the collection card, call the renew_task() function of the corresponding collection card. Its main function is: call task_move() to move the task list The first task (that is, the current task) is removed; if there are unfinished tasks in the task list, update finish_time=travel distance of the current task/travel speed of the collection truck+current time. If the starting point and end point of the current task are the same place (meaning that there is no need to drive to the next destination) call the check() function. If there is no unfinished task in the task list (the task is empty), call the collection card task assignment function of the terminal class.

S731:调用函数task-move将任务列表中的当前任务移除。S731: Call the function task-move to remove the current task in the task list.

S732:判断集卡是否还有任务未完成,若是则执行步骤S733;若否则执行步骤S736。S732: Determine whether the collection card has unfinished tasks, if yes, execute step S733; otherwise, execute step S736.

S733:更新集卡完成新任务的时间,并更新集卡总的运输时间。S733: Update the time for the collection truck to complete the new task, and update the total transportation time of the collection truck.

S734:判断新任务的起点和终点是否为同一位置,若是则执行步骤S735;若否则执行步骤S737。S734: Determine whether the start point and the end point of the new task are at the same location, if yes, execute step S735; otherwise, execute step S737.

S735:调用集卡的检测函数,对集卡的任务状态进行检测,然后执行步骤S737。S735: Call the detection function of the collection card to detect the task state of the collection card, and then execute step S737.

对集卡的任务状态进行检测,具体步骤包括:S410至S460。Detecting the task state of the collection card, the specific steps include: S410 to S460.

S736:调用集卡的任务分配函数,为集卡分配新的任务。S736: Call the task allocation function of the collection card to assign new tasks to the collection card.

S737:返回程序的调用点。S737: Return to the calling point of the program.

S740:将岸桥的当前任务移除,更新岸桥下一个任务的完成时间和净工作时间。S740: Remove the current task of the quay crane, and update the completion time and net working time of the next task of the quay crane.

S750:判断岸桥的任务列表中是否有任务未完成,若是则执行步骤S770,若否则执行步骤S760。S750: Determine whether there is any unfinished task in the task list of the quay crane, if yes, perform step S770, otherwise, perform step S760.

S760:更新系统总的运行时间(all-time)。若计时器采用从0开始计时则令all-time=current-time;若计时器采用实际的钟表时间计时则all-time=current-time——start-time。S760: Update the total running time (all-time) of the system. If the timer starts timing from 0, set all-time=current-time; if the timer uses actual clock time, then all-time=current-time——start-time.

S770:令have-work=1。S770: set have-work=1.

S780:返回程序调用点S780: Return to the program call point

S800:检测所有堆场的任务运行状态,若有任何一个堆场有任务未完成,则令总任务表的状态值have-work=1;S800: Detect the task running status of all stockyards, if there is any unfinished task in any stockyard, make the status value of the total task table have-work=1;

所述步骤S800进一步包括步骤:The step S800 further includes the steps of:

S810:判断堆场的任务列表中是否有任务未完成,若是则执行步骤S820,若否则执行步骤S880。S810: Determine whether there is an unfinished task in the task list of the storage yard, if yes, perform step S820, otherwise, perform step S880.

S820:判断堆场的当前任务完成时间(finish-time)是否等于计时器的当前时间(current-time),若是则执行步骤S830;若否则执行步骤S870。S820: Determine whether the current task finish time (finish-time) of the storage yard is equal to the current time (current-time) of the timer, if yes, execute step S830; otherwise, execute step S870.

S830:调用其服务的集卡的任务更新函数,更新集卡任务列表中的各项任务参数。例如:移除原有的任务,计算新增任务的完成时间,统计集卡i总的运输时间等等。S830: Call the task update function of the collection card served by it, and update each task parameter in the collection card task list. For example: remove the original task, calculate the completion time of the new task, count the total transportation time of the collection card i, and so on.

具体包括步骤S731至S737。Specifically, steps S731 to S737 are included.

S840:将堆场的当前任务移除,更新堆场下一个任务的完成时间和净工作时间(busy-time)。S840: Remove the current task in the yard, and update the completion time and net working time (busy-time) of the next task in the yard.

S850:判断堆场的任务列表中是否有任务未完成,若是则执行步骤S870,若否则执行步骤S860。S850: Determine whether there is an unfinished task in the task list of the storage yard, if so, perform step S870, otherwise, perform step S860.

S860:更新系统总的运行时间(all-time)。若计时器采用从0开始计时则令all-time=current-time;若计时器采用实际的钟表时间计时则all-time=current-time——start-time。S860: Update the total running time (all-time) of the system. If the timer starts timing from 0, set all-time=current-time; if the timer uses actual clock time, then all-time=current-time——start-time.

S870:令have-work=1。S870: set have-work=1.

S880:令返回程序调用点。S880: command to return to the calling point of the program.

S900:令current-time=current-time+1,即总计时器值加1。S900: set current-time=current-time+1, that is, add 1 to the total timer value.

S1000:判断have-work是否等于0,若是则结束程序系统停止工作;若否则执行步骤S100中的S120。S1000: Determine whether have-work is equal to 0, if so, end the program and the system stops working; otherwise, execute S120 in step S100.

在以上方法中将每一辆集卡看成是一个智能的Agent,其能够根据码头的当前情况和自身所在的位置从整个码头的未完成任务中选择一个使得自生的效率最高(即无用开销最小)的任务去完成。当码头的所有集卡都能以较高的效率工作时,相应的整个码头的工作效率也是较高的,从而实现减少装卸桥(岸桥)的等待时间,节省车辆行驶的总路径,降低空载率,达到提高集装箱码头装卸效率的目的。In the above method, each collection truck is regarded as an intelligent Agent, which can select one of the unfinished tasks of the entire terminal according to the current situation of the terminal and its own location so that the efficiency of self-generation is the highest (that is, the useless overhead is minimized) ) task to complete. When all the collection trucks in the terminal can work with high efficiency, the corresponding working efficiency of the entire terminal is also high, thereby reducing the waiting time of loading and unloading bridges (quay bridges), saving the total path of vehicles, and reducing space. Loading rate, to achieve the purpose of improving the efficiency of container terminal loading and unloading.

将大连海事大学陈方鼎的论文《基于群体智能算法的集装箱卡车的调度研究》中的码头数据作为实验数据,和其论文中设定一样的集卡数量(10辆集卡),所得优化结果为:平均空载率35%,所有任务完成时间14566秒。优于其论文中的结果平均空载率46%,所有任务完成时间18628秒。Taking the wharf data in the paper "Scheduling of Container Trucks Based on Swarm Intelligence Algorithm" by Chen Fangding of Dalian Maritime University as the experimental data, and setting the same number of trucks (10 trucks) as in his paper, the optimization results are: The average no-load rate is 35%, and the completion time of all tasks is 14566 seconds. Better than the results in his paper, the average empty rate is 46%, and the completion time of all tasks is 18628 seconds.

若集卡数设为15,所得优化结果为:平均空载率42%,所有任务完成时间10844秒,比理想最短作业时间(即在集卡是足够多的情况下,岸桥起重机不停地在工作没有等待时间)多15%左右。If the number of collection trucks is set to 15, the obtained optimization results are: the average no-load rate is 42%, and the completion time of all tasks is 10844 seconds, which is shorter than the ideal shortest operation time (that is, when there are enough collection trucks, the quay crane does not stop. At work without waiting time) about 15% more.

应当理解的是,本发明的应用不限于上述的举例,对本领域普通技术人员来说,可以根据上述说明加以改进或变换,所有这些改进和变换都应属于本发明所附权利要求的保护范围。It should be understood that the application of the present invention is not limited to the above examples, and those skilled in the art can make improvements or transformations according to the above descriptions, and all these improvements and transformations should belong to the protection scope of the appended claims of the present invention.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201010231666XACN101944200A (en) | 2010-07-15 | 2010-07-15 | Method and system for dispatching container trucks |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201010231666XACN101944200A (en) | 2010-07-15 | 2010-07-15 | Method and system for dispatching container trucks |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101944200Atrue CN101944200A (en) | 2011-01-12 |

Family

ID=43436182

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201010231666XAPendingCN101944200A (en) | 2010-07-15 | 2010-07-15 | Method and system for dispatching container trucks |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101944200A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104182777A (en)* | 2014-08-13 | 2014-12-03 | 成都四威高科技产业园有限公司 | RFID (Radio Frequency Identification)-based AGV (Automatic Guided Vehicle) multi-task positioning method |

| CN105319988A (en)* | 2015-11-16 | 2016-02-10 | 北京科技大学 | An emulation system and method for a multi-layer shuttle-based storage and retrieval system |

| CN107492061A (en)* | 2017-07-28 | 2017-12-19 | 武汉依迅北斗空间技术有限公司 | A kind of turn out for work verification method and system for slag-soil truck |

| CN108596446A (en)* | 2018-04-03 | 2018-09-28 | 宁波诺丁汉大学 | Truck distributing method in the port of subject container crane task queue constraint |

| CN110790143A (en)* | 2019-10-30 | 2020-02-14 | 河北工业大学 | A scheduling method for automatic dock cranes |

| CN114792159A (en)* | 2022-04-02 | 2022-07-26 | 山东港口科技集团日照有限公司 | Unmanned container terminal truck-collecting dispatching method and system for shore-following type full-automatic container terminal |

| CN115619197A (en)* | 2022-11-16 | 2023-01-17 | 湖南洋马信息有限责任公司 | Container wharf ship unloading scheduling management method and system |

| CN115724159A (en)* | 2022-11-24 | 2023-03-03 | 深圳海星智驾科技有限公司 | Method, device and system for adjusting loading and unloading sequence of containers in storage yard |

- 2010

- 2010-07-15CNCN201010231666XApatent/CN101944200A/enactivePending

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104182777A (en)* | 2014-08-13 | 2014-12-03 | 成都四威高科技产业园有限公司 | RFID (Radio Frequency Identification)-based AGV (Automatic Guided Vehicle) multi-task positioning method |

| CN104182777B (en)* | 2014-08-13 | 2017-05-03 | 成都四威高科技产业园有限公司 | RFID (Radio Frequency Identification)-based AGV (Automatic Guided Vehicle) multi-task positioning method |

| CN105319988A (en)* | 2015-11-16 | 2016-02-10 | 北京科技大学 | An emulation system and method for a multi-layer shuttle-based storage and retrieval system |

| CN107492061A (en)* | 2017-07-28 | 2017-12-19 | 武汉依迅北斗空间技术有限公司 | A kind of turn out for work verification method and system for slag-soil truck |

| CN108596446A (en)* | 2018-04-03 | 2018-09-28 | 宁波诺丁汉大学 | Truck distributing method in the port of subject container crane task queue constraint |

| CN108596446B (en)* | 2018-04-03 | 2020-12-01 | 宁波诺丁汉大学 | In-port collection truck distribution method restricted by container crane task queue |

| CN110790143A (en)* | 2019-10-30 | 2020-02-14 | 河北工业大学 | A scheduling method for automatic dock cranes |

| CN114792159A (en)* | 2022-04-02 | 2022-07-26 | 山东港口科技集团日照有限公司 | Unmanned container terminal truck-collecting dispatching method and system for shore-following type full-automatic container terminal |

| CN114792159B (en)* | 2022-04-02 | 2023-05-23 | 山东港口科技集团日照有限公司 | Unmanned integrated card dispatching method and system for coastal full-automatic container terminal |

| CN115619197A (en)* | 2022-11-16 | 2023-01-17 | 湖南洋马信息有限责任公司 | Container wharf ship unloading scheduling management method and system |

| CN115724159A (en)* | 2022-11-24 | 2023-03-03 | 深圳海星智驾科技有限公司 | Method, device and system for adjusting loading and unloading sequence of containers in storage yard |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101944200A (en) | Method and system for dispatching container trucks | |

| CN105427075A (en) | Hybrid dynamic scheduling method used for port container truck | |

| Bish et al. | Dispatching vehicles in a mega container terminal | |

| Murty et al. | Hongkong International Terminals gains elastic capacity using a data-intensive decision-support system | |

| CN111882215B (en) | Personalized customization flexible job shop scheduling method containing AGV | |

| CN110942203B (en) | An AGV path optimization method for automated container terminals | |

| CN117035371B (en) | Port scheduling method and system based on big data | |

| Wang et al. | A quay crane scheduling algorithm considering the workload of yard cranes in a container yard | |

| CN112070296B (en) | Fuzzy reasoning based truck-mounted dispatching method | |

| CN108438953B (en) | Automatic wharf loading and unloading control method | |

| CN113743739B (en) | AGV scheduling method based on mixed integer programming and combined optimization algorithm | |

| CN114331075A (en) | Yard trailer scheduling method, device, equipment and storage medium | |

| CN118037006B (en) | Site bridge job scheduling method and scheduling system | |

| Xing et al. | Dispatch problem of automated guided vehicles for serving tandem lift quay crane | |

| CN115796553B (en) | AGV task scheduling method, device and AGV scheduling system | |

| Nguyen et al. | Heuristic algorithms for constructing transporter pools in container terminals | |

| CN113780800B (en) | Multi-ship shore bridge dispatching method based on continuous ordered dispatching | |

| CN118780563B (en) | An overall scheduling method based on the operating efficiency of automated container terminal quay cranes | |

| CN115187096A (en) | Dispatching optimization method for getting-on operation of automatic driving electric container | |

| CN118953986A (en) | A synchronous loading and unloading control method and medium based on automated container terminal | |

| CN112559951A (en) | Container transport AGV scheduling method, equipment, electronic terminal and storage medium | |

| CN116495391A (en) | Task priority management method of stacker crane based on one track and two cars | |

| Chen et al. | Optimization research of joint quay crane scheduling and block selection in container terminals | |

| CN116703045A (en) | Vehicle scheduling method and device and electronic equipment | |

| Zhang et al. | The integrated scheduling problem in container terminal with dual-cycle operation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C12 | Rejection of a patent application after its publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20110112 |