CN101706177B - Thermoelectric refrigeration element capable of simultaneously generating two groups of heat pulses and heat pulser - Google Patents

Thermoelectric refrigeration element capable of simultaneously generating two groups of heat pulses and heat pulserDownload PDFInfo

- Publication number

- CN101706177B CN101706177BCN2009101992709ACN200910199270ACN101706177BCN 101706177 BCN101706177 BCN 101706177BCN 2009101992709 ACN2009101992709 ACN 2009101992709ACN 200910199270 ACN200910199270 ACN 200910199270ACN 101706177 BCN101706177 BCN 101706177B

- Authority

- CN

- China

- Prior art keywords

- thermoelectric cooling

- power supply

- cooling element

- thermal

- power

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000005057refrigerationMethods0.000titleclaimsdescription6

- 238000001816coolingMethods0.000claimsabstractdescription49

- 239000004020conductorSubstances0.000claimsabstractdescription24

- 239000000463materialSubstances0.000claimsabstractdescription19

- 239000004065semiconductorSubstances0.000claimsabstractdescription18

- 238000006243chemical reactionMethods0.000claimsabstractdescription17

- 239000012811non-conductive materialSubstances0.000claimsabstractdescription4

- 238000002955isolationMethods0.000claimsdescription7

- 239000000919ceramicSubstances0.000claimsdescription4

- 239000002184metalSubstances0.000claimsdescription4

- 238000010586diagramMethods0.000description5

- 238000000034methodMethods0.000description2

- 239000002245particleSubstances0.000description2

- 241001465754MetazoaSpecies0.000description1

- 230000017531blood circulationEffects0.000description1

- 239000003990capacitorSubstances0.000description1

- 239000003814drugSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 208000017520skin diseaseDiseases0.000description1

- 230000005068transpirationEffects0.000description1

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description1

Images

Landscapes

- Cooling Or The Like Of Semiconductors Or Solid State Devices (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种热电制冷元件及热脉冲器,尤其涉及一种能同时产生两组热脉冲的热电制冷元件及热脉冲器。The invention relates to a thermoelectric cooling element and a thermal pulser, in particular to a thermoelectric cooling element and a thermal pulser capable of simultaneously generating two sets of thermal pulses.

背景技术Background technique

热脉冲信号在生物、医学、农业、工业中都有广泛应用,如热脉冲信号用于测量树木蒸腾耗水量、动物血液流动速度、超导磁体传热,还用于某些皮肤病的治疗、数字脉冲热路的驱动等。然而,现有的热脉冲器多具有运动部件,而且往往仅能产生一组热脉冲信号,因此,迫切需要研发一种能同时产生两组热脉冲信号的器件,以提高效率。Thermal pulse signals are widely used in biology, medicine, agriculture, and industry. For example, thermal pulse signals are used to measure the transpiration water consumption of trees, the blood flow velocity of animals, and the heat transfer of superconducting magnets. They are also used in the treatment of certain skin diseases, Driving of digital pulse heat circuit, etc. However, most of the existing heat pulsers have moving parts and can only generate one set of heat pulse signals. Therefore, it is urgent to develop a device that can simultaneously generate two sets of heat pulse signals to improve efficiency.

发明内容Contents of the invention

本发明的目的在于提供一种能同时产生两组热脉冲的热电制冷元件。The object of the present invention is to provide a thermoelectric cooling element capable of generating two sets of heat pulses simultaneously.

本发明的另一目的在于提供一种基于热电制冷元件的热脉冲器。Another object of the present invention is to provide a thermal pulser based on a thermoelectric cooling element.

为了达到上述目的及其他目的,本发明的能同时产生两组热脉冲的热电制冷元件,包括:至少具有由1个P型半导体材料和N型半导体材料构成的热电制冷PN结;分别与P型半导体材料和N型半导体材料相连接且用于连接不同极性的电源的两导电体;以及各自贴附于一导电体且自身为非导电材料同时用于当两导电体连接电源的不同极性后在各自表面产生一组热脉冲的两贴附层。In order to achieve the above purpose and other purposes, the thermoelectric cooling element capable of generating two sets of thermal pulses of the present invention includes: at least a thermoelectric refrigeration PN junction composed of a P-type semiconductor material and an N-type semiconductor material; The semiconductor material is connected with the N-type semiconductor material and is used to connect two conductors of different polarity power supplies; and each is attached to a conductor and itself is a non-conductive material and is used for different polarities when the two conductors are connected to the power supply Afterwards, the two attached layers generate a set of heat pulses on their respective surfaces.

其中,所述热电制冷PN结可为毫米数量级;所述两导电体的材料可都为金属;所述两贴附层可都为陶瓷片。Wherein, the thermoelectric cooling PN junction may be on the order of millimeters; the materials of the two conductors may both be metal; the two attachment layers may both be ceramic sheets.

本发明的基于热电制冷元件的热脉冲器,包括:上述的能同时产生两组热脉冲的热电制冷元件;用于供电的直流电源;用于在所述直流电源的供电下提供控制信号和电源信号的单片机模块;以及输入端与所述单片机模块的输出端相连接、输出端与所述能同时产生两组热脉冲的热电制冷元件的两导电体相连接、且用于在所述直流电源的供电下将所述电源信号进行变换以便向所述能同时产生两组热脉冲的热电制冷元件提供所需的具有不同极性电源的电源变换电路。The thermal pulser based on the thermoelectric cooling element of the present invention includes: the above-mentioned thermoelectric cooling element capable of generating two sets of thermal pulses at the same time; a DC power supply for power supply; for providing control signals and power supply under the power supply of the DC power supply The single-chip microcomputer module of the signal; and the input end is connected with the output end of the single-chip microcomputer module, the output end is connected with the two conductors of the thermoelectric cooling element that can generate two groups of heat pulses at the same time, and is used in the DC power supply Under the power supply, the power signal is converted to provide the required power conversion circuit with different polarity power to the thermoelectric cooling element that can generate two sets of heat pulses at the same time.

其中,所述单片机模块具有光电隔离芯片、键盘和显示器,所述显示器可为LED显示器或LCD显示器。Wherein, the single-chip microcomputer module has a photoelectric isolation chip, a keyboard and a display, and the display can be an LED display or an LCD display.

综上所述,本发明的能同时产生两组热脉冲的热电制冷元件及热脉冲器能同时产生两组幅值和频率相等、波形形状相同、相位相差90度的热脉冲。In summary, the thermoelectric refrigeration element and thermal pulser capable of simultaneously generating two sets of heat pulses of the present invention can simultaneously generate two sets of heat pulses with equal amplitude and frequency, the same waveform shape, and a phase difference of 90 degrees.

附图说明Description of drawings

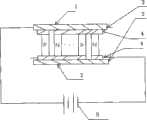

图1为本发明的能同时产生两组热脉冲的热电制冷元件的结构示意图。FIG. 1 is a schematic structural diagram of a thermoelectric cooling element capable of simultaneously generating two sets of heat pulses according to the present invention.

图2为本发明的能同时产生两组热脉冲的热电制冷元件连接电源的结构示意图。Fig. 2 is a schematic diagram of the structure of a thermoelectric cooling element capable of simultaneously generating two sets of heat pulses connected to a power source according to the present invention.

图3为本发明的基于热电制冷元件的热脉冲器的基本结构示意图。Fig. 3 is a schematic diagram of the basic structure of the thermal pulser based on the thermoelectric cooling element of the present invention.

图4为本发明的基于热电制冷元件的热脉冲器的单片机模块基本结构示意图。Fig. 4 is a schematic diagram of the basic structure of the single-chip microcomputer module of the thermal pulser based on the thermoelectric cooling element of the present invention.

图5为本发明的基于热电制冷元件的热脉冲器的电源转换电路的电路示意图。FIG. 5 is a schematic circuit diagram of the power conversion circuit of the thermal pulser based on the thermoelectric cooling element of the present invention.

具体实施方式Detailed ways

请参阅图1,本发明的能同时产生两组热脉冲的热电制冷元件包括:热电制冷PN结、两导电体4、以及两贴附层3。Please refer to FIG. 1 , the thermoelectric cooling element capable of simultaneously generating two sets of heat pulses of the present invention includes: a thermoelectric cooling PN junction, two

所述热电制冷PN结,由P型半导体材料和N型半导体材料构成,其尺寸可为毫米数量级。在本实施例中,所述热电制冷PN结有多个,由互相排列的N型和P型半导体颗粒所形成。The thermoelectric cooling PN junction is composed of a P-type semiconductor material and an N-type semiconductor material, and its size may be on the order of millimeters. In this embodiment, there are multiple thermoelectric cooling PN junctions, which are formed by mutually arranged N-type and P-type semiconductor particles.

所述两导电体4分别与P型半导体材料和N型半导体材料相连接,用于连接电源的不同极性。在本实施例中,所述两导电体4的材料都为金属,设在互相排列的N型和P型半导体颗粒两侧。The two

所述两贴附层3各自贴附于一导电体且为非导电材料,用于当两导电体4连接电源的不同极性后在各自表面产生一组热脉冲。在本实施例中,所述两贴附层3都为陶瓷片,其具有两端面,即端面1和2。The two

如图2所示,当两导电体4分别与电源5的正极性端和负极性端相连接时,绝缘陶瓷片的端面1制热而端面2制冷,改变电源5与两导电体4的连接方式,也就是改变电流方向,则端面1制冷而端面2制热。As shown in Figure 2, when the two

再请参见图3,本发明的基于热电制冷元件的热脉冲器包括:能同时产生两组热脉冲的热电制冷元件17、直流电源10、单片机模块15、及电源变换电路16。Referring to FIG. 3 again, the thermal pulser based on the thermoelectric cooling element of the present invention includes: a

所述能同时产生两组热脉冲的热电制冷元件17的结构如前所述,在此不再重述。The structure of the

所述直流电源10用于向单片机模块15和电源变换电路16提供直流电源。The

所述单片机模块15用于向电源变换电路16提供控制信号和电源信号,如图4所示,其包括单片机11和光电隔离芯片14等,且单片机11的外围接设有键盘13和显示器12,所述显示器12可为LED显示器或LCD显示器,所述光电隔离芯片14具有输出端口6、7和8,分别用于输出控制信号和电源波形信号。Described single-

如图5所示,所述电源变换电路的输入端IN1、IN2和ENA分别与所述单片机模块的光电隔离芯片14输出端口6、7和8相连接,所述电源变换电路的输出端(即P1)与所述能同时产生两组热脉冲的热电制冷元件17的两导电体4相连接,用于在所述直流电源10的供电下将所述电源信号进行变换以便向所述能同时产生两组热脉冲的热电制冷元件17提供所需的具有不同极性的电源。所述电源变换电路的输入端IN1、IN2接入光电隔离芯片14输出端口6、7两端输出的高低电平信号,由此控制P1输出的电流方向,所述电源变换电路的输入端ENA接入光电隔离芯片14输出端口8输出的电源波形信号,P1得到的电源波形信号与输出端口8输出的波形在形状和相位上相同。在本实施例中,所述电源变换电路包括芯片L298、输出单元P1、电容C、以及二极管D1、D2、D3和D4等,芯片L298的引脚和各元件的连接方式如图5所示,在此不再一一详述。As shown in Figure 5, the input terminals IN1, IN2 and ENA of the power conversion circuit are respectively connected with the

基于热电制冷元件的热脉冲器的工作原理为:直流电源10提供两组电源,两组电源不共地,一组提供给单片机模块,另一组提供给电源变换电路。单片机模块15带有键盘和显示器,热脉冲的波形、频率、幅值、功率大小等参数可通过键盘输入,实际的热脉冲的参数通过显示器显示出来。单片机模块15与电源变换电路16连接,为电源变换电路16提供控制信号。电源变换电路16与热电制冷元件的金属导电体4连接,提供驱动电源。由于电源变换电路16提供波形频率、波形形状、电流大小、电流方向变化的电源给能同时产生两组热脉冲的热电制冷元件17,能同时产生两组热脉冲的热电制冷元件17的端面1和端面2就产生温度大小、波形、频率变化的热脉冲信号。由于能同时产生两组热脉冲的热电制冷元件17的端面1和端面2的温度大小相等,方向相反,因此,能同时产生两组热脉冲的热电制冷元件17的端面1和端面2的热脉冲相位相差90度,而波形、幅值、频率相同。The working principle of the thermal pulser based on the thermoelectric refrigeration element is as follows: the

综上所述,本发明的能同时产生两组热脉冲的热电制冷元件及热脉冲器利用冷热循环原理,当两导电体被施加正负脉冲电源后,其两端面会同时产生热脉冲。通过控制正负脉冲电源输出电压的幅值、波形和频率,可实现热电制冷元件输出热脉冲的幅值、波形和频率变化,得到幅值、波形和频率可变化的两组热脉冲,两组热脉冲幅值、频率相等,波形相位相差90度。最小的基于热电制冷元件的热脉冲器的热电制冷元件可只有一个热电制冷PN结,尺寸为毫米数量级,功率为毫瓦数量级。最大的基于热电制冷元件的热脉冲器的热电制冷元件可由多个热电制冷PN结组成,尺寸为米数量级,功率为千瓦数量级。To sum up, the thermoelectric cooling element and thermal pulser capable of generating two sets of heat pulses of the present invention utilize the principle of cold and heat cycles. When positive and negative pulse power is applied to two conductors, heat pulses will be generated simultaneously on both ends of the conductors. By controlling the amplitude, waveform and frequency of the output voltage of the positive and negative pulse power supply, the amplitude, waveform and frequency of the thermal pulse output by the thermoelectric cooling element can be changed, and two sets of thermal pulses with variable amplitude, waveform and frequency can be obtained. The thermal pulse amplitude and frequency are equal, and the phase difference of the waveform is 90 degrees. The smallest thermoelectric cooling element based on a thermal pulser can have only one thermoelectric cooling PN junction, the size is on the order of millimeters, and the power is on the order of milliwatts. The thermoelectric cooling element of the largest thermoelectric cooling element-based thermal pulser can be composed of multiple thermoelectric cooling PN junctions, the size is on the order of meters, and the power is on the order of kilowatts.

上述实施例仅列示性说明本发明的原理及功效,而非用于限制本发明。任何熟悉此项技术的人员均可在不违背本发明的精神及范围下,对上述实施例进行修改。因此,本发明的权利保护范围,应如权利要求书所列。The above-mentioned embodiments only illustrate the principles and functions of the present invention, but are not intended to limit the present invention. Anyone skilled in the art can make modifications to the above-mentioned embodiments without departing from the spirit and scope of the present invention. Therefore, the protection scope of the present invention should be listed in the claims.

Claims (7)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2009101992709ACN101706177B (en) | 2009-11-24 | 2009-11-24 | Thermoelectric refrigeration element capable of simultaneously generating two groups of heat pulses and heat pulser |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2009101992709ACN101706177B (en) | 2009-11-24 | 2009-11-24 | Thermoelectric refrigeration element capable of simultaneously generating two groups of heat pulses and heat pulser |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101706177A CN101706177A (en) | 2010-05-12 |

| CN101706177Btrue CN101706177B (en) | 2012-05-02 |

Family

ID=42376417

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2009101992709AExpired - Fee RelatedCN101706177B (en) | 2009-11-24 | 2009-11-24 | Thermoelectric refrigeration element capable of simultaneously generating two groups of heat pulses and heat pulser |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101706177B (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5177486A (en)* | 1991-11-25 | 1993-01-05 | The United States Of America As Represented By The Secretary Of The Army | Optically activated hybrid pulser with patterned radiating element |

| CN2447760Y (en)* | 2000-10-20 | 2001-09-12 | 西北大学 | Semi-conductor thermoelectric sensor |

| CN200943514Y (en)* | 2006-07-21 | 2007-09-05 | 陈安村 | electromagnetic pulser |

| CN201252521Y (en)* | 2008-07-09 | 2009-06-03 | 上海第二工业大学 | Heat pulse signal generating system |

- 2009

- 2009-11-24CNCN2009101992709Apatent/CN101706177B/ennot_activeExpired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5177486A (en)* | 1991-11-25 | 1993-01-05 | The United States Of America As Represented By The Secretary Of The Army | Optically activated hybrid pulser with patterned radiating element |

| CN2447760Y (en)* | 2000-10-20 | 2001-09-12 | 西北大学 | Semi-conductor thermoelectric sensor |

| CN200943514Y (en)* | 2006-07-21 | 2007-09-05 | 陈安村 | electromagnetic pulser |

| CN201252521Y (en)* | 2008-07-09 | 2009-06-03 | 上海第二工业大学 | Heat pulse signal generating system |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101706177A (en) | 2010-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Yamamoto et al. | Efficiency bounds on thermoelectric transport in magnetic fields: The role of inelastic processes | |

| CN105651421B (en) | A kind of distributed optical fiber temperature sensor calibration calibration thermostat | |

| Daniels et al. | Evaluation of piezoelectric material properties for a higher power output from energy harvesters with insight into material selection using a coupled piezoelectric-circuit-finite element method | |

| EP2665188A3 (en) | Output module for industrial control with sink and source capability and low heat dissipation | |

| CN204513838U (en) | The DC driven of high frequency pulse tube cooler and active temperature control system | |

| CN104732006A (en) | IGBT module steady state temperature calculating method | |

| Karami et al. | New modeling approach and validation of a thermoelectric generator | |

| CN101706177B (en) | Thermoelectric refrigeration element capable of simultaneously generating two groups of heat pulses and heat pulser | |

| Morel et al. | Power semiconductor junction temperature and lifetime estimations: A review | |

| CN204808071U (en) | No surge semiconductor laser temperature control system based on H bridge circuit | |

| Zhu et al. | Development of a high-voltage pulsed electric field sterilization power supply using a new topology circuit | |

| Plesca | Thermal analysis of power semiconductor device in steady-state conditions | |

| Mikhaylov et al. | Considerations on the development of high-power density inverters for highly integrated motor drives | |

| Hasan et al. | A novel concept for three-phase cascaded multilevel inverter topologies | |

| Cardoso et al. | High efficiency transformerless photovoltaic DC/AC converter with common mode leakage current elimination: Analysis and implementation | |

| Škalic et al. | Energy Harvesting on AB-Class Power Amplifier Applying Thermoelectric Generators in Push–Pull Mode | |

| CN104410331B (en) | Flexible self-supported type thermoelectric power generation structure | |

| CN206774070U (en) | Thermal generator principle demonstration teaching aid | |

| Bui et al. | Design of a high-power multilevel sinusoidal signal and high-frequency excitation module based on FPGA for HIFU systems | |

| CN101710799B (en) | A Controllable Current Disturbance Source Main Circuit | |

| CN103874244A (en) | Ceramic heating plate | |

| CN108255211A (en) | A kind of TEC refrigerating plants | |

| CN209663678U (en) | The phase difference multichannel alien frequencies phonon excitation device controllable with the quiet phase of going out | |

| Dziurdzia et al. | From constant to temperature dependent parameters based electrothermal models of TEG | |

| CN203801085U (en) | Ceramic heating sheet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120502 Termination date:20121124 |