CN101865786A - An experimental setup for measuring spray characteristics under low air pressure conditions - Google Patents

An experimental setup for measuring spray characteristics under low air pressure conditionsDownload PDFInfo

- Publication number

- CN101865786A CN101865786ACN201010165232.4ACN201010165232ACN101865786ACN 101865786 ACN101865786 ACN 101865786ACN 201010165232 ACN201010165232 ACN 201010165232ACN 101865786 ACN101865786 ACN 101865786A

- Authority

- CN

- China

- Prior art keywords

- laser

- vacuum chamber

- vacuum

- transparent

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Testing Resistance To Weather, Investigating Materials By Mechanical Methods (AREA)

- Investigating Or Analysing Materials By Optical Means (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于安全科学与工程实验设备技术领域,特别涉及在低压条件下采用激光相位多普勒分析仪测量喷雾特性的实验装置。The invention belongs to the technical field of safety science and engineering experimental equipment, in particular to an experimental device for measuring spray characteristics by using a laser phase Doppler analyzer under low pressure conditions.

背景技术Background technique

低气压存在于高原、高空、抽真空设备等多种环境条件下。细水雾灭火技术具有灭火高效、对环境无污染、对现场人员和设备安全、用水量少等诸多优点,对其在常压条件下灭火性能的研究已开展了大量的工作,并已得到广泛的应用。但至今尚缺乏在低气压条件下细水雾特性表征方面的研究工作,更没有见到适宜于在常压地区测量低气压条件下细水雾雾滴粒径及速度的模拟实验装置。《消防科学与技术》杂志(2005,24(6):733-734)介绍了细水雾系统的概念、灭火机理、控制方式和在文物古建筑中的运用的优点和局限性,但未见涉及低压条件下对细水雾雾场特性的研究。《大气环境-A》杂志(1991,25(2):217-230)介绍了在低压环境下对97种不同水雾试样的化学组分、温度、传输速度及方向等方面的研究,但未见涉及细水雾雾化角、雾化液滴直径等雾化特性。《高海拔低气压条件对细水雾灭火性能影响的实验研究》(蔡昕,2009.05;中国科学技术大学博士论文)中介绍了低压条件下的细水雾雾特性研究,但其仅采用收集法和激光片光成像法测量分析了低气压条件对细水雾喷雾张角及其雾滴空间分布的影响。而从细水雾灭火技术在低气压环境的推广应用,特别如西藏以布达拉宫为代表的文物古建筑,以及宇宙飞船等航空航天器的火灾防护及其相应灭火系统的优化设计来说,亟需对细水雾在低气压条件下的喷雾特性进行实验测量分析。但目前缺乏测量低压条件下细水雾特性的实验装置,已有的大型激光测量系统也不适宜于在航空航天器上使用。Low air pressure exists in various environmental conditions such as plateaus, high altitudes, and vacuum equipment. Water mist fire extinguishing technology has many advantages such as high fire extinguishing efficiency, no pollution to the environment, safety to on-site personnel and equipment, and less water consumption. A lot of work has been carried out on its fire extinguishing performance under normal pressure conditions, and it has been widely Applications. But so far there is still a lack of research work on the characterization of fine water mist under low pressure conditions, and there is no simulated experimental device suitable for measuring the particle size and velocity of fine water mist droplets under low pressure conditions in normal pressure areas. "Fire Science and Technology" magazine (2005, 24 (6): 733-734) introduced the concept of fine water mist system, fire extinguishing mechanism, control method and the advantages and limitations of the application in cultural relics and ancient buildings, but did not see It involves the study of the characteristics of fine water mist fog field under low pressure conditions. "Atmospheric Environment-A" magazine (1991,25 (2): 217-230) introduced the research on the chemical composition, temperature, transmission speed and direction of 97 different water mist samples under low pressure environment, but There are no atomization characteristics related to the atomization angle of fine water mist and the diameter of atomized droplets. "Experimental Research on the Effect of High Altitude and Low Pressure Conditions on the Fire Extinguishing Performance of Fine Water Mist" (Cai Xin, 2009.05; Doctoral Thesis of University of Science and Technology of China) introduced the research on the characteristics of fine water mist under low pressure conditions, but it only uses the collection method The effects of low pressure conditions on the spray angle of fine water mist and the spatial distribution of droplets were measured and analyzed with laser sheet photoimaging. From the popularization and application of water mist fire extinguishing technology in low pressure environment, especially the cultural relics and ancient buildings represented by the Potala Palace in Tibet, as well as the fire protection of spaceships and other aerospace vehicles and the optimization design of the corresponding fire extinguishing system , there is an urgent need for experimental measurement and analysis of the spray characteristics of fine water mist under low pressure conditions. However, there is currently no experimental device for measuring the characteristics of fine water mist under low pressure conditions, and the existing large-scale laser measurement system is not suitable for use on aerospace vehicles.

“多相流体测量试验方法”(多相流技术,1994,20:261-295)介绍了激光相位多普勒测量(PDA)技术的标准,这是一种对粒子的粒径和速度进行同步测量的光学测量技术,由激光器、发射探头、信号处理器和计算机组成。激光器发射的激光经基准彩色脉冲器过滤后分别通过两个互相垂直的发射探头向真空室器壁上的两个互相垂直的第一个透明窗口和第二个透明窗口垂直发射,激光信号在真空室内聚焦后经喷雾粒子放大和折射后通过第三透明窗口被光电探测器接收,被接收的激光信号经传输光纤和色调一致设定仪后,其中的一部分信号经传输光纤进入信号处理器,经计算机上的数据处理软件处理数据,其余部分信号进入基准彩色脉冲器,循环利用。但根据对国内外文献和专利的检索,仅检索到在常压条件下利用PDA技术测量细水雾雾特性的文献,尚未见到利用PDA技术测量在低气压条件下细水雾雾特性的相关文献和专利。"Test Methods for Measurement of Multiphase Fluids" (Multiphase Flow Technology, 1994, 20: 261-295) introduces the standard for the laser phase Doppler measurement (PDA) technique, which is a method for synchronizing particle size and velocity Optical measurement technology for measurement, consisting of lasers, emission probes, signal processors and computers. The laser light emitted by the laser is filtered by the reference color pulser and then vertically emitted to the first transparent window and the second transparent window on the wall of the vacuum chamber through two mutually perpendicular emission probes. After focusing in the room, it is amplified and refracted by the spray particles and then received by the photoelectric detector through the third transparent window. The data processing software on the computer processes the data, and the remaining part of the signal enters the reference color pulser for recycling. However, according to the retrieval of domestic and foreign literature and patents, only the literature on the use of PDA technology to measure the characteristics of fine water mist under normal pressure conditions has been retrieved. literature and patents.

发明内容Contents of the invention

本发明的目的是提供一种采用激光相位多普勒测量技术测量低气压条件下喷雾特性的实验装置,为研究低气压条件下细水雾雾场分布、雾滴粒径以及雾滴速度分布等特性提供条件保障。The purpose of the present invention is to provide an experimental device that uses laser phase Doppler measurement technology to measure spray characteristics under low pressure conditions, in order to study the distribution of fine water mist fog field, droplet size and droplet velocity distribution under low pressure conditions. Features provide conditional guarantees.

本发明的采用激光相位多普勒测量低气压条件下细水雾特性的实验装置,包括器壁上设有抽气孔和真空压力表的密闭真空室,所述抽气孔经带有阀门的管道与真空泵相连;真空室顶部设有细水雾喷头,该细水雾喷头经带有阀门的管道与供水系统相连;在由激光器、发射探头、信号处理器和计算机组成的激光相位多普勒测量系统中,从激光器发射出来的激光经基准彩色脉冲器过滤后分别通过两个互相垂直的发射探头向两个互相垂直的第一、第二透明窗口垂直发射,在真空腔内聚焦后通过第三透明窗口被激光接收探头接收,被接收的激光信号经传输光纤进入信号处理器,经计算机上配备的多普勒测量数据处理软件处理后得到所需参数的测量信息;其特征在于:焊接在真空室外壁面的窗口基座连接处采用与真空室外壁面形状相匹配的内螺纹外沟槽式结构;所述三个透明窗口的玻璃分别卡插并密封镶嵌于焊接在真空室外壁面上的窗口基座的沟槽式结构内,形成易拆卸的内空腔式结构,该三个透明窗口的中心点在同一水平圆周面上,每个窗口平面与真空室外壁面切面平行,其中第一透明窗口平面方向与第二透明窗口平面方向互相垂直,第三透明窗口平面方向相对于第一透明窗口平面方向的夹角、以及与第二透明窗口所成的夹角与激光相位多普勒检测仪的激光发射、接收角度相吻合;细水雾喷头和供水系统管道的连接处采用卡箍式接头,该卡箍式接头由上下两个圆形法兰组成:上法兰和供水管道连接在一起,上法兰的横截面呈阶梯状,与卡箍的管卡相吻合;下法兰上部的形状和卡箍的管卡相吻合,下部和真空室连接在一起;真空室底部设有向下突出的蓄液管段,该蓄液管段通过阀门和大气连通。The experimental device of the present invention adopting laser phase Doppler to measure the characteristics of fine water mist under the condition of low air pressure comprises a closed vacuum chamber with an air pumping hole and a vacuum pressure gauge on the wall, and the air pumping hole is connected with a pipeline with a valve. The vacuum pump is connected; the top of the vacuum chamber is equipped with a fine water mist nozzle, which is connected to the water supply system through a pipeline with a valve; the laser phase Doppler measurement system composed of a laser, an emission probe, a signal processor and a computer In the process, the laser light emitted from the laser is filtered by the reference color pulser, and then is emitted vertically to two mutually perpendicular first and second transparent windows through two mutually perpendicular emission probes, and then passes through the third transparent window after being focused in the vacuum cavity. The window is received by the laser receiving probe, and the received laser signal enters the signal processor through the transmission fiber, and the measurement information of the required parameters is obtained after being processed by the Doppler measurement data processing software equipped on the computer; it is characterized in that: it is welded outside the vacuum chamber The connection of the window base on the wall adopts an internal thread and external groove structure that matches the shape of the outer wall of the vacuum; the glass of the three transparent windows is respectively inserted and sealed into the window base welded on the outer wall of the vacuum. In the grooved structure, an easily disassembled inner cavity structure is formed. The center points of the three transparent windows are on the same horizontal circumferential surface, and the plane of each window is parallel to the tangent plane of the outer wall of the vacuum chamber. The plane directions of the second transparent window are perpendicular to each other, the angle between the plane direction of the third transparent window relative to the plane direction of the first transparent window, and the angle between the plane direction of the second transparent window and the laser emission of the laser phase Doppler detector, The receiving angle coincides; the connection between the fine water mist nozzle and the water supply system pipe adopts a clamp joint, which is composed of two upper and lower circular flanges: the upper flange and the water supply pipe are connected together, and the upper flange The cross-section of the lower flange is stepped, which matches the pipe clip of the clamp; the shape of the upper part of the lower flange matches the pipe clip of the clamp, and the lower part is connected with the vacuum chamber; Pipe section, the liquid storage pipe section communicates with the atmosphere through a valve.

所述真空室可选用空心球体、圆柱体或长方柱体;可采用透明耐压材料制造,或采用非透明的耐压材料制造而在激光经过的相应位置留有透明窗口;设置透明窗口一方面是透过激光和接收激光的需要,同时也有利于对实验现象及过程进行观测记录;并可通过选用、更换不同耐压值的透明材料来改变真空室内的极限实验压力。The vacuum chamber can be made of hollow sphere, cylinder or rectangular cylinder; it can be made of transparent pressure-resistant material, or it can be made of non-transparent pressure-resistant material and a transparent window is left at the corresponding position where the laser passes; a transparent window is set On the one hand, it is necessary to transmit and receive laser light, and it is also conducive to the observation and recording of experimental phenomena and processes; and the ultimate experimental pressure in the vacuum chamber can be changed by selecting and replacing transparent materials with different pressure resistance values.

本发明在细水雾喷头和供水系统管道的连接处采用了卡箍式接头,使得实验过程中喷头的更换安装便捷,且不影响整体结构及密封性要求,有利于测试研究低气压条件下不同喷头的喷雾性。The invention adopts a clamp-type joint at the connection between the fine water mist nozzle and the water supply system pipeline, which makes the replacement and installation of the nozzle convenient during the experiment, and does not affect the overall structure and sealing requirements, which is conducive to testing and researching different The sprayability of the nozzle.

为了减少水雾对窗口玻璃的影响和避免侧壁积水对激光探测的影响,各透明窗口的上沿可设有向上倾斜与真空室内壁成锐角的挡水遮板;该挡水遮板的采用与否、及其向上倾斜的角度和伸出窗口的长度,与真空室腔体直径的大小、细水雾喷头设置的高度、喷雾锥角及喷头负压筒体内腔尺寸相关:若真空室腔体直径足够大、细水雾喷头设置的高度足够高、喷雾锥角足够小、或喷头负压筒体内腔尺寸足够大以至雾滴不会喷射到腔体内壁面,也就不会发生壁面凝结水流淌影响窗口测量的问题,在这种情况下该遮板也就无需伸出窗口太多甚至不需要它。In order to reduce the impact of water mist on the window glass and avoid the impact of water on the side wall on the laser detection, the upper edge of each transparent window can be provided with a water-retaining shutter that slopes upward and forms an acute angle with the inner wall of the vacuum; the water-retaining shutter Whether it is used or not, its upward tilt angle and the length of the protruding window are related to the diameter of the vacuum chamber cavity, the height of the fine water mist nozzle setting, the spray cone angle and the inner cavity size of the negative pressure cylinder of the nozzle: if the vacuum chamber cavity The diameter of the body is large enough, the height of the fine water mist nozzle is high enough, the spray cone angle is small enough, or the size of the inner cavity of the negative pressure cylinder of the nozzle is large enough so that the mist will not be sprayed on the inner wall of the cavity, and there will be no condensation on the wall. Problems with runoff affecting window measurements, in which case the shutter would not need to protrude too far out of the window or even need it.

为避免水雾与腔体内壁碰撞产生的二次水雾对窗口造成影响,腔体底部与激光聚焦点之间可保留10-20厘米的距离;所述真空室底部设向下伸出的法兰结构是为了减少液体溅射;该法兰底部通过卡箍接头和装有球阀的可控制排水量的排水管相连接,这里采取卡箍连接方式是为了确保内腔既可密封又可彻底排水。In order to avoid the impact of the secondary water mist generated by the collision between the water mist and the inner wall of the chamber, a distance of 10-20 cm can be reserved between the bottom of the chamber and the laser focus point; The flange structure is used to reduce liquid splashing; the bottom of the flange is connected to a drain pipe equipped with a ball valve to control the drainage through a clamp joint. Here, the clamp connection method is used to ensure that the inner cavity can be sealed and completely drained.

本发明中的各透明窗口设置,采取了与真空室外壁面形状相匹配的内螺纹外沟槽式结构,各透明窗口的玻璃分别卡插并密封镶嵌于真空室外壁面上的窗口基座的沟槽式内,形成易拆卸结构,以保证密封的可靠性以及安装、实验时清洁窗口等操作的方便。易拆卸结构不仅为了方便窗口玻璃的更换,同时也使研究分析不同玻璃对测量结果的影响及修正成为可能。各透明窗口采取的内空腔式结构,保证了窗口玻璃安装时相对于激光角度的可调性并确保激光垂直入射,从而避免玻璃对光的折射造成聚焦位置的偏差。The arrangement of each transparent window in the present invention adopts an internal thread and external groove structure matching the shape of the outer wall surface of the vacuum chamber, and the glass of each transparent window is respectively inserted and sealed into the groove of the window base embedded in the outer wall surface of the vacuum chamber. In the type, an easy-to-disassemble structure is formed to ensure the reliability of the seal and the convenience of installation and cleaning of the window during the experiment. The easy-to-disassemble structure is not only for the convenience of window glass replacement, but also makes it possible to study and analyze the influence of different glass on the measurement results and correct them. The inner cavity structure adopted by each transparent window ensures the adjustability of the window glass relative to the laser angle during installation and ensures the vertical incidence of the laser, thereby avoiding the deviation of the focus position caused by the refraction of the glass to the light.

开始实验时,先检查各阀门是否均已关闭;然后打开和抽气孔相连的阀门和真空泵,当真空压力表上显示的数据满足实验条件时,关闭真空泵及和抽气孔相连的阀门;开启和细水雾喷头相连的阀门与供水系统;开启激光相位多普勒测量系统(PDA),激光器发射探头发出的两束互相垂直的激光分别通过两个互相垂直的透明窗口进入真空室,穿过水雾在真空腔内一点聚焦后,产生干涉条纹并经喷雾粒子的放大和散射后通过第三透明窗口被激光接收探头接收,被接收的激光信号经传输光纤进入信号处理器,经计算机上配备的多普勒测量数据处理软件处理后得到所需的雾特性数据;数据采集完成后,依次关闭激光相位多普勒测量系统(PDA)和供水系统,关闭所有阀门,打开排水管的阀门,排出积水。When starting the experiment, first check whether all the valves are closed; then open the valve and vacuum pump connected to the exhaust hole, and when the data displayed on the vacuum pressure gauge meets the experimental conditions, close the vacuum pump and the valve connected to the exhaust hole; open and fine The valve connected to the water mist nozzle and the water supply system; the laser phase Doppler measurement system (PDA) is turned on, and the two mutually perpendicular laser beams emitted by the laser emitting probe enter the vacuum chamber through two mutually perpendicular transparent windows and pass through the water mist After focusing at one point in the vacuum chamber, interference fringes are generated, and after being amplified and scattered by the spray particles, they are received by the laser receiving probe through the third transparent window. The received laser signal enters the signal processor through the transmission optical fiber, and passes through the multi The required fog characteristic data is obtained after processing by the Puler measurement data processing software; after the data collection is completed, turn off the laser phase Doppler measurement system (PDA) and the water supply system in turn, close all valves, open the valve of the drain pipe, and discharge the accumulated water .

本发明利用现有的激光相位多普勒测量(PDA)技术,与带有真空泵和细水雾发生条件的密闭耐压真空室具体相结合,创造性地采用卡箍式连接接头、内螺纹外沟槽式易拆卸结构及内空腔式结构,从而实现了在低气压条件下喷雾特性的实验测量。采用本发明实验装置可实现在0.1~1个大气压范围内的低压条件下对喷雾特性进行测量研究;不仅可以做清水的喷雾特性实验,也可以做含有添加剂的水雾特性实验,还可测量燃油、喷涂料等介质的喷雾特性测量。本发明实验装置中的细水雾喷头可以选择采用7孔喷头或5孔喷头或其它的多孔喷头,以及具有不同流量系数的喷头,从而可以测量各类不同喷头在低气压条件下的喷雾特性。The present invention utilizes the existing laser phase Doppler measurement (PDA) technology, and combines it with a sealed pressure-resistant vacuum chamber with a vacuum pump and fine water mist generation conditions, and creatively adopts a clamp-type connection joint, an internal thread and an external groove The groove-type easy-to-detach structure and the inner cavity structure realize the experimental measurement of spray characteristics under low-pressure conditions. Using the experimental device of the present invention can realize the measurement and research of spray characteristics under low pressure conditions within the range of 0.1 to 1 atmosphere; not only the spray characteristics experiment of clear water can be done, but also the water mist characteristics experiment containing additives can be done, and fuel oil can also be measured , Spray characteristics measurement of media such as spray paint. The fine water mist nozzle in the experimental device of the present invention can choose to adopt 7-hole nozzle or 5-hole nozzle or other porous nozzles, and nozzles with different flow coefficients, so that the spray characteristics of various different nozzles under low pressure conditions can be measured.

与现有测量喷雾特性的方法及装置相比,本发明克服了现有测量方法及装置无法实现低气压条件下对喷雾特性进行测量研究的困难;与《高海拔低气压条件对细水雾灭火性能影响的实验研究》中采用的基于激光片光的雾场图像诊断方法相比较,本发明实验装置采用的激光相位多普勒测量(PDA)技术可同时测量获取雾滴粒径、速度分布及雾通量等多个参数,且具有更高的精度。Compared with the existing method and device for measuring spray characteristics, the present invention overcomes the difficulty that existing measurement methods and devices cannot realize the measurement and research of spray characteristics under low pressure conditions; Compared with the fog field image diagnosis method based on laser sheet light adopted in "Experimental Research on Performance Impact", the laser phase Doppler measurement (PDA) technology adopted in the experimental device of the present invention can simultaneously measure and obtain the droplet particle size, velocity distribution and Fog flux and other parameters, and has higher precision.

附图说明Description of drawings

图1是本发明采用PDA技术测量低气压条件下喷雾特性的实验装置的球形真空室实施例结构示意图。Fig. 1 is the schematic diagram of the structure of the embodiment of the spherical vacuum chamber of the experimental device of the present invention which adopts the PDA technology to measure the spray characteristics under the condition of low pressure.

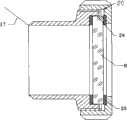

图2是本发明采用PDA技术测量低气压条件下喷雾特性的实验装置的卡箍式接头的结构截面示意图。Fig. 2 is a structural cross-sectional schematic diagram of a clip-type joint of an experimental device using PDA technology to measure spray characteristics under low-pressure conditions according to the present invention.

图3是本发明采用PDA技术测量低气压条件下喷雾特性的实验装置的内螺纹外沟槽式结构的接头截面示意图。Fig. 3 is a schematic cross-sectional view of the joint of the internal thread and external groove structure of the experimental device using PDA technology to measure spray characteristics under low pressure conditions in the present invention.

图4是本发明采用PDA技术测量低气压条件下喷雾特性的实验装置的PDA测量系统实施例结构示意图。Fig. 4 is a schematic structural diagram of a PDA measurement system embodiment of an experimental device for measuring spray characteristics under low pressure conditions using PDA technology in the present invention.

图5是本发明采用PDA技术测量低气压条件下喷雾特性的实验装置的圆柱形真空室实施例结构示意图。Fig. 5 is a schematic structural diagram of a cylindrical vacuum chamber embodiment of an experimental device for measuring spray characteristics under low pressure conditions using PDA technology in the present invention.

具体实施方式Detailed ways

实施例1:Example 1:

本实施例采用PDA技术测量低气压条件下喷雾特性的实验装置的球形真空室实验装置如图1所示:该实验装置包括器壁上设有抽气孔和真空压力表的密闭真空室,本实施例中的真空室13由上、下两个不锈钢空心半球体用螺栓和橡胶垫片固定密封组成;所述抽气孔经带有阀门5的管道16与真空泵S2相连;真空室13的顶部设有细水雾喷头3,该细水雾喷头3经带有阀门4的管道2与供水系统S1相连通;真空室13顶部中央通过顶部法兰15固定安装有和供水系统S1相连通的管道2,法兰片之间通过卡箍接头21固定,以方便拆卸更换细水雾喷头,管道2和供水系统S1之间有手动球阀4。管道2下端靠近真空室13顶部采用卡箍式接头21安装细水雾喷头3,The present embodiment adopts PDA technology to measure the spherical vacuum chamber experimental apparatus of the experimental apparatus of spray characteristic under the condition of low pressure as shown in Figure 1: this experimental apparatus comprises the airtight vacuum chamber that is provided with pumping hole and vacuum pressure gauge on the wall, this implementation The

在真空室13顶部的管道2的两侧的器壁上分别安装有真空压力表1和抽气管道16,真空压力表1通过螺纹管接头固定在真空室13的外壁上,焊接在真空室13器壁上的抽气管道16经手动球阀5和真空泵S2相连。A vacuum pressure gauge 1 and an

图2是本发明中设计采用的卡箍式接头的结构截面示意图:该接头由上下两个圆形法兰21和22组成:上法兰21和供水管道2焊接在一起,供水管道2的下端连接细水雾喷头3,上法兰21的横截面呈阶梯状,与卡箍的管卡相吻合;下法兰22上部的形状和卡箍的管卡相吻合,下部和真空室焊接在一起。这种结构使得在实验过程中便于更换安装不同的喷头,且不影响整体结构及密封性要求,有利于测试研究低气压条件下不同喷头的喷雾性。Fig. 2 is a structural cross-sectional schematic view of the clamp type joint designed and adopted in the present invention: the joint is composed of two

靠近半球体接缝14的器壁下部开有三个透明窗口:第一个透明窗口9的平面方向与第二个透明窗口7的平面方向的互相垂直,第三个透明窗口6的平面方向相对于第一个透明窗口9的平面方向在顺时针方向成120度夹角,与第二个透明窗口7成30度夹角,通过内螺纹外沟槽式结构的接头20和垫片23把透光度好并受激光影响很小的硼硅玻璃8固定在透明窗口外壁边缘,该三个透明窗口的中心点在同一个水平面圆周上。There are three transparent windows near the bottom of the wall of the hemispherical seam 14: the plane direction of the first

图3是本发明中设计采用的内螺纹外沟槽式结构的接头20截面示意图:该接头将玻璃卡插并密封镶嵌于真空室外壁面上的窗口基座的沟槽24内,形成易拆卸的内空腔式结构。保证密封的可靠性以及安装、实验时清洁窗口等操作的方便。易拆卸结构不仅为了方便窗口玻璃的更换,同时也使研究分析不同玻璃对测量结果的影响及修正成为可能。内空腔式结构保证了窗口玻璃安装时相对于激光角度的可调性并确保激光垂直入射,避免玻璃对光的折射造成聚焦位置的偏差。Fig. 3 is a schematic cross-sectional view of the

为防止内壁上的雾滴滑落到透明窗口上影响测量结果,在上述三个透明窗口上沿的内壁面上部设有向上倾斜和真空室内壁成45°角的挡板17并且挡板17的两端分别比窗口边缘突出2cm。在和三个透明窗口同一个水平面上,且离第一个透明窗口9和第二个透明窗口7的距离分别为10cm处的真空室外的位置上放置包括数据采集及处理系统的PDA测量系统。In order to prevent the mist on the inner wall from sliding onto the transparent window and affect the measurement results, a

在真空室13的底部中央焊接有直径20cm,向下突出5cm的蓄液管段12,该蓄液管12通过手动球阀10和大气连通。The bottom center of the

考虑到真空室13的稳定性,也为了实验的方便,在真空室下面设置了支架18以支撑真空室。Considering the stability of the

本实施例中供水系统采用自来水,喷头为7孔喷头,激光器为氩离子激光器。In this embodiment, the water supply system adopts tap water, the nozzle is a 7-hole nozzle, and the laser is an argon ion laser.

实验时,先检查各阀门是否均已关闭,打开和抽气孔相连的手动球阀5,启动真空泵S2,到真空压力表1上显示的数据满足实验条件时,关闭真空泵S2和与抽气孔相连的手动球阀5;开启和细水雾喷头相连的手动球阀4与供水系统S1,细水雾喷头3开始喷水雾;延迟一段时间,等水雾弥散开后,开启PDA测量系统S3。During the experiment, first check whether all the valves are closed, open the

图4是本发明采用PDA技术测量低气压条件下喷雾特性的实验装置的PDA测量系统实施例结构示意图:Fig. 4 is that the present invention adopts PDA technology to measure the PDA measuring system embodiment structural representation of the experimental device of spray characteristic under the low pressure condition:

激光器m4发射的激光经基准彩色脉冲器m5过滤后,分别经两个发射探头m6a和m6b发射的两束垂直激光分别通过第一、第二两个互相垂直的透明窗口7、9进入真空室13,穿过水雾在一点聚焦后,经雾滴粒子放大和折射后在第三个透明窗口6的激光接收探头m2被接收,经传输光纤m3、色调一致设定仪m8和滤波器m9进入信号处理器m10,然后经计算机m11记录并打印出透明窗口6处的雾特性数据;数据采集完成,依次关闭PDA测量系统S3和供水系统S1,关闭所有阀门,打开排水管的手动球阀10,排出积水。The laser light emitted by the laser m4 is filtered by the reference color pulser m5, and the two vertical laser beams emitted by the two emission probes m6a and m6b respectively enter the

实施例2:Example 2:

图5为本实施例采用PDA技术测量低气压条件下细水雾特性的圆柱形真空室实验装置的结构示意图,该真空室13中的器壁采用不锈钢,底面直径为60cm,高度为69cm,三个窗口安装的是透明钢化玻璃。Fig. 5 is the structural representation of the cylindrical vacuum chamber experimental device that adopts PDA technology to measure the characteristics of fine water mist under the low pressure condition in this embodiment. The first window is installed with transparent tempered glass.

真空室13顶部中央通过顶部法兰15固定安装有和供水系统S1相连通的管道2,法兰片之间通过卡箍接头21固定,以方便拆卸更换细水雾喷头,管道2和供水系统S1之间有手动球阀4。管道2下端靠近真空室13顶部采用卡箍式接头21安装细水雾喷头3,在顶部法兰的两侧分别安装有真空压力表1和抽气管道16,真空压力表1通过螺纹管接头固定在真空室13的外壁上,抽气管道16焊接在真空室13的器壁上,抽气管道16经手动球阀5和真空泵S2之间有。The center of the top of the

在距真空室13底部20cm处的器壁上开有三个透明窗口:第一个透明窗口9的平面方向与第二个透明窗口7的平面方向互相垂直,第三个透明窗口6的平面方向相对于第一个透明窗口9的平面方向在顺时针方向成120度夹角,与第二个透明窗口7成30度夹角;通过内螺纹外沟槽式结构的接头20和垫片23把透光度好并受激光影响很小的硼硅玻璃8固定在透明窗口外壁边缘,该三个透明窗口的中心点在同一个水平面圆周上。Three transparent windows are arranged on the wall of the

采用的内螺纹外沟槽式结构的接头20将玻璃卡插并密封镶嵌于真空室外壁面上的窗口基座的沟槽24内,形成易拆卸的内空腔式结构。保证密封的可靠性以及安装、实验时清洁窗口等操作的方便。易拆卸结构不仅为了方便窗口玻璃的更换,同时也使研究分析不同玻璃对测量结果的影响及修正成为可能。内空腔式结构,保证了窗口玻璃安装时相对于激光角度的可调性并确保激光垂直入射,避免玻璃对光的折射造成聚焦位置的偏差。The joint 20 with internal thread and external groove structure is used to insert and seal the glass into the

为防止内壁上的雾滴滑落到透明窗口上影响测量结果,在上述三个透明窗口上沿的内壁面上部设有向上倾斜和真空室内壁成30°角的挡板17并且挡板17的两端分别比窗口边缘突出2cm,在和三个透明窗口同一个水平面上,且离第一个透明窗口9和第二个透明窗口7的距离分别为10cm处的真空室外的位置上放置包括数据采集及处理系统的PDA测量系统。In order to prevent the mist on the inner wall from sliding onto the transparent window and affect the measurement results, a

在真空室13的底部中央开有一个直径20cm,向下突出5cm的蓄液管段12,经底部法兰11及螺栓和排水管道固定在一起,排水管道上通过手动球阀10和大气连通。Have a diameter 20cm in the center of the bottom of the

真空室下面设置了支架18以支撑真空室。A

本实施例中供水系统采用有添加剂(如NaCl、KCl)的自来水,喷头为5孔喷头,激光器采用的是晶体光纤激光器。In this embodiment, the water supply system uses tap water with additives (such as NaCl, KCl), the nozzle is a 5-hole nozzle, and the laser uses a crystal fiber laser.

实验时,先检查各阀门是否均已关闭,打开和抽气孔相连的手动球阀5,启动真空泵S2,到真空压力表1上显示的数据满足实验条件时,关闭真空泵S2和与抽气孔相连的手动球阀5;开启和细水雾喷头相连的手动球阀4与供水系统S1,细水雾喷头3开始喷水雾;延迟一段时间,等水雾弥散开后,开启PDA测量系统S3。During the experiment, first check whether all the valves are closed, open the

激光器m4发射的激光经基准彩色脉冲器m5过滤后,分别经两个发射探头m6a和m6b发射的两束垂直激光分别通过第一、第二两个互相垂直的透明窗口7、9进入真空室13,穿过水雾在一点聚焦后,经雾滴粒子放大和折射后在第三个透明窗口6的激光接收探头m2被接收,经传输光纤m3、色调一致设定仪m8和滤波器m9进入信号处理器m10,然后经计算机m11记录并打印出透明窗口6处的雾特性数据;数据采集完成,依次关闭PDA测量系统S3和供水系统S1,关闭所有阀门,打开排水管的手动球阀10,排出积水。The laser light emitted by the laser m4 is filtered by the reference color pulser m5, and the two vertical laser beams emitted by the two emission probes m6a and m6b respectively enter the

本发明的实验装置,其真空室也可采用不锈钢长方体形,在真空室器壁的壁面中部设置透明观察窗口。In the experimental device of the present invention, its vacuum chamber also can adopt the shape of a stainless steel cuboid, and a transparent observation window is set in the middle of the wall surface of the vacuum chamber wall.

Claims (3)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010101652324ACN101865786B (en) | 2010-04-30 | 2010-04-30 | Experimental apparatus for measuring spray characteristics under low air pressure condition |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010101652324ACN101865786B (en) | 2010-04-30 | 2010-04-30 | Experimental apparatus for measuring spray characteristics under low air pressure condition |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101865786Atrue CN101865786A (en) | 2010-10-20 |

| CN101865786B CN101865786B (en) | 2012-01-25 |

Family

ID=42957592

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010101652324AExpired - Fee RelatedCN101865786B (en) | 2010-04-30 | 2010-04-30 | Experimental apparatus for measuring spray characteristics under low air pressure condition |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101865786B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102506765A (en)* | 2011-10-21 | 2012-06-20 | 中国航空动力机械研究所 | Device for measuring spray cone angle |

| CN104089651A (en)* | 2014-07-06 | 2014-10-08 | 长春理工大学 | Smog environment simulation device for testing polarization laser transmission features |

| CN110146266A (en)* | 2019-05-21 | 2019-08-20 | 中国民用航空飞行学院 | Test method for flow coefficient of high-pressure water mist nozzles in hangars |

| WO2024021052A1 (en)* | 2022-07-25 | 2024-02-01 | 北京航空航天大学 | Fuel atomization performance testing apparatus |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5162863A (en)* | 1988-02-15 | 1992-11-10 | Canon Kabushiki Kaisha | Method and apparatus for inspecting a specimen by optical detection of antibody/antigen sensitized carriers |

| JP4183668B2 (en)* | 2004-09-02 | 2008-11-19 | 三菱重工業株式会社 | Apparatus and method for measuring nanoparticles in gas |

| CN201673116U (en)* | 2010-04-30 | 2010-12-15 | 中国科学技术大学 | An experimental setup for measuring spray characteristics under low air pressure conditions |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SU1701012A1 (en)* | 1989-11-01 | 1995-11-20 | Всесоюзный научно-исследовательский институт молекулярной биологии Научно-производственного объединения "Вектор" | Aerosol analyzer |

- 2010

- 2010-04-30CNCN2010101652324Apatent/CN101865786B/ennot_activeExpired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5162863A (en)* | 1988-02-15 | 1992-11-10 | Canon Kabushiki Kaisha | Method and apparatus for inspecting a specimen by optical detection of antibody/antigen sensitized carriers |

| JP4183668B2 (en)* | 2004-09-02 | 2008-11-19 | 三菱重工業株式会社 | Apparatus and method for measuring nanoparticles in gas |

| CN201673116U (en)* | 2010-04-30 | 2010-12-15 | 中国科学技术大学 | An experimental setup for measuring spray characteristics under low air pressure conditions |

Non-Patent Citations (1)

| Title |

|---|

| 《量子电子学报》 20010601 秦俊 细水雾流场三维LDV测量 281-284 1-3 第18卷, 第3期 2* |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102506765A (en)* | 2011-10-21 | 2012-06-20 | 中国航空动力机械研究所 | Device for measuring spray cone angle |

| CN102506765B (en)* | 2011-10-21 | 2014-03-26 | 中国航空动力机械研究所 | Device for measuring spray cone angle |

| CN104089651A (en)* | 2014-07-06 | 2014-10-08 | 长春理工大学 | Smog environment simulation device for testing polarization laser transmission features |

| CN110146266A (en)* | 2019-05-21 | 2019-08-20 | 中国民用航空飞行学院 | Test method for flow coefficient of high-pressure water mist nozzles in hangars |

| CN110146266B (en)* | 2019-05-21 | 2021-04-02 | 中国民用航空飞行学院 | Method for testing flow coefficient of high-pressure water mist spray head of hangar |

| WO2024021052A1 (en)* | 2022-07-25 | 2024-02-01 | 北京航空航天大学 | Fuel atomization performance testing apparatus |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101865786B (en) | 2012-01-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201673116U (en) | An experimental setup for measuring spray characteristics under low air pressure conditions | |

| CN202599852U (en) | Identification and measurement device of bubbles in gas-liquid two-phase bubble flow | |

| CN101865786A (en) | An experimental setup for measuring spray characteristics under low air pressure conditions | |

| CN113324727A (en) | Schlieren image processing method for compressed corner supersonic flow field structure | |

| CN104777093B (en) | A kind of thin liquid film in-situ testing device being used under microcorrosion atmosphere | |

| CN106226031A (en) | The experimental provision of particle-wall collision experiment in resisting medium | |

| CN114354290A (en) | Device and method for dynamically measuring greenhouse gas emission flux of water body | |

| CN211855745U (en) | Cylinder leakproofness detection device | |

| US20190301982A1 (en) | Shower/safety shower/fire sprinkler testing device | |

| CN111307404B (en) | Test device and test method for internal flow field of jet fan | |

| CN102914522A (en) | Gas-liquid combined laser induced breakdown spectroscopy detection device and method | |

| CN206002281U (en) | Experimental provision for particle-wall collision experiment in resisting medium | |

| CN101509822A (en) | Light organic petrochemicals water cooler leakage on-line monitoring method and instrument | |

| CN206818610U (en) | A kind of EISD | |

| CN117589643A (en) | System for studying solid particle removal patterns in pipelines and methods of use | |

| CN204705387U (en) | Blowing type liquid level measuring instrument | |

| CN115371953B (en) | A multifunctional ejector experimental test research device | |

| CN207096046U (en) | A kind of low concentrations of particulates thing measuring instrument suitable for wet flue gas | |

| CN206045990U (en) | A kind of aerosol generator based on venturi principle | |

| CN211263263U (en) | A measurement device for atmospheric contact with frozen cores | |

| CN116008141A (en) | A dual-channel fog droplet spectrometer | |

| CN2789734Y (en) | Pisten slope measuring device for gas storing box | |

| CN104089928B (en) | A kind of cryogen visualizing monitor device based on laser interferance method | |

| CN117490780A (en) | Methane escape amount detection method and device | |

| CN209372640U (en) | A kind of gaseous environment detection auxiliary device and gas ambient scene detector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120125 Termination date:20160430 |