CN101592934A - Communication method between programmable logic controller and expansion module - Google Patents

Communication method between programmable logic controller and expansion moduleDownload PDFInfo

- Publication number

- CN101592934A CN101592934ACNA2009100541571ACN200910054157ACN101592934ACN 101592934 ACN101592934 ACN 101592934ACN A2009100541571 ACNA2009100541571 ACN A2009100541571ACN 200910054157 ACN200910054157 ACN 200910054157ACN 101592934 ACN101592934 ACN 101592934A

- Authority

- CN

- China

- Prior art keywords

- expansion module

- communication

- machine controller

- plc

- programmable logic

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Programmable Controllers (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种可编程逻辑控制器(Programmable Logical Controller,PLC)的通信方法,特别涉及一种可编程逻辑控制器与扩展模块的通信方法。The present invention relates to a communication method of a programmable logic controller (Programmable Logical Controller, PLC), in particular to a communication method of a programmable logic controller and an expansion module.

背景技术Background technique

可编程逻辑控制器(Programmable Logical Controller,PLC)是一种提供输入信号并执行用户程序来控制输出信号和机械动作的电子装置,现有的可编程逻辑控制器主机的I/O端子数量都是固定的,当需要扩展更多的I/O端子时,就需要增加各种扩展模块以增加I/O端子数量。Programmable Logical Controller (PLC) is an electronic device that provides input signals and executes user programs to control output signals and mechanical actions. The number of I/O terminals of existing PLC hosts is Fixed, when more I/O terminals need to be expanded, various expansion modules need to be added to increase the number of I/O terminals.

现有的可编程逻辑控制器PLC一般都采用可编程逻辑控制器PLC主机加扩展模块的方式构成,扩展模块的连接方式有背板连接和侧面逐级连接两种,由于背板连接占用较多的硬件资源,安装空间大,成本高,只是在大型可编程逻辑控制器PLC中得到应用,小型可编程逻辑控制器PLC一般不采用该方式;而侧面逐级连接的方式成本低,接线灵活,该结构在中、小型可编程逻辑控制器PLC中常常被采用。Existing programmable logic controller PLCs are generally composed of programmable logic controller PLC mainframe plus expansion modules. The connection methods of expansion modules include backplane connection and side step-by-step connection. Since the backplane connection occupies more hardware resources, large installation space and high cost, it is only used in large-scale programmable logic controller PLC, small-scale programmable logic controller PLC generally does not use this method; and the method of side-by-side connection step by step is low in cost and flexible in wiring. This structure is often adopted in medium and small programmable logic controllers PLC.

由于可编程逻辑控制器PLC主机与扩展模块的连接是任意的,可编程逻辑控制器PLC主机必须知道连接的扩展模块地址编号和类型才能访问对应的扩展模块。在现有的技术中,有采用固定方式对扩展模块进行编址的,一般在扩展模块上有一个地址设定的拨码来设定扩展模块的地址,也有采用多根地址线传递地址的方式。Since the connection between the programmable logic controller PLC host and the expansion module is arbitrary, the programmable logic controller PLC host must know the address number and type of the connected expansion module to access the corresponding expansion module. In the existing technology, there is a fixed way to address the expansion module. Generally, there is an address setting dial on the expansion module to set the address of the expansion module, and there is also a way to transmit the address by using multiple address lines. .

如中国专利公开号为CN1936744A的发明专利,公开了一种可编程逻辑控制器、其扩展模块和其硬件扩展方法,采用多根地址线逐级向后级传递地址的,在地址分配时,前级扩展模块将地址向后级逐级递加的方式自动分配,后级扩展模块的地址由前一级扩展模块给出,在数据通信的过程中,可编程逻辑控制器PLC主机通过一组地址线选择要通信的扩展模块,再通过数据线发送命令和数据。选用一组地址线来传输地址的方式,在硬件设计上不灵活,地址线的最大数量就决定了扩展模块的最大数量,不同的可编程逻辑控制器PLC主机机型由于地址线的数量不同导致硬连接电缆线数目可能不同,并导致侧面连接的电缆不通用;而且该方式本质上还是分时的传递地址、命令和数据,地址线是并行的,抗干扰能力较差,因此选用一组地址线的方式也存在较大的缺点。另外采用拨码设定地址的方式使用不灵活,每次改动扩展模块顺序或数量都需要重新设定地址,效率低下。For example, the invention patent of Chinese Patent Publication No. CN1936744A discloses a programmable logic controller, its expansion module and its hardware expansion method. If multiple address lines are used to transmit addresses to the subsequent stages step by step, when the address is allocated, the previous The first-level expansion module automatically assigns the address to the subsequent level by increasing the address. The address of the subsequent expansion module is given by the previous expansion module. In the process of data communication, the programmable logic controller PLC host passes a set of address Select the expansion module to communicate with, and then send commands and data through the data line. The method of selecting a group of address lines to transmit addresses is inflexible in hardware design. The maximum number of address lines determines the maximum number of expansion modules. Different programmable logic controller PLC host models have different numbers of address lines. The number of hard-connected cables may be different, and the cables connected to the side are not universal; and this method is essentially time-sharing transmission of addresses, commands and data. The address lines are parallel and the anti-interference ability is poor, so a group of addresses is selected. There are also major disadvantages of the line method. In addition, it is inflexible to use the method of setting the address by dialing the code. Every time the order or quantity of the expansion modules is changed, the address needs to be reset, which is inefficient.

又如,中国专利公开号为CN1920803A的发明专利,公开了一种通信接口包含与扩展模块通信以便读与写离散输入/输出、模拟输入/输出、智能模块控制以及扩展模块状态的处理器,采用专用ASIC的串行通信方式也存在串行通信引线多,需要专用单片机搭配ASIC才能实现扩展模块的功能,导致扩展模块的使用成本较高。As another example, the invention patent with the Chinese patent publication number CN1920803A discloses a processor whose communication interface includes communication with an expansion module so as to read and write discrete input/output, analog input/output, intelligent module control, and expansion module status. The serial communication method of the dedicated ASIC also has many serial communication leads, and the function of the expansion module needs a dedicated single-chip microcomputer with an ASIC, resulting in a high cost of using the expansion module.

发明内容Contents of the invention

本发明的目的在于提供一种可编程逻辑控制器与扩展模块的通信方法,针对现有技术中PLC扩展模块逐级连接情况下所存在的缺陷,可实现对连接的扩展模块进行地址设定、地址查询、类型识别和数据的输入输出刷新功能,同时保证了扩展模块对于不同的PLC主机可以通用。The purpose of the present invention is to provide a communication method between a programmable logic controller and an expansion module, aiming at the defects in the prior art when the PLC expansion modules are connected step by step, it can realize address setting, Address query, type identification, and data input and output refresh functions, while ensuring that the expansion module can be used universally for different PLC hosts.

本发明所解决的技术问题可以采用以下技术方案来实现:The technical problem solved by the present invention can adopt following technical scheme to realize:

一种可编程逻辑控制器与扩展模块的通信方法,其特征在于,所述可编程逻辑控制器PLC主机与所述扩展模块之间通过串行通信线采用侧面逐级连接的连接方式互相连接,所述扩展模块通过通信协议状态机控制器识别所述可编程逻辑控制器PLC主机发过来的非周期性的状态数据帧,向I/O刷新状态机控制器发出通知以要求I/O刷新状态机控制器响应接收到的状态数据帧;所述扩展模块通过I/O刷新状态机控制器识别出所述可编程逻辑控制器PLC主机发过来的I/O刷新数据帧,自动响应进行数据读写。A communication method between a programmable logic controller and an expansion module, characterized in that, the programmable logic controller PLC host and the expansion module are connected to each other through a serial communication line using a side-by-side connection mode, The expansion module recognizes the aperiodic state data frame sent by the programmable logic controller PLC host through the communication protocol state machine controller, and sends a notification to the I/O refresh state machine controller to request the I/O refresh state The machine controller responds to the received state data frame; the expansion module recognizes the I/O refresh data frame sent by the programmable logic controller PLC host through the I/O refresh state machine controller, and automatically responds to perform data reading Write.

在本发明的一个实施例中,所述串行通信线包括主机数据输出信号线MOSI、主机数据输入信号线MISO、串行时钟信号线SCLK和从机选择信号线SSEL,在时钟信号的作用下,所述可编程逻辑控制器PLC主机与所述扩展模块之间通过串行通信线可以同时传递串行数据,通性效率高。In one embodiment of the present invention, the serial communication line includes the host data output signal line MOSI, the host data input signal line MISO, the serial clock signal line SCLK and the slave selection signal line SSEL, under the action of the clock signal , the programmable logic controller PLC host and the expansion module can simultaneously transmit serial data through the serial communication line, and the communication efficiency is high.

在本发明的一个实施例中,所述通信协议状态机控制器是在一片采用硬件描述语言设计的复杂可编程门电路中(CPLD/FPGA)实现。In one embodiment of the present invention, the communication protocol state machine controller is realized in a piece of complex programmable gate circuit (CPLD/FPGA) designed with hardware description language.

在本发明的一个实施例中,所述通信协议状态机控制器支持通信帧校验和检错功能,增强通信的可靠性。In one embodiment of the present invention, the communication protocol state machine controller supports communication frame check and error detection functions, so as to enhance the reliability of communication.

在本发明的一个实施例中,所述I/O刷新状态机控制器是由专用的单片机实现,也可以是选用硬件描述语言设计的时序电路,负责I/O数据的物理刷新和对所述扩展模块接收到的状态数据帧的响应。In one embodiment of the present invention, the I/O refresh state machine controller is realized by a dedicated single-chip microcomputer, and may also be a sequential circuit designed in a hardware description language, responsible for the physical refresh of I/O data and the The response of the status data frame received by the expansion module.

在本发明的一个实施例中,所述通信协议状态机控制器和I/O刷新状态机控制器通过硬件语言设计后综合在一片复杂可编程门电路中(CPLD/FPGA)实现。In one embodiment of the present invention, the communication protocol state machine controller and the I/O refresh state machine controller are integrated in a complex programmable gate circuit (CPLD/FPGA) and realized through hardware language design.

在本发明的一个实施例中,每一个所述扩展模块在检测到所述可编程逻辑控制器PLC主机通信故障或重建通信链路时,都可以禁止下一级扩展模块通信,增强了通信故障检测的可靠性。In one embodiment of the present invention, when each of the expansion modules detects the communication failure of the programmable logic controller PLC host or rebuilds the communication link, it can prohibit the communication of the next-level expansion module, which enhances the communication failure detection reliability.

在本发明的一个实施例中,所述扩展模块在自身故障时可以离线而不影响其它的所述扩展模块工作。In an embodiment of the present invention, the expansion module can go offline without affecting the work of other expansion modules when it fails.

本发明的有益效果是:可编程逻辑控制器PLC主机与所述扩展模块之间通过串行通信线采用侧面逐级连接的连接方式互相连接,解决了PLC产品扩展模块连接的通用性问题,扩展模块可以用于不同的可编程逻辑控制器PLC;串行通信技术支持更高的通信速率,抗干扰能力强,极大地提高了通信的实时性能;串行通信线选用相同的规格可以保证扩展模块对于不同可编程逻辑控制器PLC的通用性;每一个扩展模块在检测到主机通信故障或重建通信链路时,都可以禁止下一级扩展模块通信,增强了通信故障检测的可靠性;扩展模块在自身故障时可以离线而不影响其它扩展模块工作。The beneficial effects of the present invention are: the programmable logic controller PLC mainframe and the expansion module are connected to each other through the serial communication line in a side-by-side connection mode, which solves the universality problem of PLC product expansion module connection, expands The module can be used in different programmable logic controllers PLC; serial communication technology supports higher communication speed, strong anti-interference ability, which greatly improves the real-time performance of communication; the selection of the same specification of serial communication line can ensure the extension module For the commonality of different programmable logic controllers PLC; when each expansion module detects a host communication failure or rebuilds a communication link, it can prohibit the communication of the next-level expansion module, which enhances the reliability of communication failure detection; the expansion module When it fails, it can be offline without affecting the work of other expansion modules.

本发明的一种可编程逻辑控制器与扩展模块的通信方法,通过通信协议状态机控制器和I/O刷新状态机控制器识别周期性的I/O刷新数据帧和非周期性的状态数据帧,在识别出发过来的非周期性的状态数据帧时,能立即向I/O刷新状态机控制器发出通知以要求I/O刷新状态机控制器响应接收到的状态数据帧;在识别出发过来的是I/O刷新数据帧时,会自动响应进行数据读写,减轻I/O刷新状态机控制器的负担,提高通信速度和通信效率;同时,采用串行通信线进行连接,引线极少,成本很低,节约生产资料资源,实现本发明的目的。A communication method between a programmable logic controller and an expansion module of the present invention uses a communication protocol state machine controller and an I/O refresh state machine controller to identify periodic I/O refresh data frames and aperiodic state data Frame, when identifying the aperiodic state data frame that is sent out, it can immediately send a notification to the I/O refresh state machine controller to request the I/O refresh state machine controller to respond to the received state data frame; What comes over is that when the I/O refreshes the data frame, it will automatically respond to read and write data, reduce the burden on the I/O refresh state machine controller, and improve communication speed and communication efficiency; at the same time, it uses a serial communication line for connection, and the lead pole Less, the cost is very low, saves the means of production resources, and realizes the purpose of the present invention.

附图说明Description of drawings

图1为本发明的PLC主机与扩展模块连接的示意图;Fig. 1 is the schematic diagram that PLC main frame of the present invention is connected with expansion module;

图2为本发明的PLC主机与扩展模块逐级连接的内部框图;Fig. 2 is the internal block diagram that PLC host of the present invention is connected step by step with expansion module;

图3为本发明的PLC主机与扩展模块通信数据帧命令格式的示意图;Fig. 3 is the schematic diagram of PLC main frame of the present invention and expansion module communication data frame command format;

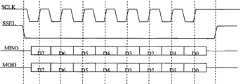

图4为本发明的扩展模块通信帧每个字节数据传输波形格式的示意图;Fig. 4 is the schematic diagram of each byte data transmission waveform format of the expansion module communication frame of the present invention;

图5为本发明的通信协议状态机控制器状态转换的示意图。FIG. 5 is a schematic diagram of the state transition of the communication protocol state machine controller of the present invention.

具体实施方式Detailed ways

为了使本发明实现的技术手段、创作特征、达成目的与功效易于明白了解,下面结合具体图示,进一步阐述本发明。In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

实施例Example

本发明的可编程逻辑控制器与扩展模块的通信方法,可编程逻辑控制器PLC主机1与扩展模块2之间通过串行通信线采用侧面逐级连接的连接方式互相连接,扩展模块2通过通信协议状态机控制器21识别可编程逻辑控制器PLC主机1发过来的非周期性的状态数据帧,向I/O刷新状态机控制器22发出通知以要求I/O刷新状态机控制器22响应接收到的状态数据帧;扩展模块2通过I/O刷新状态机控制器22识别出可编程逻辑控制器PLC主机1发过来的I/O刷新数据帧,自动响应进行数据读写。In the communication method between the programmable logic controller and the expansion module of the present invention, the programmable logic

如图1所示,按照本发明的可编程逻辑控制器与扩展模块的通信方法构成的PLC系统的结构示意图;其中,可编程逻辑控制器PLC主机1同多个扩展模块2之间通过串行通信线采用侧面逐级连接的连接方式互相连接的,对于PLC系统来说,扩展模块2可以没有或者是多个。As shown in Figure 1, the structural representation of the PLC system that forms according to the communication method of programmable logic controller of the present invention and expansion module; The communication lines are connected to each other in a side-by-side connection mode. For the PLC system, there may be no or multiple expansion modules 2 .

如图2所示,所述串行通信线包括主机数据输出信号线MOSI、主机数据输入信号线MISO、串行时钟信号线SCLK和从机选择信号线SSEL,在时钟信号的作用下,所述可编程逻辑控制器PLC主机与所述扩展模块之间通过串行通信线可以同时传递串行数据,通性效率高。As shown in Figure 2, the serial communication line includes the host data output signal line MOSI, the host data input signal line MISO, the serial clock signal line SCLK and the slave selection signal line SSEL, under the effect of the clock signal, the Serial data can be simultaneously transmitted between the programmable logic controller PLC host and the expansion module through the serial communication line, and the communication efficiency is high.

可编程逻辑控制器PLC主机1在上电的初始阶段要设定扩展模块2的地址,上一级扩展模块2在自身地址还没有设定好之前,下一级从机选择信号将禁能;在刚上电时,可编程逻辑控制器PLC主机1执行一次设定地址的过程,可编程逻辑控制器PLC主机1将从机选择信号置为有效,但此时只有最靠近可编程逻辑控制器PLC主机1的第一级扩展模块2可以接收到可编程逻辑控制器PLC主机1的通信帧。The programmable logic

在可编程逻辑控制器PLC主机1发送了设定地址的命令以后,扩展模块2的模块地址被设定成功,扩展模块2把主机的从机选择信号SSEL连通到下一个扩展模块2的从机选择信号SSEL,此时可编程逻辑控制器PLC主机1才可以设定下一个扩展模块2的地址;当所有的从机地址都被设定好以后,可编程逻辑控制器PLC主机1就可以依次访问从机的模块类型,再根据从机的模块类型进行I/O刷新;当扩展模块2检测到通信线路故障或者可编程逻辑控制器PLC主机1发出撤销通信链路的请求时,将下一级从机选择信号SSEL置为禁能态,连接的扩展模块2在对故障检测的响应速度可能不一样,但是在从机选择信号SSEL为禁能时都会立即停止通信,可以保证通信线路的安全。After the programmable logic

在本发明中,可编程逻辑控制器PLC主机1与扩展模块2之间通过串行通信线采用侧面逐级连接的连接方式互相连接的,其串行通信协议是专门设计的,可编程逻辑控制器PLC主机1与扩展模块2通信的数据帧命令格式参见图3所示,可编程逻辑控制器PLC主机1发送的命令定义如表1所示,每个字节的传送波形参见图4所示。In the present invention, the programmable logic

表1为PLC主机各命令的具体定义Table 1 is the specific definition of each command of the PLC host

在本发明中,通信协议状态机控制器21是在一片采用硬件描述语言设计的复杂可编程门电路中(CPLD/FPGA)实现;通信协议状态机控制器21支持通信帧校验和检错功能,增强通信的可靠性。I/O刷新状态机控制器22是由专用的单片机实现,也可以是选用硬件描述语言设计的时序电路,负责I/O数据的物理刷新和对扩展模块2接收到的状态数据帧的响应。通信协议状态机控制器21和I/O刷新状态机控制器22通过硬件语言设计后也可综合在一片复杂可编程门电路中(CPLD/FPGA)实现。In the present invention, the communication protocol state machine controller 21 is realized in a complex programmable gate circuit (CPLD/FPGA) that adopts a hardware description language design; the communication protocol state machine controller 21 supports communication frame checking and error detection functions , Enhance the reliability of communication. The I/O refresh state machine controller 22 is realized by a dedicated single-chip microcomputer, and may also be a sequential circuit designed in a hardware description language, responsible for the physical refresh of I/O data and the response to the status data frame received by the expansion module 2. The communication protocol state machine controller 21 and the I/O refresh state machine controller 22 can also be implemented in a complex programmable gate circuit (CPLD/FPGA) after hardware language design.

如图5所示,扩展模块2的通信协议状态机控制器21在上电时处于初始态,此时扩展模块2的地址还没有设定好。在上一级从机选择信号SSEL有效时,数据接收功能被打开。通信协议状态机控制器21不断分析接收到的数据帧,如果数据帧是完整的,且校验和正确则根据数据帧的命令内容转到I/O刷新数据和状态数据应答状态。当应答数据完成以后,从机又回到空闲态。如果在空闲态发生了通信故障或者是可编程逻辑控制器PLC主机1发出撤销通信链路的请求的情况下,转到初始态。As shown in FIG. 5 , the communication protocol state machine controller 21 of the expansion module 2 is in an initial state when powered on, and the address of the expansion module 2 has not been set yet. When the upper-level slave selection signal SSEL is valid, the data receiving function is turned on. The communication protocol state machine controller 21 constantly analyzes the received data frame, and if the data frame is complete and the checksum is correct, it will turn to the I/O refresh data and status data response state according to the command content of the data frame. When the response data is completed, the slave returns to the idle state. If a communication failure occurs in the idle state or the programmable logic

本发明中,扩展模块2的地址选用6个比特的二进制数字表示,这样扩展模块2可以达到64个,根据需要也可以修改软件协议将地址位数再增加,则地址表示范围将更大,由于只需要4根串行线传递地址和数据,保证了所有扩展模块2连接电缆可以选用相同的连接电缆标准,并且成本极低,由于连接电缆一致,保证了扩展模块2可以通用于不同的可编程控制器主机。串行通信具有抗干扰能力强的特点,可以实现高速的通信数据传输,在本发明的实施例中,使用基于CPLD的可编程芯片实现通信协议状态机控制器21,串行通信速率为25MHz,而如果使用基于单片机实现通信协议状态机控制器21,其串行通信速率在数百KHz至数MHz,远远达不到本实施例的技术水平。In the present invention, the address of expansion module 2 selects the binary number representation of 6 bits for use, and expansion module 2 can reach 64 like this, also can revise software agreement and increase address bit number again as required, then address expression range will be bigger, because Only 4 serial lines are needed to transmit the address and data, which ensures that the connection cables of all expansion modules 2 can use the same connection cable standard, and the cost is extremely low. Because the connection cables are consistent, it is guaranteed that the expansion modules 2 can be used in different programmable controller host. Serial communication has the characteristics of strong anti-interference ability, can realize high-speed communication data transmission, in the embodiment of the present invention, use the programmable chip based on CPLD to realize communication protocol state machine controller 21, serial communication rate is 25MHz, However, if a single-chip microcomputer is used to realize the communication protocol state machine controller 21, its serial communication rate is in hundreds of KHz to several MHz, which is far below the technical level of this embodiment.

以上显示和描述了本发明的基本原理和主要特征和本发明的优点。本行业的技术人员应该了解,本发明不受上述实施例的限制,上述实施例和说明书中描述的只是说明本发明的原理,在不脱离本发明精神和范围的前提下,本发明还会有各种变化和改进,这些变化和改进都落入要求保护的本发明范围内,本发明要求保护范围由所附的权利要求书及其等效物界定。The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embodiments. What are described in the above-mentioned embodiments and the description only illustrate the principle of the present invention. Without departing from the spirit and scope of the present invention, the present invention will also have Various changes and improvements fall within the scope of the claimed invention, which is defined by the appended claims and their equivalents.

Claims (8)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNA2009100541571ACN101592934A (en) | 2009-06-30 | 2009-06-30 | Communication method between programmable logic controller and expansion module |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNA2009100541571ACN101592934A (en) | 2009-06-30 | 2009-06-30 | Communication method between programmable logic controller and expansion module |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101592934Atrue CN101592934A (en) | 2009-12-02 |

Family

ID=41407631

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA2009100541571APendingCN101592934A (en) | 2009-06-30 | 2009-06-30 | Communication method between programmable logic controller and expansion module |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101592934A (en) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102478804A (en)* | 2010-11-22 | 2012-05-30 | Ls产电株式会社 | Programmable Logic Controller System |

| CN102722132A (en)* | 2012-05-25 | 2012-10-10 | 深圳市亿维自动化技术有限公司 | Dynamic frequency modulation method and control system for programmable logic controller (PLC) expansion bus |

| CN102929590A (en)* | 2012-11-08 | 2013-02-13 | 广西工学院 | Programmable logic controller (PLC) output data refresh and read-write and time schedule controller |

| CN102955444A (en)* | 2011-08-17 | 2013-03-06 | Ls产电株式会社 | PLC network extension system |

| CN102998994A (en)* | 2012-11-26 | 2013-03-27 | 深圳市开立科技有限公司 | Embedded blood analyzer control system and control method thereof |

| CN105022331A (en)* | 2014-04-30 | 2015-11-04 | 松下神视株式会社 | programmable logic controller and control method |

| CN105511387A (en)* | 2015-11-27 | 2016-04-20 | 中工科安科技有限公司 | A PLC IO expansion module and its expansion method |

| CN105843773A (en)* | 2016-05-31 | 2016-08-10 | 上海康比利仪表有限公司 | Automatic identification method of function extension module of embedded system |

| CN107290993A (en)* | 2017-07-10 | 2017-10-24 | 上海铁路局上海动车段 | A kind of electric control system |

| CN108279626A (en)* | 2018-01-05 | 2018-07-13 | 欧姆龙(上海)有限公司 | Programmable logic controller (PLC) and its control method |

| CN108614491A (en)* | 2018-06-11 | 2018-10-02 | 上海海得控制系统股份有限公司 | A kind of programmable logic controller (PLC) communication system and method |

| CN109377768A (en)* | 2018-10-24 | 2019-02-22 | 成都臻识科技发展有限公司 | A kind of parking detection method and system for curb parking |

| CN111752210A (en)* | 2020-07-07 | 2020-10-09 | 南京东唯电子科技有限公司 | Automatic address negotiation system and method for PLC (programmable logic controller) extension module |

| CN112988639A (en)* | 2021-03-15 | 2021-06-18 | 深圳市麦格米特控制技术有限公司 | Module address allocation method and device and data interaction system |

- 2009

- 2009-06-30CNCNA2009100541571Apatent/CN101592934A/enactivePending

Cited By (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8738808B2 (en) | 2010-11-22 | 2014-05-27 | Lsis Co., Ltd. | PLC system |

| CN102478804A (en)* | 2010-11-22 | 2012-05-30 | Ls产电株式会社 | Programmable Logic Controller System |

| CN102478804B (en)* | 2010-11-22 | 2014-08-13 | Ls产电株式会社 | Plc system |

| US9360862B2 (en) | 2011-08-17 | 2016-06-07 | Lsis Co., Ltd. | PLC network extension system |

| CN102955444A (en)* | 2011-08-17 | 2013-03-06 | Ls产电株式会社 | PLC network extension system |

| CN102955444B (en)* | 2011-08-17 | 2016-01-20 | Ls产电株式会社 | PLC network extension system |

| CN102722132A (en)* | 2012-05-25 | 2012-10-10 | 深圳市亿维自动化技术有限公司 | Dynamic frequency modulation method and control system for programmable logic controller (PLC) expansion bus |

| CN102929590A (en)* | 2012-11-08 | 2013-02-13 | 广西工学院 | Programmable logic controller (PLC) output data refresh and read-write and time schedule controller |

| CN102929590B (en)* | 2012-11-08 | 2015-12-16 | 广西工学院 | PLC exports Refresh Data, read-write and time schedule controller |

| CN102998994B (en)* | 2012-11-26 | 2014-08-20 | 深圳市开立科技有限公司 | Embedded blood analyzer control system and control method thereof |

| CN102998994A (en)* | 2012-11-26 | 2013-03-27 | 深圳市开立科技有限公司 | Embedded blood analyzer control system and control method thereof |

| CN105022331A (en)* | 2014-04-30 | 2015-11-04 | 松下神视株式会社 | programmable logic controller and control method |

| CN105511387B (en)* | 2015-11-27 | 2018-04-20 | 中工科安科技有限公司 | An expansion method of PLC distributed remote IO expansion module |

| CN105511387A (en)* | 2015-11-27 | 2016-04-20 | 中工科安科技有限公司 | A PLC IO expansion module and its expansion method |

| CN105843773A (en)* | 2016-05-31 | 2016-08-10 | 上海康比利仪表有限公司 | Automatic identification method of function extension module of embedded system |

| CN107290993A (en)* | 2017-07-10 | 2017-10-24 | 上海铁路局上海动车段 | A kind of electric control system |

| CN108279626A (en)* | 2018-01-05 | 2018-07-13 | 欧姆龙(上海)有限公司 | Programmable logic controller (PLC) and its control method |

| CN108279626B (en)* | 2018-01-05 | 2020-09-04 | 欧姆龙(上海)有限公司 | Programmable logic controller and control method thereof |

| CN108614491A (en)* | 2018-06-11 | 2018-10-02 | 上海海得控制系统股份有限公司 | A kind of programmable logic controller (PLC) communication system and method |

| CN108614491B (en)* | 2018-06-11 | 2024-03-15 | 上海海得控制系统股份有限公司 | Communication system and method for programmable logic controller |

| CN109377768A (en)* | 2018-10-24 | 2019-02-22 | 成都臻识科技发展有限公司 | A kind of parking detection method and system for curb parking |

| CN109377768B (en)* | 2018-10-24 | 2021-10-12 | 成都臻识科技发展有限公司 | Parking detection method and system for roadside parking |

| CN111752210A (en)* | 2020-07-07 | 2020-10-09 | 南京东唯电子科技有限公司 | Automatic address negotiation system and method for PLC (programmable logic controller) extension module |

| CN111752210B (en)* | 2020-07-07 | 2024-03-12 | 南京东唯电子科技有限公司 | Automatic address negotiation system and method for PLC (programmable logic controller) expansion module |

| CN112988639A (en)* | 2021-03-15 | 2021-06-18 | 深圳市麦格米特控制技术有限公司 | Module address allocation method and device and data interaction system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101592934A (en) | Communication method between programmable logic controller and expansion module | |

| CN107066746B (en) | Method for realizing PCA9555 function through CPLD based on I2C interface | |

| CN103714029B (en) | Novel two-line synchronous communication protocol and application | |

| CN103677671B (en) | Data reading-writing method and system of electrical port module | |

| CN114138703B (en) | Method, device and chip for communication based on serial peripheral interface | |

| CN107092570A (en) | The adaptive configuring method and system of a kind of onboard M.2 hard disk of server | |

| CN103838700A (en) | level multiplexing control serial communication device and communication method thereof | |

| CN103279125B (en) | Response simulation and test equipment for CPCI (Compact Peripheral Component Interconnect) bus missile-borne components and implementation method of response simulation and test equipment | |

| CN104714907B (en) | A kind of pci bus is converted to ISA and APB bus design methods | |

| CN114564428A (en) | Airborne electronic equipment I/O port expansion system | |

| CN102169463A (en) | Inter-integrated circuit (IIC) bus-based manufacturing information acquisition method and equipment | |

| CN104112413A (en) | LED display screen dead pixel point inspection system | |

| CN102236631A (en) | Calculator system | |

| CN212486527U (en) | Slave station conversion device based on MODBUS protocol | |

| CN120086100A (en) | Lighting control system and lighting control method | |

| US20070088874A1 (en) | Offload engine as processor peripheral | |

| CN105354157A (en) | Method, device and system for configuring IIC (Inter-Integrated Circuit) device | |

| CN113961496A (en) | Communication circuit system, method, chip and storage medium | |

| CN118503164A (en) | Hard disk backboard and server | |

| CN113434442A (en) | A switch and data access method | |

| CN108536557A (en) | A kind of server S MBUS scanning means and method | |

| CN105068962A (en) | I2C controller access method and I2C controller access system | |

| CN212229628U (en) | Slave device | |

| CN203502958U (en) | A GPIO expansion circuit of ARM processor | |

| CN114168519A (en) | Working robot control system based on serial bus communication technology |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C12 | Rejection of a patent application after its publication | ||

| RJ01 | Rejection of invention patent application after publication | Open date:20091202 |