CN101503957B - Aboveground and underground combined heat injection coal bed gas extraction method - Google Patents

Aboveground and underground combined heat injection coal bed gas extraction methodDownload PDFInfo

- Publication number

- CN101503957B CN101503957BCN200910073743ACN200910073743ACN101503957BCN 101503957 BCN101503957 BCN 101503957BCN 200910073743 ACN200910073743 ACN 200910073743ACN 200910073743 ACN200910073743 ACN 200910073743ACN 101503957 BCN101503957 BCN 101503957B

- Authority

- CN

- China

- Prior art keywords

- coal seam

- coal

- extraction

- drainage

- seam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000003245coalSubstances0.000titleclaimsabstractdescription192

- 238000000605extractionMethods0.000titleclaimsabstractdescription63

- 238000002347injectionMethods0.000titleclaimsabstractdescription52

- 239000007924injectionSubstances0.000titleclaimsabstractdescription52

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneChemical compoundCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000claimsabstractdescription128

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription21

- 238000000034methodMethods0.000claimsabstractdescription19

- 238000005086pumpingMethods0.000claimsabstractdescription13

- 238000005553drillingMethods0.000claimsabstractdescription6

- 230000032258transportEffects0.000claimsabstract2

- 238000005065miningMethods0.000claimsdescription23

- 238000010276constructionMethods0.000claimsdescription7

- 230000035699permeabilityEffects0.000abstractdescription5

- 230000007812deficiencyEffects0.000abstract1

- 239000010410layerSubstances0.000description18

- 239000011435rockSubstances0.000description7

- 239000004568cementSubstances0.000description6

- 238000007796conventional methodMethods0.000description6

- 238000005516engineering processMethods0.000description6

- 238000009933burialMethods0.000description5

- 238000010438heat treatmentMethods0.000description5

- 238000012544monitoring processMethods0.000description5

- 238000000926separation methodMethods0.000description5

- 239000002356single layerSubstances0.000description5

- 238000009833condensationMethods0.000description3

- 230000005494condensationEffects0.000description3

- 238000003795desorptionMethods0.000description3

- 238000010586diagramMethods0.000description3

- CURLTUGMZLYLDI-UHFFFAOYSA-NCarbon dioxideChemical compoundO=C=OCURLTUGMZLYLDI-UHFFFAOYSA-N0.000description2

- 238000004891communicationMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 230000005540biological transmissionEffects0.000description1

- 229910002092carbon dioxideInorganic materials0.000description1

- 239000001569carbon dioxideSubstances0.000description1

- 238000002485combustion reactionMethods0.000description1

- 238000009776industrial productionMethods0.000description1

- 239000000243solutionSubstances0.000description1

- 238000001179sorption measurementMethods0.000description1

Images

Landscapes

- Solid Fuels And Fuel-Associated Substances (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及煤层气(或称瓦斯)的抽采方法,特别是一种低渗透的单一煤层、或煤层群抽采煤层气的方法。The invention relates to a method for extracting coal bed methane (or called gas), in particular to a method for extracting coal bed methane from a single coal seam or a group of coal seams with low permeability.

背景技术Background technique

煤矿瓦斯已成为煤炭生产的重大安全隐患,由于中国煤层渗透性极低,如何有效地抽采煤层瓦斯是全国所有煤矿面临的重大技术难题,几乎全国所有煤矿为瓦斯预抽采付出了巨大的努力与代价而收效甚微。Coal mine gas has become a major safety hazard in coal production. Due to the extremely low permeability of coal seams in China, how to effectively extract coal seam gas is a major technical problem faced by all coal mines in the country. Almost all coal mines in the country have paid a huge amount for gas pre-extraction. Efforts and costs have yielded little.

公知的煤矿瓦斯对单一煤层或煤层群的主要抽采方法有:煤矿巷道内的本煤层钻孔抽采、邻近煤层穿层钻孔抽采,或顶层巷道抽采方法等;地面实施的垂直井及其相配套的压裂抽采方法、地面实施的多分支水平井抽采方法。这些常规方法对于较低渗透的煤层几乎没有什么效果。The main extraction methods of known coal mine gas to a single coal seam or coal seam group include: the coal seam drilling drainage in the coal mine roadway, the adjacent coal seam cross-layer drilling drainage, or the top roadway drainage method, etc.; the vertical well on the ground And its matching fracturing drainage method, and the multi-branch horizontal well drainage method implemented on the ground. These conventional methods have little effect on lower permeability coal seams.

目前,国内外许多学者研究了温度对煤体中瓦斯解吸速度的影响规律。虽然研究发现温度能提高煤体中的瓦斯解吸速度,但研究的温度大多在30℃~70℃之间。其结果对于快速、高效开采煤层气没有产生特别影响。因此,也未提出相应的工业应用方法。At present, many scholars at home and abroad have studied the influence of temperature on the gas desorption rate in coal. Although studies have found that temperature can increase the gas desorption rate in coal, most of the studied temperatures are between 30°C and 70°C. The results have no special impact on the rapid and efficient extraction of coalbed methane. Therefore, no corresponding industrial application method has been proposed.

中国专利200710145879.9公开了“一种煤层气开采新技术”,该技术通过建立连通地面和煤层的竖井,然后将煤层气燃烧后的高温气体注入进气井加热煤层,对采出的混合气体进行分离。目前,由于快速高效气体分离技术尚不成熟,特别是二氧化碳与甲烷气体的分离技术难度大,使得该技术很难实现工业生产应用。Chinese patent 200710145879.9 discloses "a new technology for coalbed methane mining". This technology establishes a vertical shaft connecting the ground and the coal seam, and then injects the high-temperature gas after coalbed methane combustion into the intake well to heat the coal seam, and separates the produced mixed gas. . At present, due to the immaturity of rapid and efficient gas separation technology, especially the difficulty of separation technology of carbon dioxide and methane gas, it is difficult to realize the application of this technology in industrial production.

发明内容Contents of the invention

本发明的目的在于克服现有煤层气抽采方法的不足,提供一种井上下联合注热抽采煤层气的方法。能够大面积、简易可靠、高效地、高抽采率地实施煤层、特别是低渗透煤层的煤层气的预抽采,从根本上解决煤矿瓦斯灾害与煤层气开采难题。The purpose of the present invention is to overcome the shortcomings of the existing coal bed methane extraction method, and provide a method for coal bed methane extraction with combined heat injection up and down the well. The pre-drainage of coalbed methane in coal seams, especially low-permeability coal seams, can be carried out in a large area, simply and reliably, efficiently and with high extraction rate, and fundamentally solve the problems of coal mine gas disasters and coalbed methane mining.

本发明是通过以下技术方案来实现的:The present invention is achieved through the following technical solutions:

一种井上下联合注热抽采煤层气的方法,其特征在于:从地面向煤层实施垂直钻井进入煤层,在井下沿煤层实施抽采用通道,然后密闭抽采用通道,形成井下抽采系统,由地面垂直井向煤层注入过热水蒸气或过热水,驱替煤层气沿煤层流动进入井下抽采用通道,再将抽采的煤层气输送到地面煤层气系统。A method for extracting coalbed methane by combined heat injection up and down the well, characterized in that: vertical drilling is carried out from the ground to the coal seam to enter the coal seam, the tunnel is used for pumping along the coal seam underground, and then the tunnel is sealed to form an underground drainage system. The superheated steam or superheated water is injected into the coal seam from the vertical well on the ground, and the displacing coal bed methane flows along the coal seam into the underground extraction channel, and then the extracted coal bed methane is transported to the ground coal bed methane system.

所述的垂直钻井至少一口,两口以上时,单排布置,位于井下两条抽采用通道的中部,垂直井间距50-1000m。Said vertical wells shall be at least one, and if there are more than two wells, they shall be arranged in a single row, located in the middle of the two underground pumping passages, and the vertical wells shall be spaced 50-1000m apart.

所述的过热水蒸气、或过热水是80℃~300℃高温过热水蒸气或过热水。The superheated steam or superheated water is 80°C-300°C high temperature superheated steam or superheated water.

所述的垂直钻井的结构是:垂直井进入煤层后,煤层段设置能与煤层间做流动通道的套管,煤层以上的岩层段设置双层环空管,并用耐高温的水泥固井。The structure of the vertical drilling is as follows: after the vertical well enters the coal seam, the coal seam section is provided with a casing that can be used as a flow channel between the coal seam, and the rock section above the coal seam is provided with double-layer annular pipes, and cemented with high temperature resistant cement.

所述的煤层段设置的套管,对于单煤层是一种花管,对于煤层群是一种单层套管。The casing provided in the coal seam section is a flower pipe for a single coal seam, and a single layer casing for a group of coal seams.

所述的抽采用通道,对于单一主采煤层而言,是实施与煤层开采大巷斜交或正交的沿煤层施工至少两条平行的抽采巷道,巷道间距200m以上。The said extraction channel, for a single main coal mining seam, is to implement at least two parallel extraction roadways along the coal seam, which are oblique or orthogonal to the coal seam mining roadway, and the distance between the roadways is more than 200m.

所述的抽采用通道,对于煤层群而言,是实施与煤层开采大巷斜交或正交的沿主采煤层施工至少两条平行的抽采巷道,巷道间距200m以上,沿抽采巷道向主采煤层的上下邻近煤层施工抽采钻孔。The described extraction channel, for the coal seam group, is to implement at least two parallel extraction roadways along the main coal mining seam, which are oblique or orthogonal to the coal seam mining roadway, with a distance of more than 200m between the roadways and along the extraction roadway. Drainage boreholes are constructed to the upper and lower adjacent coal seams of the main coal seam.

所述的抽采用通道,对于单一主采煤层而言,是实施与煤层开采大巷斜交或正交的沿煤层施工至少两条平行的超长钻孔,间距200m以上。Said pumping channel, for a single main coal mining seam, is to implement at least two parallel ultra-long boreholes along the coal seam, with a distance of more than 200m, obliquely or orthogonally to the coal seam mining roadway.

所述的抽采用通道,对于煤层群而言,是实施与煤层开采大巷斜交或正交的沿每一个较厚的煤层都要施工至少两条平行的超长钻孔,间距200m以上。Said pumping channel, for the coal seam group, is implemented obliquely or orthogonally to the coal seam mining roadway. Along each thicker coal seam, at least two parallel ultra-long boreholes shall be constructed, with a distance of more than 200m.

本发明所述的井上下联合注热抽采煤层气的方法,通过对煤层加热,降低煤对煤层气的吸附性,加速煤层气的解吸,由于游离气体迅速增多,大幅度增大了煤层气压力;同时,煤体加热后会产生许多新的热破裂裂缝,同步增大了煤层的渗透性,从而提高了煤层,特别是低渗透煤层的煤层气抽采率和抽采速度。由于采用井上下的联合方案,从而实现了大规模地、大面积地、简易并可靠地实施低渗透的单一煤层、或煤层群中煤层气的抽采。由于采用井下密闭的、集中的抽采系统,实现了高纯度煤层气的开采和抽采系统的集约化生产,从而根绝了复杂的、分散的、低安全性、低可靠性、高生产成本的现行技术的弊端。The method for extracting coalbed methane by combined heat injection and extraction of coalbed methane from the upper and lower wells of the present invention reduces the adsorption of coal to coalbed methane by heating the coalbed, and accelerates the desorption of coalbed methane. Due to the rapid increase of free gas, the coalbed methane is greatly increased. At the same time, many new thermal cracks will be generated after the coal body is heated, which simultaneously increases the permeability of the coal seam, thereby improving the coal bed methane extraction rate and extraction speed of the coal seam, especially the low-permeability coal seam. Due to the adoption of the joint scheme of the upper and lower wells, large-scale, large-area, simple and reliable implementation of low-permeability single coal seam or coal seam gas extraction in coal seam groups is realized. Due to the adoption of the underground closed and centralized drainage system, the exploitation of high-purity coalbed methane and the intensive production of the drainage system have been realized, thus eliminating complex, decentralized, low-safety, low-reliability, and high-production-cost systems. Disadvantages of current technology.

附图说明Description of drawings

图1是本发明针对单一煤层施工抽采巷道和注热井的平面布置图;Fig. 1 is the plane layout diagram of the present invention for single coal seam construction drainage roadway and heat injection well;

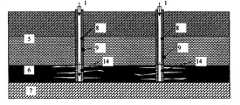

图2是图1的C-C剖面图;Fig. 2 is the C-C sectional view of Fig. 1;

图3是本发明针对单一煤层施工超长钻孔和注热井的平面布置图;Fig. 3 is the plane layout drawing of the present invention for the construction of super long boreholes and heat injection wells in a single coal seam;

图4是图3的C-C剖面图;Fig. 4 is the C-C sectional view of Fig. 3;

图5是本发明针对煤层群施工抽采巷道、邻近煤层抽采钻孔和注热井的平面布置图;Fig. 5 is the plane layout diagram of the present invention for the coal seam group construction drainage roadway, adjacent coal seam drainage boreholes and heat injection wells;

图6是图5的A-A剖面图;Fig. 6 is the A-A sectional view of Fig. 5;

图7是图5的D-D剖面图;Fig. 7 is a D-D sectional view of Fig. 5;

图8是本发明针对煤层群施工超长钻孔和注热井的示意图平面布置图;Fig. 8 is a schematic plan layout of the present invention for construction of ultra-long boreholes and heat injection wells for coal seam groups;

图9是图8的A-A剖面图;Fig. 9 is the A-A sectional view of Fig. 8;

图10是图8的D-D剖面图;Fig. 10 is a D-D sectional view of Fig. 8;

图11是本发明针对单一煤层施工一口注热井和抽采巷道的平面布置图;Fig. 11 is a plan layout diagram of a heat injection well and a drainage roadway for the construction of a single coal seam in the present invention;

图12是图11的C-C剖面图。Fig. 12 is a C-C sectional view of Fig. 11 .

下面结合附图通过较佳实施例对本发明作详细说明。The present invention will be described in detail below through preferred embodiments in conjunction with the accompanying drawings.

具体实施方式Detailed ways

实施例1:Example 1:

如图1、2所示,一种井上下联合注热抽采单一煤层煤层气的方法,在一个厚度为10m,埋藏深度100m的近水平的单一煤层中,采用本发明布置了两口垂直注热井1,井间距600m,与井下大巷3垂直,各钻井钻至煤层6中,顶板岩层段5下设双层环空管8,煤层段6下设花管14,沿双层环空管8的外层采用耐高温的水泥9固井。施工两条抽采巷道2,使之与两口注热井1的连线平行,并与大巷3垂直,在大巷入口处4密闭抽采巷道2。按照常规方法,通过密闭的抽采巷道安设抽采煤层气泵站和排水系统,以及监测系统。As shown in Figures 1 and 2, a method for extracting coalbed methane from a single coal seam with combined heat injection up and down the well, in a nearly horizontal single coal seam with a thickness of 10m and a burial depth of 100m, two vertical heat injection ports are arranged by the present invention Well 1, with a well spacing of 600m, is perpendicular to the

具体抽采步骤如下:The specific extraction steps are as follows:

1)将300℃的过热水蒸汽通过注热井1注入煤层6;1) Inject 300°C superheated steam into the

2)注入煤层的过热水蒸气沿煤层向注入井周围渗流,迅速加热煤层,煤层在高温作用下,赋存于煤层中的煤层气迅速解吸成游离煤层气,在水蒸气的驱动下,渗流传输到抽采巷道;2) The superheated steam injected into the coal seam seeps along the coal seam to the surroundings of the injection well, heating the coal seam rapidly. Transmission to the extraction roadway;

3)经抽采巷道的冷凝和分离后,煤层气经抽采泵排到地面煤层气系统,水沿排水管排出抽采巷道2。3) After condensation and separation in the extraction roadway, the coalbed methane is discharged to the surface coalbed methane system through the extraction pump, and the water is discharged out of the

4)随着过热水蒸气的不断注入煤层,注热井1和抽采巷道2控制区域内的煤体被加热,煤层中的煤层气被采出,即可停止注热。4) With the continuous injection of superheated steam into the coal seam, the coal body in the control area of the heat injection well 1 and the

实施例2:Example 2:

如图3、4所示,一种井上下联合注热抽采单一煤层煤层气的方法,在一个厚度为10m,埋藏深度100m的近水平的单一煤层中,采用本发明布置了两口垂直注热井1,井间距600m,两井的连线与井下大巷3垂直,且平行于两条抽采超长钻孔10,各钻井钻至煤层6中,顶板岩层段5下设双层环空管8,煤层段6下设花管14,沿双层环空管8的外层采用耐高温的水泥9固井。施工两条抽采超长钻孔10,使之与两口注热井1的连线平行,并与大巷3垂直,在抽采超长钻孔入口处16密闭抽采超长钻孔10。按照常规方法,通过密闭的抽采超长钻孔安设抽采煤层气泵站和排水系统,以及监测系统。As shown in Figures 3 and 4, a method for extracting coalbed methane from a single coal seam with combined heat injection up and down the well, in a nearly horizontal single coal seam with a thickness of 10m and a burial depth of 100m, two vertical heat injection ports are arranged by the

具体抽采步骤如下:The specific extraction steps are as follows:

1)将80℃的过热水蒸汽通过注热井1注入煤层6;1) Inject 80°C superheated steam into the

2)注入煤层的过热水蒸气沿煤层向注热井1周围渗流,迅速加热煤层6,煤层在高温作用下,赋存于煤层中的煤层气迅速解吸成游离煤层气,在水蒸气的驱动下,渗流传输到抽采超长钻孔10;2) The superheated steam injected into the coal seam seeps along the coal seam to the heat injection well 1 and rapidly heats the

3)抽采超长钻孔10的煤层气经抽采泵排到井下大型煤层气系统,煤层气与水分离后排到地面煤层气系统,水排在井下巷道。3) The coalbed methane extracted from the

4)随着过热水蒸气的不断注入煤层,注热井1和抽采超长钻孔10控制区域内的煤体被加热,煤层中的煤层气被采出,即可停止注热。4) With the continuous injection of superheated steam into the coal seam, the coal body in the control area of the heat injection well 1 and the extraction

实施例3:Example 3:

如图5、6、7所示,一种井上下联合注热抽采煤层群煤层气的方法,其煤层厚度分别为主采煤层6m、上邻近煤层1.5m和下邻近煤层1m,上邻近煤层与主采煤层间距3m,下邻近煤层与主采煤层间距4m,为主采煤层埋藏深度400m的近水平煤层群,采用本发明布置了两口垂直注热井1,井间距800m,与井下大巷3垂直,各钻井钻至煤层6,11,12中,顶板岩层段5下设双层环空管8,煤层段6下设单层套管15,沿双层环空管8和单层套管15的外层采用耐高温的水泥9固井,固井后在各煤层段做煤层与套管间的连通通道。施工两条抽采巷道2,使之与两口注热井1的连线平行,并与大巷3垂直。沿抽采巷道2的顶板岩层段5、底板7,施工上下邻近煤层的抽采钻孔13后,在大巷入口处4密闭抽采巷道2。按照常规方法,通过密闭的抽采巷道,安设抽采煤层气泵站和排水系统,以及监测系统。As shown in Figures 5, 6, and 7, a method for extracting coalbed methane from coal seam groups by combined heat injection up and down wells, the thickness of the coal seam is 6m for the main mining seam, 1.5m for the upper adjacent coal seam and 1m for the lower adjacent coal seam, and 1m for the upper adjacent coal seam. Adjacent coal seam and main mining coal seam spacing 3m, next adjacent coal seam and main mining coal seam spacing 4m, main mining coal seam burial depth 400m near horizontal coal seam group, adopt the present invention to arrange two vertical

具体抽采步骤如下:The specific extraction steps are as follows:

1)将300℃的过热水通过注热井1注入煤层6,11,12;1) Inject 300°C superheated water into the coal seams 6, 11, 12 through the heat injection well 1;

2)注入煤层的过热水沿煤层向注热井周围渗流,迅速加热煤层,煤层在高温作用下,赋存于煤层中的煤层气迅速解吸成游离煤层气,在过热水的驱动下,渗流传输到抽采巷道2;2) The superheated water injected into the coal seam seeps along the coal seam to the surrounding of the heat injection well, rapidly heating the coal seam, and under the high temperature of the coal seam, the coalbed methane in the coal seam is rapidly desorbed into free coalbed methane, driven by the superheated water, The seepage is transported to the

3)经抽采巷道的冷凝和分离后,煤层气经抽采泵排到地面煤层气系统,水沿排水管排出抽采巷道;3) After condensation and separation in the extraction roadway, the coalbed methane is discharged to the ground coalbed methane system through the extraction pump, and the water is discharged out of the extraction roadway along the drainage pipe;

4)随着过热水的不断注入煤层,注热井和抽采巷道控制区域内的煤体被加热,煤层中的煤层气被采出,即可停止注热。4) With the continuous injection of superheated water into the coal seam, the coal body in the control area of the heat injection well and the extraction roadway is heated, and the coalbed methane in the coal seam is extracted, and the heat injection can be stopped.

实施例4:Example 4:

如图8、9、10所示,一种井上下联合注热抽采煤层群煤层气的方法,其煤层厚度分别为主采煤层6m、上邻近煤层1.5m和下邻近煤层1m,上邻近煤层与主采煤层间距3m,下邻近煤层与主采煤层间距4m,为主采煤层埋藏深度400m的近水平煤层群,采用本发明布置了两口垂直注热井1,井间距800m,与井下大巷3垂直,各钻井钻至煤层6,11,12中,顶板岩层段5下设双层环空管8,煤层段6下设单层套管15,沿双层环空管8和单层套管15的外层采用耐高温的水泥9固井,固井后在各煤层段做煤层与套管间的连通通道。沿主采煤层和上下邻近煤层分别施工抽采超长钻孔10,与大巷3斜交60°角,使之与两口注热井1的连线基本平行。在抽采超长钻孔入口处16封孔。按照常规方法,通过密闭的抽采超长钻孔10,安设抽采煤层气泵站和排水系统,以及监测系统。As shown in Figures 8, 9, and 10, a method for extracting coalbed methane from coal seam groups by combined heat injection up and down wells, the thickness of the coal seam is 6m for the main mining seam, 1.5m for the upper adjacent coal seam and 1m for the lower adjacent coal seam, and 1m for the upper adjacent coal seam. Adjacent coal seam and main mining coal seam spacing 3m, next adjacent coal seam and main mining coal seam spacing 4m, main mining coal seam burial depth 400m near horizontal coal seam group, adopt the present invention to arrange two vertical

具体抽采步骤如下:The specific extraction steps are as follows:

1)将80℃的过热水通过注热井1注入煤层6,11,12;1) Inject 80°C superheated water into the coal seams 6, 11, 12 through the heat injection well 1;

2)注入煤层的过热水沿煤层向注入井周围渗流,迅速加热煤层,煤层在高温作用下,赋存于煤层中的煤层气迅速解吸成游离煤层气,在过热水的驱动下,渗流传输到主采煤层和上下邻近煤层的抽采超长钻孔;2) The superheated water injected into the coal seam seeps along the coal seam to the surroundings of the injection well, heating the coal seam rapidly. Drainage super-long boreholes transmitted to the main coal seam and the upper and lower adjacent coal seams;

3)抽采超长钻孔的煤层气经抽采泵排到地面煤层气系统,水沿排水管排出抽采钻孔。3) The coalbed methane extracted from the ultra-long borehole is discharged to the ground coalbed methane system through the extraction pump, and the water is discharged from the extraction borehole along the drainage pipe.

4)随着过热水的不断注入煤层,注热井和抽采巷道控制区域内的煤体被加热,煤层中的煤层气被采出,即可停止注热。4) With the continuous injection of superheated water into the coal seam, the coal body in the control area of the heat injection well and the extraction roadway is heated, and the coalbed methane in the coal seam is extracted, and the heat injection can be stopped.

实施例5:Example 5:

如图11、12所示,一种井上下联合注热抽采单一煤层煤层气的方法,在一个厚度为10m,埋藏深度100m的近水平的单一煤层中,采用本发明布置了一口垂直注热井1,与井下大巷3距离500m,位于两条抽采巷道2中部,钻井钻至煤层6中,顶板岩层段5下设双层环空管8,煤层段6下设花管14,沿双层环空管8的外层采用耐高温的水泥9固井。施工两条平行的抽采巷道2,与大巷3垂直,使注热井1位于两条抽采巷道2的中部,在大巷入口处4密闭抽采巷道2。按照常规方法,通过密闭的抽采巷道,安设抽采煤层气泵站和排水系统,以及监测系统。As shown in Figures 11 and 12, a method for extracting coalbed methane from a single coal seam with combined heat injection up and down the well, in a near-horizontal single coal seam with a thickness of 10m and a burial depth of 100m, adopts the present invention to arrange a vertical

具体抽采步骤如下:The specific extraction steps are as follows:

1)将150℃的过热水蒸汽通过注热井1注入煤层6;1) Inject 150°C superheated steam into the

2)注入煤层的过热水蒸气沿煤层向注热井周围渗流,迅速加热煤层,煤层在高温作用下,赋存于煤层中的煤层气迅速解吸成游离煤层气,在水蒸气的驱动下,渗流传输到抽采巷道;2) The superheated steam injected into the coal seam seeps along the coal seam to the surroundings of the heat injection well, rapidly heating the coal seam, and under the high temperature of the coal seam, the coalbed methane in the coal seam is rapidly desorbed into free coalbed methane, driven by water vapor, The seepage is transported to the drainage roadway;

3)经抽采巷道的冷凝和分离后,煤层气经抽采泵排到地面煤层气系统,水沿排水管排出抽采巷道。3) After condensation and separation in the extraction roadway, the coalbed methane is discharged to the ground coalbed methane system through the extraction pump, and the water is discharged out of the extraction roadway along the drainage pipe.

4)随着过热水蒸气的不断注入煤层,注热井和抽采巷道控制区域内的煤体被加热,煤层中的煤层气被采出,即可停止注热。4) With the continuous injection of superheated steam into the coal seam, the coal body in the control area of the heat injection well and the extraction roadway is heated, and the coalbed methane in the coal seam is extracted, and the heat injection can be stopped.

Claims (2)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200910073743ACN101503957B (en) | 2009-01-23 | 2009-01-23 | Aboveground and underground combined heat injection coal bed gas extraction method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200910073743ACN101503957B (en) | 2009-01-23 | 2009-01-23 | Aboveground and underground combined heat injection coal bed gas extraction method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101503957A CN101503957A (en) | 2009-08-12 |

| CN101503957Btrue CN101503957B (en) | 2012-09-26 |

Family

ID=40976320

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200910073743AExpired - Fee RelatedCN101503957B (en) | 2009-01-23 | 2009-01-23 | Aboveground and underground combined heat injection coal bed gas extraction method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101503957B (en) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102162352A (en)* | 2011-04-19 | 2011-08-24 | 王正东 | Novel method for exploiting coal-bed gas |

| CN102392678A (en)* | 2011-10-21 | 2012-03-28 | 河南煤业化工集团研究院有限责任公司 | Gas drainage method combining surface and underground fracturing and permeability improvement |

| CN102817603B (en)* | 2012-08-15 | 2015-10-28 | 新疆工程学院 | A kind of method being communicated with ground and underground coal seam gas |

| CN104314609B (en)* | 2014-09-28 | 2016-05-25 | 太原理工大学 | A kind of method for increasing that colds and heat succeed each other for drilling well for gas drainage |

| CN104481575B (en)* | 2014-11-06 | 2016-06-08 | 中国矿业大学 | A kind of vapours displacement gas improves the method for gas pumping efficiency |

| CN104632270B (en)* | 2015-01-06 | 2016-11-16 | 中国矿业大学 | A gas extraction method of oscillating pulse high-energy gas fracturing and heat injection alternately |

| CN104533514B (en)* | 2015-01-12 | 2017-07-07 | 中国矿业大学 | Hot displacement type enhanced gas extraction method in one kind drilling |

| CN110454134A (en)* | 2019-09-05 | 2019-11-15 | 湖南科技大学 | A kind of method of underground raw coal gasification |

| CN110965964B (en)* | 2019-12-16 | 2021-10-12 | 临沂矿业集团菏泽煤电有限公司 | Gas extraction method for ultra-thick coal seam |

| CN113982589B (en)* | 2021-10-26 | 2022-12-23 | 西安交通大学 | A temperature control method and system for in-situ mining of oil-rich coal |

| CN114320440A (en)* | 2021-11-29 | 2022-04-12 | 淮北矿业股份有限公司 | Up-down combined extraction method for well |

| CN114658392B (en)* | 2021-12-21 | 2023-12-05 | 重庆大学 | A combined uphole and downhole gas drainage system and method |

| CN114483160B (en)* | 2021-12-28 | 2023-03-21 | 西安交通大学 | Gas extraction method for connecting roadway |

| CN114704234B (en)* | 2022-03-22 | 2024-02-27 | 太原理工大学 | Method for alternately and circularly injecting heat to extract gas from underground adjacent drilling holes |

| CN114856518B (en)* | 2022-05-09 | 2023-02-03 | 大连理工大学 | A method for increasing production of coalbed methane by using medium and low enthalpy dry rock geothermal heat |

| CN116025309B (en)* | 2022-11-24 | 2025-06-27 | 中煤科工西安研究院(集团)有限公司 | Coal bed methane development method for increasing temperature and improving yield of stratum injection |

| CN116241217A (en)* | 2023-04-18 | 2023-06-09 | 辽宁工程技术大学 | A coal seam fracturing combined heat injection synchronous gas extraction device and method |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1508387A (en)* | 2002-12-13 | 2004-06-30 | 石油大学(北京) | Coalbed Gas Thermal Exploitation Method |

| CN1676870A (en)* | 2005-04-20 | 2005-10-05 | 太原理工大学 | Method for convection heating oil shale to recover oil and gas |

| CN101122217A (en)* | 2007-09-19 | 2008-02-13 | 中国科学院武汉岩土力学研究所 | Mixed gas displacement coalbed methane mining system and method in underground drainage roadway |

- 2009

- 2009-01-23CNCN200910073743Apatent/CN101503957B/ennot_activeExpired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1508387A (en)* | 2002-12-13 | 2004-06-30 | 石油大学(北京) | Coalbed Gas Thermal Exploitation Method |

| CN1676870A (en)* | 2005-04-20 | 2005-10-05 | 太原理工大学 | Method for convection heating oil shale to recover oil and gas |

| CN101122217A (en)* | 2007-09-19 | 2008-02-13 | 中国科学院武汉岩土力学研究所 | Mixed gas displacement coalbed methane mining system and method in underground drainage roadway |

Non-Patent Citations (2)

| Title |

|---|

| 胡春岩,等.突出矿井瓦斯井上下共同抽放.《煤炭技术》.2008,第27卷(第1期),58-59.* |

| 说明书附图1-2. |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101503957A (en) | 2009-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101503957B (en) | Aboveground and underground combined heat injection coal bed gas extraction method | |

| CN101832149B (en) | Method for extracting coal seam gas by underground heat injection | |

| CN101418679B (en) | Method for pumping coalbed gas by heating coal bed | |

| CN106884638B (en) | An in-situ heating method for thermal mining of coalbed methane | |

| CN106703752B (en) | System closing method for underground in-situ exploitation of oil shale | |

| CN111561297B (en) | Coal-geothermal water collaborative mining method based on fault water-flowing fractured zone | |

| CN104879108B (en) | A kind of coal bed gas U-shaped well heat injection enhanced gas extraction method | |

| CN114876438B (en) | Coal mining method for in-situ hydrogen production of filled coal | |

| CN101251028A (en) | Gas Drainage Method of Y-type Ventilation and Pressure Relief in Gobside Gobside Retention in High Gas Coal Seam Group Mining | |

| CN104832176B (en) | A kind of multiplex method for arranging in lane of low air permeability coal seam group's pressure relief gas pumping mining suction road | |

| CN103670338A (en) | Method for extracting coalbed methane and coal together | |

| CN108756839B (en) | In-situ conversion method and system for oil shale heat insulation and efficiency enhancement | |

| CN112796730B (en) | A method for laying out well pattern of surface drilling wells in multi-level cross-mining area | |

| CN101915086B (en) | Coal mine underground gas borehole fracturing method | |

| WO2015103861A1 (en) | Method for extracting gas by drilling hole in gob-side entry retaining y-type ventilation high-position return airway | |

| CN113803104B (en) | Method for integrally arranging upper mining area buried pipe and downward drilling and extracting full-period gas | |

| CN114856518B (en) | A method for increasing production of coalbed methane by using medium and low enthalpy dry rock geothermal heat | |

| WO2020143066A1 (en) | Geothermal exploitation system and construction method therefor | |

| CN111577279B (en) | Coal-geothermal water collaborative mining method based on collapse column water guide channel | |

| CN107575185A (en) | A kind of method in underground using the effect extraction coal bed gas that colds and heat succeed each other | |

| CN103362539A (en) | Method for extracting pressure relief gas by retained roadway drill site drilling | |

| CN109630081A (en) | A kind of coal bed drilling note high pressure-temperature vapor strengthens coal bed gas drainage device and method | |

| CN115234209A (en) | Synchronous exploitation method for same well of hot dry rock horizontal well and injection-production tubular column structure | |

| CN115596418B (en) | System and method for increasing coal bed gas by deep geothermal energy | |

| CN113803048A (en) | Coal in-situ separation mining method based on pyrolysis |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120926 |