CN101923348A - A CANopen-based on-board fault diagnosis system and method for hybrid electric vehicles - Google Patents

A CANopen-based on-board fault diagnosis system and method for hybrid electric vehiclesDownload PDFInfo

- Publication number

- CN101923348A CN101923348ACN 201010233264CN201010233264ACN101923348ACN 101923348 ACN101923348 ACN 101923348ACN 201010233264CN201010233264CN 201010233264CN 201010233264 ACN201010233264 ACN 201010233264ACN 101923348 ACN101923348 ACN 101923348A

- Authority

- CN

- China

- Prior art keywords

- fault

- information

- canopen

- module

- vehicle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000003745diagnosisMethods0.000titleclaimsabstractdescription86

- 238000000034methodMethods0.000titleclaimsabstractdescription21

- 239000004973liquid crystal related substanceSubstances0.000claimsabstractdescription8

- 238000004891communicationMethods0.000claimsdescription28

- 238000007726management methodMethods0.000claimsdescription14

- 238000012544monitoring processMethods0.000claimsdescription13

- 230000005540biological transmissionEffects0.000claimsdescription7

- 238000013500data storageMethods0.000claimsdescription7

- 238000004458analytical methodMethods0.000claimsdescription5

- 230000003993interactionEffects0.000claimsdescription5

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000claimsdescription3

- 229910052760oxygenInorganic materials0.000claimsdescription3

- 239000001301oxygenSubstances0.000claimsdescription3

- 238000012545processingMethods0.000claimsdescription2

- 230000006870functionEffects0.000description9

- 238000012423maintenanceMethods0.000description9

- 238000002405diagnostic procedureMethods0.000description3

- 238000010586diagramMethods0.000description3

- 238000005516engineering processMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000011161developmentMethods0.000description1

- 230000000694effectsEffects0.000description1

- 239000000446fuelSubstances0.000description1

- 238000002347injectionMethods0.000description1

- 239000007924injectionSubstances0.000description1

- 238000004092self-diagnosisMethods0.000description1

- 239000000243solutionSubstances0.000description1

- 230000001052transient effectEffects0.000description1

- 230000001960triggered effectEffects0.000description1

- 238000013024troubleshootingMethods0.000description1

Images

Landscapes

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种基于CANopen的混合动力汽车车载故障诊断系统和诊断方法,以CANopen高层协议作为混合动力汽车总线协议,制定针对混合动力汽车的CANopen故障诊断通信规范,并将其应用于本诊断系统中,属于混合动力汽车车载故障诊断领域。The present invention relates to a CANopen-based vehicle-mounted fault diagnosis system and diagnostic method for hybrid electric vehicles. Using the CANopen high-level protocol as the hybrid electric vehicle bus protocol, the CANopen fault diagnosis communication specification for hybrid electric vehicles is formulated and applied to the diagnostic system Among them, it belongs to the field of on-board fault diagnosis of hybrid electric vehicles.

背景技术Background technique

随着现代汽车工业的发展,汽车电子化程度日益提高,汽车电子控制系统(燃油喷射系统、制动防爆死系统、安全气囊等)不断增多,另外混合动力汽车在传统汽车的基础上增加了蓄电池、电机等设备,技术科技含量比较高,结构更加复杂。这些复杂的系统,使得汽车的维修变得很困难。为了便于维修与监测,在汽车控制系统的控制器中,一般都设计有自诊断功能即车载诊断功能。指的是利用车上的诊断设备进行的实时诊断,诊断信息以故障代码的形式实时的存储存储在存储器中,以及通过点亮故障指示灯通知驾驶员出现故障。如果驾驶员想详细知道哪个部分发生故障以及发生故障的原因,必须到维修站由维修人员用故障诊断仪读出故障码,然后对照相应车型维修手册或诊断手册上的故障码表得到该故障码的具体解释,以及检测故障的步骤和排除故障的方法。为了适应上述需要,有必要开发一种基于混合动力汽车的车载故障诊断系统,既能够进行整车的监测,又能够使传统的车载故障诊断系统与故障诊断仪的功能相结合。当故障发生时,车载诊断系统实时的存储和显示故障报警信息。驾驶员根据故障级别决定处理方法。对于轻微的故障,驾驶员可以根据故障信息提示自行解决,做到故障的及时排除,防止事故的发生。对于严重故障,需要维修人员通过本故障诊断系统获得更详细的故障信息,以及时的确定故障发生部位,减少了维修的复杂程度。With the development of the modern automobile industry, the degree of automobile electronics is increasing day by day, and the number of automobile electronic control systems (fuel injection system, brake explosion-proof system, safety airbag, etc.) , motors and other equipment, the technical content is relatively high, and the structure is more complicated. These complex systems make car maintenance difficult. In order to facilitate maintenance and monitoring, the controller of the vehicle control system is generally designed with a self-diagnosis function, that is, an on-board diagnostic function. Refers to the real-time diagnosis using the diagnostic equipment on the vehicle. The diagnostic information is stored in the memory in real-time in the form of fault codes, and the driver is notified of the fault by lighting the fault indicator light. If the driver wants to know in detail which part is faulty and the cause of the fault, he must go to the maintenance station and have the maintenance personnel read out the fault code with a fault diagnosis instrument, and then obtain the fault code by referring to the fault code list in the maintenance manual or diagnostic manual of the corresponding model. Detailed explanations, as well as the steps to detect the fault and the method of troubleshooting. In order to meet the above needs, it is necessary to develop an on-board fault diagnosis system based on hybrid electric vehicles, which can not only monitor the whole vehicle, but also combine the functions of the traditional on-board fault diagnosis system with the fault diagnosis instrument. When a fault occurs, the on-board diagnostic system stores and displays fault alarm information in real time. The driver decides the handling method according to the fault level. For minor faults, the driver can solve them by himself according to the fault information prompts, so as to eliminate the faults in time and prevent accidents. For serious faults, maintenance personnel need to obtain more detailed fault information through this fault diagnosis system, so as to determine the location of the fault in time, which reduces the complexity of maintenance.

近年来,CAN网络已经被广泛地应用在汽车上,将CAN作为标准的车内通信协议也已经确定下来。但是与开放系统互连模型(OSI)一致,CAN规范只定义了模型的最下面两层:物理层和数据链路层。CANopen作为高层协议,支持各种CAN厂商设备的互用性、互换性,能够实现在CAN网路中提供标准的、统一的系统通讯模式,并且提供设备功能的描述方式,执行网络管理等功能。本发明以CANopen协议为混合动力汽车总线协议,制定针对混合动力汽车的CANopen故障诊断通信规范,一方面探索CANopen在故障诊断系统中的应用,填补国内空白。另一方面利用CANopen协议的模块化特点,增强系统的灵活性、适应性。In recent years, CAN networks have been widely used in automobiles, and CAN has been determined as a standard in-vehicle communication protocol. But consistent with the open system interconnection model (OSI), the CAN specification only defines the bottom two layers of the model: the physical layer and the data link layer. As a high-level protocol, CANopen supports the interoperability and interchangeability of various CAN manufacturers' equipment, and can provide a standard and unified system communication mode in the CAN network, and provide description methods for equipment functions and perform network management functions. . The invention uses the CANopen protocol as the hybrid electric vehicle bus protocol, formulates the CANopen fault diagnosis communication specification for the hybrid electric vehicle, explores the application of CANopen in the fault diagnosis system on the one hand, and fills up the domestic blank. On the other hand, the modularization feature of the CANopen protocol is used to enhance the flexibility and adaptability of the system.

发明内容Contents of the invention

本发明的目的是为了解决现有混合动力汽车诊断技术之不足,提出了一种基于CANopen的混合动力汽车车载故障诊断系统的实现方法。该系统使传统车载故障诊断系统与故障诊断仪相结合,将故障诊断仪完善的数据通信功能、友好的界面显示与在板故障诊断的实时性相结合,完成故障信息如故障诊断码、故障描述等的实时采集与显示,以及故障信息的有效管理。该系统不仅有故障诊断的功能,还有车辆实时信息显示的功能。The purpose of the present invention is in order to solve the deficiency of existing hybrid electric vehicle diagnosis technology, proposes a kind of realization method of hybrid electric vehicle on-board fault diagnosis system based on CANopen. This system combines the traditional on-board fault diagnosis system with the fault diagnosis instrument, combines the perfect data communication function and friendly interface display of the fault diagnosis instrument with the real-time performance of on-board fault diagnosis, and completes fault information such as fault diagnosis code and fault description Real-time collection and display, etc., as well as effective management of fault information. The system not only has the function of fault diagnosis, but also has the function of displaying real-time vehicle information.

本发明采取如下技术方案来实现上述目的:The present invention takes the following technical solutions to achieve the above object:

一种基于CANopen的混合动力汽车车载故障诊断系统,其特征在于:包括如下模块:A CANopen-based hybrid vehicle vehicle fault diagnosis system is characterized in that: comprising the following modules:

1)故障诊断接口,通过诊断接口将车载CANopen网络与信息采集模块相连。1) Fault diagnosis interface, connect the vehicle CANopen network with the information acquisition module through the diagnosis interface.

2)信息采集模块,用于各个电子控制单元ECU与主控制模块CANopen网络通讯。2) The information collection module is used for communication between each electronic control unit ECU and the main control module CANopen network.

3)存储模块,用于存储程序、CANopen通讯协议、车型信息以及故障信息。3) The storage module is used to store programs, CANopen communication protocol, vehicle model information and fault information.

4)液晶显示模块,用于显示故障指示灯,详细的故障信息及车辆实时数据的监测显示。4) Liquid crystal display module, used to display fault indicator lights, detailed fault information and monitoring display of real-time vehicle data.

5)语音报警模块,用于故障信息的声音提示及警报。5) Voice alarm module, used for voice prompt and alarm of fault information.

6)触摸屏及键盘模块,用于显示界面的切换,实现人机交互。6) The touch screen and keyboard module are used to switch the display interface to realize human-computer interaction.

7)主控制模块,是整个系统的核心,采用TI公司的ARM926EJ-S内核的TMS320DM355为主控芯片,该模块通过运行存储模块中的程序和CANopen协议,可接收信息采集模块的CANopen报文,实现对整车CANopen网络的管理以及对CANopen报文的解析,获取到故障信息及车辆实时数据,将故障信息放入存储模块,将显示内容送液晶显示模块同时将故障报警信息送语音报警模块进行声音提示,以及接收触摸屏及键盘模块的人机交互信息。7) The main control module is the core of the whole system. It adopts the TMS320DM355 of TI's ARM926EJ-S core as the main control chip. This module can receive the CANopen message of the information acquisition module by running the program in the storage module and the CANopen protocol. Realize the management of the vehicle CANopen network and the analysis of CANopen messages, obtain fault information and vehicle real-time data, put the fault information into the storage module, send the displayed content to the LCD module and send the fault alarm information to the voice alarm module for further processing Sound prompts, and receive human-computer interaction information from the touch screen and keyboard modules.

8)电源模块,用于为整个系统供电。8) The power supply module is used to supply power to the whole system.

本系统通过故障诊断接口与车载CANopen网络系统相连接。存储模块、液晶显示模块、语音报警模块、触摸屏及键盘模块、信息采集模块分别与主控模块交互连接。The system is connected with the vehicle CANopen network system through the fault diagnosis interface. The storage module, the liquid crystal display module, the voice alarm module, the touch screen and the keyboard module, and the information collection module are interactively connected with the main control module respectively.

基于CANopen的混合动力汽车车载故障诊断系统,根据不同的故障级别,在液晶显示模块中用不同颜色指示灯闪烁显示。最严重的一类,只要发生一次就触发红色指示灯闪烁;次严重的一类故障,只有在连续的两次行驶过程中发生才使黄色指示灯闪烁;瞬时轻微故障,绿色指示灯闪烁。The on-board fault diagnosis system of hybrid electric vehicles based on CANopen, according to different fault levels, flashes and displays with different color indicator lights in the liquid crystal display module. The most serious type of fault will trigger the red indicator light to flash as long as it occurs once; the second serious type of fault will cause the yellow indicator light to flash only if it occurs during two consecutive driving processes; the green indicator light will flash for instantaneous minor faults.

系统检测到严重故障时,通过CANopen网络控制发动机管理系统和自动变速箱控制模块,限制发动机转速,将车速限制在10km/H。When the system detects a serious fault, it controls the engine management system and the automatic transmission control module through the CANopen network to limit the engine speed and limit the vehicle speed to 10km/H.

一种基于CANopen的混合动力汽车车载故障诊断方法,是以CANopen高层协议作为混合动力汽车总线协议,根据制定的针对混合动力汽车的CANopen故障诊断通信规范,对混合动力汽车进行车载故障诊断。具体采用如下步骤:A CANopen-based on-board fault diagnosis method for hybrid electric vehicles uses the CANopen high-level protocol as the hybrid electric vehicle bus protocol, and performs on-board fault diagnosis for hybrid electric vehicles according to the CANopen fault diagnosis communication specification for hybrid electric vehicles. Specifically take the following steps:

1)在整个汽车网络中,车载故障诊断系统作为CANopen主站,车载电子控制单元ECU都为从节点;故障诊断系统中CANopen设备的故障信息存储在对象字典中,每一个标准的故障码都对应一个对象字典项。当故障发生时,车载诊断系统利用应急报文,该应急报文中包含当前发生故障的故障信息所存放的对象字典的索引和子索引,去触发一个SDO(服务数据对象),来读取此故障所对应对象字典项的故障诊断信息。1) In the entire automobile network, the on-board fault diagnosis system acts as the CANopen master station, and the on-board electronic control unit ECU is the slave node; the fault information of CANopen devices in the fault diagnosis system is stored in the object dictionary, and each standard fault code corresponds to An object dictionary entry. When a fault occurs, the on-board diagnostic system uses the emergency message, which contains the index and sub-index of the object dictionary stored in the fault information of the current fault, to trigger an SDO (service data object) to read the fault Fault diagnosis information of the corresponding object dictionary item.

2)故障诊断系统通过解析SDO报文,获取故障诊断信息。故障信息包括故障码、故障级别、冻结帧三部分,故障码中包含汽车电控系统代号、故障所在子系统代号、故障代码等信息。系统会根据故障的级别报警,同时将获取的故障信息存入数据存储管理单元中。2) The fault diagnosis system obtains fault diagnosis information by analyzing the SDO message. Fault information includes three parts: fault code, fault level, and freeze frame. The fault code includes information such as the code of the automotive electronic control system, the code of the subsystem where the fault is located, and the fault code. The system will alarm according to the level of the fault, and store the obtained fault information into the data storage management unit at the same time.

3)数据存储管理单元存储有:汽车当前正在发生的或最近发生的还未被排除的故障的信息,过去发生的故障所产生的还未被清除的故障信息,故障所属汽车的子控制系统和该故障诊断系统的所有故障码以及这些故障码的中英文描述。通过当前故障表、故障码总表、子系统表之间的相互检索,获得故障码的具体描述以及发生故障的电控系统,然后将故障信息显示。3) The data storage management unit stores: the information of the current or recent faults that have not been eliminated, the fault information of the past faults that have not been cleared, the sub-control system and the sub-control system of the car to which the fault belongs All fault codes of the fault diagnosis system and their descriptions in Chinese and English. Through mutual retrieval among the current fault table, fault code general table and subsystem table, the specific description of the fault code and the faulty electronic control system are obtained, and then the fault information is displayed.

4)故障信息显示单元不仅具有故障信息显示,还可以进行车辆实时数据监测显示,实时数据的监控是通过CANopen的通讯对象PDO(过程数据对象)来实现,通过对PDO报文的解析,将汽车内部传感器和执行器的工作电压和状态实时显示。4) The fault information display unit not only has fault information display, but also can monitor and display the real-time data of the vehicle. The monitoring of real-time data is realized through the communication object PDO (process data object) of CANopen. By analyzing the PDO message, the vehicle The operating voltage and status of internal sensors and actuators are displayed in real time.

上述步骤中故障信息的显示包括故障指示灯,当前故障码信息,历史故障码信息。The display of fault information in the above steps includes fault indicator light, current fault code information, and historical fault code information.

上述步骤中在车辆实时数据监测显示界面中,实现了对发动机转速、电动机温度、电池电压车辆信息的实时数据的监测,对电机电流波形,氧传感器波形采用图形化的显示方法。In the above steps, in the vehicle real-time data monitoring display interface, real-time data monitoring of engine speed, motor temperature, and battery voltage vehicle information is realized, and a graphical display method is adopted for the motor current waveform and the oxygen sensor waveform.

与现有的汽车故障诊断系统与方法相比,本发明可以取得如下有益效果,由于采用了嵌入式微处理器作为主控芯片和7寸液晶触摸屏作为人机交互接口,相对于现有故障诊断技术中使用的计算机系统,体积小,成本低,更加便于安装与操作。本系统一方面实现了车载故障诊断的功能,同时可对车辆实时数据进行监测显示。由于基于CANopen协议,在与各个ECU的通讯时更加高效,诊断通讯更加规范,诊断效果好。另外本系统存储了不同车型的信息,可以实现车型选择,适用于国内外多种车辆,增加了系统的使用范围。Compared with the existing automobile fault diagnosis system and method, the present invention can achieve the following beneficial effects, because the embedded microprocessor is used as the main control chip and the 7-inch liquid crystal touch screen as the human-computer interaction interface, compared with the existing fault diagnosis technology The computer system used in the machine is small in size, low in cost, and easier to install and operate. On the one hand, this system realizes the function of on-board fault diagnosis, and at the same time, it can monitor and display the real-time data of the vehicle. Based on the CANopen protocol, the communication with each ECU is more efficient, the diagnostic communication is more standardized, and the diagnostic effect is good. In addition, the system stores the information of different models, which can realize the selection of models, and is suitable for various vehicles at home and abroad, increasing the scope of use of the system.

附图说明Description of drawings

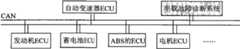

图1一种基于CANopen的混合动力汽车车载故障诊断系统的网络结构图。Figure 1 is a network structure diagram of a CANopen-based on-board fault diagnosis system for hybrid electric vehicles.

图2一种基于CANopen的混合动力汽车车载故障诊断系统和诊断方法的故障信息通讯示意图。Fig. 2 is a schematic diagram of fault information communication of a CANopen-based on-board fault diagnosis system and diagnostic method for a hybrid electric vehicle.

图3一种基于CANopen的混合动力汽车车载故障诊断系统和诊断方法故障信息SDO报文结构。Figure 3 is a CANopen-based vehicle-mounted fault diagnosis system and diagnostic method for hybrid electric vehicle fault information SDO message structure.

图4一种基于CANopen的混合动力汽车车载故障诊断系统和诊断方法的系统故障诊断工作流程图。Fig. 4 is a system fault diagnosis work flow chart of a CANopen-based on-board fault diagnosis system and diagnosis method for a hybrid electric vehicle.

具体实施方式Detailed ways

下面结合附图和具体实施方式对本发明所公开的一种基于CANopen的混合动力汽车车载故障诊断系统和诊断方法所进一步地说明。A CANopen-based on-board fault diagnosis system and diagnosis method for a hybrid electric vehicle disclosed in the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

实施例1:Example 1:

如图1所示,混合动力汽车需要电机、发动机、中央仪表监控、整车控制器和电池等部件的协同工作,各个部件都挂接在CAN总线上,但CAN本身并非是一个完整的协议,它只包括物理层和数据链路层,要进行高效率的通讯还要进一步开发高层协议。CANopen是在CAN2.0基础上发展起来的应用层通讯协议,是一种公共开放通用的协议,而且精练透明、容易开发,并且具有可配置性,很容易扩展以构成特定的网络应用。基于这些特点,该混合动力汽车车载故障诊断系统采用CANopen通讯协议。混合动力汽车内的各个控制系统作为CANopen网络的节点,通过CAN总线进行数据交换。车载故障诊断系统作为其中的一个节点,通过CANopen网络和各个节点之间实现通讯,获得总线上的故障信息报文,实现对汽车上的各个电控系统的监测和故障诊断。As shown in Figure 1, a hybrid electric vehicle requires the coordination of components such as the motor, engine, central instrument monitoring, vehicle controller, and battery. All components are connected to the CAN bus, but CAN itself is not a complete protocol. It only includes the physical layer and the data link layer, and high-level protocols must be further developed for efficient communication. CANopen is an application layer communication protocol developed on the basis of CAN2.0. It is a public, open and general protocol. It is concise, transparent, easy to develop, and configurable. It is easy to expand to form specific network applications. Based on these characteristics, the on-board fault diagnosis system of hybrid electric vehicle adopts CANopen communication protocol. Each control system in the hybrid electric vehicle, as a node of the CANopen network, exchanges data through the CAN bus. As one of the nodes, the on-board fault diagnosis system communicates with each node through the CANopen network, obtains fault information messages on the bus, and realizes the monitoring and fault diagnosis of each electronic control system on the vehicle.

为了故障诊断通信,制定了故障诊断系统的CANopen诊断通信规范制定,即利用CANopen应急报文和通讯对象SDO的通信规范的故障诊断。各个电子控制单元分布有多个传感器和执行机构,移植有CANopen协议从站,故障信息储存在其对象字典中,每一个标准的故障码都对应一个对象字典项。当其检测到故障时,会发送包含有当前发生故障的故障信息所存放的对象字典的索引和子索引的CANopen应急报文,去触发一个SDO来读取此故障所对应对象字典项的故障诊断信息。以汽车中发动机节点发生故障为例,具体通讯示意图如图2所示。For fault diagnosis communication, the CANopen diagnostic communication specification of the fault diagnosis system is formulated, that is, the fault diagnosis using the communication specification of CANopen emergency message and communication object SDO. Each electronic control unit is distributed with multiple sensors and actuators, transplanted with CANopen protocol slave stations, and the fault information is stored in its object dictionary, and each standard fault code corresponds to an object dictionary item. When it detects a fault, it will send a CANopen emergency message containing the index and sub-index of the object dictionary stored in the current fault information to trigger an SDO to read the fault diagnosis information of the object dictionary item corresponding to the fault . Taking the failure of the engine node in the car as an example, the specific communication diagram is shown in Figure 2.

根据应急报文各部分的定义,应急错误代码和错误寄存器中都有与设备相关的错误的规定。利用报文中制造商特定错误区域来传送与设备相关的错误信息。应急报文如表1所示。According to the definition of each part of the emergency message, the emergency error code and the error register have regulations related to equipment errors. Use the manufacturer-specific error field in the telegram to transmit device-related error information. The emergency message is shown in Table 1.

表1与故障相关应急报文Table 1 Emergency messages related to faults

SDO加速传送最多传输4字节数据,故障码和故障级别要使用3个字节表示,有些冻结帧数据的长度大于1个字节,所以SDO采用加速传送和分段传送两种传送方式。SDO报文结构如图3所示。SDO accelerated transmission can transmit up to 4 bytes of data, and the fault code and fault level should be represented by 3 bytes. The length of some freeze frame data is greater than 1 byte, so SDO adopts two transmission methods: accelerated transmission and segmented transmission. The structure of the SDO message is shown in Figure 3.

故障码是采用OBD-II标准的故障码格式,故障码和故障级别在报文中的结构如表2所示。冻结帧数据是指当故障发生时截取的相应电控系统的一些重要运行参数,以供汽车维修时参考。不同的电控系统,冻结帧数据所代表的参数类型是不同的,由故障码的第一和第三位来区分,具体对应关系如表3。The fault code adopts the fault code format of the OBD-II standard, and the structure of the fault code and fault level in the message is shown in Table 2. Freeze frame data refers to some important operating parameters of the corresponding electronic control system intercepted when a fault occurs, for reference during vehicle maintenance. For different electronic control systems, the types of parameters represented by the freeze frame data are different, which are distinguished by the first and third digits of the fault code. The specific corresponding relationship is shown in Table 3.

表2故障诊断码和故障级别结构Table 2 DTC and fault level structure

D1:表示故障码的第一个字母的代码,动力系统P为00,车身系统B为01,底盘系统C为10,网络通信系统U为11。D1: Indicates the code of the first letter of the fault code, the power system P is 00, the body system B is 01, the chassis system C is 10, and the network communication system U is 11.

D2、D3、D4、D5:分别表示故障码的第二、第三、第四、第五个数字。G:表示故障级别,00H表示最严重的故障,红色故障指示灯闪烁。01H表示次严重的故障,黄色故障指示灯闪烁。10H表示轻微故障,绿色故障指示灯闪烁。D2, D3, D4, D5: respectively represent the second, third, fourth and fifth digits of the fault code. G: Indicates the fault level, 00H represents the most serious fault, and the red fault indicator flashes. 01H indicates a minor fault, and the yellow fault indicator flashes. 10H means a minor fault, and the green fault indicator light is flashing.

表3汽车电控系统与冻结帧数据的对应关系Table 3 Correspondence between automotive electronic control system and freeze frame data

在对象字典中故障信息存放区位于索引9000-9FFF处,如表4所示,故障信息的具体分配见附录。故障信息包括故障码、故障级别、冻结帧三部分。In the object dictionary, the fault information storage area is located at the index 9000-9FFF, as shown in Table 4. For the specific allocation of fault information, see the appendix. Fault information includes three parts: fault code, fault level, and freeze frame.

表4对象字典中的故障信息分配Table 4 Distribution of fault information in the object dictionary

PDO用来传输汽车实时数据,优先级比较高,可以事件触发,并且可以被一个节点发送网络中的多个节点进行接收,尤其是在汽车网络中有利于实现汽车内部重要参数的共享。PDO is used to transmit real-time data of automobiles. It has a high priority and can be triggered by events, and can be received by multiple nodes in a node sending network, especially in the automobile network, which is conducive to the sharing of important internal parameters of the automobile.

综上所述改系统利用CANopen应急报文和通讯对象SDO故障诊断规范,利用通讯对象PDO实时监控规范,利用了CANopen标准的通信模式,并且可以传输大的数据,有利于大量诊断数据的传输和整车实时监控。In summary, the modified system utilizes the CANopen emergency message and communication object SDO fault diagnosis specification, utilizes the communication object PDO real-time monitoring specification, utilizes the CANopen standard communication mode, and can transmit large data, which is conducive to the transmission of a large number of diagnostic data and Vehicle real-time monitoring.

车载故障诊断系统通过分析CANopen报文,从而获得故障诊断信息、汽车实时运行参数等信息。根据故障的级别点亮相应的故障报警指示灯。分析故障信息,把它们存储在数据存储管理单元中的当前故障表中,通过一定的分析检索获得故障码的具体描述。将故障码、故障所属系统、故障描述等信息显示在故障诊断界面中。The on-board fault diagnosis system obtains fault diagnosis information, vehicle real-time operating parameters and other information by analyzing CANopen messages. Light up the corresponding fault alarm indicator light according to the fault level. Analyze the fault information, store them in the current fault table in the data storage management unit, and obtain the specific description of the fault code through certain analysis and retrieval. Display the fault code, fault system, fault description and other information in the fault diagnosis interface.

本发明中故障诊断系统的故障码采用OBD-II标准的定义方式,每一个故障码代表着一个唯一的故障。为了方便存储以及管理这些标准的故障码以及当前的、历史的故障诊断信息,在数据存储管理单元中分别建立了当前故障表、历史故障表、故障码总表和子系统表。当前故障表中存储有汽车当前故障所产生的故障码、当前故障发生时间、当前故障的级别、当前故障发生时的冻结帧数据。历史故障表中存储有历史故障产生的故障码、历史故障发生时间、历史故障级别、该历史故障码的中文解释、该历史故障码的英文解释、以及该故障曾经发生时的冻结帧数据。故障码总表中存储有该故障诊断系统的所有故障码以及这些故障码的中英文描述,包括所有OBD-II标准的故障码以及自定义的一些故障码。OBD-II标准的故障码由五位组成,每一位代表着不同的含义。部分数据如表5所示。子系统表中用来存储故障所属汽车的子控制系统。通过当前故障表、故障码总表、子系统表之间的相互检索,获得故障码的具体描述以及发生故障的电控系统。The fault codes of the fault diagnosis system in the present invention adopt the definition method of OBD-II standard, and each fault code represents a unique fault. In order to facilitate the storage and management of these standard fault codes and current and historical fault diagnosis information, the current fault table, historical fault table, fault code general table and subsystem table are respectively established in the data storage management unit. The current fault table stores the fault code generated by the current fault of the vehicle, the time when the current fault occurs, the level of the current fault, and the freeze frame data when the current fault occurs. The historical fault table stores the fault codes generated by historical faults, the time of historical faults, the level of historical faults, the Chinese interpretation of the historical fault codes, the English interpretation of the historical fault codes, and the freeze frame data when the faults once occurred. All fault codes of the fault diagnosis system and their Chinese and English descriptions are stored in the fault code table, including all OBD-II standard fault codes and some custom fault codes. The fault code of the OBD-II standard consists of five digits, and each digit represents a different meaning. Some data are shown in Table 5. The subsystem table is used to store the subsystem control system of the vehicle to which the fault belongs. The specific description of the fault code and the electronic control system where the fault occurs can be obtained through the mutual retrieval among the current fault table, the fault code general table and the subsystem table.

表5部分故障码数据表Table 5 part of the fault code data table

系统的故障诊断工作流程图如图4所示:将车载诊断仪安装在车辆适当位置,方便驾驶员操作使用。汽车启动运行,诊断装置工作后,诊断系统首先进行一些数据存储管理单元和CANOpen主站以及网络的初始化的工作。当ECU监测到故障信息后,会发送包含有当前发生故障的故障信息所存放的对象字典的索引和子索引的CANopen应急报文。当诊断系统受到应急报文后,会触发一个SDO来读取此故障所对应对象字典项的故障诊断信息。通过对报文的解析,首先根据故障的级别进行指示灯闪烁报警和语音报警。故障被分为三个级别A、B、C类。A类故障是最严重的一类,只要发生一次就触发红色指示灯闪烁。B类故障是次严重的一类故障,只有在连续的两次行驶过程中发生才使黄色指示灯闪烁。C类故障表示发生一个瞬时轻微故障,绿色指示灯闪烁。在对故障信息进行查询时,通过存储的故障信息获取具体故障描述以及发生故障的位置,显示当前故障码信息,历史故障码信息。没有故障发生时,本系统还可以对发动机转速、电动机温度、电池电压信息进行实时的监视显示,对电机电流波形,氧传感器波形一些参量可采用图形化的显示方法。驾驶员或维修人员可以通过触摸屏或者按键进行界面的切换。The fault diagnosis work flow chart of the system is shown in Figure 4: install the on-board diagnostic instrument in an appropriate position of the vehicle, which is convenient for the driver to operate and use. After the car starts running and the diagnostic device works, the diagnostic system first performs some initialization work of the data storage management unit, the CANOpen master station and the network. When the ECU monitors the fault information, it will send a CANopen emergency message containing the index and sub-index of the object dictionary stored in the fault information of the current fault. When the diagnosis system receives the emergency message, it will trigger an SDO to read the fault diagnosis information of the object dictionary item corresponding to the fault. Through the analysis of the message, first of all, according to the level of the fault, the indicator light flashes and the voice alarm is given. Faults are classified into three classes A, B, and C. Type A faults are the most serious, triggering the red light to flash as long as they occur once. Class B failure is the second serious type of failure, and the yellow indicator light will flash only if it occurs during two consecutive driving. Class C fault means that a transient minor fault occurs, and the green indicator light flashes. When querying the fault information, the specific fault description and the location of the fault are obtained through the stored fault information, and the current fault code information and historical fault code information are displayed. When there is no fault, the system can also monitor and display the engine speed, motor temperature, and battery voltage information in real time, and can display some parameters of the motor current waveform and oxygen sensor waveform graphically. The driver or maintenance personnel can switch the interface through the touch screen or keys.

Claims (6)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201010233264CN101923348A (en) | 2010-07-16 | 2010-07-16 | A CANopen-based on-board fault diagnosis system and method for hybrid electric vehicles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201010233264CN101923348A (en) | 2010-07-16 | 2010-07-16 | A CANopen-based on-board fault diagnosis system and method for hybrid electric vehicles |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101923348Atrue CN101923348A (en) | 2010-12-22 |

Family

ID=43338331

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201010233264PendingCN101923348A (en) | 2010-07-16 | 2010-07-16 | A CANopen-based on-board fault diagnosis system and method for hybrid electric vehicles |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101923348A (en) |

Cited By (67)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102323814A (en)* | 2011-06-07 | 2012-01-18 | 广州汽车集团股份有限公司 | Definition and reading method of freeze frame and its device |

| CN102385378A (en)* | 2011-09-19 | 2012-03-21 | 重庆长安汽车股份有限公司 | Offline-detection auxiliary apparatus for new energy automobiles |

| CN102385380A (en)* | 2011-09-23 | 2012-03-21 | 广西三原高新科技有限公司 | Cluster automobile diagnosis information platform |

| CN102393733A (en)* | 2011-10-28 | 2012-03-28 | 北京清佰华通科技有限公司 | Failure diagnosis method, fault diagnosis instrument and system thereof |

| CN102589896A (en)* | 2012-01-12 | 2012-07-18 | 浙江师范大学 | State testing equipment for automobiles |

| CN102620932A (en)* | 2012-03-28 | 2012-08-01 | 奇瑞汽车股份有限公司 | Online fault diagnosis prediction method and device thereof of automatic gearbox |

| CN102681526A (en)* | 2011-03-16 | 2012-09-19 | 北汽福田汽车股份有限公司 | CAN (controller area network) bus system and fault diagnosis method thereof |

| CN102975670A (en)* | 2012-11-23 | 2013-03-20 | 三一重工股份有限公司 | Transient fault processing method and system of vehicle bus control system and vehicle |

| CN103061910A (en)* | 2012-12-27 | 2013-04-24 | 潍柴动力股份有限公司 | System and method for distinguishing present fault and ancient fault of motor |

| CN103076183A (en)* | 2012-12-24 | 2013-05-01 | 中国北车集团大连机车研究所有限公司 | Function test bed of driver display unit of electric locomotive |

| CN103116285A (en)* | 2011-11-17 | 2013-05-22 | 上海航天测控通信研究所 | Double central processing unit (CPU) unibus computer system for deep space probe |

| CN103279120A (en)* | 2013-05-09 | 2013-09-04 | 三一矿机有限公司 | Portable data collection and diagnosis device and mechanical vehicle |

| CN103328948A (en)* | 2011-02-15 | 2013-09-25 | 洋马株式会社 | Data collection device and system communicating therewith |

| CN103455023A (en)* | 2012-06-01 | 2013-12-18 | 北汽福田汽车股份有限公司 | Testing device and method used for power system of new energy automobile |

| CN103527294A (en)* | 2013-10-16 | 2014-01-22 | 潍柴动力股份有限公司 | Postprocessing system control method, postprocessing electronic control unit and controller |

| CN103607327A (en)* | 2013-12-03 | 2014-02-26 | 北京经纬恒润科技有限公司 | Diagnostic method and integrated ECU |

| CN103640555A (en)* | 2013-12-20 | 2014-03-19 | 北京理工大学 | HEV (Hybrid Electric Vehicle) control system manager |

| CN103649861A (en)* | 2011-07-07 | 2014-03-19 | 宝马股份公司 | Documentation of faults in a fault memory of a motor vehicle |

| CN103661170A (en)* | 2013-12-23 | 2014-03-26 | 深圳市航盛电子股份有限公司 | Automatic informing device and method of vehicle body information changing |

| CN103728966A (en)* | 2012-10-12 | 2014-04-16 | 洛克威尔自动控制技术股份有限公司 | Error diagnostics and prognostics in motor drives |

| CN103902746A (en)* | 2014-03-11 | 2014-07-02 | 深圳市元征科技股份有限公司 | Fault code, data stream and freeze frame data storage and playback method |

| CN103942261A (en)* | 2014-03-24 | 2014-07-23 | 北京航天发射技术研究所 | Allocation input method for vehicle-mounted system fault dictionary |

| CN104169976A (en)* | 2012-01-13 | 2014-11-26 | 斯堪尼亚商用车有限公司 | System and method for providing diagnostic fault information |

| CN104579816A (en)* | 2013-10-11 | 2015-04-29 | 通用汽车环球科技运作有限责任公司 | Vehicle network health assessment |

| CN104590163A (en)* | 2014-12-29 | 2015-05-06 | 联想(北京)有限公司 | Information processing method, device and automobile |

| CN104766472A (en)* | 2014-01-03 | 2015-07-08 | 上海通用汽车有限公司 | Vehicle state monitoring method |

| CN104834303A (en)* | 2014-12-19 | 2015-08-12 | 北汽福田汽车股份有限公司 | Vehicle fault diagnosis method and system, and vehicle |

| CN105022380A (en)* | 2014-04-24 | 2015-11-04 | 广西金奔腾汽车科技有限公司 | Technology related to decoder fault code indexing |

| CN105022381A (en)* | 2014-04-24 | 2015-11-04 | 广西金奔腾汽车科技有限公司 | Application technology related to data flow callback function |

| CN103197930B (en)* | 2013-03-27 | 2016-08-03 | 北京经纬恒润科技有限公司 | The method that automobile diagnostic software automatically generates |

| CN103661170B (en)* | 2013-12-23 | 2016-11-30 | 深圳市航盛电子股份有限公司 | Vehicle body information changing automatic informing device and method |

| CN106356576A (en)* | 2016-10-19 | 2017-01-25 | 深圳市沃特玛电池有限公司 | Alarm system and alarm method |

| CN106371429A (en)* | 2016-11-12 | 2017-02-01 | 驭联智能科技发展(上海)有限公司 | Inside-vehicle equipment centralized detection method and system |

| CN106444692A (en)* | 2015-08-06 | 2017-02-22 | 北汽福田汽车股份有限公司 | Vehicle maintenance assistance method and system |

| CN106569486A (en)* | 2016-11-15 | 2017-04-19 | 华晨汽车集团控股有限公司 | Fault warning evaluation system based on motor vehicle CAN network |

| CN107528293A (en)* | 2017-07-28 | 2017-12-29 | 珠海格力电器股份有限公司 | Unit fault processing method and device |

| WO2018096492A1 (en)* | 2016-11-24 | 2018-05-31 | Tvs Motor Company Limited | Fault diagnostic system for a two-wheeled vehicle and a control method thereof |

| CN108319254A (en)* | 2018-01-24 | 2018-07-24 | 广东远峰汽车电子有限公司 | Automobile log collection method, vehicle-mounted terminal and log collection server |

| CN109144037A (en)* | 2018-10-22 | 2019-01-04 | 江西博能上饶客车有限公司 | A kind of portable integral new-energy passenger fault diagnosis system and device |

| CN109624968A (en)* | 2018-12-17 | 2019-04-16 | 苏州比雷艾斯电子科技有限公司 | A kind of environment protection multifunctional automotive safety speed change system |

| CN109866710A (en)* | 2019-02-18 | 2019-06-11 | 苏州工业园区职业技术学院 | A kind of In-vehicle networking abnormality detection system |

| WO2019109915A1 (en)* | 2017-12-08 | 2019-06-13 | 深圳市道通科技股份有限公司 | Vehicle trouble diagnosis method, vehicle trouble diagnosis apparatus and electronic device |

| CN109885036A (en)* | 2019-03-26 | 2019-06-14 | 重庆长安新能源汽车科技有限公司 | It a kind of vehicle and its closes weight signal and shows and the device and method of fault diagnosis |

| CN109921956A (en)* | 2018-12-10 | 2019-06-21 | 东莞职业技术学院 | A kind of detection method of automotive networking signal |

| CN109960237A (en)* | 2017-12-25 | 2019-07-02 | 郑州宇通客车股份有限公司 | A kind of car fault diagnosis and data analysis system and vehicle |

| CN109991561A (en)* | 2019-04-11 | 2019-07-09 | 珠海格力智能装备有限公司 | Testing method and system, household appliance and terminal module |

| CN110641280A (en)* | 2019-09-29 | 2020-01-03 | 奇瑞汽车股份有限公司 | Alarm method of automobile instrument |

| CN110850838A (en)* | 2018-08-21 | 2020-02-28 | 上海博泰悦臻网络技术服务有限公司 | Vehicle fault reminding method and system |

| CN110968070A (en)* | 2018-09-29 | 2020-04-07 | 湖南中车时代电动汽车股份有限公司 | Intelligent ECU fault diagnosis system |

| CN111694341A (en)* | 2020-06-05 | 2020-09-22 | 中国第一汽车股份有限公司 | Fault data storage method and device, vehicle-mounted equipment and storage medium |

| CN112147518A (en)* | 2019-06-27 | 2020-12-29 | 北京新能源汽车股份有限公司 | Electric automobile charging testing arrangement and system |

| CN112162997A (en)* | 2020-09-25 | 2021-01-01 | 重庆长安汽车股份有限公司 | Vehicle failure interpretation method and storage medium |

| CN112196712A (en)* | 2020-09-29 | 2021-01-08 | 哈尔滨东安汽车动力股份有限公司 | Fault diagnosis instrument for electronic fuel injection system of national six-engine |

| CN112319402A (en)* | 2020-11-26 | 2021-02-05 | 哈尔滨北方防务装备股份有限公司 | Fault guiding and protecting system based on double-section crawler transport vehicle |

| CN112650201A (en)* | 2020-12-29 | 2021-04-13 | 广州橙行智动汽车科技有限公司 | Vehicle fault diagnosis method and device, vehicle and storage medium |

| CN113359661A (en)* | 2021-05-12 | 2021-09-07 | 江铃汽车股份有限公司 | Vehicle fault detection method and system and automobile |

| CN113589786A (en)* | 2021-07-21 | 2021-11-02 | 陕汽集团商用车有限公司 | Whole vehicle fault detection and diagnosis system for new energy automobile |

| CN113882947A (en)* | 2021-09-30 | 2022-01-04 | 潍柴动力股份有限公司 | An instrument display method that can identify and respond to different faults |

| CN114019878A (en)* | 2021-11-08 | 2022-02-08 | 中国北方车辆研究所 | Digital driver control device for heavy-duty truck |

| CN114252719A (en)* | 2021-12-20 | 2022-03-29 | 南京懂玫驱动技术有限公司 | Fault detection method, device and system for electric power-assisted bicycle |

| CN115394058A (en)* | 2022-07-13 | 2022-11-25 | 陕西千山航空电子有限责任公司 | Method of device status alarm display |

| CN115755673A (en)* | 2022-10-28 | 2023-03-07 | 潍柴雷沃智慧农业科技股份有限公司 | Lighting control method, system, medium and equipment for combine harvester working device |

| CN115857472A (en)* | 2022-12-09 | 2023-03-28 | 安徽德孚转向系统股份有限公司 | Endurance testing device and method for electric power steering control unit |

| CN116055485A (en)* | 2022-11-30 | 2023-05-02 | 重庆长安汽车股份有限公司 | Whole vehicle health management method, device, equipment and medium |

| CN116578056A (en)* | 2023-03-23 | 2023-08-11 | 深圳市博诺技术有限公司 | Quick diagnosis method for automobile diagnosis equipment and automobile diagnosis user interaction system |

| CN116724542A (en)* | 2021-01-13 | 2023-09-08 | 佳能株式会社 | Control devices, systems, lithography apparatus, article manufacturing methods, control methods and procedures |

| CN117319355A (en)* | 2023-11-30 | 2023-12-29 | 韦普泰克(常州)测控系统设备有限公司 | Method and system for detecting CANopen (code addressable by digital weighing instrument) |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101222510A (en)* | 2008-01-25 | 2008-07-16 | 北京工业大学 | A Method to Realize CANopen Master Station |

| CN201820127U (en)* | 2010-07-16 | 2011-05-04 | 北京工业大学 | On-board Fault Diagnosis System of Hybrid Electric Vehicle Based on CANopen |

- 2010

- 2010-07-16CNCN 201010233264patent/CN101923348A/enactivePending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101222510A (en)* | 2008-01-25 | 2008-07-16 | 北京工业大学 | A Method to Realize CANopen Master Station |

| CN201820127U (en)* | 2010-07-16 | 2011-05-04 | 北京工业大学 | On-board Fault Diagnosis System of Hybrid Electric Vehicle Based on CANopen |

Non-Patent Citations (3)

| Title |

|---|

| 《中国仪器仪表学会2008学术年会第二届智能检测控制技术及仪表装置发展研讨会论文集》 20081101 余春喧等 多线程技术在数字化汽车仪表设计中的应用 第240-245页 1-6 , 2* |

| 《北京工业大学硕士学位论文》 2008 张明杰 基于CANopen的混合动力汽车车载故障诊断系统的研究与实现 第I,7-9,10-13,25,31,37-38,42-49页 1-6 , 2* |

| 《机械与电子》 2008 余春喧等 混合动力汽车的在板故障诊断系统研究 第39-42页 1-6 , 第06期 2* |

Cited By (89)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103328948A (en)* | 2011-02-15 | 2013-09-25 | 洋马株式会社 | Data collection device and system communicating therewith |

| CN102681526A (en)* | 2011-03-16 | 2012-09-19 | 北汽福田汽车股份有限公司 | CAN (controller area network) bus system and fault diagnosis method thereof |

| CN102323814A (en)* | 2011-06-07 | 2012-01-18 | 广州汽车集团股份有限公司 | Definition and reading method of freeze frame and its device |

| CN103649861A (en)* | 2011-07-07 | 2014-03-19 | 宝马股份公司 | Documentation of faults in a fault memory of a motor vehicle |

| CN103649861B (en)* | 2011-07-07 | 2015-11-25 | 宝马股份公司 | Fault registration in the fault memorizer of vehicle |

| CN102385378A (en)* | 2011-09-19 | 2012-03-21 | 重庆长安汽车股份有限公司 | Offline-detection auxiliary apparatus for new energy automobiles |

| CN102385380A (en)* | 2011-09-23 | 2012-03-21 | 广西三原高新科技有限公司 | Cluster automobile diagnosis information platform |

| CN102393733B (en)* | 2011-10-28 | 2014-04-23 | 北京清佰华通科技有限公司 | Failure diagnosis method, fault diagnosis instrument and system thereof, new energy automobile |

| CN102393733A (en)* | 2011-10-28 | 2012-03-28 | 北京清佰华通科技有限公司 | Failure diagnosis method, fault diagnosis instrument and system thereof |

| CN103116285B (en)* | 2011-11-17 | 2016-04-20 | 上海航天测控通信研究所 | For the dual processors unibus computer system of deep space probe |

| CN103116285A (en)* | 2011-11-17 | 2013-05-22 | 上海航天测控通信研究所 | Double central processing unit (CPU) unibus computer system for deep space probe |

| CN102589896A (en)* | 2012-01-12 | 2012-07-18 | 浙江师范大学 | State testing equipment for automobiles |

| CN104169976B (en)* | 2012-01-13 | 2017-05-03 | 斯堪尼亚商用车有限公司 | system and method for providing diagnostic fault information |

| CN104169976A (en)* | 2012-01-13 | 2014-11-26 | 斯堪尼亚商用车有限公司 | System and method for providing diagnostic fault information |

| CN102620932A (en)* | 2012-03-28 | 2012-08-01 | 奇瑞汽车股份有限公司 | Online fault diagnosis prediction method and device thereof of automatic gearbox |

| CN103455023B (en)* | 2012-06-01 | 2016-05-04 | 北汽福田汽车股份有限公司 | Be used for testing arrangement and the method for the dynamical system of new-energy automobile |

| CN103455023A (en)* | 2012-06-01 | 2013-12-18 | 北汽福田汽车股份有限公司 | Testing device and method used for power system of new energy automobile |

| CN103728966B (en)* | 2012-10-12 | 2016-11-30 | 洛克威尔自动控制技术股份有限公司 | motor driver |

| CN103728966A (en)* | 2012-10-12 | 2014-04-16 | 洛克威尔自动控制技术股份有限公司 | Error diagnostics and prognostics in motor drives |

| CN102975670A (en)* | 2012-11-23 | 2013-03-20 | 三一重工股份有限公司 | Transient fault processing method and system of vehicle bus control system and vehicle |

| CN102975670B (en)* | 2012-11-23 | 2015-10-28 | 三一汽车制造有限公司 | The processing method of vehicle bus control system transient fault and system, vehicle |

| CN103076183A (en)* | 2012-12-24 | 2013-05-01 | 中国北车集团大连机车研究所有限公司 | Function test bed of driver display unit of electric locomotive |

| CN103061910A (en)* | 2012-12-27 | 2013-04-24 | 潍柴动力股份有限公司 | System and method for distinguishing present fault and ancient fault of motor |

| CN103061910B (en)* | 2012-12-27 | 2015-07-08 | 潍柴动力股份有限公司 | System and method for distinguishing present fault and ancient fault of motor |

| CN103197930B (en)* | 2013-03-27 | 2016-08-03 | 北京经纬恒润科技有限公司 | The method that automobile diagnostic software automatically generates |

| CN103279120A (en)* | 2013-05-09 | 2013-09-04 | 三一矿机有限公司 | Portable data collection and diagnosis device and mechanical vehicle |

| CN104579816A (en)* | 2013-10-11 | 2015-04-29 | 通用汽车环球科技运作有限责任公司 | Vehicle network health assessment |

| CN104579816B (en)* | 2013-10-11 | 2019-01-18 | 通用汽车环球科技运作有限责任公司 | Diagnose the method and system of vehicle network |

| CN103527294A (en)* | 2013-10-16 | 2014-01-22 | 潍柴动力股份有限公司 | Postprocessing system control method, postprocessing electronic control unit and controller |

| CN103607327B (en)* | 2013-12-03 | 2017-01-18 | 北京经纬恒润科技有限公司 | Diagnostic method and integrated ECU |

| CN103607327A (en)* | 2013-12-03 | 2014-02-26 | 北京经纬恒润科技有限公司 | Diagnostic method and integrated ECU |

| CN103640555A (en)* | 2013-12-20 | 2014-03-19 | 北京理工大学 | HEV (Hybrid Electric Vehicle) control system manager |

| CN103661170A (en)* | 2013-12-23 | 2014-03-26 | 深圳市航盛电子股份有限公司 | Automatic informing device and method of vehicle body information changing |

| CN103661170B (en)* | 2013-12-23 | 2016-11-30 | 深圳市航盛电子股份有限公司 | Vehicle body information changing automatic informing device and method |

| CN104766472A (en)* | 2014-01-03 | 2015-07-08 | 上海通用汽车有限公司 | Vehicle state monitoring method |

| CN103902746B (en)* | 2014-03-11 | 2017-10-27 | 深圳市元征科技股份有限公司 | DTC, data flow and the method for freezing frame data preservation and playback |

| CN103902746A (en)* | 2014-03-11 | 2014-07-02 | 深圳市元征科技股份有限公司 | Fault code, data stream and freeze frame data storage and playback method |

| CN103942261B (en)* | 2014-03-24 | 2017-12-12 | 北京航天发射技术研究所 | A kind of configuration input method for onboard system fault dictionary |

| CN103942261A (en)* | 2014-03-24 | 2014-07-23 | 北京航天发射技术研究所 | Allocation input method for vehicle-mounted system fault dictionary |

| CN105022380A (en)* | 2014-04-24 | 2015-11-04 | 广西金奔腾汽车科技有限公司 | Technology related to decoder fault code indexing |

| CN105022381A (en)* | 2014-04-24 | 2015-11-04 | 广西金奔腾汽车科技有限公司 | Application technology related to data flow callback function |

| CN104834303A (en)* | 2014-12-19 | 2015-08-12 | 北汽福田汽车股份有限公司 | Vehicle fault diagnosis method and system, and vehicle |

| CN104590163A (en)* | 2014-12-29 | 2015-05-06 | 联想(北京)有限公司 | Information processing method, device and automobile |

| CN106444692A (en)* | 2015-08-06 | 2017-02-22 | 北汽福田汽车股份有限公司 | Vehicle maintenance assistance method and system |

| CN106444692B (en)* | 2015-08-06 | 2019-07-23 | 北京宝沃汽车有限公司 | Vehicle maintenance assisted method and system |

| EP3315347A1 (en)* | 2016-10-19 | 2018-05-02 | Optimum Battery Co., Ltd. | Electric vehicle, battery storage power system, and alarm system and alarm method thereof |

| CN106356576A (en)* | 2016-10-19 | 2017-01-25 | 深圳市沃特玛电池有限公司 | Alarm system and alarm method |

| CN106371429A (en)* | 2016-11-12 | 2017-02-01 | 驭联智能科技发展(上海)有限公司 | Inside-vehicle equipment centralized detection method and system |

| CN106569486A (en)* | 2016-11-15 | 2017-04-19 | 华晨汽车集团控股有限公司 | Fault warning evaluation system based on motor vehicle CAN network |

| WO2018096492A1 (en)* | 2016-11-24 | 2018-05-31 | Tvs Motor Company Limited | Fault diagnostic system for a two-wheeled vehicle and a control method thereof |

| TWI760389B (en)* | 2016-11-24 | 2022-04-11 | 印度商Tvs電機股份有限公司 | Fault diagnostic system for a two-wheeled vehicle and a control method thereof |

| CN107528293A (en)* | 2017-07-28 | 2017-12-29 | 珠海格力电器股份有限公司 | Unit fault processing method and device |

| WO2019109915A1 (en)* | 2017-12-08 | 2019-06-13 | 深圳市道通科技股份有限公司 | Vehicle trouble diagnosis method, vehicle trouble diagnosis apparatus and electronic device |

| CN109960237A (en)* | 2017-12-25 | 2019-07-02 | 郑州宇通客车股份有限公司 | A kind of car fault diagnosis and data analysis system and vehicle |

| CN108319254A (en)* | 2018-01-24 | 2018-07-24 | 广东远峰汽车电子有限公司 | Automobile log collection method, vehicle-mounted terminal and log collection server |

| CN110850838A (en)* | 2018-08-21 | 2020-02-28 | 上海博泰悦臻网络技术服务有限公司 | Vehicle fault reminding method and system |

| CN110968070A (en)* | 2018-09-29 | 2020-04-07 | 湖南中车时代电动汽车股份有限公司 | Intelligent ECU fault diagnosis system |

| CN109144037A (en)* | 2018-10-22 | 2019-01-04 | 江西博能上饶客车有限公司 | A kind of portable integral new-energy passenger fault diagnosis system and device |

| CN109921956B (en)* | 2018-12-10 | 2024-05-24 | 东莞职业技术学院 | Detection method for automobile network signals |

| CN109921956A (en)* | 2018-12-10 | 2019-06-21 | 东莞职业技术学院 | A kind of detection method of automotive networking signal |

| CN109624968A (en)* | 2018-12-17 | 2019-04-16 | 苏州比雷艾斯电子科技有限公司 | A kind of environment protection multifunctional automotive safety speed change system |

| CN109866710A (en)* | 2019-02-18 | 2019-06-11 | 苏州工业园区职业技术学院 | A kind of In-vehicle networking abnormality detection system |

| CN109885036A (en)* | 2019-03-26 | 2019-06-14 | 重庆长安新能源汽车科技有限公司 | It a kind of vehicle and its closes weight signal and shows and the device and method of fault diagnosis |

| CN109991561A (en)* | 2019-04-11 | 2019-07-09 | 珠海格力智能装备有限公司 | Testing method and system, household appliance and terminal module |

| CN112147518A (en)* | 2019-06-27 | 2020-12-29 | 北京新能源汽车股份有限公司 | Electric automobile charging testing arrangement and system |

| CN112147518B (en)* | 2019-06-27 | 2024-04-26 | 北京新能源汽车股份有限公司 | Electric automobile test device and system that charges |

| CN110641280A (en)* | 2019-09-29 | 2020-01-03 | 奇瑞汽车股份有限公司 | Alarm method of automobile instrument |

| CN111694341A (en)* | 2020-06-05 | 2020-09-22 | 中国第一汽车股份有限公司 | Fault data storage method and device, vehicle-mounted equipment and storage medium |

| CN112162997B (en)* | 2020-09-25 | 2024-04-12 | 重庆长安汽车股份有限公司 | Vehicle fault interpretation method and storage medium |

| CN112162997A (en)* | 2020-09-25 | 2021-01-01 | 重庆长安汽车股份有限公司 | Vehicle failure interpretation method and storage medium |

| CN112196712A (en)* | 2020-09-29 | 2021-01-08 | 哈尔滨东安汽车动力股份有限公司 | Fault diagnosis instrument for electronic fuel injection system of national six-engine |

| CN112319402A (en)* | 2020-11-26 | 2021-02-05 | 哈尔滨北方防务装备股份有限公司 | Fault guiding and protecting system based on double-section crawler transport vehicle |

| CN112650201B (en)* | 2020-12-29 | 2022-03-11 | 广州橙行智动汽车科技有限公司 | Vehicle fault diagnosis method and device, vehicle and storage medium |

| CN112650201A (en)* | 2020-12-29 | 2021-04-13 | 广州橙行智动汽车科技有限公司 | Vehicle fault diagnosis method and device, vehicle and storage medium |

| CN116724542A (en)* | 2021-01-13 | 2023-09-08 | 佳能株式会社 | Control devices, systems, lithography apparatus, article manufacturing methods, control methods and procedures |

| CN113359661A (en)* | 2021-05-12 | 2021-09-07 | 江铃汽车股份有限公司 | Vehicle fault detection method and system and automobile |

| CN113589786A (en)* | 2021-07-21 | 2021-11-02 | 陕汽集团商用车有限公司 | Whole vehicle fault detection and diagnosis system for new energy automobile |

| CN113882947A (en)* | 2021-09-30 | 2022-01-04 | 潍柴动力股份有限公司 | An instrument display method that can identify and respond to different faults |

| CN114019878A (en)* | 2021-11-08 | 2022-02-08 | 中国北方车辆研究所 | Digital driver control device for heavy-duty truck |

| CN114019878B (en)* | 2021-11-08 | 2023-07-28 | 中国北方车辆研究所 | Digital driver control device of heavy-duty truck |

| CN114252719A (en)* | 2021-12-20 | 2022-03-29 | 南京懂玫驱动技术有限公司 | Fault detection method, device and system for electric power-assisted bicycle |

| CN115394058A (en)* | 2022-07-13 | 2022-11-25 | 陕西千山航空电子有限责任公司 | Method of device status alarm display |

| CN115755673A (en)* | 2022-10-28 | 2023-03-07 | 潍柴雷沃智慧农业科技股份有限公司 | Lighting control method, system, medium and equipment for combine harvester working device |

| CN116055485A (en)* | 2022-11-30 | 2023-05-02 | 重庆长安汽车股份有限公司 | Whole vehicle health management method, device, equipment and medium |

| CN116055485B (en)* | 2022-11-30 | 2024-08-13 | 重庆长安汽车股份有限公司 | Whole vehicle health management method, device, equipment and medium |

| CN115857472A (en)* | 2022-12-09 | 2023-03-28 | 安徽德孚转向系统股份有限公司 | Endurance testing device and method for electric power steering control unit |

| CN116578056A (en)* | 2023-03-23 | 2023-08-11 | 深圳市博诺技术有限公司 | Quick diagnosis method for automobile diagnosis equipment and automobile diagnosis user interaction system |

| CN117319355A (en)* | 2023-11-30 | 2023-12-29 | 韦普泰克(常州)测控系统设备有限公司 | Method and system for detecting CANopen (code addressable by digital weighing instrument) |

| CN117319355B (en)* | 2023-11-30 | 2024-02-09 | 韦普泰克(常州)测控系统设备有限公司 | Method and system for detecting CANopen (code addressable by digital weighing instrument) |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101923348A (en) | A CANopen-based on-board fault diagnosis system and method for hybrid electric vehicles | |

| CN201820127U (en) | On-board Fault Diagnosis System of Hybrid Electric Vehicle Based on CANopen | |

| CN102120441B (en) | Passenger vehicles diagnosis method of passenger vehicles diagnosis system | |

| CN103019235B (en) | Intelligent remote diagnosis system and intelligent remote diagnosis method | |

| CN103632211B (en) | A kind of vehicle trouble early warning and recall forecasting system | |

| CN110233768B (en) | UDS-based CAN bus test system and CAN bus test method | |

| CN200993741Y (en) | Hybrid power electric automobile matching demarcation device based on serial communication | |

| CN106227122A (en) | A kind of vehicle mounted failure detection and early warning system | |

| CN103995511B (en) | A kind of intelligent bus CAN body control system | |

| CN1417980A (en) | Intelligent gateway device for vehicle controller LAN | |

| CN110609491B (en) | Accident identification method and system for semi-physical simulation of electric vehicle controller | |

| CN104699686A (en) | Vehicle-mounted control module and matching method thereof | |

| CN106569486A (en) | Fault warning evaluation system based on motor vehicle CAN network | |

| CN201804238U (en) | Vehicle performance remote monitoring system | |

| CN106740121A (en) | Electric automobile smart circuit management system and its management control method | |

| CN201805439U (en) | Portable Automotive Diagnostic System | |

| CN112146885A (en) | Remote vehicle-mounted troubleshooting and repairing method and system | |

| CN107179764A (en) | Vehicle device equipment with vehicle diagnostics function | |

| CN201716592U (en) | Diagnostic instrument for vehicle failure | |

| CN108990013A (en) | Intelligent vehicle-mounted system based on OBD-II and Bluetooth | |

| Zhou et al. | Development method of simulation and test system for vehicle body CAN bus based on CANoe | |

| Hu et al. | Developing PC-based automobile diagnostic system based on OBD system | |

| CN207274587U (en) | Electric automobile electric-control system | |

| CN202073640U (en) | Monitoring device for state of automobile engine | |

| MXPA05009235A (en) | User adaptive automated pre-trip inspection system. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Open date:20101222 |