CN101798924A - Icebound type pressure-maintaining and temperature-preserving sampler - Google Patents

Icebound type pressure-maintaining and temperature-preserving samplerDownload PDFInfo

- Publication number

- CN101798924A CN101798924ACN201010131896ACN201010131896ACN101798924ACN 101798924 ACN101798924 ACN 101798924ACN 201010131896 ACN201010131896 ACN 201010131896ACN 201010131896 ACN201010131896 ACN 201010131896ACN 101798924 ACN101798924 ACN 101798924A

- Authority

- CN

- China

- Prior art keywords

- valve

- joint

- circulation pipe

- valve seat

- preserving

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000007789sealingMethods0.000claimsabstractdescription23

- 239000007788liquidSubstances0.000claimsabstractdescription20

- 238000007710freezingMethods0.000claimsabstractdescription8

- 230000008014freezingEffects0.000claimsabstractdescription8

- 239000011435rockSubstances0.000claimsdescription24

- 238000010079rubber tappingMethods0.000claims3

- 238000005553drillingMethods0.000abstractdescription26

- 238000005070samplingMethods0.000abstractdescription17

- 239000003507refrigerantSubstances0.000abstractdescription11

- 238000011065in-situ storageMethods0.000abstractdescription5

- 238000000034methodMethods0.000abstractdescription4

- 238000011084recoveryMethods0.000abstractdescription4

- 239000012535impuritySubstances0.000abstractdescription2

- 239000007787solidSubstances0.000abstractdescription2

- 239000000110cooling liquidSubstances0.000description7

- NMJORVOYSJLJGU-UHFFFAOYSA-Nmethane clathrateChemical compoundC.C.C.C.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.O.ONMJORVOYSJLJGU-UHFFFAOYSA-N0.000description7

- 238000009413insulationMethods0.000description4

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneNatural productsCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000description4

- 238000011010flushing procedureMethods0.000description3

- 239000003345natural gasSubstances0.000description3

- 238000004321preservationMethods0.000description3

- 238000003860storageMethods0.000description3

- 230000009286beneficial effectEffects0.000description2

- 238000013461designMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 239000000203mixtureSubstances0.000description2

- -1natural gas hydratesChemical class0.000description2

- CURLTUGMZLYLDI-UHFFFAOYSA-NCarbon dioxideChemical compoundO=C=OCURLTUGMZLYLDI-UHFFFAOYSA-N0.000description1

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description1

- 241000282414Homo sapiensSpecies0.000description1

- 235000011089carbon dioxideNutrition0.000description1

- 239000003245coalSubstances0.000description1

- 238000001816coolingMethods0.000description1

- 230000006378damageEffects0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000011161developmentMethods0.000description1

- 238000010586diagramMethods0.000description1

- 238000009826distributionMethods0.000description1

- 230000000694effectsEffects0.000description1

- 239000012530fluidSubstances0.000description1

- 238000010438heat treatmentMethods0.000description1

- 238000012423maintenanceMethods0.000description1

- 239000003921oilSubstances0.000description1

- 239000000843powderSubstances0.000description1

- 238000011160researchMethods0.000description1

Images

Landscapes

- Investigation Of Foundation Soil And Reinforcement Of Foundation Soil By Compacting Or Drainage (AREA)

- Sampling And Sample Adjustment (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域:Technical field:

本发明涉及一种钻探取样机具,尤其是天然气水合物钻探取样用的保压保温取样钻具。The invention relates to a drilling and sampling tool, in particular to a pressure-preserving and heat-retaining sampling drilling tool for natural gas hydrate drilling and sampling.

背景技术Background technique

天然气水合物具有分布广、储量巨大、能量密度高等特点,是人类未来的潜在洁净新能源,对全球环境和海洋钻井生产安全有重要影响。专家初步估算我国天然气水合物蕴含的总能量约为境内已知石油、天然气和煤炭能量之和的1倍以上,勘探开发天然气水合物意义重大。Natural gas hydrate has the characteristics of wide distribution, huge reserves, and high energy density. It is a potential clean new energy for human beings in the future, and has an important impact on the global environment and the safety of marine drilling production. Experts preliminarily estimate that the total energy contained in natural gas hydrates in my country is more than twice the sum of the energy of known oil, natural gas and coal in the country. The exploration and development of natural gas hydrates is of great significance.

天然气水合物的特殊形态决定了其稳定存在需要高压低温条件,要求钻探取样钻具具有保压保温功能。国内外现有保压钻具采用球阀或板阀等机械结构关闭取样钻具下部端口,从而实现保压功能,存在的突出问题是,球阀或板阀常常难以正常关闭,从而不能正常发挥保压功能,发挥保压功能的次数占总取样次数的比例不到60%,可靠性差;而且,球阀或板阀在设计上占用较大的径向尺寸,因而天然气水合物岩心直径较小而容易被破坏,造成岩心采取率较低,往往不到50%,不能很好地满足天然气水合物勘探要求和科学研究需要。The special form of natural gas hydrate determines that its stable existence requires high-pressure and low-temperature conditions, and the drilling tools for drilling and sampling are required to have the function of maintaining pressure and heat preservation. The existing pressure-holding drilling tools at home and abroad use mechanical structures such as ball valves or plate valves to close the lower port of the sampling drilling tool, so as to realize the pressure-holding function. The outstanding problem is that the ball valve or plate valve is often difficult to close normally, so that the pressure-holding cannot be performed normally. function, the number of times the function of maintaining pressure accounts for less than 60% of the total sampling times, and the reliability is poor; moreover, the ball valve or plate valve occupies a large radial dimension in design, so the diameter of the gas hydrate core is small and it is easy to be Destruction, resulting in a low core recovery rate, often less than 50%, which cannot well meet the requirements of gas hydrate exploration and scientific research.

发明内容:Invention content:

本发明的目的就在于针对上述现有技术的不足,提供一种具有良好保压保温功能的冰封式保压保温取样器。The object of the present invention is to address the above-mentioned deficiencies in the prior art, and provide an ice-sealed pressure-preserving and heat-preserving sampler with good pressure-preserving and heat-preserving functions.

本发明的目的是通过以下技术方案实现的:The purpose of the present invention is achieved through the following technical solutions:

冰封式保压保温取样器,是由钻进/取样切换机构、冷冻液循环系统、泥浆冰阀和岩心阀原位生成机构、岩心容纳管单动机构和通道I、II、III、IV、V、VI构成;The ice-sealed pressure-preserving and heat-preserving sampler is composed of a drilling/sampling switching mechanism, a refrigerant circulation system, a mud ice valve and a core valve in-situ generating mechanism, a single-action mechanism for a core holding tube and channels I, II, III, IV, V, VI composition;

钻进/取样切换机构:是由异径接头1通过螺纹与分流阀座2连接,分流阀座2通过螺纹与折返接头8连接,折返接头8通过螺纹与外管17连接,分流阀阀心6插入分流阀座2并通过挡圈3和分流阀弹簧7定位;Drilling/sampling switching mechanism: the different-diameter joint 1 is connected to the

冷冻液循环系统:是由外缸14插入折返接头8内并用密封圈密封,外缸14通过螺纹与外泵体20连接,下缸盖16、缸体13、上缸盖12、射流元件11及垫片10自下而上依次插入外缸14中并在需要位置用密封圈密封,潜孔锤上接头9通过螺纹连接到外缸14的最上部,潜孔锤活塞15沿缸体13、下缸盖16、外泵体20内壁滑动形成滑动副,往复泵活塞18与外泵体20间用密封圈密封,内泵体22、排液阀阀座25、进液阀阀座28自上而下依次插入外泵体20中并通过外泵体20的凸台进行定位,排液阀阀心24插入到排液阀阀座25中形成滑动副,进液阀阀心27插入到进液阀阀座28中形成滑动副,冷冻液保温容器32通过螺纹连接到外泵体20上,吸液管30通过螺纹连接到进液阀阀座28上,上外循环管29、上内循环管31通过螺纹连接到外泵体20上;Refrigerating liquid circulation system: the outer cylinder 14 is inserted into the

泥浆冰阀和岩心阀原位生成机构:是由上部冰阀生成机构,岩心容纳管上部的排水杆34插入带有内部环槽的循环管接头33中,并通过螺纹连接,且在循环管接头与排水杆用密封圈密封;下部“岩心阀”生成机构,下外循环管40、下内循环管41通过螺纹连接到循环管接头33上,下端盖44通过螺纹连接到下外循环管40上,且其与岩心容纳管下端42连接处用密封圈密封;Mud ice valve and core valve in-situ generating mechanism: it is the upper ice valve generating mechanism, the

岩心容纳管单动机构:是由推力轴承37套在排水杆上,并由球阀座39和岩心容纳管上接头36固定,球阀座与排水杆下端通过螺纹连接,且在岩心容纳管上接头内侧用Yx密封圈密封。The single-action mechanism of the rock core holding pipe: the thrust bearing 37 is set on the drain rod, and is fixed by the

本发明的目的还可以通过以下技术方案实现:The purpose of the present invention can also be achieved through the following technical solutions:

通道I是由分流阀座2贯通孔道与折返接头8内通道,外管17与相邻循环管够成的环状间隙组成。Channel I is made up of the through channel of the

通道II:由分流阀座2的贯通孔道及潜孔锤上接头9和垫片10的中心孔道组成。Channel II: It consists of the through channel of the

通道III:由内泵体22的径向通孔,外泵体20的贯通孔道,上内循环管31和冷冻液保温容器32构成的环状间隙,循环管接头33的内环状内腔和贯通孔道,下内循环管41和岩心容纳管42构成的环状间隙组成。Channel III: the radial through hole of the inner pump body 22, the through hole of the outer pump body 20, the annular gap formed by the upper

通道IV:由进液阀阀座28的贯通孔道,外泵体20的贯通孔道,上外循环管29和上内循环管31构成的环状间隙,循环管接头33的贯通孔道,下外循环管40和下内循环管41构成的环状间隙组成。Channel IV: the through hole of the inlet valve seat 28, the through hole of the outer pump body 20, the annular gap formed by the upper

通道V:由排水杆34的中心孔道和循环管接头33的径向通孔组成。Channel V: composed of the central channel of the

通道VI:由折返接头8的径向通孔组成。Channel VI: consists of the radial through-holes of the

有益效果:本发明改变现有的保压取样钻具的设计思路,以冻结生成的冰阀和岩心阀代替球阀或板阀等机械阀门关闭取样钻具上下部端口,不需要精密的配合表面,关闭过程不受孔内固体杂质的影响,可靠性高,解决了现有机械阀门启动困难、配合表面精密度高、容易被孔内杂物卡塞而不易关闭等问题,提高了保压可靠性和成功率,且径向尺寸可以较小,有利于获得较大直径的岩心,从而有利于提高水合物岩心采取率。实验结果表明,冰阀可以可靠实现25MPa的密封,因此采用冰阀结构适用于孔内液柱达2500米的水合物钻孔,完全可以满足在我国海洋和陆地永冻带水合物钻井取样对密封压力的要求。在地面制作低温冷冻液并将其存放于钻具中的冷冻液保温容器中,当需要保压取样时,启动潜孔往复泵驱动冷冻液循环,冷冻液流经循环管接头下部环槽时,对岩心容纳管上部排水杆内的泥浆有冷却作用,逐渐将其冻结形成泥浆冰阀,冷冻液继续下行在岩心容纳管下端通过换热窗口冷却岩心根部一小段,将其与泥浆冻结形成岩心阀,从而实现密封保压,免去了干冰在钻具内的存放和与酒精的混合过程,有利于腾出径向尺寸增大岩心直径;冷冻液的存放可以充分利用钻具的轴向尺寸,存放量容易做到完全充足,保证制作做够长、温度足够低的泥浆冰阀和岩心阀需要;冷冻液循环时间可控并且可多次启动和中止循环,可保证泥浆冰阀和岩心阀从孔底到地面始终可靠存在和有效密封,所有这些特点可以有效保证天然气水合物保压取样的成功率和岩心采取率。采用液动潜孔锤驱动往复泵,充分利用了泥浆作为动力介质,避免了采用电气结构带来的复杂性,简单可靠。Beneficial effects: the present invention changes the design idea of the existing pressure-holding sampling drilling tool, replaces mechanical valves such as ball valves or plate valves with ice valves and core valves generated by freezing to close the upper and lower ports of the sampling drilling tool, and does not require precise matching surfaces. The closing process is not affected by solid impurities in the hole, and the reliability is high. It solves the problems of the existing mechanical valves, such as difficulty in starting, high precision of the matching surface, easy to be blocked by debris in the hole and difficult to close, etc., and improves the reliability of pressure holding. and the success rate, and the radial size can be smaller, which is beneficial to obtain a larger diameter core, thereby helping to improve the recovery rate of hydrate cores. The experimental results show that the ice valve can reliably achieve a seal of 25MPa. Therefore, the ice valve structure is suitable for hydrate drilling with a liquid column in the hole of 2500 meters, which can fully meet the sealing requirements of hydrate drilling sampling in my country's oceans and land permafrost zones. pressure requirements. Make low-temperature freezing liquid on the ground and store it in the cooling liquid insulation container in the drilling tool. When it is necessary to maintain pressure and take samples, start the submersible reciprocating pump to drive the cooling liquid circulation. When the cooling liquid flows through the lower ring groove of the circulation pipe joint, It has a cooling effect on the mud in the drain rod on the upper part of the core holding pipe, and gradually freezes it to form a mud ice valve. The freezing liquid continues to descend at the lower end of the core holding pipe through the heat exchange window to cool a short section of the root of the core, and freezes it with the mud to form a core valve. , so as to achieve sealing and pressure maintenance, eliminating the storage of dry ice in the drilling tool and the mixing process with alcohol, which is conducive to freeing up the radial dimension to increase the core diameter; the storage of refrigerant can make full use of the axial dimension of the drilling tool, The storage capacity is easy to be completely sufficient to ensure the production of mud ice valves and core valves that are long enough and low enough in temperature; the cycle time of the refrigerant is controllable and the cycle can be started and stopped multiple times to ensure that the mud ice valves and core valves are kept from There is always reliable existence and effective sealing from the bottom of the hole to the surface. All these features can effectively ensure the success rate of gas hydrate pressure-holding sampling and the rate of core recovery. The hydraulic down-the-hole hammer is used to drive the reciprocating pump, which makes full use of the mud as the power medium, avoids the complexity brought by the electrical structure, and is simple and reliable.

附图说明:Description of drawings:

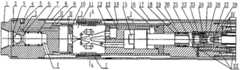

附图1为冰封式保压保温取样器结构图Accompanying drawing 1 is the structural diagram of ice-packed pressure-preserving and heat-preserving sampler

附图2为附图1A-A剖面射流元件断面图。Accompanying

1异径接头,2分流阀座,3挡圈,4弹子球,5丝堵,6分流阀阀心,7分流阀弹簧,8折返接头,9潜孔锤上接头,10垫片,11射流元件,12上缸盖,13缸体,14外缸,15潜孔锤活塞,16下缸盖,17外管,18往复泵活塞,19刮尘圈,20外泵体,21堵头,22内泵体,23排液阀弹簧,24排液阀阀心,25排液阀阀座,26进液阀弹簧,27进液阀阀心,28进液阀阀座,29上外循环管,30吸液管,31上内循环管,32冷冻液保温容器,33循环管接头,34排水杆35密封圈,36岩心容纳管上接头,37推力轴承,38球阀,39球阀座,40下外循环管,41下内循环管,42岩心容纳管,43螺旋内腔,44下端盖,45钻头1 different diameter joint, 2 diverter valve seat, 3 retaining ring, 4 pinball, 5 plug, 6 diverter valve core, 7 diverter valve spring, 8 return joint, 9 down-the-hole hammer upper joint, 10 gasket, 11 jet Components, 12 Upper cylinder head, 13 Cylinder body, 14 Outer cylinder, 15 DTH hammer piston, 16 Lower cylinder head, 17 Outer pipe, 18 Reciprocating pump piston, 19 Scraper ring, 20 Outer pump body, 21 Plug, 22 Inner pump body, 23 discharge valve spring, 24 discharge valve core, 25 discharge valve seat, 26 inlet valve spring, 27 inlet valve core, 28 inlet valve seat, 29 upper external circulation pipe, 30 suction pipe, 31 upper internal circulation pipe, 32 cooling liquid insulation container, 33 circulation pipe joint, 34

I-正常钻进时的泥浆通道;II-高压泥浆进入潜孔往复泵的通道;III-低温冷冻液流向下内循环管41下端的通道;IV-冷冻液从下内循环管41下端流回冷冻液保温容器的通道;V-岩芯管回水通道;VI-低压泥浆从射流元件排空孔流向钻具与井壁环状间隙的通道。I-the mud channel during normal drilling; II-the channel where the high-pressure mud enters the submersible reciprocating pump; III-the channel where the low-temperature refrigerant flows to the lower end of the lower

具体实施方式:Detailed ways:

下面结合附图和实施例作进一步详细说明:Below in conjunction with accompanying drawing and embodiment describe in further detail:

附图1a的右端接附图1b的左端构成完整的冰封式保压保温取样器。The right end of accompanying drawing 1a is connected with the left end of accompanying drawing 1b to form a complete ice-sealed pressure-preserving and heat-preserving sampler.

冰封式保压保温取样器,是由钻进/取样切换机构、冷冻液循环系统、泥浆冰阀和岩心阀原位生成机构、岩心容纳管单动机构和通道I、II、III、IV、V、VI构成;The ice-sealed pressure-preserving and heat-preserving sampler is composed of a drilling/sampling switching mechanism, a refrigerant circulation system, a mud ice valve and a core valve in-situ generating mechanism, a single-action mechanism for a core holding tube and channels I, II, III, IV, V, VI composition;

钻进/取样切换机构:是由异径接头1通过螺纹与分流阀座2连接,分流阀座2通过螺纹与折返接头8连接,折返接头8通过螺纹与外管17连接,分流阀阀心6插入分流阀座2并通过挡圈3和分流阀弹簧7定位;Drilling/sampling switching mechanism: the different-diameter joint 1 is connected to the

冷冻液循环系统:是由外缸14插入折返接头8内并用密封圈密封,外缸14通过螺纹与外泵体20连接,下缸盖16、缸体13、上缸盖12、射流元件11及垫片10自下而上依次插入外缸14中并在需要位置用密封圈密封,潜孔锤上接头9通过螺纹连接到外缸14的最上部,潜孔锤活塞15沿缸体13、下缸盖16、外泵体20内壁滑动形成滑动副,往复泵活塞18与外泵体20间用密封圈密封,内泵体22、排液阀阀座25、进液阀阀座28自上而下依次插入外泵体20中并通过外泵体20的凸台进行定位,排液阀阀心24插入到排液阀阀座25中形成滑动副,进液阀阀心27插入到进液阀阀座28中形成滑动副,冷冻液保温容器32通过螺纹连接到外泵体20上,吸液管30通过螺纹连接到进液阀阀座28上,上外循环管29、上内循环管31通过螺纹连接到外泵体20上;Refrigerating liquid circulation system: the outer cylinder 14 is inserted into the

泥浆冰阀和岩心阀原位生成机构:是由上部冰阀生成机构,岩心容纳管上部的排水杆34插入带有内部环槽的循环管接头33中,并通过螺纹连接,且在循环管接头与排水杆用密封圈密封;下部泥浆冰阀和岩心阀生成机构,下外循环管40、下内循环管41通过螺纹连接到循环管接头33上,下端盖44通过螺纹连接到下外循环管40上,且其与岩心容纳管下端42连接处用密封圈密封;Mud ice valve and core valve in-situ generating mechanism: it is the upper ice valve generating mechanism, the

岩心容纳管单动机构:是由推力轴承37套在排水杆上,并由球阀座39和岩心容纳管上接头36固定,球阀座与排水杆下端通过螺纹连接,且在岩心容纳管上接头内侧用Yx密封圈密封。The single-action mechanism of the rock core holding pipe: the

通道I:由分流阀座2贯通孔道及折返接头8内通道,外管17与相邻循环管够成的环状间隙组成。Channel I: It is composed of the through hole of the

通道II:由分流阀座2的贯通孔道及潜孔锤上接头9和垫片10的中心孔道组成。Channel II: It consists of the through channel of the

通道III:由内泵体22的径向通孔,外泵体20的贯通孔道,上内循环管31和冷冻液保温容器32构成的环状间隙,循环管接头33的内环状内腔和贯通孔道,下内循环管41和岩心容纳管42构成的环状间隙组成。Channel III: the radial through hole of the inner pump body 22, the through hole of the outer pump body 20, the annular gap formed by the upper

通道IV:由进液阀阀座28的贯通孔道,外泵体20的贯通孔道,上外循环管29和上内循环管31构成的环状间隙,循环管接头33的贯通孔道,下外循环管40和下内循环管41构成的环状间隙组成。Channel IV: the through hole of the inlet valve seat 28, the through hole of the outer pump body 20, the annular gap formed by the upper

通道V:由排水杆34的中心孔道和循环管接头33的径向通孔组成。Channel V: composed of the central channel of the

通道VI:由折返接头8的径向通孔组成。Channel VI: consists of the radial through-holes of the

正常钻进时:分流阀阀心6的中心孔道打开,在分流阀弹簧7作用下分流阀阀心6位于上位,低温泥浆通过通道I进入孔底,冷却钻头,携带岩粉上返。岩心容纳管在单动机构的作用下保持相对不动,保护进入岩心容纳管的天然气水合物岩样,岩心容纳管内进入的泥浆通过通道V排出。During normal drilling: the central channel of the

保压取心时:停钻,投入弹子球4,使分流阀阀心6中心孔道关闭,开泵,在冲洗液压力作用下压缩分流阀弹簧7,使分流阀阀心6位于下位,通道I关闭而通道II打开,流入通道II内的冲洗液进入射流元件11,进行附壁和切换,从而驱动潜孔锤活塞15带动往复泵活塞18往复运动,往复泵活塞18的往复运动带动进液阀和排液阀的交替开闭,从而驱动冷冻液保温容器32内的冷冻液进入循环通道III和IV,冷冻液进入循环管接头内的环形内腔,可使排水杆内的液体形成冰阀,实现岩心容纳管上端密封,而随着冷冻液在通道III中的继续下行,在下内循环管41的底部和岩心容纳管下部内腔处,将一小段岩心与泥浆冻结生成“岩心阀”封堵岩心容纳管下端,从而保证岩心容纳管内的高压环境。进入射流元件的冲洗液在驱动活塞完成往复运动后通过通道VI进入外管17和孔壁的环状间隙上返至地表,不会对岩心容纳管42处造成影响。最后提钻取样,将钻头45和外管17、下端盖44和下外循环管40和下内循环管41依次卸下,然后将排水杆34从循环管接头33拧下即可将岩心容纳管取出。保压观测分析后,通过加热使岩心阀消融,将岩心倒出。岩心容纳管内亦可安装众所周知的半合管,卸开岩心容纳管上接头36与岩心容纳管42之间的螺纹,可容易地将半合管与岩心取出。During pressure-holding coring: stop drilling, put in pinball 4, close the central channel of diverter valve core 6, turn on the pump, compress diverter valve spring 7 under the pressure of flushing fluid, make diverter valve valve core 6 in the lower position, channel I When channel II is closed and channel II is opened, the flushing liquid flowing into channel II enters the jet element 11 for wall attachment and switching, thereby driving the down-the-hole hammer piston 15 to drive the reciprocating pump piston 18 to reciprocate, and the reciprocating motion of the reciprocating pump piston 18 drives the liquid inlet valve Alternate opening and closing of the discharge valve and the liquid discharge valve, thereby driving the refrigerant liquid in the refrigerant liquid insulation container 32 to enter the circulation channels III and IV, and the refrigerant liquid enters the annular inner cavity in the circulation pipe joint, so that the liquid in the drain rod can form an ice valve, Realize the sealing of the upper end of the core holding pipe, and as the refrigerant continues to descend in the channel III, a small section of core and mud are frozen at the bottom of the lower internal circulation pipe 41 and the lower inner cavity of the core holding pipe to form a "core valve" to block The lower end of the rock core holding pipe ensures the high-pressure environment in the rock core holding pipe. The flushing liquid entering the jet element enters the annular gap between the outer tube 17 and the hole wall through the channel VI after the driving piston completes the reciprocating motion and returns to the surface without affecting the

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201010131896CN101798924B (en) | 2010-03-25 | 2010-03-25 | Icebound type pressure-maintaining and temperature-preserving sampler |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201010131896CN101798924B (en) | 2010-03-25 | 2010-03-25 | Icebound type pressure-maintaining and temperature-preserving sampler |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101798924Atrue CN101798924A (en) | 2010-08-11 |

| CN101798924B CN101798924B (en) | 2013-08-21 |

Family

ID=42594750

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201010131896Expired - Fee RelatedCN101798924B (en) | 2010-03-25 | 2010-03-25 | Icebound type pressure-maintaining and temperature-preserving sampler |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101798924B (en) |

Cited By (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102182454A (en)* | 2011-04-12 | 2011-09-14 | 吉林大学 | Mechanism for quickly forming ice valve and improving strength of same |

| CN102494428A (en)* | 2011-12-06 | 2012-06-13 | 吉林大学 | Hydraulic down-hole refrigerator |

| CN102828689A (en)* | 2012-07-25 | 2012-12-19 | 吉林大学 | Cable suspending type air partial reverse circulating motor mechanical core bit |

| CN102943641A (en)* | 2012-12-08 | 2013-02-27 | 吉林大学 | Liquid nitrogen hole bottom frozen rope core drilling tool and core-drilling method |

| CN103267657A (en)* | 2013-05-28 | 2013-08-28 | 中国地质大学(武汉) | Fidelity secondary sampling equipment for bottom sediments |

| CN104653176A (en)* | 2015-02-08 | 2015-05-27 | 吉林大学 | Evaporation direct-cooling frozen pressure maintaining mechanism |

| CN105814429A (en)* | 2013-12-09 | 2016-07-27 | 独立行政法人产业技术综合研究所 | Subsampling device and method |

| CN106194089A (en)* | 2016-09-13 | 2016-12-07 | 吉林大学 | Low-temperature receiver external gas hydrate hole-bottom frozen rope sampler |

| CN107219090A (en)* | 2017-03-23 | 2017-09-29 | 吉林大学 | Seabed refrigerating and pressure keeping formula gravity piston sampler and its sampling method |

| CN108150122A (en)* | 2018-03-01 | 2018-06-12 | 中国地质调查局油气资源调查中心 | A kind of mud shale chip resistant self set-up type chilled sampling apparatus and its sampling method |

| CN108316863A (en)* | 2018-04-13 | 2018-07-24 | 吉林大学 | Subglacial lake sample drilling hot melting drill head |

| CN108518191A (en)* | 2018-05-30 | 2018-09-11 | 广州海洋地质调查局 | Gas hydrates coring drilling with keep up pressure device |

| CN108547614A (en)* | 2018-06-20 | 2018-09-18 | 河南理工大学 | A kind of closed coal sample collection device of pressurize and acquisition method |

| CN108625775A (en)* | 2018-07-09 | 2018-10-09 | 吉林大学 | A kind of revolution cutting type ice sheet hot melt drilling apparatus |

| CN108999583A (en)* | 2018-08-13 | 2018-12-14 | 四川大学 | Pressure maintaining cylinder top seal structure with explosion prevention function |

| CN109113611A (en)* | 2018-08-13 | 2019-01-01 | 四川大学 | Core fidelity cabin with temperature incubation function |

| CN109403901A (en)* | 2018-11-08 | 2019-03-01 | 深圳大学 | Core drilling rig fluid passage structure |

| CN109736736A (en)* | 2019-03-11 | 2019-05-10 | 吉林大学 | Evaporative direct cooling coring tool for loose and fragile formations on the seabed |

| CN110552644A (en)* | 2019-10-05 | 2019-12-10 | 中国石油大学(华东) | In-situ coal rock heat-preservation pressure-maintaining coring device and application method |

| CN112593881A (en)* | 2020-11-30 | 2021-04-02 | 中国地质大学(北京) | Multifunctional shale geological exploration drill bit and working method thereof |

| CN112627755A (en)* | 2020-12-25 | 2021-04-09 | 吉林大学 | Lifting drilling type large-diameter well bottom in-situ pressure maintaining coring drilling tool |

| CN112878941A (en)* | 2021-01-22 | 2021-06-01 | 东北石油大学 | Horizontal well burial type continuous coring inner barrel assembly |

| CN113187422A (en)* | 2021-01-04 | 2021-07-30 | 成都理工大学 | Detachable stress-preserving rock core containing device in high-ground-stress environment drilling |

| CN113530485A (en)* | 2021-08-12 | 2021-10-22 | 深圳大学 | Chemical heat-preserving pressure-maintaining coring method |

| CN116220597A (en)* | 2023-05-09 | 2023-06-06 | 青岛科技大学 | Submarine natural gas freezing pressure-maintaining core exploratory drilling equipment |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1470737A (en)* | 2002-11-29 | 2004-01-28 | 青岛海洋地质研究所 | Natural Gas Hydrate Deepwater Shallow Hole Pressure Keeping and Insulation Core Drilling Tool |

| CN2617915Y (en)* | 2003-04-22 | 2004-05-26 | 中国地质科学院勘探技术研究所 | Preserved sampling drill |

| CN1818323A (en)* | 2006-03-20 | 2006-08-16 | 国家海洋局第一海洋研究所 | Shallow-hole thermal-insulating and pressure-retaining driller in deep water with natural gas hydrate for taking out ocre |

| CN201679497U (en)* | 2010-03-25 | 2010-12-22 | 吉林大学 | Ice-packed pressure-preserving and heat-preserving sampler |

- 2010

- 2010-03-25CNCN 201010131896patent/CN101798924B/ennot_activeExpired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1470737A (en)* | 2002-11-29 | 2004-01-28 | 青岛海洋地质研究所 | Natural Gas Hydrate Deepwater Shallow Hole Pressure Keeping and Insulation Core Drilling Tool |

| CN2617915Y (en)* | 2003-04-22 | 2004-05-26 | 中国地质科学院勘探技术研究所 | Preserved sampling drill |

| CN1818323A (en)* | 2006-03-20 | 2006-08-16 | 国家海洋局第一海洋研究所 | Shallow-hole thermal-insulating and pressure-retaining driller in deep water with natural gas hydrate for taking out ocre |

| CN201679497U (en)* | 2010-03-25 | 2010-12-22 | 吉林大学 | Ice-packed pressure-preserving and heat-preserving sampler |

Cited By (45)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102182454B (en)* | 2011-04-12 | 2013-05-08 | 吉林大学 | Mechanism for quickly forming ice valve and improving strength of same |

| CN102182454A (en)* | 2011-04-12 | 2011-09-14 | 吉林大学 | Mechanism for quickly forming ice valve and improving strength of same |

| CN102494428A (en)* | 2011-12-06 | 2012-06-13 | 吉林大学 | Hydraulic down-hole refrigerator |

| CN102828689A (en)* | 2012-07-25 | 2012-12-19 | 吉林大学 | Cable suspending type air partial reverse circulating motor mechanical core bit |

| CN102828689B (en)* | 2012-07-25 | 2014-08-06 | 吉林大学 | Cable suspending type air partial reverse circulating motor mechanical core bit |

| CN102943641A (en)* | 2012-12-08 | 2013-02-27 | 吉林大学 | Liquid nitrogen hole bottom frozen rope core drilling tool and core-drilling method |

| CN102943641B (en)* | 2012-12-08 | 2015-02-18 | 吉林大学 | Liquid nitrogen hole bottom frozen rope core drilling tool and core-drilling method |

| CN103267657A (en)* | 2013-05-28 | 2013-08-28 | 中国地质大学(武汉) | Fidelity secondary sampling equipment for bottom sediments |

| CN103267657B (en)* | 2013-05-28 | 2015-01-21 | 中国地质大学(武汉) | Fidelity secondary sampling equipment for bottom sediments |

| CN105814429B (en)* | 2013-12-09 | 2018-11-20 | 国立研究开发法人产业技术综合研究所 | sub-sampling device and method |

| CN105814429A (en)* | 2013-12-09 | 2016-07-27 | 独立行政法人产业技术综合研究所 | Subsampling device and method |

| CN104653176A (en)* | 2015-02-08 | 2015-05-27 | 吉林大学 | Evaporation direct-cooling frozen pressure maintaining mechanism |

| CN106194089B (en)* | 2016-09-13 | 2018-07-17 | 吉林大学 | Low-temperature receiver external gas hydrate hole-bottom frozen rope sampler |

| CN106194089A (en)* | 2016-09-13 | 2016-12-07 | 吉林大学 | Low-temperature receiver external gas hydrate hole-bottom frozen rope sampler |

| CN107219090A (en)* | 2017-03-23 | 2017-09-29 | 吉林大学 | Seabed refrigerating and pressure keeping formula gravity piston sampler and its sampling method |

| CN107219090B (en)* | 2017-03-23 | 2023-04-07 | 吉林大学 | Seabed freezing pressure-maintaining gravity piston sampler and sampling method thereof |

| CN108150122A (en)* | 2018-03-01 | 2018-06-12 | 中国地质调查局油气资源调查中心 | A kind of mud shale chip resistant self set-up type chilled sampling apparatus and its sampling method |

| CN108150122B (en)* | 2018-03-01 | 2024-05-31 | 中国地质调查局油气资源调查中心 | Shale anti-fragmentation self-starting type freezing sampler and sampling method thereof |

| CN108316863A (en)* | 2018-04-13 | 2018-07-24 | 吉林大学 | Subglacial lake sample drilling hot melting drill head |

| CN108316863B (en)* | 2018-04-13 | 2023-12-15 | 吉林大学 | Hot melt drill bit for sampling and drilling under ice lake |

| CN108518191A (en)* | 2018-05-30 | 2018-09-11 | 广州海洋地质调查局 | Gas hydrates coring drilling with keep up pressure device |

| CN108547614A (en)* | 2018-06-20 | 2018-09-18 | 河南理工大学 | A kind of closed coal sample collection device of pressurize and acquisition method |

| CN108625775A (en)* | 2018-07-09 | 2018-10-09 | 吉林大学 | A kind of revolution cutting type ice sheet hot melt drilling apparatus |

| CN108625775B (en)* | 2018-07-09 | 2023-09-15 | 吉林大学 | Rotary cutting type ice layer hot melting drilling device |

| CN109113611A (en)* | 2018-08-13 | 2019-01-01 | 四川大学 | Core fidelity cabin with temperature incubation function |

| CN108999583A (en)* | 2018-08-13 | 2018-12-14 | 四川大学 | Pressure maintaining cylinder top seal structure with explosion prevention function |

| CN109113611B (en)* | 2018-08-13 | 2023-08-22 | 四川大学 | Rock core fidelity cabin with constant temperature function |

| CN108999583B (en)* | 2018-08-13 | 2023-06-30 | 四川大学 | The upper sealing structure of the pressure-holding cylinder with explosion-proof function |

| CN109403901A (en)* | 2018-11-08 | 2019-03-01 | 深圳大学 | Core drilling rig fluid passage structure |

| CN109403901B (en)* | 2018-11-08 | 2023-11-10 | 深圳大学 | Drilling fluid channel structure of core drilling rig |

| CN109736736A (en)* | 2019-03-11 | 2019-05-10 | 吉林大学 | Evaporative direct cooling coring tool for loose and fragile formations on the seabed |

| CN109736736B (en)* | 2019-03-11 | 2021-07-27 | 吉林大学 | Evaporative direct cooling coring tool for loose and fragile formations on the seabed |

| CN110552644B (en)* | 2019-10-05 | 2024-01-23 | 中国石油大学(华东) | In-situ coal rock heat-preserving pressure-maintaining coring device and application method |

| CN110552644A (en)* | 2019-10-05 | 2019-12-10 | 中国石油大学(华东) | In-situ coal rock heat-preservation pressure-maintaining coring device and application method |

| CN112593881A (en)* | 2020-11-30 | 2021-04-02 | 中国地质大学(北京) | Multifunctional shale geological exploration drill bit and working method thereof |

| CN112593881B (en)* | 2020-11-30 | 2021-10-26 | 中国地质大学(北京) | Multifunctional shale geological exploration drill bit and working method thereof |

| CN112627755A (en)* | 2020-12-25 | 2021-04-09 | 吉林大学 | Lifting drilling type large-diameter well bottom in-situ pressure maintaining coring drilling tool |

| CN112627755B (en)* | 2020-12-25 | 2024-05-07 | 吉林大学 | Lifting drill type large-diameter well bottom in-situ pressure maintaining coring drilling tool |

| CN113187422A (en)* | 2021-01-04 | 2021-07-30 | 成都理工大学 | Detachable stress-preserving rock core containing device in high-ground-stress environment drilling |

| CN113187422B (en)* | 2021-01-04 | 2022-06-28 | 成都理工大学 | Detachable stress-preserving rock core containing device in high-ground-stress environment drilling |

| CN112878941A (en)* | 2021-01-22 | 2021-06-01 | 东北石油大学 | Horizontal well burial type continuous coring inner barrel assembly |

| CN112878941B (en)* | 2021-01-22 | 2022-05-13 | 东北石油大学 | Horizontal well burial type continuous coring inner barrel assembly |

| CN113530485A (en)* | 2021-08-12 | 2021-10-22 | 深圳大学 | Chemical heat-preserving pressure-maintaining coring method |

| CN116220597B (en)* | 2023-05-09 | 2023-09-05 | 青岛科技大学 | Submarine natural gas freezing pressure-maintaining core exploratory drilling equipment |

| CN116220597A (en)* | 2023-05-09 | 2023-06-06 | 青岛科技大学 | Submarine natural gas freezing pressure-maintaining core exploratory drilling equipment |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101798924B (en) | 2013-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101798924A (en) | Icebound type pressure-maintaining and temperature-preserving sampler | |

| CN201679497U (en) | Ice-packed pressure-preserving and heat-preserving sampler | |

| CN109113613B (en) | Natural gas hydrate rotary type freezing pressure maintaining rope coring drilling tool and coring method | |

| CN101706379A (en) | Ice valve type pressure-maintaining and heat-preservation sampler | |

| CN104653134B (en) | Liquid nitrogen gas hydrate hole-bottom frozen core plugging notifying mechanism of rope core drilling | |

| CN108590742B (en) | Coal mine gas drainage system and method for increasing gas drainage concentration with variable diameter hole expansion | |

| CN102494428B (en) | Hydraulic submersible refrigerator | |

| CN106194168B (en) | Coal seam low-temperature fixed-point ice-sealed sampling device and using method thereof | |

| CN202939061U (en) | Multi-section rotary thin wall type soil sampler | |

| CN105156056B (en) | Gas hydrate hole-bottom frozen surges cord coring drill and coring method | |

| CN106150409B (en) | A kind of huge discharge continous way underground sand removal de-plugging tubing string and sand removal de-plugging process | |

| CN102287358B (en) | Long-plunger type dual-barrel coal-dust resistant discharging and extracting pump | |

| CN109138882A (en) | Gas hydrates refrigerating and pressure keeping Sampling driller and sampling method | |

| CN119777861B (en) | Deep sea mining object collection excavating device | |

| CN103573214A (en) | Circulation bottom valve which works with pressure | |

| CN204511373U (en) | Oil drilling integral core switching type drilling tool inner blowout preventer | |

| CN204024592U (en) | Bruising shut-in valve in down-hole for well cementation | |

| CN102312659A (en) | Pollution-free well workover process for oil field | |

| CN104653176B (en) | The ice-bound pressure-keeping mechanism of evaporation direct-cooling type | |

| CN110043211A (en) | Semiconductor refrigeration type freezes corer | |

| CN106481297B (en) | A kind of vortex tube heat preservation Sampling driller | |

| CN105156055B (en) | Electric compression evaporation direct cooling type ice-sealing pressure-maintaining corer | |

| CN212177024U (en) | Immersed pneumatic down-the-hole hammer drilling device for exploiting geothermal energy of dry hot rock | |

| CN203614079U (en) | Circulating bottom valve operated under pressure | |

| CN206319848U (en) | A kind of vortex tube is incubated Sampling driller |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20130821 Termination date:20160325 | |

| CF01 | Termination of patent right due to non-payment of annual fee |