CN101804918A - Dual-channel adjustable pebble coal feeding device - Google Patents

Dual-channel adjustable pebble coal feeding deviceDownload PDFInfo

- Publication number

- CN101804918A CN101804918ACN 201010117923CN201010117923ACN101804918ACN 101804918 ACN101804918 ACN 101804918ACN 201010117923CN201010117923CN 201010117923CN 201010117923 ACN201010117923 ACN 201010117923ACN 101804918 ACN101804918 ACN 101804918A

- Authority

- CN

- China

- Prior art keywords

- pebble coal

- air inlet

- plate

- housing

- shell

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000003245coalSubstances0.000titleclaimsabstractdescription59

- 239000000463materialSubstances0.000claimsabstractdescription32

- 239000004575stoneSubstances0.000claimsdescription3

- 238000009423ventilationMethods0.000claims2

- 238000007599dischargingMethods0.000claims1

- 230000001105regulatory effectEffects0.000abstractdescription10

- 239000002245particleSubstances0.000abstractdescription7

- 238000000034methodMethods0.000description4

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description1

- 238000003491arrayMethods0.000description1

- 229910052799carbonInorganic materials0.000description1

- -1comes from gangueSubstances0.000description1

- 238000012423maintenanceMethods0.000description1

- 238000005192partitionMethods0.000description1

- NIFIFKQPDTWWGU-UHFFFAOYSA-NpyriteChemical compound[Fe+2].[S-][S-]NIFIFKQPDTWWGU-UHFFFAOYSA-N0.000description1

- 229910052683pyriteInorganic materials0.000description1

- 239000011028pyriteSubstances0.000description1

Images

Landscapes

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种用于火电厂石子煤气力输送系统中的物料输送部件,具体是一种双通道可调节型石子煤进料装置。The invention relates to a material conveying component used in a pebble coal pneumatic conveying system in a thermal power plant, in particular to a dual-channel adjustable pebble coal feeding device.

背景技术Background technique

中速磨煤机由于投资少、经济性好在火电厂得到大量应用。中速磨煤机在运行过程中会产生石子煤。石子煤主要来源于原煤中密度较大、难磨的矸石、黄铁矿等,它在磨煤机运行时从其下部的石子煤排放口排出。石子煤需要及时排放,如果石子煤排放不及时,在磨煤机内大量堆积,容易造成刮板、炭精密封磨损或脱落,堆积的石子煤还会堵塞风道,在热风的作用下着火,烧损风道、刮板和石子煤箱等磨煤机部件,造成磨煤机故障停运。Medium-speed coal mills are widely used in thermal power plants due to their low investment and good economy. The medium-speed coal mill will produce pebble coal during operation. The pebble coal mainly comes from gangue, pyrite, etc., which are dense and difficult to grind in the raw coal, and it is discharged from the pebble coal discharge port at the lower part of the coal mill when it is running. The pebble coal needs to be discharged in time. If the pebble coal is not discharged in time, it will accumulate in a large amount in the coal mill, which will easily cause the scraper and carbon seal to wear or fall off. The accumulated pebble coal will also block the air duct and catch fire under the action of hot air. The coal mill components such as the air duct, scraper and stone coal box were burned, causing the coal mill to fail and stop operating.

常见的石子煤排放有人工排放、水力排放、机械输送排放等形式。目前,由于电厂煤种多变,原煤煤质普遍变差,原煤中石头、矸石、矿石等杂物较以前增多,石子煤排放量大大增加,严重影响火电厂的安全运行,常规石子煤排放方式都难以解决目前石子煤量大大增加的问题。Common pebble coal discharges include artificial discharge, hydraulic discharge, and mechanical transportation discharge. At present, due to the variety of coal types in power plants, the quality of raw coal generally deteriorates. The amount of stones, gangue, ore and other sundries in raw coal has increased compared with before, and the discharge of pebble coal has greatly increased, which seriously affects the safe operation of thermal power plants. Conventional pebble coal discharge methods It is difficult to solve the problem that the amount of pebble coal increases greatly at present.

近期国内少数电厂对石子煤处理采用了气力输送系统。用运动的气流为介质输送物料,是工业上早已使用的运输方法,称为气力输送。气力输送系统的优点是:设备构造简单,输送效率高、劳动卫生条件好。气力输送的输送管道,便于因地制宜地设置管网,布置简便灵活,可以充分利用车间面积,易于适应车间环境。Recently, a small number of power plants in China have adopted pneumatic conveying systems for the treatment of pebble coal. Using moving air as the medium to convey materials is a transportation method that has long been used in industry, and is called pneumatic conveying. The advantages of the pneumatic conveying system are: simple equipment structure, high conveying efficiency, and good labor hygiene conditions. The conveying pipeline for pneumatic conveying is convenient to set up the pipe network according to local conditions, the layout is simple and flexible, it can make full use of the workshop area, and it is easy to adapt to the workshop environment.

但目前实际应用于石子煤输送的气力输送系统存在很多问题,主要为:However, there are many problems in the pneumatic conveying system actually applied to the transportation of pebble coal, mainly as follows:

1、输送能力不足。气力输送系统石子煤的进料装置主要采用螺旋给料机,螺旋给料机给料速度非常有限,在石子煤量大的情况下,无法将石子煤及时输送走;1. Insufficient conveying capacity. The feeding device of the pebble coal in the pneumatic conveying system mainly adopts the screw feeder, and the feeding speed of the screw feeder is very limited. In the case of a large amount of pebble coal, the pebble coal cannot be transported away in time;

2、无法输送大粒径物料。石子煤中粒径较大的物料较多,螺旋给料机对于粒径大的石子煤无法输送,限制了气力输送系统的应用范围;2. Unable to convey large particle size materials. There are many materials with larger particle sizes in the pebble coal, and the screw feeder cannot transport the pebble coal with large particle size, which limits the application range of the pneumatic conveying system;

3、螺旋给料机作为转动件,在输送石子煤时非常容易发生故障,也容易磨损,经常需要检修,可靠性很差。3. As a rotating part, the screw feeder is very prone to failure and wear when conveying pebble coal. It often needs maintenance and has poor reliability.

发明内容Contents of the invention

本发明所要解决的技术问题是,提供一种结构简单、输送速度快、适应的石子煤粒径范围大、输送条件可调节、运行可靠性高的双通道可调节型石子煤进料装置。The technical problem to be solved by the present invention is to provide a dual-channel adjustable pebble coal feeding device with simple structure, fast conveying speed, wide range of suitable pebble coal particle sizes, adjustable conveying conditions, and high operational reliability.

本发明的双通道可调节型石子煤进料装置包括有一个壳体,壳体的顶部设置与石子煤料斗相通的进料口,壳体后端设置有进风口,壳体前端设置有与气力输送系统的负压管道相通的出料口;在进料口下方的壳体内腔中部设置有一个一级接料板,一级接料板与进风口之间设置有一个进风调节板,进风调节板前端与壳体铰接连接,使进风调节板与水平进风方向之间的夹角可调节并固定在不同角度位置。The double-channel adjustable pebble coal feeding device of the present invention includes a shell, the top of the shell is provided with a feed port communicating with the pebble coal hopper, the rear end of the shell is provided with an air inlet, and the front end of the shell is provided with an air inlet. The discharge port where the negative pressure pipes of the conveying system are connected; a first-level material receiving plate is arranged in the middle of the shell cavity below the material inlet, and an air inlet regulating plate is arranged between the first-level material receiving plate and the air inlet. The front end of the air regulating plate is hingedly connected with the housing, so that the included angle between the air inlet regulating plate and the horizontal air inlet direction can be adjusted and fixed at different angle positions.

所述一级接料板通过位于壳体两侧的插槽插装在壳体上,所述插槽由下至上设置有多组,使一级接料板可插装在不同的高度位置上。The first-stage material receiving plate is inserted into the housing through the slots on both sides of the housing, and the slots are arranged in multiple groups from bottom to top, so that the first-level material receiving plate can be inserted at different height positions .

所述一级接料板前下方还设置有一个二级接料板。A secondary material receiving plate is also arranged on the front and lower side of the first level material receiving plate.

本发明的优点是可使石子煤与空气从两个通道分别进入混合室,以防止石子煤过快下落形成堵塞;一级接料板通过插装在不同高度的插槽上,可改变石子煤流通面积,从而实现对不同粒径石子煤的进料,可以适应大粒径石子煤输送,二级分隔板可以使石子煤有初始速度且处于气流流速最高区域,有利于石子煤输送。空气由进风调节板分成两部分,一部分从壳体内腔下部通过,用于提供主要输送动力,一部分从一级接料板上部通过用于推动石子煤进入前端的混合腔,通过调节进风调节板开度可以改变两部分风的比例,调节输送空气与石子煤的比例从而改变系统输送能力。该装置没有采用任何转动件,运行可靠性高,不易磨损。The advantage of the present invention is that the pebble coal and air can enter the mixing chamber respectively from two passages, so as to prevent the pebble coal from falling too fast to form a blockage; The flow area is large, so as to realize the feeding of pebble coal with different particle sizes, which can adapt to the transportation of large-size pebble coal. The two-stage partition plate can make the pebble coal have an initial velocity and be in the highest air flow area, which is conducive to the transportation of pebble coal. The air is divided into two parts by the air inlet adjustment plate, one part passes through the lower part of the inner cavity of the shell to provide the main conveying power, and the other part passes through the upper part of the primary material receiving plate to push the pebble coal into the mixing chamber at the front end, and is adjusted by adjusting the air inlet. The opening of the plate can change the ratio of the two parts of the air, and adjust the ratio of conveying air to pebble coal to change the conveying capacity of the system. The device does not use any rotating parts, has high operating reliability and is not easy to wear.

附图说明Description of drawings

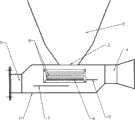

图1是本发明的结构示意图。Fig. 1 is a schematic structural view of the present invention.

具体实施方式Detailed ways

附图标记包括:壳体1、石子煤料斗2、进料口3、进风口4、出料口5、一级接料板6、二级接料板7、插槽8、进风调节板9。The reference signs include: shell 1,

如图所示,本发明的进料装置的运行过程是:石子煤料斗2内的石子煤从进料口3进入壳体1内,落在一级接料板6上,一级接料板6插在壳体两侧的插槽8上,插槽根据与进料口距离不同布置有数组,一级接料板6通过插在不同的插槽8而改变石子煤流通面积,从而实现对不同粒径石子煤的进料,空气由进风口4进入,由进风调节板9分成两部分,一部分从一级接料板6下部通过到达出料口用于气力输送,一部分在一级接料板6上部用于推动石子煤到达出料口;通过调节进风调节板9的开度可以改变两部分风的比例,从而改变系统输送能力,将进风调节板9开度开大可以增加下部输送风量、减少上部推动风量从而降低输送量,将进风调节板调节板9开度关小可以减少下部输送风量、增加上部推动风量从而增加输送量;最后石子煤从一级接料板6落到二级接料板7上与气流混合从出料口5流出。As shown in the figure, the operation process of the feeding device of the present invention is: the pebble coal in the

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010101179237ACN101804918B (en) | 2010-03-05 | 2010-03-05 | Dual-channel adjustable pebble coal feeding device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010101179237ACN101804918B (en) | 2010-03-05 | 2010-03-05 | Dual-channel adjustable pebble coal feeding device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101804918Atrue CN101804918A (en) | 2010-08-18 |

| CN101804918B CN101804918B (en) | 2012-07-04 |

Family

ID=42606907

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010101179237AExpired - Fee RelatedCN101804918B (en) | 2010-03-05 | 2010-03-05 | Dual-channel adjustable pebble coal feeding device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101804918B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105173737A (en)* | 2015-08-13 | 2015-12-23 | 郑州三迪建筑科技有限公司 | Powder and granular material positive-pressure conveying pump |

| CN112758639A (en)* | 2020-12-22 | 2021-05-07 | 中国矿业大学(北京) | Method for reducing initial pressure at bottom of large-scale storage bin |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3807807A (en)* | 1971-05-10 | 1974-04-30 | Eastern Cyclone Ind Inc | Feeding device for bulk material to a pneumatic conveying system |

| WO1991000234A1 (en)* | 1989-06-24 | 1991-01-10 | M & Y Air Systems Limited | Material discharge unit |

| CN2706446Y (en)* | 2004-05-27 | 2005-06-29 | 李蔓球 | Air powder mixer |

| CN201313067Y (en)* | 2008-12-03 | 2009-09-23 | 江苏中能电力设备有限公司 | Negative pressure conveying system for pebble coal |

| CN201320501Y (en)* | 2008-10-22 | 2009-10-07 | 毛恒松 | Pebble coal air-drive cleaning apparatus |

| CN201619881U (en)* | 2010-03-05 | 2010-11-03 | 江苏中能电力设备有限公司 | A double-channel adjustable pebble coal feeding device |

- 2010

- 2010-03-05CNCN2010101179237Apatent/CN101804918B/ennot_activeExpired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3807807A (en)* | 1971-05-10 | 1974-04-30 | Eastern Cyclone Ind Inc | Feeding device for bulk material to a pneumatic conveying system |

| WO1991000234A1 (en)* | 1989-06-24 | 1991-01-10 | M & Y Air Systems Limited | Material discharge unit |

| CN2706446Y (en)* | 2004-05-27 | 2005-06-29 | 李蔓球 | Air powder mixer |

| CN201320501Y (en)* | 2008-10-22 | 2009-10-07 | 毛恒松 | Pebble coal air-drive cleaning apparatus |

| CN201313067Y (en)* | 2008-12-03 | 2009-09-23 | 江苏中能电力设备有限公司 | Negative pressure conveying system for pebble coal |

| CN201619881U (en)* | 2010-03-05 | 2010-11-03 | 江苏中能电力设备有限公司 | A double-channel adjustable pebble coal feeding device |

Non-Patent Citations (1)

| Title |

|---|

| 《制冷空调与电力机械》 20080831 张森 浅谈火力发电厂石子煤收集系统 第88页-第91页 1-3 第29卷, 第122期 2* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105173737A (en)* | 2015-08-13 | 2015-12-23 | 郑州三迪建筑科技有限公司 | Powder and granular material positive-pressure conveying pump |

| CN112758639A (en)* | 2020-12-22 | 2021-05-07 | 中国矿业大学(北京) | Method for reducing initial pressure at bottom of large-scale storage bin |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101804918B (en) | 2012-07-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201437476U (en) | Pebble Coal Unloading Negative Pressure Pneumatic Conveying System | |

| CN201721974U (en) | Micro-positive low pressure continuous pneumatic convey device | |

| CN201619881U (en) | A double-channel adjustable pebble coal feeding device | |

| CN102784757B (en) | Efficient airflow classification fine-coal remover for power coal before selecting | |

| CN202704570U (en) | Pneumatic conveying and supplying generator | |

| CN106185368A (en) | A kind of coal dust feeding device | |

| CN102923485A (en) | Efficient positive-pressure pneumatic conveying system of pebble coal | |

| CN101804918B (en) | Dual-channel adjustable pebble coal feeding device | |

| CN202935946U (en) | Efficient positive-pressure pneumatic conveying system of pebble coal | |

| CN115339906A (en) | A high-temperature powder feeding device, method and metallurgical production line | |

| CN101804380B (en) | High-efficiency environment-friendly type negative-pressure pneumatic transmission system for pebble coal | |

| CN202784855U (en) | Pebble coal feeding device having separation function | |

| CN203229205U (en) | Turbulence delivery double-sleeve combination | |

| CN201603602U (en) | A high-efficiency and environment-friendly pebble coal negative pressure pneumatic conveying system | |

| CN202784856U (en) | Power air trough conveyor | |

| CN203794222U (en) | Pneumatic conveying device and dust conveying device using same | |

| CN202912388U (en) | Rapid delivery device of powder materials | |

| CN201619819U (en) | A self-adaptive pebble coal feeding device | |

| CN202935943U (en) | Dual adjustable pebble coal positive pressure force feeding device | |

| CN206747028U (en) | A kind of wood powder wind send removal of impurities separator | |

| CN201694657U (en) | Boosting-type automatic block-proof device of pneumatic ash conveying system | |

| CN218260832U (en) | Pneumatic conveying system | |

| CN205011034U (en) | Strength slagging -off conveying system | |

| CN105149070B (en) | A kind of Geldart-D particle for producing no vanadium rare-earth-based titanium tungsten powder, fine grinding system | |

| CN202725501U (en) | Fines removal all-in-one machine used for dry-method classification before steam coal preparation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120704 Termination date:20160305 |