CN101647386A - Plant stereoscopic cultivation tower - Google Patents

Plant stereoscopic cultivation towerDownload PDFInfo

- Publication number

- CN101647386A CN101647386ACN200810146286ACN200810146286ACN101647386ACN 101647386 ACN101647386 ACN 101647386ACN 200810146286 ACN200810146286 ACN 200810146286ACN 200810146286 ACN200810146286 ACN 200810146286ACN 101647386 ACN101647386 ACN 101647386A

- Authority

- CN

- China

- Prior art keywords

- cultivation

- tower

- layer

- dimensional

- plant

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription23

- 230000007246mechanismEffects0.000claimsabstractdescription18

- 238000003860storageMethods0.000claimsabstractdescription15

- 241000196324EmbryophytaSpecies0.000claimsdescription75

- CURLTUGMZLYLDI-UHFFFAOYSA-NCarbon dioxideChemical compoundO=C=OCURLTUGMZLYLDI-UHFFFAOYSA-N0.000claimsdescription16

- 229910002092carbon dioxideInorganic materials0.000claimsdescription8

- 239000001569carbon dioxideSubstances0.000claimsdescription8

- 230000032258transportEffects0.000claimsdescription6

- 238000004146energy storageMethods0.000claimsdescription5

- 239000013589supplementSubstances0.000claimsdescription5

- 239000001963growth mediumSubstances0.000claimsdescription4

- 235000015097nutrientsNutrition0.000claimsdescription4

- 230000001502supplementing effectEffects0.000claimsdescription3

- 239000000463materialSubstances0.000claimsdescription2

- 238000010248power generationMethods0.000claimsdescription2

- 239000012531culture fluidSubstances0.000claims1

- 238000005192partitionMethods0.000abstractdescription4

- 238000004519manufacturing processMethods0.000description9

- 238000003306harvestingMethods0.000description5

- 235000013311vegetablesNutrition0.000description5

- 230000008901benefitEffects0.000description4

- 239000007789gasSubstances0.000description4

- 239000007788liquidSubstances0.000description3

- 238000000034methodMethods0.000description3

- 230000005540biological transmissionEffects0.000description2

- 210000000078clawAnatomy0.000description2

- 238000010586diagramMethods0.000description2

- 230000029553photosynthesisEffects0.000description2

- 238000010672photosynthesisMethods0.000description2

- 239000002689soilSubstances0.000description2

- 241000607479Yersinia pestisSpecies0.000description1

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000description1

- 238000012364cultivation methodMethods0.000description1

- 201000010099diseaseDiseases0.000description1

- 208000037265diseases, disorders, signs and symptomsDiseases0.000description1

- 230000000694effectsEffects0.000description1

- 238000005516engineering processMethods0.000description1

- 239000003501hydroponicsSubstances0.000description1

- 230000006872improvementEffects0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000003287optical effectEffects0.000description1

- 229910052760oxygenInorganic materials0.000description1

- 239000001301oxygenSubstances0.000description1

- 230000002093peripheral effectEffects0.000description1

- 230000008569processEffects0.000description1

- 239000000126substanceSubstances0.000description1

- 230000009469supplementationEffects0.000description1

- 230000007723transport mechanismEffects0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01G—HORTICULTURE; CULTIVATION OF VEGETABLES, FLOWERS, RICE, FRUIT, VINES, HOPS OR SEAWEED; FORESTRY; WATERING

- A01G31/00—Soilless cultivation, e.g. hydroponics

- A01G31/02—Special apparatus therefor

- A01G31/04—Hydroponic culture on conveyors

- A01G31/042—Hydroponic culture on conveyors with containers travelling on a belt or the like, or conveyed by chains

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P60/00—Technologies relating to agriculture, livestock or agroalimentary industries

- Y02P60/20—Reduction of greenhouse gas [GHG] emissions in agriculture, e.g. CO2

- Y02P60/21—Dinitrogen oxide [N2O], e.g. using aquaponics, hydroponics or efficiency measures

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Environmental Sciences (AREA)

- Cultivation Receptacles Or Flower-Pots, Or Pots For Seedlings (AREA)

- Hydroponics (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种植物立体栽培塔,特别涉及一种向上构建的塔台结构体,其在无人参与管理的情况下,植物小苗从进口进入,经过各层成熟后从出口输送出来,进行采收,从而形成多个连续的植物生产线。The present invention relates to a three-dimensional plant cultivation tower, in particular to an upwardly constructed tower structure, under the condition that no one participates in the management, plant seedlings enter from the entrance, and after each layer matures, they are transported out from the exit for harvesting , thus forming multiple continuous plant production lines.

背景技术Background technique

植物水耕法即一般所谓无土栽培法,该方法不需要土壤,可完全在室内进行,甚至不需要自然阳光,能完全以人工光照取代,植物的根部生长于水槽中或攀附在无机物质的架构上。在养份充足供应的情况下,其产量几乎可达同等面积土壤栽培的2~4倍,且在室内还可免除极端气候变化的伤害及大部分的病虫害。Plant hydroponics is the so-called soilless cultivation method. This method does not require soil and can be carried out completely indoors. It does not even require natural sunlight. It can be completely replaced by artificial light. The roots of plants grow in water tanks or climb on the surface of inorganic substances. architecturally. In the case of sufficient nutrient supply, its yield can almost reach 2 to 4 times that of soil cultivation in the same area, and it can also avoid the damage of extreme climate changes and most of the pests and diseases indoors.

为了争取更多的植物栽培空间,已知有许多立体栽培的相关技术被提出,如图4所示为台湾文献第M317159号公开的一种多个层式的蔬菜栽培装置,其主要包括多个用来栽培植物的倒锥形筒状植栽容器40,共同被支持在一支撑架20上,彼此之间呈现上下不同高低位差的立体架设状态;并且在最顶层植栽容器40上方罩设一网罩60等。这样设计,能充分利用并节省蔬菜栽培面积,增加栽培产量和效益。In order to strive for more plant cultivation space, it is known that many related technologies of three-dimensional cultivation have been proposed. As shown in Figure 4, it is a multi-layer vegetable cultivation device disclosed in Taiwan Document No. M317159, which mainly includes multiple The inverted cone-shaped

又如图5所示为台湾文献第158107号公开的一种立体栽培系统,其主要包括一架体10,其内部具有一容置空间。两个输送带31,相隔固定间距,两者互相对应平行枢设在所述架体10上,并位于所述容置空间两侧,其上方对应具有一连续波形的采光段311,下方则形成一水平的给养段312。多个栽培床40用于栽培植物,其可拆卸地吊挂在所述输送带31上,并随之移动。一传动装置50,用于驱动所述两个输送带31同步转动。通过所述传动装置50将所述栽培床40在采光段311和给养段312之间交替地移动。Also shown in Figure 5 is a three-dimensional cultivation system disclosed in Taiwan Document No. 158107, which mainly includes a

上述文献公开的现有技术基本上都是通过立体栽培来取得更多的植物栽培空间,但本领域的技术人员可以发现,所述现有技术所节省的空间有限,仍有改善的余地。The prior art disclosed in the above-mentioned documents basically uses three-dimensional cultivation to obtain more plant cultivation space, but those skilled in the art can find that the space saved by the prior art is limited, and there is still room for improvement.

发明内容Contents of the invention

针对上述现有技术存在的节省空间有限的技术问题,本发明的主要目的在于提供一种植物立体栽培塔,其能以最小的土地成本、最少的人力需求,达到最大的经济效益,同时可在无人参与决策的情况下,控制包括培养液供给、人工光照和气体补充等的生产管理流程,从而实现自动化生产。Aiming at the technical problem of limited space saving in the above-mentioned prior art, the main purpose of the present invention is to provide a three-dimensional plant cultivation tower, which can achieve the greatest economic benefit with the least land cost and the least manpower demand, and can be used in In the absence of human participation in decision-making, control the production management process including culture medium supply, artificial lighting and gas supplementation, so as to realize automated production.

为实现上述目的,本发明植物立体栽培塔包括由侧壁围成具有内部空间的塔台结构体,在所述内部空间中使用隔板分隔成多个层,所述塔台结构体的底部一侧设有进口,另一侧设有出口。其中,所述层底面上,分别设置有支持架,对应于所述支持架特定位置处配置有培养液管路及顶面上配置多个光源装置。至少一储槽,用于储存培养液,及通过一水泵装置将培养液泵送到各层的管路中。多个栽培槽,用于定置植栽。至少一上架装置,配置在进口侧,其至少包括一垂直输送机构,受控将栽种有植物小苗的栽培槽从进口输送到各个层;至少一平移机构,用于将栽培槽平移到所述支持架上。多个水平移动装置,至少每一层配置一个,受控将栽培槽向出口侧移动。至少一下架装置,配置在出口侧,其至少包括一平移机构,用于将成熟植物的栽培槽从所述支持架平移下来;及至少一垂直输送机构,受控将栽培槽输送到出口。一控制单元,根据反馈生成控制信号,以控制所述光源装置在光照不足时补充光照,控制所述水泵装置定时定量补充培养液,控制所述上架装置、水平移动装置及下架装置的运转等。这样设计,使得植物小苗分批次沿所述进口移动到层空间,成熟后再输送到出口分批次采收,从而形成多个连续的植物生产线。In order to achieve the above object, the three-dimensional plant cultivation tower of the present invention includes a tower structure body surrounded by side walls with an internal space, and the internal space is divided into multiple layers by partition plates, and the bottom side of the tower structure body is provided with There is an entrance and an exit on the other side. Wherein, support frames are respectively arranged on the bottom surface of the layer, and a culture liquid pipeline is arranged corresponding to a specific position of the support frame, and a plurality of light source devices are arranged on the top surface. At least one storage tank is used to store the culture solution, and the culture solution is pumped to the pipelines of each layer through a water pump device. Multiple cultivation slots for fixed planting. At least one racking device is arranged on the entrance side, and it includes at least one vertical conveying mechanism, which is controlled to transport the cultivation tanks planted with plant seedlings from the entrance to each layer; at least one translation mechanism is used to translate the cultivation tanks to the support on the shelf. A plurality of horizontal moving devices, at least one for each layer, is controlled to move the cultivation tank to the outlet side. At least one lower shelf device is arranged on the outlet side, which includes at least one translation mechanism for moving the cultivation tank of mature plants down from the support frame; and at least one vertical conveying mechanism for controlling the cultivation tank to the outlet. A control unit, generating a control signal according to the feedback, to control the light source device to supplement the light when the light is insufficient, to control the water pump device to replenish the culture medium in a regular and quantitative manner, to control the operation of the racking device, horizontal moving device and unloading device, etc. . This design makes the plant seedlings move in batches along the inlet to the layer space, and then transport them to the outlet for harvesting in batches after maturity, thereby forming a plurality of continuous plant production lines.

根据本发明,在所述塔台结构体最高层的顶部上,配置有太阳能集电设备或风能发电设备,并通过一储能设备储存,能以自生能源提供植物工厂所需的部分能源,从而以更低的成本来生产植物。According to the present invention, on the top of the highest layer of the tower structure, solar power collecting equipment or wind energy generating equipment is arranged, and stored by an energy storage device, which can provide part of the energy required by the plant factory with self-generated energy, so as to Lower cost to produce plants.

本发明的植物立体栽培塔能够很好的节省种植空间,并且形成多个连续的植物生产线,而且在无人进行管理的情况下,能够自动的进行植物栽培,实现自动化生产,从而以最小的土地成本和最少的人力需求,达到最大的经济效益。The three-dimensional plant cultivation tower of the present invention can save planting space very well, and form a plurality of continuous plant production lines, and can automatically carry out plant cultivation and realize automatic production under the condition of unmanned management, thereby using the smallest land Cost and minimum manpower requirement to achieve maximum economic benefit.

附图说明Description of drawings

图1为本发明的植物立体栽培塔的第一实施例的纵断面示意图,其中植物小苗从进口经过各层成熟后向出口方向移动。Fig. 1 is the longitudinal sectional schematic view of the first embodiment of the three-dimensional plant cultivation tower of the present invention, wherein the plant seedlings move toward the exit direction after each layer matures from the entrance.

图1a为图1中的1a-1a向局部剖面示意图。FIG. 1a is a schematic partial cross-sectional view along the line 1a-1a in FIG. 1 .

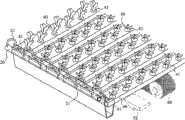

图1b为图1a的局部立体示意图。Fig. 1b is a partial perspective view of Fig. 1a.

图2为本发明的植物立体栽培塔的第二实施例的纵断面示意图,其中植物小苗从进口沿最低层向最高层方向移动,成熟后移动到出口。Fig. 2 is the schematic longitudinal section of the second embodiment of the three-dimensional cultivation tower for plants of the present invention, wherein the plant seedlings move from the entrance along the lowest level to the highest level, and move to the exit after maturity.

图3为本发明的植物立体栽培塔的第三实施例的纵断面示意图,其中植物小苗从进口沿最高层向最低层方向移动,成熟后移动到出口。Fig. 3 is the longitudinal sectional schematic view of the third embodiment of the three-dimensional plant cultivation tower of the present invention, wherein the plant seedlings move from the entrance along the highest level to the lowest level, and move to the exit after maturity.

图4为台湾文献第M317159号公开的一种多个层式的蔬菜栽培装置的示意图。Fig. 4 is a schematic diagram of a multi-layer vegetable cultivation device disclosed in Taiwan Document No. M317159.

图5为台湾文献第158107号公开的一种立体栽培系统的示意图。Fig. 5 is a schematic diagram of a three-dimensional cultivation system disclosed in Taiwan Document No. 158107.

具体实施方式Detailed ways

以下将配合实施例对本发明技术特点作进一步地说明,所述实施例仅为优选的范例,并非用来限定本发明的实施范围,通过参考附图并结合下列详细说明,对本发明将会有更进一步的理解。The technical characteristics of the present invention will be further described in conjunction with the following examples. Said examples are only preferred examples and are not intended to limit the scope of the present invention. By referring to the accompanying drawings and in conjunction with the following detailed descriptions, the present invention will be further described further understanding.

首先,请参考图1至图1b,本发明植物立体栽培塔包括由侧壁10围成具有内部空间的塔台结构体1,在所述内部空间中使用隔板11分隔成多个层12,所述塔台结构体1可以是一般大楼建筑物,所述隔板11可以是楼层地板。所述塔台结构体1的一侧形成有一通道1a及其底部设有进口15,另一侧形成有一通道1b及其底部设有出口17。First of all, please refer to Fig. 1 to Fig. 1 b, the three-dimensional plant cultivation tower of the present invention includes a

所述每一层12底面上,分别设置有支持架13,对应于所述支持架13特定位置处配置有培养液管路20,每一层12顶面上配置多个光源装置30。其中在所述塔台结构体1最高层12n的顶部上配置有太阳能集电设备90或风能发电设备91,并通过一储能设备(未示出)储存以备用。The bottom surface of each

至少一储槽14,用来储存培养液,所述储槽14可以设置在所述塔台结构体1地下层12b,通过一水泵装置141将培养液泵送到各个层12的管路20中。At least one

多个栽培槽40,例如配合所述支持架13宽度裁切成固定长度的中空槽状结构,将两端封闭后,在其一端设有一承接培养液的进水口41,另一端设有一排放培养液的出水口42;及,沿所述栽培槽40长度方向的表面上形成多个栽培孔43,用来定置植栽例如蔬菜或花卉等(成如图1a及1b所示)。A plurality of cultivation grooves 40, such as matching the width of the

至少一上架装置50,配置在所述塔台结构体1进口15侧的通道中,其至少包括一垂直输送机构51,例如公知链条带动的起重机等,优选地有一对沿所述栽培槽40长度方向两端均衡配置,所述垂直输送机构51至少设有一爪部511能挟持或释放所述栽培槽40,受控将栽种有植物小苗的栽培槽40自进口15输送到各层12。及,至少一平移机构52,例如公知的机械臂等,优选地有一对沿所述栽培槽40长度方向两端均衡配置,可在所述垂直输送机构51输送到达定位时,用于将栽培槽40平移上支持架13。At least one racking

多个水平移动装置60,至少每一层12配置一个,例如步进式输送带等,优选地有一对,沿所述栽培槽40长度方向两端均衡配置,可受控将栽培槽40向出口17侧方向固定距离移动。A plurality of horizontal

至少一下架装置70,配置在所述塔台结构体1出口17侧的通道中,其至少包括一平移机构72,例如公知的机械臂等,优选地有一对沿所述栽培槽40长度方向两端均衡配置,用于将成熟植物的栽培槽40平移下支持架13。至少一垂直输送机构71,例如公知链条带动的起重机等,优选地有一对沿所述栽培槽40长度方向两端均衡配置,所述垂直输送机构71至少设有一爪部711能挟持或释放所述栽培槽40,可受控将下架的成熟植物栽培槽40输送到出口17采收。At least the

一控制单元80,由公知的控制电路及控制组件所组成,可根据植物生长期而反馈生成控制信号,以控制所述光源装置30在光照不足时补充光照,控制所述水泵装置141定时定量补充培养液和控制所述上架装置50、水平移动装置60及下架装置70的运转等。A

根据本发明,如图1a及图1b所示,所述每一层12中,培养液管路20形成多个分歧管21,将培养液分别导引至栽培槽40的进水41中。上述水泵装置141,例如一种可调控泵,可通过一定时器(未示出)控制,将培养液定时定量从储槽14通过进水管20a输送到每一层12的管路20中,并以一压力自分歧管21挤压出分配到每一栽培槽40,如此能控制管路20流量或压力可达到液体变量输出的效果。所述培养液从进水口41进入流经栽培槽40从另一端的出水口42流出。其中,包括集水槽25、25’,分别承接在所述栽培槽40的进水口41和出水口42的下方,培养液被收集后经一排水管20b回流至储槽14形成一循环回路。位于所述储槽14上方设有一给料装置142,其通过一检测器(未示出)控制,用于在培养液浓度不足时将养料补充至储槽14中。另外,包括一空气补充装置143,可通过一定时器控制定时定量将空气补充至储槽14的培养液中,以增加养液溶氧量。According to the present invention, as shown in FIG. 1 a and FIG. 1 b , in each

根据本发明,所述塔台结构体1的侧壁10可由透光材料所构成,形成密闭式。所述光源装置30配置在除了层12四周边缘的外,集中在各层12中央的顶面上,可以节省光源装置30的使用数量。所述光源装置30,例如由多个单一波长或组合波长的发光二极管LED所构成的光管、光条或光盘等,其部分电源可来自上述太阳能集电设备90或风能发电设备91输出的通过储能设备所储存的储备电源。所述控制单元80至少包括一光感测控制器(未示出),用于控制光源装置30在光照不足时补充光照。所述控制单元80也可以通过设定允许各层空间12采不同的给光时机,以控制各层空间12的植株处于亮期或暗期,如此暗期植物所产生的二氧化碳可以提供给处于亮期植株以进行光合作用的使用。另外,还包括一气体补充装置81,通过一气体传感器(未示出)控制,用于感测二氧化碳浓度低于默认值时,通过所述气体补充装置81补充二氧化碳,将塔内各层12中的二氧化碳浓度维持在一适当范围,以提高植物光合作用。According to the present invention, the

可以根据植物例如蔬菜或花卉等的生长期进行设定,使小苗分批次沿进口进入,并被输送到各层空间中,根据生长期间分先后批次向出口方向移动,同时将成熟植物输送到出口采收,形成多个连续的植物生产线,从而能以最小的土地成本和最少的人力需求,达到最大的经济效益。It can be set according to the growth period of plants such as vegetables or flowers, so that the seedlings enter in batches along the entrance and are transported to each layer of space, and move towards the exit in batches according to the growth period, and at the same time transport mature plants From harvesting to export, multiple continuous plant production lines are formed, so that the maximum economic benefits can be achieved with the minimum land cost and the minimum manpower demand.

图2所示为本发明植物立体栽培塔的第二实施例。本实施例与上述实施例相同之处不再重复叙述,其不同的处在于:所述控制单元80通过设定,控制所述上架装置50、水平移动装置60及下架装置70,将栽种有植物小苗的栽培槽40从进口15输送到层12的最低层121,根据生长期间将植物小面按照先后批次交互地向最高层12n方向移动,同时将最高层12n的成熟植物的栽培槽40输送到出口17采收,形成多个连续的植物生产线。Fig. 2 shows the second embodiment of the three-dimensional plant cultivation tower of the present invention. The similarities between this embodiment and the above-mentioned embodiment will not be described again, and the difference is that the

图3所示为本发明植物立体栽培塔的第三实施例。本实施例基本上与第二实施例恰恰相反,其不同的处在于:所述控制单元80通过设定,控制所述上架装置50、水平移动装置60及下架装置70等,将栽种有植物小苗的栽培槽40从进口15输送到层12的最高层12n,根据生长期间将植物小苗按照先后批次交互地向最低层121方向移动,同时将最低层121的成熟植物的栽培槽40输送到出口17采收,形成多个连续的植物生产线。Fig. 3 shows the third embodiment of the three-dimensional plant cultivation tower of the present invention. This embodiment is basically just the opposite of the second embodiment, and the difference is that the

以上,仅为本发明的优选实施例,其并不局限本发明的实施和保护范围,在不偏离本发明的范围内所作的等价变化和修改,应仍在本发明的涵盖范围之内。The above are only preferred embodiments of the present invention, which do not limit the implementation and protection scope of the present invention. Equivalent changes and modifications made within the scope of the present invention should still be within the scope of the present invention.

Claims (22)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200810146286ACN101647386A (en) | 2008-08-14 | 2008-08-14 | Plant stereoscopic cultivation tower |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200810146286ACN101647386A (en) | 2008-08-14 | 2008-08-14 | Plant stereoscopic cultivation tower |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101647386Atrue CN101647386A (en) | 2010-02-17 |

Family

ID=41669799

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200810146286APendingCN101647386A (en) | 2008-08-14 | 2008-08-14 | Plant stereoscopic cultivation tower |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101647386A (en) |

Cited By (46)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101965790A (en)* | 2010-08-31 | 2011-02-09 | 中国科学院植物研究所 | Vegetable cultivation device capable of utilizing natural light source and being detached and assembled |

| CN102162308A (en)* | 2011-01-20 | 2011-08-24 | 南京云泰电气制造有限公司 | Indoor three-dimensional ecological planting and breeding system |

| CN102172227A (en)* | 2011-04-02 | 2011-09-07 | 江阴市银浪水族用品有限公司 | Aquarium with soilless culture device |

| CN102265783A (en)* | 2011-04-27 | 2011-12-07 | 建德市农科开发服务有限公司 | Intelligent vegetable culturing machine |

| CN102287711A (en)* | 2011-08-10 | 2011-12-21 | 华南师范大学 | Full-automatic illumination device for plants |

| CN102308745A (en)* | 2010-07-08 | 2012-01-11 | 陈吉宗 | Cultivation device and its cultivation water supply module |

| CN102499051A (en)* | 2011-11-18 | 2012-06-20 | 海峡(厦门)现代农业研究院有限公司 | Cabinet-type household vegetable machine |

| CN103109779A (en)* | 2013-02-20 | 2013-05-22 | 广州市重盈工元贸易有限公司 | Three-dimensional farm and cultivation method |

| RU2489847C1 (en)* | 2011-02-17 | 2013-08-20 | Грин Плас Ко., Лтд. | System of plant cultivation |

| CN103929945A (en)* | 2011-07-22 | 2014-07-16 | 自然创意有限公司 | Equipment and growing devices for growing plants |

| CN104663418A (en)* | 2015-03-29 | 2015-06-03 | 巫立斌 | Intelligent self-circulating plant planting tank |

| WO2015082924A1 (en)* | 2013-12-04 | 2015-06-11 | Intelligent Growth Solutions Limited | Automated tower with many novel applications |

| CN105638409A (en)* | 2015-12-31 | 2016-06-08 | 天津市云翔联动科技发展有限公司 | New-energy water culturing device |

| CN105746246A (en)* | 2016-04-30 | 2016-07-13 | 桂林明莹生物科技开发有限公司 | Automatic three-dimensional layer frame type plant factory |

| CN105918097A (en)* | 2016-05-17 | 2016-09-07 | 东北师范大学 | Ginseng cultivation system for experiments and application of ginseng cultivation system |

| CN105918100A (en)* | 2016-05-24 | 2016-09-07 | 中山弗雷德机械有限公司 | An internal nutrient source agricultural planting facility |

| CN106035038A (en)* | 2016-06-30 | 2016-10-26 | 梁健丰 | Soilless melon planting device |

| CN106134818A (en)* | 2015-03-30 | 2016-11-23 | 郭书祥 | Three-dimensional dynamic plant cultivation equipment and implementation method thereof |

| CN106231892A (en)* | 2014-02-20 | 2016-12-14 | 阿菲诺尔格罗威尔斯有限公司 | For automatic vertical gardening and the method and apparatus of agricultural |

| CN106499227A (en)* | 2016-10-19 | 2017-03-15 | 周全 | Automatization's green energy resource three-dimensional agriculture method |

| CN107197770A (en)* | 2017-07-31 | 2017-09-26 | 深圳前海弘稼科技有限公司 | A kind of culture apparatus |

| CN107396824A (en)* | 2017-08-15 | 2017-11-28 | 合肥市日之丰农业发展有限公司 | A kind of cultivation apparatus without soil with intelligent illumination system |

| CN107637509A (en)* | 2017-09-28 | 2018-01-30 | 贵州省宏荣特种生态种植养殖观光有限公司 | Vegetable soilless culture planting unit |

| CN107711468A (en)* | 2017-11-23 | 2018-02-23 | 中实创科技(广东)有限公司 | Intelligent soilless planting method |

| CN107711487A (en)* | 2017-11-23 | 2018-02-23 | 中实创科技(广东)有限公司 | Automated water cultivates plant production line |

| CN107920483A (en)* | 2015-06-30 | 2018-04-17 | 绿色生产系统公司 | Cultivation system |

| CN107926682A (en)* | 2017-11-27 | 2018-04-20 | 杭州蓝匠光环境科技有限公司 | Vertical planting system |

| CN108012714A (en)* | 2018-01-27 | 2018-05-11 | 温州市景林市政工程有限公司 | A kind of greening wall |

| CN108901806A (en)* | 2018-07-11 | 2018-11-30 | 福建省中科生物股份有限公司 | A kind of plant water-cultivation device and water culture method |

| CN109429787A (en)* | 2018-10-28 | 2019-03-08 | 田敬尚 | One kind is based on luminous energy, the vertical farm of wind energy supply Abandoned Underground Space and method |

| WO2019101128A1 (en)* | 2017-11-23 | 2019-05-31 | 中实创科技(广东)有限公司 | Distributed intelligent plant factory |

| CN110177460A (en)* | 2017-06-14 | 2019-08-27 | 成长方案技术有限责任公司 | System and method for providing airflow in a growth chamber |

| CN110301343A (en)* | 2019-08-01 | 2019-10-08 | 北京中农绿源工程技术有限公司 | A kind of full-automatic plantation hydroponic system |

| WO2020092506A1 (en)* | 2018-10-30 | 2020-05-07 | Mjnn Llc | Production facility layout for automated controlled environment agriculture |

| USD896690S1 (en) | 2019-03-06 | 2020-09-22 | Affinor Growers Inc. | Growing tower |

| CN111727868A (en)* | 2017-05-30 | 2020-10-02 | 弗劳恩霍夫应用研究促进协会 | device for promoting plant growth |

| US10842084B2 (en) | 2014-02-20 | 2020-11-24 | Affinor Growers Inc. | Vertical growing tower for automated horticulture and agriculture |

| CN112249613A (en)* | 2020-10-31 | 2021-01-22 | 广东省现代农业装备研究所 | Automatic production line of plant factory |

| CN113395897A (en)* | 2018-12-21 | 2021-09-14 | Mjnn有限责任公司 | Indexing plants in two and three dimensional spaces in a controlled growth environment |

| US20220095552A1 (en)* | 2020-09-30 | 2022-03-31 | Cambridge Research & Development, Inc. | Methods for cultivation using protected growing wells and related structures |

| US11570958B2 (en) | 2019-09-20 | 2023-02-07 | Mjnn Llc | Catch mechanism facilitating loading of vertical grow towers onto grow lines in a vertical farm system |

| US20230067626A1 (en)* | 2021-08-25 | 2023-03-02 | N. Athula Kulatunga | Vertical farming/gardening systems and methods of growing and/or dehydrating therewith |

| US11832569B2 (en) | 2018-10-30 | 2023-12-05 | Mjnn Llc | Grow tower processing for controlled environment agriculture system |

| US11856902B2 (en) | 2019-09-20 | 2024-01-02 | Mjnn Llc | Production facility layouts for automated controlled environment agriculture |

| CN117602766A (en)* | 2023-12-20 | 2024-02-27 | 安徽伊尔思生态科技有限公司 | A decentralized sewage treatment method |

| US11944049B2 (en) | 2019-09-20 | 2024-04-02 | Mjnn Llc | Vertical grow tower conveyance system for controlled environment agriculture including tower shuttle |

- 2008

- 2008-08-14CNCN200810146286Apatent/CN101647386A/enactivePending

Cited By (61)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102308745B (en)* | 2010-07-08 | 2013-06-19 | 陈吉宗 | Cultivation device and its cultivation water supply module |

| CN102308745A (en)* | 2010-07-08 | 2012-01-11 | 陈吉宗 | Cultivation device and its cultivation water supply module |

| CN101965790A (en)* | 2010-08-31 | 2011-02-09 | 中国科学院植物研究所 | Vegetable cultivation device capable of utilizing natural light source and being detached and assembled |

| CN101965790B (en)* | 2010-08-31 | 2013-07-31 | 中国科学院植物研究所 | Vegetable cultivation device capable of utilizing natural light source and being detached and assembled |

| CN102162308A (en)* | 2011-01-20 | 2011-08-24 | 南京云泰电气制造有限公司 | Indoor three-dimensional ecological planting and breeding system |

| RU2489847C1 (en)* | 2011-02-17 | 2013-08-20 | Грин Плас Ко., Лтд. | System of plant cultivation |

| CN102172227A (en)* | 2011-04-02 | 2011-09-07 | 江阴市银浪水族用品有限公司 | Aquarium with soilless culture device |

| CN102265783A (en)* | 2011-04-27 | 2011-12-07 | 建德市农科开发服务有限公司 | Intelligent vegetable culturing machine |

| CN103929945A (en)* | 2011-07-22 | 2014-07-16 | 自然创意有限公司 | Equipment and growing devices for growing plants |

| US10694684B2 (en) | 2011-07-22 | 2020-06-30 | Naturvention Oy | Apparatus for the growing of plants and a growing device |

| CN111418385A (en)* | 2011-07-22 | 2020-07-17 | 自然创意有限公司 | Equipment and growing devices for plant growth |

| CN102287711A (en)* | 2011-08-10 | 2011-12-21 | 华南师范大学 | Full-automatic illumination device for plants |

| CN102499051A (en)* | 2011-11-18 | 2012-06-20 | 海峡(厦门)现代农业研究院有限公司 | Cabinet-type household vegetable machine |

| CN102499051B (en)* | 2011-11-18 | 2013-12-25 | 海峡(厦门)现代农业研究院有限公司 | Cabinet-type household vegetable machine |

| CN103109779A (en)* | 2013-02-20 | 2013-05-22 | 广州市重盈工元贸易有限公司 | Three-dimensional farm and cultivation method |

| CN103109779B (en)* | 2013-02-20 | 2015-11-18 | 广州市重盈工元贸易有限公司 | Three-dimensional culture field and cultural method |

| WO2015082924A1 (en)* | 2013-12-04 | 2015-06-11 | Intelligent Growth Solutions Limited | Automated tower with many novel applications |

| JP2016539662A (en)* | 2013-12-04 | 2016-12-22 | インテリジェント グロース ソリューションズ リミテッドIntelligent Growth Solutions Limited | Automatic tower with many new uses |

| US9974252B2 (en) | 2013-12-04 | 2018-05-22 | Intelligent Growth Solutions Limited | Automated tower with many novel applications |

| US10842084B2 (en) | 2014-02-20 | 2020-11-24 | Affinor Growers Inc. | Vertical growing tower for automated horticulture and agriculture |

| CN106231892A (en)* | 2014-02-20 | 2016-12-14 | 阿菲诺尔格罗威尔斯有限公司 | For automatic vertical gardening and the method and apparatus of agricultural |

| CN104663418A (en)* | 2015-03-29 | 2015-06-03 | 巫立斌 | Intelligent self-circulating plant planting tank |

| CN106134818A (en)* | 2015-03-30 | 2016-11-23 | 郭书祥 | Three-dimensional dynamic plant cultivation equipment and implementation method thereof |

| CN107920483A (en)* | 2015-06-30 | 2018-04-17 | 绿色生产系统公司 | Cultivation system |

| CN107920483B (en)* | 2015-06-30 | 2020-07-03 | 绿色生产系统公司 | Cultivation system |

| CN105638409A (en)* | 2015-12-31 | 2016-06-08 | 天津市云翔联动科技发展有限公司 | New-energy water culturing device |

| CN105746246A (en)* | 2016-04-30 | 2016-07-13 | 桂林明莹生物科技开发有限公司 | Automatic three-dimensional layer frame type plant factory |

| CN105918097A (en)* | 2016-05-17 | 2016-09-07 | 东北师范大学 | Ginseng cultivation system for experiments and application of ginseng cultivation system |

| CN105918100A (en)* | 2016-05-24 | 2016-09-07 | 中山弗雷德机械有限公司 | An internal nutrient source agricultural planting facility |

| CN106035038A (en)* | 2016-06-30 | 2016-10-26 | 梁健丰 | Soilless melon planting device |

| CN106499227A (en)* | 2016-10-19 | 2017-03-15 | 周全 | Automatization's green energy resource three-dimensional agriculture method |

| CN111727868A (en)* | 2017-05-30 | 2020-10-02 | 弗劳恩霍夫应用研究促进协会 | device for promoting plant growth |

| CN110177460A (en)* | 2017-06-14 | 2019-08-27 | 成长方案技术有限责任公司 | System and method for providing airflow in a growth chamber |

| CN110177460B (en)* | 2017-06-14 | 2022-01-04 | 成长方案技术有限责任公司 | System and method for providing airflow in a growth pod |

| CN107197770A (en)* | 2017-07-31 | 2017-09-26 | 深圳前海弘稼科技有限公司 | A kind of culture apparatus |

| CN107396824A (en)* | 2017-08-15 | 2017-11-28 | 合肥市日之丰农业发展有限公司 | A kind of cultivation apparatus without soil with intelligent illumination system |

| CN107637509A (en)* | 2017-09-28 | 2018-01-30 | 贵州省宏荣特种生态种植养殖观光有限公司 | Vegetable soilless culture planting unit |

| CN107711487A (en)* | 2017-11-23 | 2018-02-23 | 中实创科技(广东)有限公司 | Automated water cultivates plant production line |

| WO2019101128A1 (en)* | 2017-11-23 | 2019-05-31 | 中实创科技(广东)有限公司 | Distributed intelligent plant factory |

| WO2019101131A1 (en)* | 2017-11-23 | 2019-05-31 | 中实创科技(广东)有限公司 | Intelligent soil-less planting method |

| CN107711468A (en)* | 2017-11-23 | 2018-02-23 | 中实创科技(广东)有限公司 | Intelligent soilless planting method |

| CN107926682A (en)* | 2017-11-27 | 2018-04-20 | 杭州蓝匠光环境科技有限公司 | Vertical planting system |

| CN108012714A (en)* | 2018-01-27 | 2018-05-11 | 温州市景林市政工程有限公司 | A kind of greening wall |

| CN108901806A (en)* | 2018-07-11 | 2018-11-30 | 福建省中科生物股份有限公司 | A kind of plant water-cultivation device and water culture method |

| CN109429787A (en)* | 2018-10-28 | 2019-03-08 | 田敬尚 | One kind is based on luminous energy, the vertical farm of wind energy supply Abandoned Underground Space and method |

| WO2020092506A1 (en)* | 2018-10-30 | 2020-05-07 | Mjnn Llc | Production facility layout for automated controlled environment agriculture |

| US11700804B2 (en) | 2018-10-30 | 2023-07-18 | Mjnn Llc | Production facility layout for automated controlled environment agriculture |

| US11832569B2 (en) | 2018-10-30 | 2023-12-05 | Mjnn Llc | Grow tower processing for controlled environment agriculture system |

| CN113395897B (en)* | 2018-12-21 | 2023-12-22 | Mjnn有限责任公司 | Indexing plants in two-and three-dimensional spaces in a controlled growth environment |

| CN113395897A (en)* | 2018-12-21 | 2021-09-14 | Mjnn有限责任公司 | Indexing plants in two and three dimensional spaces in a controlled growth environment |

| USD896690S1 (en) | 2019-03-06 | 2020-09-22 | Affinor Growers Inc. | Growing tower |

| CN110301343A (en)* | 2019-08-01 | 2019-10-08 | 北京中农绿源工程技术有限公司 | A kind of full-automatic plantation hydroponic system |

| CN110301343B (en)* | 2019-08-01 | 2022-05-17 | 北京中农绿源智慧农业有限公司 | Full-automatic planting hydroponic system |

| US11570958B2 (en) | 2019-09-20 | 2023-02-07 | Mjnn Llc | Catch mechanism facilitating loading of vertical grow towers onto grow lines in a vertical farm system |

| US11856902B2 (en) | 2019-09-20 | 2024-01-02 | Mjnn Llc | Production facility layouts for automated controlled environment agriculture |

| US11944049B2 (en) | 2019-09-20 | 2024-04-02 | Mjnn Llc | Vertical grow tower conveyance system for controlled environment agriculture including tower shuttle |

| US20220095552A1 (en)* | 2020-09-30 | 2022-03-31 | Cambridge Research & Development, Inc. | Methods for cultivation using protected growing wells and related structures |

| CN112249613A (en)* | 2020-10-31 | 2021-01-22 | 广东省现代农业装备研究所 | Automatic production line of plant factory |

| US20230067626A1 (en)* | 2021-08-25 | 2023-03-02 | N. Athula Kulatunga | Vertical farming/gardening systems and methods of growing and/or dehydrating therewith |

| US12114619B2 (en)* | 2021-08-25 | 2024-10-15 | N. Athula Kulatunga | Vertical farming/gardening systems and methods of growing and/or dehydrating therewith |

| CN117602766A (en)* | 2023-12-20 | 2024-02-27 | 安徽伊尔思生态科技有限公司 | A decentralized sewage treatment method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101647386A (en) | Plant stereoscopic cultivation tower | |

| US11547070B2 (en) | Vertical-hive green box cultivation systems | |

| US10980198B2 (en) | Automated hydroponic greenhouse factory | |

| US12010959B2 (en) | Systems and methods for hydroponic plant growth | |

| CN105075817B (en) | Nutrient solution cultivation method and plant cultivation facility | |

| CN108575725B (en) | Indoor plant factory system | |

| KR101970026B1 (en) | Method and apparatus for growing plants along an undulating path | |

| KR101423127B1 (en) | A hydroponics culture apparatus | |

| KR101022025B1 (en) | Plant growing equipment | |

| CN104082119A (en) | Movable LED lighting circulation plant water-culture device | |

| CN103262783A (en) | Three-dimensional soil-less cultivating device | |

| TWI332819B (en) | ||

| KR102060055B1 (en) | Plant cultivating apparatus | |

| KR102241200B1 (en) | Vertical Hydroponic Cultivation | |

| JP2001095404A (en) | Method for automated culture of plant and apparatus for automated culture | |

| KR100921605B1 (en) | Horizontal crop cultivator improves cultivation efficiency | |

| CN205567363U (en) | Cabinet style vegetables production unit | |

| JP4279379B2 (en) | Plant cultivation equipment | |

| KR101477721B1 (en) | Indoor plant cultivation apparatus | |

| CN101658126A (en) | Multilayer multi-stage thick-planting cultivation device | |

| CN117281033A (en) | Uniform-light and uniform-water plant cultivation system | |

| KR101835185B1 (en) | Plant growing apparatus for being quipped onto wall including longitudinally installed LED modules and plant growing tray | |

| KR102273724B1 (en) | Continuos incubating apparatus for microalgae capable of selective controlling of cultivation environment | |

| CN216820851U (en) | Circulating water constant temperature vegetable planting frame | |

| JP2021029173A (en) | Plant cultivation equipment and plant manufacturing method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Open date:20100217 |