CN101448990B - Nonwoven fabric - Google Patents

Nonwoven fabricDownload PDFInfo

- Publication number

- CN101448990B CN101448990BCN2007800182366ACN200780018236ACN101448990BCN 101448990 BCN101448990 BCN 101448990BCN 2007800182366 ACN2007800182366 ACN 2007800182366ACN 200780018236 ACN200780018236 ACN 200780018236ACN 101448990 BCN101448990 BCN 101448990B

- Authority

- CN

- China

- Prior art keywords

- aforementioned

- nonwoven fabric

- fibers

- bondedfibre fabric

- fiber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Nonwoven Fabrics (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及无纺织物。This invention relates to nonwoven fabrics.

背景技术Background technique

过去,无纺织物用于纸尿布或卫生巾等卫生用品、擦拭器等清扫用品、口罩等医疗用品等广泛的领域。这样,无纺织物在各种各样的不同的领域使用,但是在实际用于各个领域的制品的情况下,有必要以适合于各种制品的用途的性质或结构的方式进行制造。In the past, nonwoven fabrics have been used in a wide range of fields, including hygiene products such as disposable diapers and sanitary napkins, cleaning products such as wipes, and medical products such as masks. In this way, nonwoven fabrics are used in various fields, but when they are actually used as products in various fields, they must be manufactured with properties and structures suitable for the uses of various products.

无纺织物,例如,通过利用干式法或湿式法等形成纤维层(纤维网),利用化学粘合法或热粘合法等将形成纤维层的纤维彼此结合来形成。在将形成纤维层的纤维结合起来的工艺中,也存在着包含将多个针反复刺入该纤维层的方法、或喷射水流的方法等从外部向纤维层施加物理的力的方法。A nonwoven fabric is formed, for example, by forming a fiber layer (fibrous web) by a dry method or a wet method, and bonding fibers forming the fiber layer to each other by a chemical bonding method or a thermal bonding method. In the process of bonding the fibers forming the fiber layer, there is also a method of applying physical force to the fiber layer from the outside, including a method of repeatedly piercing the fiber layer with a plurality of needles, or a method of spraying water.

但是,这些方法终究只是将纤维相互交织,并没有调整纤维层中的纤维的取向或配置,或者纤维层的形状等。即,利用这些方法制造的只不过是简单的片状的无纺织物。However, these methods merely interweave the fibers, and do not adjust the orientation or arrangement of the fibers in the fiber layer, or the shape of the fiber layer. That is, what is produced by these methods is only a simple sheet-shaped nonwoven fabric.

另外,也提出过设置有开口的无纺织物的方案。所述方案揭示了为了在无纺织物上形成开口,将无纺织物夹在配备有向外侧突出的针等的突起的压模与承接该突起的承接侧的支承体之间,通过使突起部分贯通无纺织物立体地开口的方法等(例如,参照专利文献1)。In addition, a nonwoven fabric provided with openings has also been proposed. Said proposal discloses that in order to form openings on the nonwoven fabric, the nonwoven fabric is sandwiched between a stamper equipped with protrusions such as needles protruding outward and a support on the receiving side that receives the protrusions, by making the protrusions A method of opening three-dimensionally through a nonwoven fabric, etc. (for example, refer to Patent Document 1).

专利文献1:特开平6-330443号公报Patent Document 1: JP-A-6-330443

发明内容Contents of the invention

例如,在将以高粘度的液体为对象、设置有开口部的无纺织物作为吸收性物品的表面片使用的情况下,优选地,开口的直径大,进而,为了提高开口率,缩小开口与开口之间的连接部。但是,由于专利文献1所述的无纺织物,通过将构成无纺织物的纤维集合体咬入到突起部分与承接侧的支承体之间,形成凹凸或开口,所以,开口之间的连接部处的密度与开口的周围的密度几乎相同,另外,纤维取向也主要集中朝向长度方向。这样,特别是在连接部排列配置有窄的开口的情况下,在将该无纺织物作为表面片使用的吸收性物品的穿用过程中,当向宽度方向施加摩擦力时,存在着连接部的纤维容易松开,会破损的情况的课题。For example, when using a nonwoven fabric with openings for high-viscosity liquids as a top sheet of an absorbent article, it is preferable that the diameter of the openings be large, and that the ratio of openings and openings be reduced to increase the opening ratio. connection between openings. However, in the nonwoven fabric described in

本发明的目的是提供一种无纺织物,在形成有开口的无纺织物中,在该无纺织物的使用过程中不容易破损。An object of the present invention is to provide a nonwoven fabric in which openings are formed which is not easily damaged during use of the nonwoven fabric.

解决课题的方案Solution to the problem

本发明人等发现,通过从上面侧向利用规定的通气性支承构件从下面侧支承的纤维网上喷射气体,可以使构成该纤维网的纤维移动,至少可以形成开口或凹凸,从而完成本发明。The present inventors found that by injecting gas from the upper side onto a fiber web supported from the lower side by a predetermined air-permeable support member, the fibers constituting the fiber web can be moved and at least openings or irregularities can be formed, thereby completing the present invention.

(1)一种无纺织物,是具有第一方向及第二方向的无纺织物,该无纺织物包括:沿着前述第一方向形成的多个开口部、和形成在前述多个开口部中的规定的开口部与在前述第一方向上相邻的开口部之间的多个连接部,前述多个连接部中的每一个中,在前述第二方向上取向的第二方向取向纤维的含有率比在前述第一方向上取向的第一方向取向纤维的含有率高,同时,在前述连接部处的纤维密度比沿着形成前述多个开口部及前述多个连接部的区域的多个周边区域的每一个的纤维密度高。(1) A nonwoven fabric having a first direction and a second direction, the nonwoven fabric comprising: a plurality of openings formed along the first direction, and a plurality of openings formed in the plurality of openings. A plurality of connecting portions between a predetermined opening portion in the aforementioned first direction and adjacent opening portions in the first direction, in each of the aforementioned plurality of connecting portions, the second direction oriented fibers oriented in the aforementioned second direction The content rate is higher than the content rate of the first direction oriented fibers oriented in the first direction, and at the same time, the fiber density at the connecting portion is higher than that along the region where the openings and the connecting portions are formed. Each of the plurality of peripheral regions has a high fiber density.

(2)如前述第(1)项中所述的无纺织物,前述连接部的每一个在前述第二方向上的长度与前述第一方向上的长度之比在0.7以下。(2) The nonwoven fabric as described in the aforementioned item (1), wherein the ratio of the length in the second direction to the length in the first direction of each of the connecting portions is 0.7 or less.

(3)如前述第(1)或(2)项中所述的无纺织物,前述开口部的每一个,在该开口部的每一个的周缘处的纤维沿着该开口部的每一个的周缘取向。(3) The nonwoven fabric as described in the aforementioned item (1) or (2), each of the aforementioned openings, the fibers at the periphery of each of the openings along the Peripheral Orientation.

(4)如前述第(1)至(3)中任何一项所述的无纺织物,前述开口部的每一个呈大致的圆形或者大致的椭圆形。(4) The nonwoven fabric according to any one of (1) to (3) above, wherein each of the openings has a substantially circular or substantially elliptical shape.

(5)如前述第(1)至(4)中任何一项所述的无纺织物,前述开口部的每一个在前述第一方向上的直径与在前述第二方向上的直径的比例不足1。(5) The nonwoven fabric described in any one of the aforementioned items (1) to (4), wherein the ratio of the diameter of each of the aforementioned openings in the aforementioned first direction to the diameter in the aforementioned second direction is insufficient 1.

(6)如第(1)至(5)中任何一项所述的无纺织物,前述开口部的每一个在前述第二方向上的长度为4至30mm。(6) The nonwoven fabric according to any one of (1) to (5), wherein each of the aforementioned openings has a length of 4 to 30 mm in the aforementioned second direction.

(7)如第(1)至(6)中任何一项所述的无纺织物,形成前述多个开口部及多个连接部的区域,在该无纺织物的第一面侧形成于在厚度方向上凹入的多个槽部中,并且所述无纺织物还具有以沿着前述多个槽部的方式邻接的、在前述第一面侧在厚度方向上突出的多个凸状部。(7) The nonwoven fabric as described in any one of (1) to (6), wherein the region where the plurality of openings and the plurality of connection portions are formed is formed on the first surface side of the nonwoven fabric. The nonwoven fabric further has a plurality of grooves recessed in the thickness direction, and the nonwoven fabric further has a plurality of convex portions protruding in the thickness direction on the first surface side adjacent to the plurality of grooves. .

(8)如第(7)项中所述的无纺织物,前述槽部的每一个在该无纺织物的厚度方向的高度在前述凸状部的每一个的前述高度的90%以下。(8) The nonwoven fabric described in item (7), wherein the height of each of the grooves in the thickness direction of the nonwoven fabric is 90% or less of the height of each of the convex portions.

(9)如第(7)或(8)项中所述的无纺织物,前述多个凸状部中的规定的凸状部与隔着前述多个槽部中的规定的槽部相邻的凸状部相比,前述高度不同。(9) The nonwoven fabric described in item (7) or (8), wherein a predetermined convex portion among the plurality of convex portions is adjacent to a predetermined groove portion of the plurality of groove portions Compared with the convex part, the aforementioned height is different.

(10)如第(7)至(9)项中任何一项所述的无纺织物,前述凸状部的每一个的顶部呈大致的扁平状。(10) The nonwoven fabric according to any one of items (7) to (9), wherein the top of each of the aforementioned convex portions has a substantially flat shape.

(11)如第(7)至(10)项中任何一项所述的无纺织物,在作为该无纺织物的与前述第一面相反侧的面的第二面侧,形成向与前述凸状部的突出方向相反侧突出的多个突出区域。(11) The nonwoven fabric as described in any one of items (7) to (10), in which, on the second surface side of the nonwoven fabric opposite to the first surface, a A plurality of protruding regions protruding on the side opposite to the protruding direction of the convex portion.

(12)如第(7)至(11)项中任何一项所述的无纺织物,在前述第一方向上呈波浪状起伏。(12) The nonwoven fabric as described in any one of items (7) to (11), which is undulated in the aforementioned first direction.

(13)如第(1)至(10)项中任何一项所述的无纺织物,该无纺织物中的前述第二面侧是大致平坦的。(13) The nonwoven fabric according to any one of items (1) to (10), wherein the second surface side in the nonwoven fabric is substantially flat.

(14)如第(7)至(13)项中任何一项所述的无纺织物,前述多个凸状部的侧部的前述第一方向取向纤维的含有率比前述第二方向取向纤维的含有率高。(14) The nonwoven fabric according to any one of items (7) to (13), wherein the content of the fibers oriented in the first direction is higher than the fibers oriented in the second direction in the side portions of the plurality of convex portions. The content rate is high.

(15)如第(7)至(14)项中任何一项所述的无纺织物,前述多个凸状部的每一个的从前述第一面侧测定的空间面积率比从该无纺织物中的前述第二面侧测定的空间面积率大。(15) The nonwoven fabric according to any one of items (7) to (14), wherein the space area ratio of each of the plurality of convex portions measured from the first surface side is greater than that measured from the nonwoven fabric. The space area ratio measured on the aforementioned second surface side in the object is large.

(16)如第(1)至(15)项中任何一项所述的无纺织物,前述连接部的每一个中的纤维密度在0.05g/cm3以上。(16) The nonwoven fabric as described in any one of items (1) to (15), wherein the fiber density in each of the aforementioned connecting portions is 0.05 g/cm3 or more.

(17)如第(1)至(16)项中任何一项所述的无纺织物,构成该无纺织物的纤维混合有憎水性的纤维。(17) The nonwoven fabric as described in any one of items (1) to (16), wherein fibers constituting the nonwoven fabric are mixed with hydrophobic fibers.

发明的效果The effect of the invention

本发明可以提供一种具有开口、在使用中不容易破损的无纺织物。The present invention can provide a non-woven fabric which has openings and is not easily damaged during use.

附图说明Description of drawings

图1A是第一种实施形式的无纺织物的平面图。Fig. 1A is a plan view of a nonwoven fabric of a first embodiment.

图1B是第一种实施形式的无纺织物的底面图。Fig. 1B is a bottom view of the nonwoven fabric of the first embodiment.

图2是图1中的区域X的放大透视图。FIG. 2 is an enlarged perspective view of a region X in FIG. 1 .

图3A是将细长状构件等间隔地并列配置在网状支承构件上的支承构件的平面图。3A is a plan view of a support member in which elongated members are arranged side by side on a mesh support member at equal intervals.

图3B是将细长状构件等间隔地并列配置在网状支承构件上的支承构件的透视图。Fig. 3B is a perspective view of a support member in which elongated members are arranged side by side on a mesh support member at equal intervals.

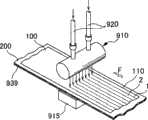

图4是表示在纤维网被图3的支承构件支承下面侧的状态下,向上面侧喷射气体、制造图1的第一种实施形式的无纺织物的状态的图示。Fig. 4 is a view showing a state in which the nonwoven fabric of the first embodiment shown in Fig. 1 is produced by injecting gas toward the upper side while the fiber web is supported on the lower side by the support member shown in Fig. 3 .

图5是可以制造第一种实施形式的无纺织物的另外的支承构件的放大正视图。Fig. 5 is an enlarged front view of another support member from which the nonwoven fabric of the first embodiment can be produced.

图6是说明第一种实施形式的无纺织物的制造装置的侧视图。Fig. 6 is a side view illustrating the nonwoven fabric manufacturing apparatus of the first embodiment.

图7是说明图6的无纺织物的制造装置的平面图。Fig. 7 is a plan view illustrating the nonwoven fabric manufacturing apparatus of Fig. 6 .

图8是图6中的区域Z的放大透视图。FIG. 8 is an enlarged perspective view of a region Z in FIG. 6 .

图9是图8中的喷出部的底面图。Fig. 9 is a bottom view of the ejection unit in Fig. 8 .

图10是第二种实施形式的无纺织物的透视剖面图。Fig. 10 is a perspective sectional view of a second embodiment of the nonwoven fabric.

图11是第三种实施形式的无纺织物的透视剖面图。Fig. 11 is a perspective sectional view of a third embodiment of a nonwoven fabric.

图12是第三种实施形式的支承构件的放大透视图。Fig. 12 is an enlarged perspective view of a supporting member of a third embodiment.

图13是第四种实施形式的无纺织物的透视剖面图。Fig. 13 is a perspective sectional view of a fourth embodiment of a nonwoven fabric.

图14是将根据本发明的无纺织物用于卫生巾的表面片的情况下的透视图。Fig. 14 is a perspective view of a case where the nonwoven fabric according to the present invention is used for a top sheet of a sanitary napkin.

图15是将根据本发明的无纺织物用于尿布的表面片的情况下的透视图。Fig. 15 is a perspective view of a case where the nonwoven fabric according to the present invention is used for a topsheet of a diaper.

图16是将根据本发明的无纺织物作为吸收性物品的中间片使用的情况下的透视图。Fig. 16 is a perspective view of a case where the nonwoven fabric according to the present invention is used as a middle sheet of an absorbent article.

图17是将根据本发明的无纺织物作为吸收性物品的外部背面(アウタ-バツク)使用的情况下的透视图。Fig. 17 is a perspective view of a case where the nonwoven fabric according to the present invention is used as an outer back (outa-back) of an absorbent article.

具体实施方式Detailed ways

下面,参照附图说明用于实施本发明的最佳形式。Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

图1A及图1B是第一种实施形式的无纺织物的平面图及底面图。图2是图1中的区域X的放大透视图。图3A及图3B是将细长状构件等间隔地并列配置在网状支承构件上的支承构件的平面图及透视图。图4是表示在纤维网被图3的支承构件支承下面侧的状态下向上面侧喷射气体、制造图1的第一种实施形式的无纺织物的状态的图示。图5是可以制造第一种实施形式的无纺织物的其它的支承构件的放大正视图。图6是说明第一种实施形式的无纺织物的制造装置的侧视图。图7是说明图6的无纺织物的制造装置的平面图。图8是图6中的区域Z的放大透视图。图9是图8中的喷出部的底面图。1A and 1B are a plan view and a bottom view of a nonwoven fabric according to a first embodiment. FIG. 2 is an enlarged perspective view of a region X in FIG. 1 . 3A and 3B are plan views and perspective views of a support member in which elongated members are arranged side by side on a mesh support member at equal intervals. Fig. 4 is a diagram showing a state in which the nonwoven fabric of the first embodiment shown in Fig. 1 is produced by injecting gas toward the upper side while the fiber web is supported on the lower side by the support member shown in Fig. 3 . Fig. 5 is an enlarged front view of another support member from which the nonwoven fabric of the first embodiment can be produced. Fig. 6 is a side view illustrating the nonwoven fabric manufacturing apparatus of the first embodiment. Fig. 7 is a plan view illustrating the nonwoven fabric manufacturing apparatus of Fig. 6 . FIG. 8 is an enlarged perspective view of a region Z in FIG. 6 . Fig. 9 is a bottom view of the ejection unit in Fig. 8 .

图10是第二种实施形式的无纺织物的透视剖面图。图11是第三种实施形式的无纺织物的透视剖面图。图12是第三种实施形式的支承构件的放大透视图。图13是第四种实施形式的无纺织物的放大透视图。图14是将根据本发明的无纺织物用于卫生巾的表面片的情况下的透视图。Fig. 10 is a perspective sectional view of a second embodiment of a nonwoven fabric. Fig. 11 is a perspective sectional view of a third embodiment of a nonwoven fabric. Fig. 12 is an enlarged perspective view of a supporting member of a third embodiment. Fig. 13 is an enlarged perspective view of a nonwoven fabric of a fourth embodiment. Fig. 14 is a perspective view of a case where the nonwoven fabric according to the present invention is used for a top sheet of a sanitary napkin.

图15是将根据本发明的无纺织物用于尿布的表面片的情况下的透视图。图16是将根据本发明的无纺织物作为吸收性物品的中间片使用的情况下的透视图。图17是将根据本发明的无纺织物作为吸收性物品的外部背面使用的情况下的透视图。Fig. 15 is a perspective view of a case where the nonwoven fabric according to the present invention is used for a topsheet of a diaper. Fig. 16 is a perspective view of a case where the nonwoven fabric according to the present invention is used as a middle sheet of an absorbent article. Fig. 17 is a perspective view of the case where the nonwoven fabric according to the present invention is used as the outer back of an absorbent article.

本发明的无纺织物是通过在利用规定的通气性支承构件从一面侧支承的形成大致片状的纤维集合体、即在构成该纤维集合体的纤维具有自由度的状态下的纤维集合体上,喷射主要由气体构成的流体,至少形成了规定的开口部的无纺织物。The nonwoven fabric of the present invention is formed by forming a substantially sheet-shaped fiber aggregate supported from one side by a predetermined air-permeable support member, that is, a fiber aggregate in a state where the fibers constituting the fiber aggregate have degrees of freedom. , spraying a fluid mainly composed of gas to form at least a non-woven fabric with predetermined openings.

[第一种实施形式][First implementation form]

下面,利用图1A、图1B、图2、图4说明本发明的无纺织物的第一种实施形式。Next, a first embodiment of the nonwoven fabric of the present invention will be described with reference to FIGS. 1A , 1B, 2 and 4 .

[1.1]形状[1.1] Shape

如图1A、图1B、图2所示,本实施形式的无纺织物180,在该无纺织物180的一面侧沿着第一方向(下面也称为长度方向)以大致相等的间隔并列地形成有多个槽部1。在无纺织物的该槽部1上,以大致相等的间隔交替地形成有开口部3及连接部4。该多个开口部3的每一个形成大致圆形或者大致椭圆形。这里,在本实施形式中,槽部1以大致相等的间隔并列地形成,但是,并不局限于此,相邻的槽部1彼此的间隔也可以分别不同。另外,也可以以使槽部1彼此的间隔变化的方式形成。As shown in FIG. 1A, FIG. 1B, and FIG. 2, the

另外,在以大致相等的间隔形成的多个槽部1的每一个之间,分别形成有多个凸状部2。该凸状部2与槽部1一样,以大致相等的间隔并列地形成。在本实施形式的无纺织物180的凸状部2的高度(厚度方向)大致均等,但是,也可以按照使相互邻接的凸状部2的高度不同的方式形成。例如,通过调整喷出主要由气体形成的流体的后面所述的喷出口913的间隔,可以调整凸状部2的高度。例如,通过缩小喷出口913的间隔,可以降低凸状部2的高度,反之,通过扩大喷出口913的间隔,可以提高凸状部2的高度。进而,通过以窄的间隔和宽的间隔交替的方式形成喷出口913的间隔,可以交替地形成高度不同的凸状部2。另外,这样,如果使凸状部2的高度部分地变化,由于和皮肤接触的面积减小,所以具有可以减轻给予皮肤的负担的优点。In addition, a plurality of

另外,凸状部2在该无纺织物180的厚度方向的高度,以比槽部1高的方式形成。可以列举出凸状部2在无纺织物180的厚度方向上的高度为0.3至15mm,优选为0.5至5mm。另外,可以列举出凸状部2在宽度方向上的长度为0.5至30mm,优选为1.0至10mm。另外,可以列举出隔着槽部1邻接的凸状部2相互之间的距离为0.5至30mm,优选为3至10mm。In addition, the height of the

另外,槽部1在无纺织物180的厚度方向上的高度,以低于凸状部2的方式形成。具体地说,可以列举出槽部1在无纺织物180的厚度方向上的高度为凸状部2在厚度方向上的高度的90%以下,优选为1%至50%,更优选为0%至20%的高度。槽部1在宽度方向上的长度例如为0.1至30mm,优选为0.5至10mm。可以列举出隔着凸状部2相邻的槽部1相互之间的距离为0.5至20mm,优选为3至10mm。这里,所谓厚度方向上的高度为0%表示该区域为开口部3。Moreover, the height of the

通过这样设计,例如,在作为吸收性物品的表面片使用该无纺织物180的情况下,可以形成在大量的规定的液体被排泄时,适合于难以在表面上大范围地扩展的槽部1。另外,即使变成在施加过分的外部压力时凸状部2塌溃的状态下,也易于保持由槽部1形成的空间,即使在施加外部压力的状态下规定的液体被排泄的情况下,也难以在表面上大范围地扩展。进而,即使在一度被吸收体等吸收的规定的液体在外部压力下返回的情况下,由于通过在该无纺织物180的表面上形成有凹凸,减少了与皮肤的接触面积,所以难以再次大范围地附着到皮肤上。By designing in this way, for example, when the

这里,槽部1或者凸状部2的高度或节距、宽度的测定方法如下所述。例如,将无纺织物180在不加压的状态下载置到工作台上,利用显微镜由无纺织物180的截面照片或者截面映象进行测定。Here, the method of measuring the height, pitch, and width of the

在测定高度(厚度方向上的长度)时,将从无纺织物180的最下部的位置(即,工作台的表面)到朝向上方的凸状部2和槽部1的各自的最高位置作为高度进行测定。When measuring the height (length in the thickness direction), the height is defined as the height from the lowest position of the nonwoven fabric 180 (that is, the surface of the table) to the highest positions of the

另外,作为凸状部2的节距,测定相互邻接的凸状部2的中心位置相互之间的距离。同样地,作为槽部1的节距,测定相互邻接的槽部1的中心位置彼此之间的距离。In addition, the distance between the center positions of the adjacent

在测定凸状部2的宽度时,从无纺织物180的最下部位置(即,工作台的表面)测定朝向上方的凸状部2的底面的最大宽度,也以同样的方式测定槽部1。When measuring the width of the

这里,对于凸状部2的截面形状没有特定的限制。例如,可以列举出拱顶状、梯形、三角形、Ω状,四角形等。为了使肌肤的触感良好,凸状部2的顶面附近及侧面优选为曲面。另外,为了即使在外部压力下凸状部2塌溃的情况下,也能够保持由槽部1形成的空间,优选地,从凸状部2的底面到顶面,宽度变窄。凸状部2的顶面优选为大致为拱顶状等的曲线(曲面)。Here, there is no particular limitation on the cross-sectional shape of the

另外,如图1A、图1B所示,本实施形式的无纺织物180是沿着槽部1形成有多个开口部3的无纺织物。并且,在所述多个开口部3的各个之间形成连接部4,将与该槽部1邻接的凸状部2相互连接起来。换句话说,以规定的间隔形成的多个连接部4将凸状部2和与之邻接的凸状部2连接起来。In addition, as shown in FIGS. 1A and 1B , the

在本实施形式中,开口部3以大致相等的间隔形成,但是,本发明并不局限于此,也可以隔开不同的间隔形成。In this embodiment, the

作为开口部3的每一个的长度方向的长度及宽度方向的长度,例如可以均为4至30mm,优选为5至10mm。The length in the longitudinal direction and the length in the width direction of each

另外,可以列举出开口部3的每一个的长度方向的长度与宽度方向的长度的比例不足1.0。Moreover, the ratio of the length of each opening

在连接部4处的无纺织物180的厚度方向的高度与凸状部2在无纺织物180的厚度方向上的高度相等或者小于该高度,优选为20%至100%,更优选为40%至70%。The height in the thickness direction of the

另外,连接部4的每一个在长度方向上的长度和宽度方向上的长度的比例优选在0.7以下。在该比例在0.7以下的情况下,该连接部4的纤维密度形成得比凸状部2的纤维密度高。在大于0.7的情况下,该连接部4的纤维密度形成得比凸状部2的纤维密度低。In addition, the ratio of the length in the longitudinal direction to the length in the width direction of each of the

这里,所谓连接部4的长度方向指的是沿着槽部1或者凸状部2延伸方向的方向,另外,所谓连接部4的宽度方向指的是相对于槽部1或者凸状部2延伸的方向大致正交的方向。换句话说,连接部4的宽度方向是槽部1的宽度,或者成为开口部3的宽度。从而,也可以说,所谓连接部4的宽度方向的长度是槽部1的宽度的长度,并且,是开口部3的宽度的长度。Here, the length direction of the connecting

具体地说,连接部4的宽度方向的长度例如可以是4至30mm,优选为5至10mm。Specifically, the length of the connecting

另外,连接部4在该无纺织物的长度方向上的截面形状呈大致的四角形的形状。另外,连接部4的长度方向的截面形状并不局限于四角形,也可以是拱顶形、梯形、三角形、Ω形等,没有特定的限制。为了抑制在槽部1处的规定的液体的扩展,优选为大致的四角形。另外,为了在过剩的外部压力下连接部4与皮肤等接触不会给予异物感,该连接部4的顶面优选为平面或者曲面。In addition, the cross-sectional shape of the

[1.2]纤维取向[1.2] Fiber Orientation

如图1A、图1B或者图2所示,该无纺织物180沿着纤维101被主要由气体构成的流体被喷射的区域,形成含有沿第一方向(无纺织物中的规定的纵向方向)取向的第一方向取向纤维(下面也称为纵向取向纤维)的含有率分别不同的区域。各个不同的区域例如可以列举出凸状部2及连接部4等。As shown in Fig. 1A, Fig. 1B or Fig. 2, this

这里,所谓纤维101在长度方向(纵向方向)上取向,指的是纤维101相对于作为第一方向、在这里为经由制造无纺织物的机械将无纺织物或者纤维网送出的方向(MD方向)的规定的纵向方向在从-45度至+45度的范围内的取向,另外,将在第一方向上取向的纤维称为纵向取向纤维。另外,纤维101在第二方向(无纺织物的规定的横向方向)上的取向,指的是纤维101相对于作为第二方向、这里为与MD方向正交的方向(CD方向)的无纺织物的规定的宽度方向从-45度至+45度的范围内的取向,另外,将在宽度方向上取向的纤维称为横向取向纤维。Here, the

对于凸状部2,优选地,纵向取向纤维和横向取向纤维适度地混合。凸状部2在与开口部3连接的部分,以纵向取向纤维的含有率比横向取向纤维的含有率高的方式形成。For the

另外,在凸状部2中面对支承构件240的一侧,如图1B、图2所示,在和连接部4邻接的区域,部分地以横向取向纤维的含有率比其它区域的横向取向纤维的含有率高的方式形成。In addition, on the side facing the supporting

槽部1是如前面所述被直接喷射主要由气体构成的流体(例如热风)、向该无纺织物的厚度方向凹入的区域。进而,在槽部1中形成开口部3及连接部4。通过喷射主要由气体构成的流体,在长度方向上取向的纤维101(纵向取向纤维)被喷吹到凸状部2的侧部8侧。并且,借助被喷射的主要由气体构成的流体和/或喷射到作为后面描述的支承构件240的不通气部的细长状构件245上、其流动方向改变的主要由气体构成的流体,沿宽度方向取向的纤维101(横向取向纤维)被喷吹到连接部4侧。换句话说,开口部3的周缘处的纤维101沿着该开口形状取向。The

在该无纺织物180中,连接部4中的纵向取向纤维的含有率最低。换句话说,连接部4的横向取向纤维的含有率最高。具体地说,以横向取向纤维的含有率为55%至100%、优选为60%至100%的方式形成。在横向取向纤维的含有率低于55%的情况下,如后面所述,由于槽部1的单位面积重量低,所以难以提高无纺织物在宽度方向上的强度。这样,例如,在作为吸收性物品的表面片使用该无纺织物180的情况下,在使用该吸收性物品的过程中,由于和身体的摩擦,在宽度方向上产生经纬滑动,或者产生破损的危险性。In this

纤维取向的测定,利用株式会社キ—エンス制造的デジタルマイクロスコ—プ(数字显微镜)VHX-100进行,以下面所述的方法进行。(1)将样品以其长度方向处于正确的方向的方式置于观察台上。(2)将不规则地出现在近前的纤维除去,使透镜的焦点与样品的最靠近前的纤维相一致,(3)设定摄影深度(纵深),在PC画面上制成样品的3D图像。其次,(4)将3D图像转换成2D图像,(5)在测定范围内,在画面上画出将长度方向恰当地等分的多个平行线。(6)在画出平行线细分化的各个单元中,观察纤维的取向是第一方向(长度方向)还是第二方向(宽度方向),测定朝向各个方向的纤维的根数。然后,(7)通过计算相对于在设定范围内的全部纤维根数而言、朝向第一方向(长度方向)的纤维取向的纤维根数的比例,以及朝向第二方向(宽度方向)的纤维取向的纤维根数的比例,可以测定并计算出纤维的取向。The measurement of fiber orientation was carried out using Digital Microscope VHX-100 manufactured by Keyence Co., Ltd., by the method described below. (1) The sample is placed on the observation table in such a manner that its longitudinal direction is in the correct direction. (2) Remove the fibers that appear irregularly near the front, and make the focal point of the lens coincide with the fiber closest to the front of the sample, (3) Set the imaging depth (depth), and make a 3D image of the sample on the PC screen . Next, (4) convert the 3D image into a 2D image, and (5) draw a plurality of parallel lines on the screen that properly divide the longitudinal direction into equal parts within the measurement range. (6) In each subdivided unit drawn by parallel lines, observe whether the orientation of the fibers is in the first direction (longitudinal direction) or the second direction (width direction), and measure the number of fibers oriented in each direction. Then, (7) by calculating the ratio of the number of fibers oriented in the first direction (length direction) to the total number of fibers in the set range, and the ratio of the number of fibers oriented in the second direction (width direction) The ratio of the number of fibers in which the fibers are oriented can be measured and calculated for the orientation of the fibers.

[1.3]纤维的疏密[1.3] Density of fibers

如图1A、图1B所示,对连接部4进行调整,使其纤维密度比凸状部2的纤维密度高。As shown in FIGS. 1A and 1B , the

具体地说,连接部4的纤维密度可以列举出在0.05g/cm3以上,优选为0.10至0.50g/cm3,更优选为0.15至0.20g/cm3。在该连接部4的纤维密度小于0.05g/cm3的情况下,在施加过大的外部压力、凸状部2塌溃的情况下,存在该连接部4同样也会塌溃的情况。Specifically, the fiber density of the connecting

调整凸状部2,使其平均纤维密度比连接部4的低。具体地说,可以为0.005至0.20g/cm3,优选为0.007至0.07g/cm3。在该凸状部2的纤维密度小于0.005g/cm3的情况下,由于包含在该凸状部2内的液体的自身重量或外部压力,不仅凸状部2容易塌溃,而且存在一度被吸收的液体在加压状态下容易返回的情况。另外,在凸状部2的纤维密度大于0.20g/cm3的情况下,该凸状部2带来的液体难以向下方移动,存在液体滞留在该凸状部2内,给予使用者潮湿的感觉的情况。The

另外,从开口部3的长度方向侧部的大致中央部朝向两端的周边区域的纤维密度以向该开口部3的长度方向两个端部纤维密度逐渐变高的方式形成。即,连接开口部3的长度方向的侧部的凸状部2的侧部处的纤维密度以随着靠近开口部3的长度方向两端而逐渐变高的方式形成。这是因为,随着开口部3的大小变大,主要由气体构成的流体被喷吹到连接部4侧的纤维101的量变多。In addition, the fiber density of the peripheral region from the substantially central portion of the longitudinal side portion of the

另外,该无纺织物180,以从形成槽部1及凸状部2的一面侧测定的空间面积率比从作为与从形成槽部1及凸状部2的面相反一侧的面的另一面侧测定的空间面积率低的方式形成。In addition, the

对于在后面描述的在支承构件240之上被输送的纤维网100,借助重力,纤维101向与主要由气体构成的流体喷射的面相反的面侧移动,在靠近该相反的面侧的部位的纤维之间的距离有变窄的倾向。另一方面,随着从面对支承构件240一侧接近被主要由气体构成的流体喷射的面侧,纤维间的距离有变宽的倾向。With regard to the

进而,通过喷射主要由气体构成的流体,靠近支承构件240侧的纤维101被压到该支承构件240上,朝向支承构件240的平面方向。从而,纤维间距离进一步变窄,纤维彼此容易密集。并且,在这种状态下,通过加热炉处理等的热处理,纤维彼此热粘结,纤维101的自由度变低,在无纺织物180的另一面侧的纤维之间的空间的量变低。Furthermore, by spraying a fluid mainly composed of gas, the

另一方面,随着从支承构件240侧的面朝向被主要由气体构成的流体喷射的面侧,纤维彼此不会被过度压扁,另外,在凸状部2处,通过被喷射的主要由气体构成的流体碰到支承构件240而弹回,纤维101部分地存在以变为相对于该支承构件240垂直的方式朝向的纤维。在这种状态下,通过将纤维彼此热粘结,提高在纤维网100的截面中的空间面积率。On the other hand, as the surface on the side of the supporting

这里,所谓空间面积率指的是不存在纤维的空间面积相对于总面积的比例。另外,空间面积率的测定方法如下所述。Here, the term "space area ratio" refers to the ratio of the space area where fibers do not exist to the total area. In addition, the measuring method of a space area ratio is as follows.

测定设备使用株式会社キ—エンス制造的デジタルマイクロスコ—プ(数字显微镜)VHX-100。首先,(1)在观察台上,以沿着槽部1及凸状部2的方向成为纵向方向的方式将样品置于测定设备上,(2)在凸状部2的顶点,从凸状部2突出的面并且从与凸状部2突出的面相反侧的面,分别进行以下的测定。As a measurement device, Digital Microscope VHX-100 manufactured by Keyence Co., Ltd. was used. First, (1) place the sample on the measurement device so that the direction along the

(3)适当地设定测定设备的透镜放大率和个人计算机画面上的放大率,将透镜的焦点对准样品的最靠近前侧的纤维(除掉不规则的出现在近前的纤维)。然后,(4)适当地设定摄影深度(纵深),制成样品的3D图像。(3) Appropriately set the lens magnification of the measuring device and the magnification on the personal computer screen, and focus the lens on the fiber closest to the front side of the sample (removing irregular fibers that appear near the front). Then, (4) appropriately set the imaging depth (depth), and create a 3D image of the sample.

(5)将3D图像转换成2D图像,将设定的体积平面化,指定在该范围内的纤维之间的空间。进而,(6)对于2D图像进行二进制化(二值化)处理,使纤维存在的部位为白色,纤维不存在的部位为黑色。然后,(7)将颜色反转,使纤维不存在的部位为白色,测定白色化的面积等。(5) Convert the 3D image into a 2D image, planarize the set volume, and specify the space between fibers within the range. Furthermore, (6) perform binarization (binarization) processing on the 2D image, and make the portion where the fiber exists white and the portion where the fiber does not exist black. Then, (7) the color is reversed, the portion where the fiber does not exist is made white, and the whitened area is measured.

这里,在本文献中,使放大率为300倍、摄影深度为220μm(每20μm摄影一次,共计摄影11次),进行n=10的测定,取平均值。Here, in this document, the magnification ratio is 300 times, and the imaging depth is 220 μm (11 imaging times in total at every 20 μm), n=10 measurements are performed, and the average value is taken.

另外,按如下方式计算空间面积率。In addition, the space area ratio is calculated as follows.

空间面积率(%)=(空间总面积(mm2)/测定范围面积(mm2))×100Space area ratio (%) = (total space area (mm2 )/measurement range area (mm2 ))×100

这里,空间总面积,可以由(测定时的空间总面积/测定时的放大倍数)算出,另外,测定范围面积可以由(测定时的测定范围面积/测定时的放大倍数)算出。Here, the total space area can be calculated from (total space area during measurement/magnification during measurement), and the measurement range area can be calculated from (area of measurement range during measurement/magnification during measurement).

由于空间面积率越高,相当于纤维间距离越宽越粗,所以,纤维容易移动,自由度高。进而,对于通过开口处理等部分地将纤维间的距离扩大的无纺织物,通过提高每一个空间的空间面积率,在无纺织物中的整个被主要由气体构成的流体喷射的面上,纤维间距离变宽。因此,例如,在将该无纺织物用于吸收性物品等的情况下,可以整体地降低排泄物等规定的液体透过该无纺织物180时的阻力,使液体更容易向吸收体等内移动。Since a higher space area ratio corresponds to a wider and thicker distance between fibers, the fibers are easier to move and have a higher degree of freedom. Furthermore, for the nonwoven fabric in which the distance between the fibers is partially enlarged by opening treatment, etc., by increasing the space area ratio of each space, the fibers are completely sprayed on the entire surface of the nonwoven fabric that is sprayed with a fluid mainly composed of gas. distance widens. Therefore, for example, when the nonwoven fabric is used in an absorbent article, etc., the resistance when a predetermined liquid such as excrement permeates through the

这里,所谓每个空间的空间面积率,指的是纤维不存在的空间的总面积相对于在规定的范围内的纤维不存在的空间的个数的比例。空间面积可以用下面的计算公式进行计算。Here, the space area ratio per space refers to the ratio of the total area of spaces where fibers do not exist to the number of spaces where fibers do not exist within a predetermined range. The space area can be calculated with the following calculation formula.

空间面积(mm2/个)=(空间总面积(mm2)/空间个数(个))Space area (mm2 /piece) = (total space area (mm2 )/number of spaces (piece))

从凸状部2中的该凸状部2突出侧的面测定的空间面积率与从和该凸状部2突出的面相反侧的面测定的空间面积率的差为5%至100%,优选为5%至80%,更优选为15%至40%。The difference between the space area ratio measured from the surface on the protruding side of the

另外,从凸状部2突出侧的面测定的空间面积率可以列举为50%至100%,优选为50%至90%,更优选为50%至80%。In addition, the space area ratio measured from the protruding surface of the

进而,从凸状部2突出侧的面测定的每一个空间的空间面积可以列举为3000μm2以上,优选为3000至30000μm2,更优选为5000至20000μm2。Furthermore, the space area per space measured from the protruding surface of the

[1.4]单位面积重量[1.4] Weight per unit area

无纺织物180整体的平均单位面积重量,具体地,可以列举为10至200g/m2,优选为20至100g/m2。例如,在将该无纺织物180用于吸收性物品的表面片的情况下,当平均单位面积重量低于10g/m2时,存在在使用过程中容易破损的情况。另外,在该无纺织物180的平均单位面积重量高于200g/m2的情况下,存在难以顺滑地使带来的液体向下方移动的情况。The average weight per unit area of the entire

如上所述,对凸状部2进行调整,以便与槽部1相比,纤维101的单位面积重量变高。这里,凸状部2的单位面积重量,具体地,可以列举为15至250g/m2,优选为20至120g/m2。在该凸状部2的单位面积重量低于15g/m2的情况下,由于包含在该凸状部2内的液体的自身重量或外部压力,凸状部2不仅容易塌溃,而且,有时一度吸收的液体在加压下容易返回。另外,在凸状部2的单位面积重量大于250g/m2的情况下,难以使该凸状部2带来的液体向下方移动,有时液体滞留在该凸状部2中,给予使用者以潮湿的感觉。As described above, the

调整槽部1的平均单位面积重量,使之比包含槽部1和凸状部2的整体的平均单位面积重量低。具体地说,可以列举出在槽部1的底部的平均单位面积重量为3至150g/m2,优选为5至80g/m2。在该槽部1的底部的平均单位面积重量小于3g/m2的情况下,在使用过程中,存在容易破损的情况。另外,在该槽部1的底部的平均单位面积重量大于150g/m2的情况下,该槽部1带来的液体难以向下方(另一面侧)移动,滞留在槽部1内,有给予使用者以潮湿感的可能性。The average basis weight of the

进而,调整槽部1整体的平均单位面积重量,使之低于凸状部2整体的单位面积重量的平均值。具体地说,槽部1整体的平均单位面积重量相对于凸状部2的单位面积重量在90%以下,优选为3%至90%,更优选为3%至70%。在槽部1整体的平均单位面积重量相对于凸状部2的单位面积重量大于90%的情况下,落入槽部1的液体向无纺织物180的下方(另一面侧)移动时的阻力变高,存在液体从槽部1溢出的情况。另外,在槽部1的底部的单位面积重量相对于凸状部2的单位面积重量小于3%的情况下,在使用过程中有时容易破损。Furthermore, the average basis weight of the

[1.5]其它[1.5] Others

例如,为了使规定的液体吸收或者透过而使用本实施形式的无纺织物180的情况下,槽部1使液体透过,由于凸状部2是多孔结构,所以难以保持液体。进而,形成在槽部1中的开口部3,除液体之外,也能够使固体透过。For example, when the

槽部1由于形成有开口部3,所以适合于使液体或固体透过。进而,由于在槽部1的底部的纤维101大多数沿宽度方向取向,所以,可以防止液体沿槽部1的长度方向过分流动、大范围扩展。虽然槽部1平均单位面积重量低,但是,由于在连接部4处纤维密度高,纤维101在该槽部1的宽度方向上取向(CD取向),所以,无纺织物180向宽度方向的强度(CD强度)提高。因此,即使具有比较大的开口部3,宽度方向的强度也会提高。Since the

另外,槽部1每单位面积的横向取向纤维的含有率比凸状部2高,在凸状部2的侧部,每单位面积的纵向取向纤维的含有率比凸状部2的中央部的高。并且,在凸状部2中含有的沿厚度方向取向的纤维101比槽部1的多。借此,即使例如通过向凸状部2施加厚度方向的负荷、凸状部2的厚度减少,在释放负荷的情况下,由于在其厚度方向上取向的纤维101的刚性也易于恢复到原来的高度。即,可以说是一种压缩恢复性高的无纺织物。In addition, the content rate of transversely oriented fibers per unit area in the

[1.6]制造方法[1.6] Manufacturing method

下面利用图3至图9说明制造本实施形式中的无纺织物180的方法。首先,将纤维网100载置到作为通气性支承构件的支承构件240的上面侧。换句话说,利用支承构件240从下侧支承纤维网100。Next, a method of manufacturing the

并且,将处于支承该纤维网100的状态下的支承构件240向规定的方向移动,通过从该移动的纤维网100的上面侧连续地喷射气体,可以制造本实施形式中的无纺织物180。Then, the

这里,如图3所示,对于支承构件240,可以列举出以规定的间隔将多个细长状构件245大致平行地配置在网状支承构件210的上面的支承构件。Here, as shown in FIG. 3 , as the

细长状构件245是不使主要由气体构成的流体向下方侧通气的不通气部。并且,喷射到细长状构件245上的主要由气体构成的流体,其流动方向改变。这样,借助被喷射的主要由气体构成的流体和/或被细长状构件245改变其方向的主要由气体构成的流体,纤维101被移动,形成开口部3及连接部4。The

详细地说,在被主要由气体构成的流体喷射的区域,该区域中的纵向取向纤维被喷吹到与该区域邻接的区域,并且,通过沿厚度方向凹入,形成多个槽部。In detail, in a region sprayed with a fluid mainly composed of gas, longitudinally oriented fibers in the region are blown to a region adjacent to the region, and are formed by recessing in the thickness direction to form a plurality of grooves.

而且,在多个槽部1之间形成凸状部2,由于从该槽部1被喷吹的纤维101,该凸状部2的侧部8的纤维密度变高,同时,在该侧部8的纵向取向纤维的含有率变高。Moreover, the

同时,在槽部1中,被喷射的主要由气体构成的流体借助细长状构件245改变其流动方向,借助喷射的主要由气体构成的流体和/或流动方向改变的主要由气体构成的流体,纵向取向纤维被喷吹到凸状部2侧,另外,横向取向纤维被喷吹到被喷射的规定方向的前后,形成开口部3及连接部4。At the same time, in the

另外,为了形成具有开口部3的无纺织物180,也可以使用不同的支承构件。利用所使用的支承构件,可以改变槽部1、凸状部2、开口部3及连接部4的大小或排列等。Moreover, in order to form the

例如,可以列举出在图3所示的规定的网状构件上以规定的图形配置有不通气部的构件,或如图5所示的在织入的金属丝与金属丝之间形成有多个规定孔部的构件等。For example, a member in which a non-ventilated portion is arranged in a predetermined pattern on a predetermined mesh member shown in FIG. A member that defines a hole, etc.

作为在该规定的网状构件上以规定的图形配置不通气部的构件,是如上面所述的那样,但是,作为另外的实施形式,也可以列举出适当地改变作为不通气部的细长状构件245的形状或配置的构件。不通气部除了将图3所示的细长状构件245配置在网状支承构件210的一面侧的情况之外,也可以通过填埋(例如,利用软焊料、树脂等)作为通气部的网状孔来形成。The member that arranges the non-ventilated portion in a predetermined pattern on the predetermined mesh member is as described above, but as another embodiment, it is also possible to appropriately change the length of the non-ventilated portion. The shape of the

作为在织入的金属丝与金属丝之间形成多个规定的孔部的构件,可以列举出图5所示的支承构件275。支承构件275例如是相对于大致平行地排列的规定粗度的金属丝276以与多个金属丝276彼此桥接的方式将其它规定粗度的金属丝277交替地卷绕成螺旋状地形成的螺旋编织的通气性网。A support member 275 shown in FIG. 5 is exemplified as a member that forms a plurality of predetermined hole portions between woven wires. The supporting member 275 is, for example, a helix formed by alternately winding metal wires 277 of a predetermined thickness in a helical shape with respect to the wires 276 of a predetermined thickness arranged substantially parallel to each other so as to bridge the plurality of wires 276 . Woven breathable mesh.

在该支承构件275中的金属丝276及金属丝277成为不通气部。另外,被该支承构件275中的金属丝276及金属丝277包围的部分变成作为通气部的孔部278。The wire 276 and the wire 277 in the support member 275 form an air-impermeable portion. In addition, the portion surrounded by the wire 276 and the wire 277 in the support member 275 becomes a hole portion 278 as a vent portion.

在这种支承构件的情况下,通过使织入的方法或丝的粗度、丝的形状部分地发生变化,可以部分地使通气度发生变化。例如,可以使金属丝276为不锈钢的圆形丝,金属丝277为不锈钢的扁平丝,进行螺旋编织的支承构件。In the case of such a support member, the air permeability can be partially changed by partially changing the weaving method, the thickness of the threads, or the shape of the threads. For example, the metal wire 276 may be a stainless steel round wire, and the metal wire 277 may be a stainless flat wire, and may be a supporting member that is spirally woven.

但是,在这种情况下的成为不通气部的金属丝276及金属丝277(特别是,金属丝的交点部分)的通气度相对于在作为通气部的孔部278处的通气度在90%以下,优选在0至50%,更优选为0至20%。在这里,0%指的是实质上主要由气体构成的流体是不能通气的。However, in this case, the air permeability of the metal wire 276 and the wire 277 (particularly, the intersection portion of the metal wire) that become the non-ventilated portion is 90% relative to the air permeability at the hole portion 278 that is the vent portion. Below, it is preferably 0 to 50%, more preferably 0 to 20%. Here, 0% means that the fluid consisting essentially of gas is not breathable.

这里。在无纺织物制造装置90中,一边由规定的方向依次移动纤维网100一边形成无纺织物180。制造本实施形式的无纺织物180的无纺织物制造装置90包括:通气性支承构件200,该通气性支承构件200从一面侧支承作为纤维集合体的纤维网100;作为喷射机构的喷出部910及图中未示出的送气部,所述喷射机构从作为该纤维集合体的纤维网100处的另一面侧向由通气性支承构件200从前述一面侧支承的作为该纤维集合体的纤维网100喷射主要由气体构成的流体;作为移动机构的输送器930,所述移动机构将作为纤维集合体的纤维网100向规定的方向F移动。here. In the nonwoven

另外,输送器930包括:通气性的通气性带部939,所述通气性带部939形成载置通气性支承构件200的横向长的环状;旋转部931、933,所述旋转部931、933位于形成横向长的环状的通气性带部939的内侧、配置在长度方向的两端,使该环状的通气性带部939向规定的方向旋转。In addition, the

如上所述,输送器930使处于从下面侧支承纤维网100的状态的通气性支承构件200沿规定方向F移动。具体地说,如图6所示,使纤维网100以通过喷出部910的下侧的方式移动。进而,使纤维网100以通过作为加热机构的两侧面开口的加热器部950的内部的方式移动。As described above, the

如图8所示,喷射机构包括图中未示出的送气部及喷出部910。图中未示出的送气部经由送气管920连接到喷出部910上。送气管920能够通气地连接到喷出部910的上侧。如图9所示,在喷出部910上以规定的间隔形成多个喷出口913。As shown in FIG. 8 , the spray mechanism includes an air supply unit and a

从图中未示出的送气部经由送气管920被送气到喷出部910的气体,从形成在喷出部910上的多个喷出口913喷出。从多个喷出口913喷出的气体连续地喷射到被从下面侧支承在通气性支承构件200上的纤维网100的上面侧。具体地说,从多个喷出口913喷出的气体连续地喷射到处于被输送器930向规定的方向F移动的状态下的纤维网100的上面侧。The gas fed from a gas supply unit (not shown) to the

在喷出部910的下方、配置在通气性支承构件200的下侧的吸气部915对从喷出部910喷出、通过通气性支承构件200的气体等进行吸气。这里,通过利用该吸气部915进行吸气,能够以贴紧到通气性支承构件200上的方式将纤维网100定位。进而,通过吸气,可以在进一步保持由空气流成形的槽部(凹凸)等形状的状态下,在加热器部950内进行输送。在这种情况下,优选地,与利用空气流成形的同时,一边吸气一边输送到加热器部950。The

通过该吸气部915吸引(吸气)被喷射的主要由气体构成的流体,可以防止碰到通气性支承构件200的主要由气体构成的流体过剩地弹回,防止纤维网100的形状紊乱。The injected fluid mainly composed of gas is sucked (suctioned) by the

吸引主要由气体构成的流体的强度,达到将被主要由气体构成的流体喷射的区域的纤维101推压到支承构件上的程度的强度即可。The strength of attracting the fluid mainly composed of gas may be such that the

另外,通过调整喷射的主要由气体构成的流体的风量或温度、引入量、支承构件的通气性、纤维网100的单位面积重量等,可以使凸状部2的形状发生变化。例如,在使喷射的主要由气体构成的流体的量和吸引(吸气)的主要由气体构成的流体的量几乎均等、或者吸引(吸气)的主要由气体构成的流体的量多的情况下,例如,无纺织物115(无纺织物180)中的凸状部2的背面侧以沿着通气性支承构件200的形状的方式形成。从而,在通气性支承构件200是平坦的情况下,该无纺织物115(无纺织物180)中的作为与形成槽部1及凸状部2的面相反一侧的面的背面侧成为大致平坦的。In addition, the shape of the

这里,通过从通气性支承构件200的下侧引入主要由气体构成的流体,由于喷射主要由气体构成的流体的区域的纤维一边被推压到该通气性支承构件200侧一边移动,所以纤维集中在通气性支承构件200侧。另外,在凸状部2处,通过被喷射的主要由气体构成的流体碰撞通气性支承构件200,适当地弹回,变成纤维部分地朝向厚度方向的状态。Here, by introducing the fluid mainly composed of gas from the lower side of the air-

从各个喷出口913喷出的主要由气体构成的流体的温度,也可以是常温的,但是,例如,为了使槽部(凹凸)、开口部的成形性良好,可以将该温度调整到构成纤维集合体的至少热塑性纤维的软化点以上,优选调整到熔点的+50℃至-50℃的温度范围内。当纤维软化时,由于纤维本身的反弹力降低,所以,容易利用空气流等保持纤维再排列的形状,当进一步提高温度时,由于纤维彼此的热粘合开始,所以更容易保持槽部(凹凸)等的形状。从而,在保持槽部(凹凸)等的形状的状态下,容易在加热器部950内进行输送。The temperature of the fluid mainly composed of gas ejected from each

作为加热机构的加热器部950在规定方向F的两端开口。借此,载置在被输送器930移动的通气性支承构件200上的纤维网100(无纺织物120)以规定的时间滞留在形成于加热器部950内部的加热空间中,并连续地移动。例如,在构成纤维网100(无纺织物180)的纤维101中含有热塑性纤维的情况下,可以获得通过在该加热器部950中加热,纤维101相互结合起来的无纺织物115。The

通气性支承构件200根据制造的无纺织物可以适当地更换。例如,在制造本实施形式的无纺织物180的情况下,作为通气性支承构件200,可以使用上述支承构件240。The air-permeable supporting

在使用上述支承构件240作为通气性支承构件的情况下,将纤维网100载置到上面侧的支承构件240沿着与细长状构件245的长度方向大致正交的方向移动。借此,在与细长状构件245大致正交的方向上连续地向纤维网100的上面侧喷射气体。即,沿着与细长状构件245大致正交的方向形成槽部1。并且,后面描述的开口部3形成于细长状构件245与槽部1交叉的位置。When the

开口部3的大小或节距可以由支承构件的不通气部(图3、4的细长状构件245或图5的金属丝276等)的形状和喷出口913的形状任意决定。即,开口部3的MD尺寸(长度方向的尺寸)依存于各个支承构件中不通气部的MD尺寸(长度方向的尺寸),开口部3的CD尺寸(宽度方向的尺寸)依存于喷出口913的CD尺寸(宽度方向上的尺寸)。另外,开口部3的MD节距(在长度方向上相邻的开口部3处的该开口部3的中心位置之间的长度)依存于各个支承构件上的不通气部的MD节距(长度方向上相邻的不通气部处的中间位置之间的长度)。通过适时地改变它们,可以形成所希望的大小或节距的开口部3。另外,喷出口的形状可以列举出正圆、椭圆、正方形、长方形等,在加大开口部3的CD尺寸(宽度方向的长度)的情况下,横向方向长的长方形或椭圆形是优选的。The size or pitch of the

如上所述,细长状构件245是不通气性构件,例如,不使从上方侧喷射的气体向下方侧通气。换句话说,被喷射到细长状构件245上的气体,其流动方向被改变。As described above, the

另外,细长状构件245不使纤维网100中的纤维101向支承构件240的下方侧移动。In addition, the

因此,构成纤维网100的纤维101的移动,借助从纤维网100的上面侧喷射的气体和/或作为被喷射的气体、通过纤维网100通气,同时,被由细长状构件245改变流动方向的气体移动。Therefore, the movement of the

例如,在被气体喷射的区域中的纤维101,向与该区域邻接的区域移动。并且,由于被气体喷射的区域向规定方向移动,所以结果,向被气体喷射的规定方向上连续的区域中的侧方的区域移动。For example, the

从而,在形成槽部1的同时,在槽部1中的底部的纤维101以在宽度方向上取向的方式移动。另外,在槽部1与槽部1之间形成凸状部2,在该凸状部2的侧方部的纤维密度变高,纤维101沿长度方向取向等。Thus, while the

进而,作为被喷射的气体、将纤维网100通气,同时,被细长状构件225改变流动方向的气体使构成纤维网100的纤维101向与上述不同的方向移动。Furthermore, as the injected gas, the

由于构成支承构件240的网状支承构件210及细长状构件245限制纤维101向支承构件240的下面侧移动,所以,纤维101在沿着支承构件240的上面的方向上移动。Since the

详细地说,喷射到细长状构件245上的气体变成在沿着该细长状构件245的方向上流动。这样流动被改变的气体,使配置在细长状构件245的上面的纤维101从细长状构件245的上面向周围区域移动。借此,形成规定形状的开口部3。另外,可以调整纤维101的取向、疏密或者单位面积重量中的一或两项以上。In detail, the gas injected onto the

另外,通过调整被喷射到纤维网100上的主要由气体构成的流体的温度、量或者强度,并且调整移动机构中的纤维网100的移动速度,调整张力等,即使用相同的支承构件,也可以制造开口部3、槽部1、凸状部2的形态或单位面积重量或纤维密度不同的无纺织物。另外,通过调整被喷射到纤维网100上的主要由气体构成的流体的温度、量或者强度,并且调整移动机构中的纤维网100的移动速度,调整张力等,即使是不同的支承构件,也可以制造开口部3、槽部1、凸状部2的形态或单位面积重量或纤维密度相同的无纺织物。In addition, by adjusting the temperature, amount or strength of the fluid mainly composed of gas sprayed onto the

另外,在使用上述支承构件275(图5)的情况下,在槽部1中,当主要由气体构成的流体被喷射到支承构件275处的金属丝276和金属丝277的交点部分上时,该主要由气体构成的流体被该交点部分改变流动方向。因此,将被该交点部分支承的纤维101向前后左右喷射,形成开口部3。In addition, in the case of using the above-mentioned support member 275 ( FIG. 5 ), in the

并且,被槽部1中的交点部分之外的部分支承的区域,由于纤维101被推压在该支承构件275上,所以被限制向下方的移动。另外,通过借助金属丝的交点部分移动横向取向纤维,形成连接部4。Further, since the

这里,在成为通气部的区域中的通气度,例如,可以为10000至60000cc/cm2·min,优选为20000至50000cc/cm2·min。但是,在通气性支承构件中,例如,在挖通金属板等形成通气部的情况下,由于不存在主要由气体构成的流体通向该板部分的阻力,所以,有时通气度在上述记载的数值以上。Here, the air permeability in the region serving as the air vent can be, for example, 10000 to 60000 cc/cm2 ·min, preferably 20000 to 50000 cc/cm2 ·min. However, in the air-permeable support member, for example, when a metal plate is dug through to form a vent portion, since there is no resistance to the passage of fluid mainly composed of gas to the plate portion, the air permeability is sometimes in the range described above. value above.

所使用的支承构件,成为不通气部的区域与形成通气部的区域相比,表面滑动性高时是优选的。通过提高滑动性,在主要由气体构成的流体喷射的区域与不通气部交叉的区域,纤维101易于移动,所以,可以提高开口部3及连接部4的成形性。In the support member used, it is preferable that the region serving as the non-ventilated portion has higher surface slidability than the region forming the ventilated portion. By improving the slidability, the

其它实施形式Other forms of implementation

下面,说明本发明的无纺织物的实施形式的变形形式。另外,在下面的变形形式中,没有特别说明的部分与第一种实施形式是一样的,在附图中所付的标号也与第一种实施形式一样的情况下,采用相同的标号。Next, modified forms of embodiments of the nonwoven fabric of the present invention will be described. In addition, in the following variants, parts not particularly described are the same as those of the first embodiment, and when the same reference numerals are attached to the drawings as those of the first embodiment, the same reference numerals are used.

利用图10至图13,对本发明的无纺织物中的第二种实施形式到第四中实施形式进行说明。第二种实施形式是与形成无纺织物的凸状部的面相一反侧的面不同的形态的实施形式。第三种实施形式是无纺织物整体的形状不同的实施形式。第四种实施形式是无纺织物的凸状部不同的实施形式。The second to fourth embodiments of the nonwoven fabric of the present invention will be described with reference to FIGS. 10 to 13 . The second embodiment is an embodiment in a different form from the surface opposite to the surface forming the convex portion of the nonwoven fabric. A third embodiment is an embodiment in which the shape of the nonwoven as a whole is different. A fourth embodiment is a different embodiment of the convexity of the nonwoven.

[2.1]第二种实施形式[2.1] The second implementation form

利用图10说明本发明的无纺织物的第二种实施形式。A second embodiment of the nonwoven fabric according to the invention is described with reference to FIG. 10 .

如图10所示,本实施形式的无纺织物182,其与形成有该无纺织物182中的槽部1及凸状部2的面相反一侧的面的形态与第一种实施形式不同。下面以和第一种实施形式的不同点为中心进行说明。As shown in FIG. 10, the nonwoven fabric 182 of this embodiment differs from the first embodiment in the form of the surface on the opposite side to the surface on which the

[2.1.1]无纺织物[2.1.1] Non-woven fabric

本实施形式的无纺织物182,在其一面侧交替地并列形成槽部1及凸状部2。并且,在无纺织物182的另一个面侧,位于凸状部2的底面的区域以向该凸状部2突出侧突出的方式形成。换句话说,无纺织物182,在该无纺织物182的另一面侧,在该一面侧的位于凸状部2的底面上的区域凹入而形成凹部。位于该一面侧的槽部1的底面上的另一面侧的区域,向与一面侧的凸状部相反的方向突出,形成凸状部。In the nonwoven fabric 182 of this embodiment, the

[2.1.2]制造方法及支承构件[2.1.2] Manufacturing method and supporting member

本实施形式的无纺织物182的制造方法与第一种实施形式的记载相同。另外,对于在制造该无纺织物182时使用的支承构件,可以使用和第一种实施形式中的支承构件240同样的支承构件。The manufacturing method of the nonwoven fabric 182 in this embodiment is the same as that described in the first embodiment. In addition, as the support member used when manufacturing this nonwoven fabric 182, the same support member as the

该无纺织物182,在从其下面侧利用支承构件240支承的状态下,喷射主要由气体构成的流体,同时,从支承构件240的下方吸引(吸气)主要由气体构成的流体。并且,通过使被吸引(吸气)的主要由气体构成的流体的量小于被喷射的主要由气体构成的流体的量。当被喷射的主要由气体构成的流体比被吸引(吸气)的主要由气体构成的流体的量大时,被喷射的主要由气体构成的流体例如与作为通气性支承构件的支承构件240碰撞,弹回一些。借此,以向与凸状部2的上面侧的凸状部2相同的方向突出的方式形成作为凸状部2的里侧的下面侧(底面侧)。换句话说,按着凸状部2向凸侧突出的情况,下面侧也突出。The nonwoven fabric 182 jets a fluid mainly composed of gas while being supported by the supporting

当无纺织物182的凸状部2向上面侧弯曲时,与凸状部邻接的槽部1的另一面侧的区域相对地突出,形成向下面侧突出的凸状部。即,形成向与凸状部中的突出方向相反的一侧突出的突出区域,无纺织物182变成由凸状部和槽部构成的波浪形。When the

[2.2]第三种实施形式[2.2] The third implementation form

利用图11及图12说明本发明的无纺织物的第三种实施形式。A third embodiment of the nonwoven fabric of the present invention will be described with reference to FIGS. 11 and 12 .

[2.2.1]无纺织物[2.2.1] Non-woven fabric

如图11所示,本实施形式的无纺织物184在无纺织物184整个呈波浪状起伏这一点上与第一种实施形式不同。下面,以和第一种实施形式的不同点为中心进行说明。As shown in FIG. 11 , the

本实施形式的无纺织物184以该无纺织物184整体具有相对于槽部1及凸状部2延伸的方向大致正交的波浪状起伏的方式形成。The

[2.2.2]制造方法[2.2.2] Manufacturing method

对于制造本实施形式的无纺织物184的制造方法,与第一种实施形式一样,但是,作为通气性支承构件的支承构件的形态不同。本实施形式的支承构件280,如图12所示,是一种在网状支承构件260的上面以规定的间隔大致平行地配置有多个细长状构件285的支承构件。The manufacturing method of the

本实施形式的支承构件280,如图12所示,是在支承构件280的长度方向或者短的方向中的任何一个方向上沿平行方向具有波浪状起伏的支承构件。构成支承构件280的网状支承构件260形成有多个孔径小的孔部263,从纤维网100的上面侧喷射的气体不受该网状支承构件260的妨碍,向下方通气。该网状支承构件260不会对喷射的主要由气体构成的流体的流动引起大的变化,另外,不使纤维101向该网状支承构件260的下方移动。The

进而,配置在构成支承构件280的网状支承构件260的上面的细长状构件285是不使从上面喷射的主要由气体构成的流体向下方通气的不通气部。而且,使从上面喷射的主要由气体构成的流体的流动方向改变。借此,喷射到细长状构件285上的主要由气体构成的流体和/或喷射到该细长状构件285上、其流动方向被改变的主要由气体构成的流体使纤维101移动,形成开口部3。Furthermore, the

进而,由于构成该支承构件280的网状支承构件260本身具有起伏,所以,借助从纤维网100的上面侧喷射的主要由气体构成的流体,纤维网100成形为具有沿着该支承构件280的形状的起伏的形状。Furthermore, since the

在本实施形式中,通过一边向载置在支承构件280的上面的纤维网100喷射主要由气体构成的流体,一边使该纤维网100沿着轴X方向移动,可以形成本实施形式的该无纺织物184。In this embodiment, the

支承构件280中的起伏的形态可以任意设定。例如,如图12所示的向X方向上的起伏的顶部之间的节距例如可以是1至30mm,优选为3至10mm。另外,该支承构件280上的起伏的顶部与底部的高低差,例如,可以为0.5至20mm,优选为3至10mm。进而,在该支承构件280在X方向上的截面形状并不局限于图12所示的波浪状,例如,也可以是以起伏的各个顶点形成锐角的方式将大致三角形连起来的形状,或者,以起伏的各个顶点大致平坦的方式将大致的四角形状的凹凸连起来的形状等。The form of undulations in the

本实施形式的无纺织物184可以利用上述无纺织物制造装置90进行制造。该无纺织物制造装置90的无纺织物184的制造方法等可以参考第一种实施形式的无纺织物180的制造方法及无纺织物制造装置90的说明中的记载。The

[2.3]第四种实施形式[2.3] The fourth implementation form

利用图13说明本发明的无纺织物的第四种实施形式。A fourth embodiment of the nonwoven fabric according to the invention will be described with reference to FIG. 13 .

如图13所示,本实施形式的无纺织物186与第一种实施形式的不同点在于形成在该无纺织物186的一面侧形成的凸状部2的厚度方向上的高度不同的第二凸状部22。下面,说明与第一种实施形式的不同点。As shown in FIG. 13 , the

[2.3.1]无纺织物[2.3.1] Non-woven fabric

这是在该无纺织物186的一面侧并列地形成有多个槽部1的无纺织物。并且,在多个槽部1的每一个之间,分别交替地形成多个凸状部2及多个第二凸状部22。所述凸状部2及第二凸状部22与多个槽部1一样并列地形成。另外,在槽部1的每一个上形成开口部3和连接部4。This is a nonwoven fabric in which a plurality of

凸状部2及第二凸状部22是纤维网100中的不被主要由气体构成的流体喷射的区域,通过形成槽部1,成为相对地突出的区域。第二凸状部22,例如,与凸状部2相比,在该无纺织物186的厚度方向上的高度低,在宽度方向上的长度也形成的小,但是,对于该第二凸状部22中的纤维的疏密、纤维取向及单位面积重量等,与凸状部2同样地形成。The

无纺织物186中的凸状部2及第二凸状部22的配置,在并列地形成的多个槽部1的每一个之间,形成凸状部2及第二凸状部22。并且,凸状部2以隔着槽部1与第二凸状部22相邻的方式形成。另外,反之,第二凸状部22以隔着槽部1与凸状部2相邻的方式形成。即,凸状部2和第二凸状部22隔着槽部1交替地形成。具体地说,以凸状部2、槽部1、第二凸状部22、槽部1、凸状部2的顺序重复地形成这种配置图形。另外,凸状部2及第二凸状部22的位置关系并不局限于此,可以按照至少无纺织物186的一部分以隔着槽部1、多个凸状部2分别相邻的方式形成。另外,多个第二凸状部22也可以以分别相邻的方式形成。The arrangement of the

[2.3.2]制造方法及支承构件[2.3.2] Manufacturing method and supporting member

本实施形式中的无纺织物186的制造方法与第一种实施形式中所述的一样,但是,用于无纺织物186的制造的无纺织物制造装置90的喷出口913的形态不同。The manufacturing method of the

通过一边将主要由气体构成的流体喷射到载置在支承构件240的上面的纤维网100上,一边使之沿规定方向移动,形成无纺织物186。在喷射主要由气体构成的流体时,形成槽部1、凸状部2、第二凸状部22、开口部3及连接部4,但是,它们的形成可以借助无纺织物制造装置90中的主要由气体构成的流体的喷出口913的形态任意地改变。

例如,如图13所示,为了形成该无纺织物186,例如,可以通过调整喷射主要由气体构成的流体的喷出口913的间隔来进行。例如,通过使喷出口913的间隔比第一种实施形式的喷出口913的间隔窄,可以形成与凸状部2相比厚度方向的高度低的第二凸状部22。另外,通过使喷出口913的间隔比第一种实施形式的喷出口913的间隔宽,也可以形成与凸状部2相比厚度方向的高度高的凸状部。而且,在形成喷出口913的间隔处,通过以窄的间隔和宽的间隔交替的方式配置,可以形成凸状部2和第二凸状部22隔着槽部1交替地并列配置的该无纺织物186。该喷出口913的间隔并不局限于此,通过想要形成的无纺织物的凸状部2的高度及第二凸状部22的排列,可以任意地形成。并且,在形成喷出口913的间隔处,通过以窄的间隔和宽的间隔交替的方式配置,形成凸状部2和第二凸状部22隔着槽部1交替地并列配置的该无纺织物186。For example, as shown in FIG. 13 , in order to form the

本实施形式的无纺织物186可以利用上述无纺织物制造装置90制造。在该无纺织物制造装置90中的无纺织物186的制造方法等,可以参照第一种实施形式的无纺织物180的制造方法及无纺织物制造装置90的说明中的记载。The

实施例Example

<纤维结构><fibrous structure>

使用具有高密度聚乙烯和聚对苯二甲酸乙酯的芯鞘结构、平均纤度为3.3dtex、平均纤维长度51mm、涂布亲水油剂的纤维A,和在涂布憎水性油剂这一点上与纤维A不同的纤维B的混棉。使用纤维A和纤维B的混合比为70:30,单位面积重量调整到40g/m2的纤维集合体。Fiber A with a core-sheath structure of high-density polyethylene and polyethylene terephthalate, an average fineness of 3.3 dtex, an average fiber length of 51 mm, and a coating of a hydrophobic oil agent is used. A blend of fiber B different from fiber A. The mixing ratio of fiber A and fiber B was 70:30, and the fiber aggregate was adjusted to 40 g/m2 of basis weight.

<制造条件><Manufacturing conditions>

图9所示的喷出口913的形状为横向长的长方形,喷出口913的截面形状为方柱形。以纵向1.0mm、横向6.0mm、喷出口913间的节距14mm形成多个喷出口913。另外,喷出部910的宽度为500mm。在温度105℃、风量10001???/分钟的条件下喷射热风。The shape of the

支承体使用长度2mm、宽度70mm的拐角呈圆形的横向长的长方形形状的挖通的不锈钢类的套筒。在该套筒中,在MD方向(长度方向:槽部或者凸状部延伸的方向)隔开12mm的间隔,在CD方向(短的方向:与槽部或者凸状部延伸的方向大致正交的方向)隔开3mm的间隔,将上述挖通的图形配置成网格状。另外,套筒的厚度为0.5mm。As the support body, a dug-through stainless steel-based sleeve in a horizontally long rectangular shape with rounded corners of 2 mm in length and 70 mm in width was used. In this sleeve, there is an interval of 12 mm in the MD direction (longitudinal direction: the direction in which the groove or convex portion extends), and in the CD direction (short direction: approximately perpendicular to the direction in which the groove or convex portion extends). direction) at an interval of 3 mm, and the above-mentioned digging patterns are arranged in a grid pattern. In addition, the thickness of the sleeve is 0.5mm.

将前面所述的纤维结构的纤维用速度为20m/分钟的梳理机开纤,制成纤维网,以450mm的宽度裁断纤维网。然后,以3m/分钟的速度利用20目的通气性网输送纤维网。利用前面所述的喷出部910及喷出口913的设计,在温度105℃、风量1200l/分钟的条件下,喷射空气流。然后,从通气性网的下方以小于热风量的吸收量进行吸引(吸气)。之后,在利用通气性网输送该纤维网的状态下,在设定成温度125℃、热风风量10Hz的炉内输送约30秒钟。The fibers of the aforementioned fiber structure were opened with a carding machine at a speed of 20 m/min to form a fiber web, and the fiber web was cut with a width of 450 mm. Then, the fiber web was conveyed by a 20-mesh air-permeable net at a speed of 3 m/min. Utilizing the above-mentioned design of the

<结果><result>

凸状部:单位面积重量为52g/m2,厚度方向的长度为3.8mm,纤维密度为0.01g/cm3,该凸状部的每一个的宽度为8.5mm,节距为14mm。Convex part: weight per unit area is 52 g/m2 , length in thickness direction is 3.8 mm, fiber density is 0.01 g/cm3 , width of each protruding part is 8.5 mm, and pitch is 14 mm.

槽部:单位面积重量为11g/m2,厚度方向的长度为1.8mm,纤维密度为0.007g/cm3,该槽部的每一个的宽度为5.5mm,节距为14mm。Grooves: Weight per unit area is 11 g/m2 , length in thickness direction is 1.8 mm, fiber density is 0.007 g/cm3 , each groove has a width of 5.5 mm and a pitch of 14 mm.

连接部:单位面积重量为30g/m2,厚度方向的长度为1.8mm,纤维密度为0.02g/cm3,该连接部的每一个的宽度为5.5mm,连接部的每一个的长度为2.1mm,MD方向的节距为15.0mm,CD方向的节距为14.0mm。Connecting part: the weight per unit area is 30g/m2 , the length in the thickness direction is 1.8mm, the fiber density is 0.02g/cm3 , the width of each connecting part is 5.5mm, and the length of each connecting part is 2.1 mm, the pitch in the MD direction is 15.0mm, and the pitch in the CD direction is 14.0mm.

开口部:该开口部的每一个的宽度为5.3mm,开口部的每一个的长度为11.5mm,MD方向的节距为15.0mm,CD方向的节距为14.0mm。Openings: the width of each opening is 5.3 mm, the length of each opening is 11.5 mm, the pitch in the MD direction is 15.0 mm, and the pitch in the CD direction is 14.0 mm.

形状:分别形成凸状部、槽部、开口部及连接部,凸状部的背面向与凸状部相同的方向隆起,成为不形成该无纺织物的最里面的形状。另外,在槽部,沿着该槽部延伸的方向交替地形成多个连接部和开口部。呈该开口部的面积为61.0mm2的纵向长的长方形形状,拐角呈圆形形状。Shape: a convex portion, a groove portion, an opening, and a connection portion are respectively formed, the back of the convex portion rises in the same direction as the convex portion, and the innermost shape of the nonwoven fabric is not formed. In addition, in the groove portion, a plurality of connection portions and opening portions are alternately formed along the direction in which the groove portion extends. The opening has a vertically long rectangular shape with an area of 61.0 mm2 , and its corners are rounded.

用途例Application example

作为本发明的无纺织物的用途,例如,可以列举出卫生巾、衬里、尿布等的吸收性物品中的表面片等。在这种情况下,凸状部可以是皮肤面侧、背面侧中的任何一个,但是,通过形成为皮肤侧,由于可以降低与皮肤接触的面积,所以,不容易给予由液体引起的潮湿感。另外,也可以作为吸收性物品的表面片与吸收体之间的中间片使用。由于与表面片或者吸收体的接触面积减小,所以存在不容易从吸收体返回的情况。另外,由于和皮肤的接触面积减小或具有缓冲感,所以,也可以在吸收性物品的侧片、尿布等的外表面(最外部)及面扣件(面フアスナ-)的阴性材料等中使用。另外,也可以用于除去附着在床或身体上的尘埃等的擦拭器、口罩、母乳垫等多个方面。Examples of uses of the nonwoven fabric of the present invention include topsheets in absorbent articles such as sanitary napkins, liners, and diapers. In this case, the convex portion may be on the skin side or the back side, but by forming it on the skin side, since the area in contact with the skin can be reduced, it is not easy to give a moist feeling due to liquid. . Moreover, it can also be used as an intermediate sheet|seat between the top sheet of an absorbent article, and an absorber. Since the contact area with the surface sheet or the absorber decreases, it may not be easy to return from the absorber. In addition, since the contact area with the skin is reduced or has a cushioning feeling, it can also be used in the side panels of absorbent articles, the outer surface (outermost) of diapers, and the negative material of surface fasteners use. In addition, it can also be used in various fields such as wipers, masks, and breast milk pads to remove dust and the like attached to beds and bodies.

[4.1]吸收性物品的表面片[4.1] Top sheet of absorbent article

作为本发明的无纺织物的用途,如图14、15所示,例如,可以列举出将具有凹凸、在凹部设置有多个开口部和与凸状部相比纤维密度相对较高的连接部的无纺织物作为吸收性物品的表面片301、302使用的情况。在这种情况下,优选地,以形成有凸状部的面成为皮肤侧的方式配置该无纺织物。As the use of the nonwoven fabric of the present invention, as shown in FIGS. 14 and 15 , for example, there are concavities and convexities, a plurality of openings are provided in the concavity, and a connecting portion having a relatively high fiber density compared with the convex portion. The case where the nonwoven fabric is used as the

在将该无纺织物作为吸收性物品的表面片301、302使用的情况下,当规定的液体被排泄时,该液体主要落入槽部。另外,由于设置有开口部,所以,例如,即使是含有固体成分的具有粘性的液体,借助开口部也容易向吸收体移动,可以抑制液体在表面上大范围地扩展。When the nonwoven fabric is used as the

进而,由于在连接部处的纤维的大部分沿着宽度方向取向,所以,向宽度方向的抗拉强度高,在吸收性物品的穿用过程中,可以防止施加朝向宽度方向的摩擦等的力而使该表面片301、302破损。Furthermore, since most of the fibers at the connecting portion are oriented in the width direction, the tensile strength in the width direction is high, and during wearing of the absorbent article, it is possible to prevent force such as friction in the width direction from being applied. Thus, the

另一方面,凸状部的侧部由于纤维彼此密集,所以刚性高。而且,由于沿长度方向取向的纵向取向纤维的含有率高,所以即使负荷施加到凸状部上,也可以防止被容易地压溃,例如,即使凸状部被负荷压溃,压缩恢复性也是很高的。On the other hand, the side portion of the convex portion has high rigidity because the fibers are densely packed. Moreover, since the content of longitudinally oriented fibers oriented in the longitudinal direction is high, even if a load is applied to the convex portion, it can be prevented from being easily crushed, for example, even if the convex portion is crushed by a load, the compression recovery property is excellent very high.

因此,即使由身体的姿势变化而施加到表片301、302上的负荷变化,也可以保持与皮肤的接触面积低,所以可以维持触感性,进而,即使一度被吸收体吸收的液体返回,也难以再次大范围地附着到皮肤上。Therefore, even if the load applied to the

[4.2]吸收性物品的中间片[4.2] Middle sheet of absorbent article

作为本发明的无纺织物的用途,如图16所示,例如,可以列举出将具有凹凸、在凹部设置有多个开口部和与凸状部2相比纤维密度相对高的连接部的该无纺织物作为吸收性物品的中间片311使用的情况。在这种情况下,优选地,以形成有凸状部的面成为表面片310侧的方式配置该无纺织物。As the use of the nonwoven fabric of the present invention, as shown in FIG. 16, for example, the non-woven fabric having concavo-convex, a plurality of openings are provided in the concavity, and a connecting portion having a relatively high fiber density compared with the protruding

根据本发明的无纺织物,由于连接部的纤维密度高,进而,连接部的大部分纤维向宽度方向取向,所以,以宽度方向的抗拉强度高的方式形成。借此,在该吸收性物品的穿用过程中,即使将吸收性物品变形等而向中间片311上施加朝向宽度方向拉伸的负荷,也可以防止中间片311破损。According to the nonwoven fabric of the present invention, since the fiber density of the connecting portion is high, and most of the fibers of the connecting portion are oriented in the width direction, the tensile strength in the width direction is formed so as to be high. Thereby, even if a load stretching in the width direction is applied to the middle sheet 311 due to deformation of the absorbent article or the like during wearing of the absorbent article, the middle sheet 311 can be prevented from being damaged.

另外,通过以形成有凸状部的面成为表面片310侧的方式将该无纺织物作为中间片311配置,可以在表面片310与中间片311之间设置多个空间。进而,通过在中间片311上设置开口部,即使在短时间排泄大量液体的情况下,妨碍液体透过的因素少,也可以迅速地使该液体向吸收体移动。并且,可以防止该液体返回表面片310并大范围地扩展。In addition, by arranging the nonwoven fabric as the intermediate sheet 311 so that the surface on which the convex portion is formed faces the surface sheet 310 side, a plurality of spaces can be provided between the surface sheet 310 and the intermediate sheet 311 . Furthermore, by providing the openings in the intermediate sheet 311, even when a large amount of liquid is excreted in a short time, the liquid can be rapidly moved to the absorber with few factors preventing liquid permeation. And, the liquid can be prevented from returning to the surface sheet 310 and spreading widely.

进而,即使一度透过中间片311被吸收体吸收的液体返回,由于中间片311与表面片310的接触率低,所以该液体难以返回表面片310再次大范围地附着在皮肤上。Furthermore, even if the liquid once absorbed by the absorber through the intermediate sheet 311 returns, since the contact rate between the intermediate sheet 311 and the top sheet 310 is low, it is difficult for the liquid to return to the top sheet 310 and adhere to the skin again in a wide range.

另外,由于凸状部的中央部与侧部或槽部相比,含有沿厚度方向取向的纤维多,该中间片311上的凸状部的顶点和表面片310接触,所以,容易将残留在表面片310上的液体向厚度方向引入。借此,液体难以残留表面片310上。In addition, since the central portion of the convex portion contains more fibers oriented in the thickness direction than the side portions or groove portions, the apexes of the convex portion on the intermediate sheet 311 are in contact with the surface sheet 310, so it is easy to leave the fibers remaining on the surface sheet 310. The liquid on the surface sheet 310 is introduced in the thickness direction. This makes it difficult for liquid to remain on the surface sheet 310 .

这样,可以获得表面片310中的定点性和液体的低残留性,可以防止液体大范围长时间地附着在皮肤上。进而,由于在中间片311中的凸状部的侧部,沿长度方向取向的纵向取向纤维的含有率高,所以,可以将从表面片310移动到侧部的液体向长度方向引导。借此,即使在中间片311中,液体向宽度方向扩散,也可以防止诱发从吸收性物品的泄漏,可以提高吸收体的吸收效率。In this way, the fixed point and low liquid residue in the top sheet 310 can be obtained, and the liquid can be prevented from adhering to the skin over a wide area for a long time. Furthermore, since the side portion of the convex portion in the intermediate sheet 311 has a high content of longitudinally oriented fibers oriented in the longitudinal direction, the liquid moved from the surface sheet 310 to the side portion can be guided in the longitudinal direction. Thereby, even if the liquid spreads in the width direction in the intermediate sheet 311, it is possible to prevent the leakage from the absorbent article from being induced, and it is possible to improve the absorption efficiency of the absorbent body.

[4.3]吸收性物品的最外部[4.3] The outermost part of the absorbent article

作为本发明的无纺织物的用途,如图17所示,例如,可以列举出将具有凹凸、在凹部设有多个开口部和与凸状部相比纤维密度相对较高的连接部的无纺织物作为吸收性物品的最外部321使用的情况。在这种情况下,优选地,以形成有凸状部的面成为该吸收性物品的外侧的方式配置该无纺织物。As the use of the nonwoven fabric of the present invention, as shown in FIG. 17 , for example, nonwoven fabrics having unevenness, a plurality of openings in the concave portion, and a connection portion with a relatively high fiber density compared with the convex portion can be cited. The case where the textile is used as the

最外部321由于以形成有凸状部的面成为吸收性物品的外侧的方式配置,所以在使用该吸收性物品时,在主要用手触摸的情况下,触感良好。另外,借助于槽部的开口部,通气性良好。Since the

各结构物Each structure

下面详细描述各个结构物。Each structure is described in detail below.

[5.1]关于无纺织物[5.1] Regarding non-woven fabrics

[5.1.1]纤维集合体[5.1.1] Fiber assembly

纤维集合体是形成大致片状的纤维集合体,处于构成该纤维集合体的纤维具有自由度的状态。换句话说,是具有纤维之间的自由度的纤维集合体。这里,所谓纤维之间的自由度,指的是作为纤维集合体的纤维网借助主要由气体构成的流体使纤维能够自由移动的程度。该纤维集合体,例如,可以通过将多个纤维混合的混合纤维以形成规定厚度的纤维层的方式喷出来形成。另外,例如,可以通过将多个不同的纤维的每一个以分多次叠层形成纤维层的方式喷出来形成。The fiber aggregate is a fiber aggregate formed in a substantially sheet shape, and the fibers constituting the fiber aggregate have degrees of freedom. In other words, it is a fiber aggregate having degrees of freedom between fibers. Here, the degree of freedom between fibers refers to the degree to which fibers can freely move in a fiber web as a fiber aggregate through a fluid mainly composed of gas. The fiber aggregate can be formed, for example, by spraying mixed fibers obtained by mixing a plurality of fibers to form a fiber layer of a predetermined thickness. Also, for example, it may be formed by spraying each of a plurality of different fibers so as to form a fiber layer by laminating in multiple times.

作为本发明的纤维集合体,例如,可以列举出利用梳理法形成的纤维网,或者热粘合并将纤维彼此之间的热粘合固化之前的纤维网。另外,可以列举出通过气流成网法形成的网,或者热粘合并将纤维彼此之间的热粘合固化之前的纤维网。另外,可以列举出利用点粘法压花的热粘合固化之前的纤维网。另外,可以列举出利用纺粘法纺丝并被压花以前的纤维集合体,或者被压花的热粘合固化之前的纤维集合体。另外,可以列举出利用针刺法形成的、半交织的纤维网。另外,可以列举出利用射流喷网法形成的半交织纤维网。另外,可以列举出利用熔喷法纺丝、纤维彼此的热粘合固化之前的纤维集合体。另外,可以列举出利用溶剂粘结法形成的利用溶剂将纤维彼此固化之前的纤维集合体。The fiber aggregate of the present invention includes, for example, a fiber web formed by a carding method, or a fiber web before thermal bonding and thermal bonding between fibers are cured. In addition, a web formed by an air-laid method, or a fiber web before thermal bonding and thermal bonding between fibers is cured may be mentioned. In addition, fiber webs before thermobonding and curing by point bonding embossing can be mentioned. In addition, a fiber aggregate before being spun by a spunbond method and embossed, or a fiber aggregate before being embossed and thermally bonded and cured can be mentioned. In addition, a semi-interlaced fiber web formed by a needle punching method can be mentioned. In addition, a semi-entangled fiber web formed by a spunlace method can be mentioned. In addition, fiber aggregates before spinning by a melt-blowing method and thermal bonding and solidification of fibers can be mentioned. In addition, a fiber aggregate formed by a solvent bonding method before the fibers are solidified with a solvent can be mentioned.

另外,优选地,利用空气(气体)流容易将纤维再排列的是用使用比较长的纤维的梳理法形成的纤维网,进而,可以列举出纤维彼此的自由度高、只通过交织形成的热粘合以前的网。另外,在利用多个空气(气体)流形成槽部(凹凸)之后,为了保持其形状不变地使其无纺织物化,通过利用规定的加热装置等进行加热炉处理(加热处理),使包含在纤维集合体中的热塑性纤维热粘合的热风法是优选的。In addition, it is preferable to use air (gas) flow to easily rearrange the fibers by using a fiber web formed by a carding method using relatively long fibers. Furthermore, the fibers have a high degree of freedom and heat formed only by entanglement. Glue the previous mesh. In addition, after forming grooves (concavities and convexities) with a plurality of air (gas) flows, in order to keep its shape unchanged, it is made into a nonwoven fabric, and is subjected to furnace treatment (heat treatment) by using a predetermined heating device, etc., to make the The through-air method of thermal bonding of thermoplastic fibers in a fiber assembly is preferred.

[5.1.2]纤维[5.1.2] Fiber

作为构成纤维集合体的纤维(例如,构成纤维网100的纤维101),例如,可以列举出用低密度聚乙烯、高密度的聚乙烯、直链状的聚乙烯、聚丙烯、聚对苯二甲酸乙酯、改性的聚丙烯、改性的聚对苯二甲酸乙酯、尼龙、聚酰胺等热塑性树脂构成、单独使用各个树脂或者将各个树脂复合起来的纤维。As the fibers (for example, the

复合形状,例如,可以列举出芯成分的熔点比鞘成分的熔点高的芯鞘型、芯鞘的偏心型、左右成分的熔点不同的并列排列型。另外,也可以将中空型、扁平或Y型或C型等异形、或者隐藏的卷缩或明显的卷缩的立体卷缩纤维、利用水流或热或压花等物理负荷分割的分割纤维等混合。Composite shapes include, for example, a core-sheath type in which the melting point of the core component is higher than that of the sheath component, an eccentric core-sheath type, and a side-by-side type in which the left and right components have different melting points. In addition, it is also possible to mix hollow, flat, Y-shaped or C-shaped three-dimensional crimped fibers with hidden crimps or obvious crimps, split fibers that are split by physical loads such as water flow, heat, or embossing, etc. .

另外,为了形成三维卷缩形状,可以将规定的明显的卷缩或隐藏的卷缩的纤维配合起来。这里,所谓三维卷缩形状,是螺旋状、之字状、Ω状等,纤维取向主要朝向平面方向,部分地,纤维取向朝向厚度方向。借此,由于纤维本身的压曲强度向厚度方向作用,所以,即使施加外部压力,其体积也不容易被塌溃。进而,其中,如果是螺旋状的形状,当将外部压力释放时,其形状会返回原状,所以,即使由于过大的外部压力而使体积被压溃一些,在外部压力释放之后,也容易恢复原来的厚度。In addition, in order to form a three-dimensional crimped shape, fibers with prescribed obvious crimps or hidden crimps may be combined. Here, the so-called three-dimensional crimped shape is a spiral shape, a zigzag shape, an Ω shape, etc., and the fiber orientation is mainly oriented in the plane direction, and partially, the fiber orientation is oriented in the thickness direction. Thereby, since the buckling strength of the fiber itself acts in the thickness direction, even if an external pressure is applied, the volume thereof is not easily collapsed. Furthermore, among them, if it is a spiral shape, when the external pressure is released, its shape will return to its original shape, so even if the volume is crushed due to excessive external pressure, it is easy to recover after the external pressure is released. original thickness.

明显卷缩的纤维是通过机械卷缩赋予形状,或者芯鞘结构是偏心型、并列排列等预先卷缩的纤维的总称。隐藏的卷缩纤维是通过加热可以出现卷缩的纤维。Significantly crimped fibers are a general term for pre-crimped fibers such as fibers that have been crimped mechanically or have a core-sheath structure that is eccentric or juxtaposed. Hidden crimped fibers are fibers that crimp when heated.

对于机械卷缩,可以借助线速度的周速差、热、加压对纺丝后的连续的直线状的纤维进行控制,每单位长度的卷缩个数越多,越可以提高对于外部压力下的压曲强度。例如,卷起的个数在10至35个/英寸的范围内,更优选地,在15至30个/英寸的范围内。For mechanical crimping, the continuous linear fiber after spinning can be controlled by means of the peripheral speed difference of the line speed, heat, and pressure. The more crimps per unit length, the more it can improve the resistance to external pressure. of buckling strength. For example, the number of rolls is in the range of 10 to 35 pieces/inch, more preferably, in the range of 15 to 30 pieces/inch.

对于利用热收缩赋予形状而言,由于由熔点不同的两个以上的树脂构成,当加热时,由于熔点差使热收缩率变化,所以,是所谓的三维卷缩的纤维。对于纤维截面的树脂结构,可以列举出芯鞘结构的偏心型、左右成分的熔点不同的并列型。这种纤维的热收缩率,例如,可以在5%至90%的范围内,更优选地在10%至80%的范围内。The shape imparted by heat shrinkage is a so-called three-dimensionally crimped fiber because it is composed of two or more resins with different melting points, and when heated, the heat shrinkage rate changes due to the difference in melting point. Examples of the resin structure of the fiber cross-section include an eccentric core-sheath structure and a side-by-side type in which the left and right components have different melting points. The thermal shrinkage of such fibers may, for example, be in the range of 5% to 90%, more preferably in the range of 10% to 80%.

热收缩率的测定方法为(1)以100%的测定的纤维制成200g/m2的网,(2)制成裁剪成250×250mm大小的样品,(3)将该样品在145℃(418.15K)的加热炉内放置5分钟,(4)测定收缩后的长度尺寸,(5)可以由热收缩前后的长度尺寸差计算出热收缩率。The measuring method of thermal shrinkage rate is (1) make the net of 200g/m2 with the measured fiber of 100%, (2) make the sample that cuts into 250 * 250mm size, (3) put this sample at 145 ℃ ( 418.15K) in a heating furnace for 5 minutes, (4) measure the length dimension after shrinkage, (5) calculate the heat shrinkage rate from the length dimension difference before and after heat shrinkage.

在将本无纺织物用作表面片的情况下,例如,考虑到液体的进入或触及皮肤的感觉,优选地,纤度在1.1至8.8dtex的范围内。In the case of using the present nonwoven fabric as a surface sheet, for example, in view of the penetration of liquid or the feeling of touching the skin, it is preferable that the fineness is in the range of 1.1 to 8.8 dtex.

在将本无纺织物用作表面片的情况下,作为构成纤维集合体的纤维,例如,为了吸收残留在皮肤上的少量经血或汗等,也可以含有纸浆、化学纸浆、人造丝,醋酯纤维、天然棉等纤维素类的亲水性纤维。但是,由于纤维素类纤维不容易排出一度吸收的液体,所以,例如,作为优选的形式,以相对于整体为0.1质量%至5质量%的范围混入。When using this nonwoven fabric as a surface sheet, as the fibers constituting the fiber assembly, for example, in order to absorb a small amount of menstrual blood or sweat remaining on the skin, pulp, chemical pulp, rayon, acetate, etc. Fiber, natural cotton and other cellulose-based hydrophilic fibers. However, since the cellulose fiber does not easily discharge the once-absorbed liquid, for example, as a preferable form, it is mixed in the range of 0.1 mass % to 5 mass % with respect to the whole.

在利用本无纺织物作为表面片的情况下,例如,考虑到液体的进入性及回湿(リウエツトバツク),也可以在前面列举的憎水性合成纤维中加入亲水剂或憎水剂等或者进行涂敷等。另外,也可以进行电晕处理或者等离子体处理,赋予亲水性。另外,也可以含有憎水性纤维。这里,所谓憎水性纤维指的是进行过已知的憎水处理的纤维。In the case of using this nonwoven fabric as the surface sheet, for example, considering the penetration of liquid and rewetting (リウエツトッツク), it is also possible to add a hydrophilic agent or a water-repellent agent to the aforementioned hydrophobic synthetic fibers or carry out coating etc. In addition, corona treatment or plasma treatment may be performed to impart hydrophilicity. In addition, hydrophobic fibers may also be contained. Here, the so-called water-repellent fibers refer to fibers subjected to a known water-repellent treatment.

另外,为了提高白化性,例如,也可以含有二氧化钛、硫酸钡、碳酸钙等无机填料。在芯鞘型的复合纤维的情况下,可以只在芯中含有所述无机填料,也可以在鞘中含有所述无机填料。Moreover, in order to improve whitening property, for example, inorganic fillers, such as titanium dioxide, barium sulfate, and calcium carbonate, may be contained. In the case of a core-sheath type composite fiber, the inorganic filler may be contained only in the core, or may be contained in the sheath.

另外,如前面所述,容易利用空气流再排列纤维的是使用比较长的纤维、利用梳理法形成的纤维网,为了利用多个空气流形成槽部(凹凸化)等之后,保持其形状不变地使之无纺织物化,优选利用加热炉处理(加热处理)使热塑性纤维热粘合的热风法。作为适合于这种方法的纤维,为了纤维彼此的交点热粘结,优选使用芯鞘结构、并列结构的纤维,更优选地,用鞘彼此容易可靠地热粘结的芯鞘结构的纤维构成。特别是,优选地,使用由聚对苯二甲酸乙酯和聚乙烯构成的芯鞘复合纤维、或聚丙烯和聚乙烯构成的芯鞘复合纤维。这些纤维可以单独地或者将两种以上组合使用。另外,纤维长度为20至100mm,特别地,优选为35至65mm。In addition, as mentioned above, it is easier to rearrange the fibers by air flow when using relatively long fibers and fiber webs formed by carding. To make it into a non-woven fabric, the hot-air method of thermally bonding thermoplastic fibers by furnace treatment (heat treatment) is preferable. As fibers suitable for this method, fibers having a core-sheath structure or side-by-side structure are preferably used for thermally bonding the intersection points of fibers, and more preferably, fibers having a core-sheath structure in which the sheaths are easily and reliably thermally bonded to each other are used. In particular, it is preferable to use a core-sheath composite fiber composed of polyethylene terephthalate and polyethylene, or a core-sheath composite fiber composed of polypropylene and polyethylene. These fibers can be used alone or in combination of two or more. In addition, the fiber length is 20 to 100 mm, particularly, preferably 35 to 65 mm.

[5.2]关于无纺织物的制造装置[5.2] Regarding nonwoven fabric manufacturing equipment

[5.2.1]主要由气体构成的流体[5.2.1] Fluids mainly composed of gases

根据本发明的主要由气体构成的流体,例如,可以列举出调整到常温或者规定温度的气体,或者在该气体内含有固体或者液体的微粒子的气溶胶。The fluid mainly composed of gas according to the present invention includes, for example, gas adjusted to a normal temperature or a predetermined temperature, or an aerosol containing solid or liquid fine particles in the gas.

作为气体,例如,可以是空气、氮气等。另外,气体也可以含有水蒸气等的液体的蒸气。As the gas, for example, air, nitrogen or the like may be used. In addition, the gas may contain liquid vapor such as water vapor.

所谓气溶胶指的是在气体中分散有液体或者固体的物质,下面,列举其例子。例如,可以列举出分散有:着色用的墨水;提高柔软性用的硅酮等柔软剂;防止带电及控制润湿性用的亲水性或者憎水性的活性剂;提高流体能量用的二氧化钛、硫酸钡等无机填料;在提高流体能量的同时、在加热处理中提高凹凸成形保持性用的聚乙烯等粉末粘合剂;止痒用的盐酸苯海拉明、麝香草酚等抗组胺剂;保湿剂;杀菌剂等的材料。这里,固体也包括凝胶状的物体。The term "aerosol" refers to a substance in which a liquid or a solid is dispersed in a gas, and examples thereof are given below. For example, it is possible to disperse: ink for coloring; softening agents such as silicone for improving flexibility; hydrophilic or hydrophobic active agents for preventing electrification and controlling wettability; titanium dioxide for improving fluid energy, Inorganic fillers such as barium sulfate; powder binders such as polyethylene for improving the retention of concave-convex shape during heat treatment while increasing fluid energy; antihistamines such as diphenhydramine hydrochloride and thymol for antipruritic ; Humectants; fungicides and other materials. Here, solid also includes gel-like objects.

可以适当调整主要由气体构成的流体的温度。可以根据构成纤维集合体的纤维的性质、将要制造的无纺织物的形状,进行适当的调整。The temperature of the fluid mainly composed of gas can be adjusted appropriately. It can be appropriately adjusted according to the properties of the fibers constituting the fiber aggregate and the shape of the nonwoven fabric to be produced.

这里,例如,为了使构成纤维集合体的纤维恰当地移动,对于主要由气体构成的流体的温度,为增大构成纤维集合体的纤维的自由度,在一定程度上较高的温度是优选的。另外,在纤维集合体中包含热塑性纤维的情况下,可以通过将主要由气体构成的流体的温度调整到能够软化该热塑性纤维的温度,使配置在主要由气体构成的流体喷射的区域等内的热塑性纤维软化或者熔融,同时,使之再次硬化。Here, for example, in order to properly move the fibers constituting the fiber aggregate, the temperature of the fluid mainly composed of gas is preferably higher to some extent in order to increase the degree of freedom of the fibers constituting the fiber aggregate. . In addition, when thermoplastic fibers are included in the fiber aggregate, the temperature of the fluid mainly composed of gas can be adjusted to a temperature at which the thermoplastic fibers can be softened, so that the fibers arranged in the region where the fluid mainly composed of gas is sprayed, etc. The thermoplastic fibers are softened or melted and, at the same time, hardened again.

借此,例如,通过喷射主要由气体构成的流体,保持无纺织物的形状。另外,例如,在利用规定的移动机构移动纤维集合体时,给予该纤维集合体(无纺织物)不散开的程度的强度。Thereby, for example, by spraying a fluid mainly composed of gas, the shape of the nonwoven fabric is maintained. In addition, for example, when the fiber aggregate is moved by a predetermined moving mechanism, the fiber aggregate (nonwoven fabric) is given such strength that it does not unravel.

对于主要由气体构成的流体的流量可以适当地调整。作为纤维彼此之间具有自由度的纤维集合体的具体例子,例如,可以列举出利用高密度的聚乙烯构成鞘,利用聚对苯二甲酸乙酯构成芯,以纤维长度20至100mm、优选为35至65mm、纤度1.1至8.8dtex、优选为2.2至5.6dtex的芯鞘纤维为主体,使用如果利用梳理法开纤则纤维长度为20至100mm、优选为35至65mm的纤维,如果利用空气沉降法开纤则纤维长度为1至50mm、优选为3至20mm的纤维,调整到10至1000g/m2,优选为15至100g/m2的纤维网100。作为主要由气体构成的流体的条件,例如,可以列举出在图8或者图9所示的形成有多个喷出口913的喷出部910(喷出口913:直径0.1至30mm,优选为0.3至10mm,节距0.5至20mm,优选为3至10mm,形状为正圆、椭圆或长方形)中,在以风量为3至50[L/(分钟·孔)]、优选为5至20[L/(分钟·孔)]的条件下对纤维网100喷射温度15至300℃(288.15K至573.15K)、优选为100至200℃(373.15K至473.15K)的热风的情况。例如,在以上述条件喷射主要由气体构成的流体的情况下,所构成的纤维能够改变其位置、方向的纤维集合体是本发明中的纤维集合体中合适的一种。通过利用这种纤维、制造条件进行制作,例如,可以形成图1、2所示的无纺织物。槽部1、凸状部2的尺寸、单位面积重量可以在以下的范围内获得。对于槽部1,厚度在0.05至10mm、优选为0.1至5mm的范围内,宽度在0.1至30mm、优选为0.5至5mm的范围内,单位面积重量在2至900g/m2、优选为10至90g/m2的范围内。对于凸状部2,厚度在0.1至15mm、优选为0.5至10mm的范围内,宽度在0.5至30mm、优选为1.0至10mm的范围内,单位面积重量在5至1000g/m2、优选为10至100g/m2的范围内。另外,在槽部1中以规定的间隔形成开口部3,在开口部3与开口部3之间形成连接部4。开口部3、连接部4的尺寸、单位面积重量,可以在以下的范围内获得。对于连接部4,厚度与凸状部2相同或者比凸状部2小,优选地在20%至100%、特别优选在40%至70%的范围内,宽度及长度在4至30mm、优选在5至10mm的范围内,单位面积重量在5至200g/m2、优选在10至100g/m2的范围内。对于开口部3,宽度及长度在4至30mm、优选为5至10mm的范围内。另外,尽管可以在大致的上述数值范围内制成无纺织物,但是,并不局限于该范围。The flow rate for fluids mainly composed of gas can be appropriately adjusted. As a specific example of a fiber assembly having a degree of freedom between fibers, for example, a sheath is made of high-density polyethylene, a core is made of polyethylene terephthalate, and the fiber length is 20 to 100 mm, preferably 20 to 100 mm. 35 to 65mm, fineness 1.1 to 8.8dtex, preferably 2.2 to 5.6dtex core-sheath fiber as the main body, use the fiber with a fiber length of 20 to 100mm, preferably 35 to 65mm if the carding method is used to open the fiber, if using air deposition According to the fiber opening method, fibers with a fiber length of 1 to 50 mm, preferably 3 to 20 mm, are adjusted to a

[5.2.2]通气性支承构件[5.2.2] Air-permeable support member

作为通气性支承构件200,可以列举出这样的支承构件:支承纤维网100的一侧呈大致平面状或者大致曲面状,同时,大致平面状或者大致曲面状的表面是大致平坦的。作为大致的平面状或者大致曲面状,例如,可以列举出板状或者圆筒状。另外所谓大致平坦状,例如,指的是在支承构件中的载置纤维网100的面本身不形成凹凸状等。具体地说,可以列举出网状支承构件210中的网不形成凹凸状等的支承构件。Examples of the air-

作为该通气性支承构件200,例如,可以列举出板状的支承构件或圆筒状的支承构件。具体地说,可以列举出上述的支承构件240、支承构件275。As this air-

这里,通气性支承构件200能够可拆卸地配置在无纺织物制造装置90上。从而,可以适当地配置对应于所希望的无纺织物的通气性支承构件200。换句话说,在无纺织物制造装置90中,通气性支承构件200可以与从不同的多个通气性支承构件中选择出来的其它通气性支承构件进行交换。Here, the air-

下面对于图3所示的网状支承构件240中的网状部分、图5所示的支承构件275进行说明。作为该通气性的网状部分,例如,可以列举出利用聚酯、聚亚苯基聚苯硫醚、尼龙、导电性单丝等树脂形成的丝,或者由不锈钢、铜、铝等金属形成的丝等,通过平纹织、斜纹织、缎纹织、双层织、螺旋织等织入的通气性网等。Next, the mesh portion of the

这里,该通气性网的通气度,例如,通过部分地使织入的方法、丝的粗度、丝的形状变化,可以部分地使通气度变化。具体地,可以列举出由聚酯制成的螺旋织的通气性筛网、利用不锈钢制成的扁平丝和圆形丝进行螺旋织的通气性筛网。Here, the air permeability of the air-permeable net can be partially changed by, for example, partially changing the weaving method, the thickness of the threads, and the shape of the threads. Specifically, a spirally woven air-permeable mesh made of polyester, and an air-permeable mesh spirally woven with flat and round wires made of stainless steel are exemplified.

另外,可以使用板状的支承构件。例如,可以列举出利用不锈钢、铜、铝等金属制成的套筒。对于套筒,可以列举出将上述金属板以规定的图形部分地挖通形成的套筒。将该金属挖通的部位成为通气部,金属未被挖通的部位成为不通气部。另外,和上面所述的一样,在不通气部,为了提高表面的滑动性,其表面优选是平滑的。In addition, a plate-shaped supporting member may be used. For example, sleeves made of metals such as stainless steel, copper, and aluminum are mentioned. Examples of the sleeve include those formed by partially digging the above-mentioned metal plate in a predetermined pattern. The part where the metal is dug through becomes the ventilation part, and the part where the metal is not dug through becomes the non-ventilation part. In addition, as described above, in order to improve the slipperiness of the surface of the non-ventilated portion, the surface is preferably smooth.

作为套筒,例如,可以列举出以长度3mm、宽度40mm的将各个拐角制成圆形的横向方向长的长方形的形状,将金属挖通形成的孔部在流水作业线方向(移动方向)隔开2mm的间隔、在宽度方向隔开3mm的间隔配置成网格状的厚度为0.3mm的不锈钢制的套筒。As the sleeve, for example, a rectangular shape with a length of 3 mm and a width of 40 mm, each corner of which is rounded in the lateral direction, and the holes formed by digging through the metal are spaced apart in the direction of the line (moving direction). Stainless steel sleeves with a thickness of 0.3 mm were arranged in a grid at intervals of 2 mm and at intervals of 3 mm in the width direction.

另外,可以列举出将孔部配置成交错状的套筒。例如,可以列举出将以直径4mm的圆形挖通金属的孔部配置成在流水作业线方向(移动方向)节距为12mm、在轴向方向节距为6mm的交错状的厚度0.3mm的不锈钢制的套筒。这样,可以恰当地设定挖通的图形(形成的孔部)或配置。In addition, a sleeve in which the holes are arranged in a zigzag shape can be used. For example, it is possible to cite a method in which circular holes with a diameter of 4 mm are cut through the metal and are arranged in a zigzag shape with a pitch of 12 mm in the line direction (moving direction) and a pitch of 6 mm in the axial direction with a thickness of 0.3 mm. Stainless steel sleeve. In this way, it is possible to appropriately set the pattern (hole portion to be formed) and arrangement of the excavation.

进而,可以列举出设置有规定的起伏的通气性支承构件200。例如,可以列举出不直接喷射主要由气体构成的流体的部位向流水作业线方向(移动方向)交替地具有起伏(例如,波浪状)的通气性支承构件。通过使用这样形状的通气性支承构件200,例如,可以获得在形成规定的开口部的同时、整体地在通气性支承构件200上交替地形成起伏(例如,波浪状)的形状的无纺织物。Furthermore, an air-

[5.2.3]喷射机构[5.2.3] Injection mechanism

对于喷出部910,通过能够改变主要由气体构成的流体的方向,例如,可以适当地调整形成的凹凸中的凹部(槽部)的间隔或凸状部的高度等。另外,例如,通过自动地改变上述流体的方向的结构,例如,可以适当地进行调整,将槽部等形成曲折的形状(波浪状、之字状)或其它形状。另外,通过调整主要由气体构成的流体的喷出量或喷出时间,可以适当地调整槽部或开口部的形状或形成图形。主要由气体构成的流体对纤维网100的喷射角度可以是垂直的,另外,也可以在纤维网100的移动方向F上,以规定的角度朝向作为该移动方向F的流水作业线方向,也可以以规定的角度朝向与流水作业线方向相反的方向。In the

[5.2.4]加热机构[5.2.4] Heating mechanism

作为使形成有规定的开口部的无纺织物180中的纤维101粘结的方法,例如,可以列举出利用针刺法、射流喷网法、溶剂粘结法进行的粘结,或者利用点粘法、热风法进行的热粘结,但是,为了保持所形成的规定的开口部的形状,优选采用热风法。另外,例如,利用加热器部950的热风法中的热处理是优选的。As a method of bonding the

[5.2.5]其它[5.2.5] Others

利用加热器部950加热制造的无纺织物115由输送器930及在规定方向F上连续的输送器940,例如,移送到将无纺织物115切断成规定形状的工序、卷取工序。输送器940与输送器930一样,也可以配备有带部949和旋转部941等。The

Claims (15)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2006174505 | 2006-06-23 | ||

| JP174505/2006 | 2006-06-23 | ||

| JP270110/2006 | 2006-09-29 | ||

| JP2006270110AJP5123512B2 (en) | 2006-06-23 | 2006-09-29 | Non-woven |

| PCT/JP2007/060548WO2007148502A1 (en) | 2006-06-23 | 2007-05-23 | Nonwoven fabric |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101448990A CN101448990A (en) | 2009-06-03 |

| CN101448990Btrue CN101448990B (en) | 2011-12-07 |

Family

ID=40727157

Family Applications (10)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2007800172186AActiveCN101443501B (en) | 2006-06-23 | 2007-05-23 | non-woven fabric |

| CN2007800182563AActiveCN101448991B (en) | 2006-06-23 | 2007-05-23 | non-woven fabric |

| CN2007800182366AActiveCN101448990B (en) | 2006-06-23 | 2007-05-23 | Nonwoven fabric |

| CN2007800167614AActiveCN101443499B (en) | 2006-06-23 | 2007-05-23 | Nonwoven fabric |

| CN2007800172364AExpired - Fee RelatedCN101542032B (en) | 2006-06-23 | 2007-05-23 | non-woven fabric |

| CN2007800173348AExpired - Fee RelatedCN101443502B (en) | 2006-06-23 | 2007-05-23 | Nonwoven fabric |

| CN2007800183424AExpired - Fee RelatedCN101448992B (en) | 2006-06-23 | 2007-06-06 | Absorbent body, multilayer absorbent body and absorbent article |

| CN2007800172082AExpired - Fee RelatedCN101443500B (en) | 2006-06-23 | 2007-06-06 | Multilayer nonwoven fabric and method for producing multilayer nonwoven fabric |

| CN2007800182686AActiveCN101448989B (en) | 2006-06-23 | 2007-06-08 | Nonwoven fabric |

| CN2007800227846AActiveCN101473081B (en) | 2006-06-23 | 2007-06-22 | absorbent article |