CN101357716A - Distribution center distribution line automatic replenishment system - Google Patents

Distribution center distribution line automatic replenishment systemDownload PDFInfo

- Publication number

- CN101357716A CN101357716ACNA200810120970XACN200810120970ACN101357716ACN 101357716 ACN101357716 ACN 101357716ACN A200810120970X ACNA200810120970X ACN A200810120970XACN 200810120970 ACN200810120970 ACN 200810120970ACN 101357716 ACN101357716 ACN 101357716A

- Authority

- CN

- China

- Prior art keywords

- conveyor

- box

- article

- belt conveyor

- item

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000012856packingMethods0.000claimsdescription15

- 230000003139buffering effectEffects0.000claimsdescription9

- 239000002184metalSubstances0.000claimsdescription7

- 238000004806packaging method and processMethods0.000claimsdescription6

- 238000009434installationMethods0.000claimsdescription3

- 229910052755nonmetalInorganic materials0.000claimsdescription3

- 230000001960triggered effectEffects0.000description4

- 238000010586diagramMethods0.000description3

- 230000009286beneficial effectEffects0.000description1

- 238000000034methodMethods0.000description1

Images

Landscapes

- Control Of Conveyors (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及物流自动化装备技术领域,具体涉及一种配送中心配货线自动补货系统。The invention relates to the technical field of logistics automation equipment, in particular to an automatic replenishment system for a distribution line of a distribution center.

技术背景technical background

随着现代流通的发展,物流配送越来越呈现出其在满足社会需求、提供优质服务和提高流通企业的市场竞争力中的重要作用。分拣配货系统在物流配送中心的规模化经营和高效率运作方面已经成为有力的工具,配送服务越来越集中化,配送中心的配送能力、工作效率、准确性的要求需进一步提高。在自动分拣配货流水作业线的许多应用场合,需要不断地向配货流水线补充配货物品,以保证流水线的不间断作业,现在一般都是由人工来完成配货物品向流水线的补货,这种作业方式费时费力,并时常伴有差错发生,已不能适应大规模集中配送的需求,因此需要开发出适合于自动分拣配货线应用需求的自动补货系统。With the development of modern circulation, logistics distribution is increasingly showing its important role in meeting social needs, providing high-quality services and improving the market competitiveness of circulation enterprises. The sorting and distribution system has become a powerful tool in the large-scale operation and high-efficiency operation of the logistics distribution center. The distribution service is becoming more and more centralized, and the requirements for the distribution capacity, work efficiency and accuracy of the distribution center need to be further improved. In many applications of the automatic sorting and distribution line, it is necessary to continuously replenish the distribution line with goods to ensure the uninterrupted operation of the line. Now it is generally done manually to replenish the goods to the line. , this operation method is time-consuming and laborious, and is often accompanied by errors. It can no longer meet the needs of large-scale centralized distribution. Therefore, it is necessary to develop an automatic replenishment system suitable for the application requirements of automatic sorting and distribution lines.

发明内容Contents of the invention

本发明的目的在于提供一种配送中心配货线自动补货系统,使配送中心在应用分拣配货线的时候,自动完成配货物品的拆箱和定位传输,实现向分拣配货线的自动补货,大大提高分拣配货线的运行效率,减轻配送中心操作人员的劳动强度,提高配货操作准确度和工作效率,加强配送中心的配送能力。The purpose of the present invention is to provide an automatic replenishment system for the distribution line of the distribution center, so that when the distribution center uses the sorting and distribution line, it can automatically complete the unpacking and positioning of the distribution items, and realize the delivery to the sorting and distribution line. The automatic replenishment of goods greatly improves the operating efficiency of the sorting and distribution line, reduces the labor intensity of the distribution center operators, improves the accuracy and work efficiency of the distribution operation, and strengthens the distribution capacity of the distribution center.

本发明采用的技术方案是:The technical scheme adopted in the present invention is:

在辊筒输送机的一端的两侧并与辊筒输送机在同一水平面上且垂直于辊筒输送机运转方向,分别固定安装有输送箱内物品的皮带输送机和箱内物品推出设备,远离辊筒输送机一侧的第一段皮带输送机的一端连接安装第二段皮带输送机,在第二段皮带输送机两侧面分别安装有物品侧向推出设备和箱内物品缓存平台,在第二段皮带输送机的末端和箱内物品缓存平台并垂直于第二段皮带输送机运动方向安装有带有格栅的步进式物品输送机,相对于步进式物品输送机在箱内物品缓存平台的另一侧安装有物品推入设备,在步进式物品输送机的两侧分别对应安装有一组补货物品推出设备和一组相同数量的配货缓存输送机,自动控制设备中的物品运动传感器和控制器分别安装在上述设备上。On both sides of one end of the roller conveyor and on the same horizontal plane as the roller conveyor and perpendicular to the running direction of the roller conveyor, the belt conveyor for conveying the items in the box and the equipment for pushing out the items in the box are fixed respectively, away from One end of the first section of the belt conveyor on the side of the roller conveyor is connected to the second section of the belt conveyor. On both sides of the second section of the belt conveyor are installed sideways push-out equipment and a storage platform for items in the box. The end of the second-stage belt conveyor and the item buffer platform in the box are installed with a stepping item conveyor with a grid perpendicular to the moving direction of the second-section belt conveyor. Compared with the stepping item conveyor, the items in the box On the other side of the buffer platform, there is an item push-in device. On both sides of the stepping item conveyor, a set of supplementary item push-out equipment and a set of distribution buffer conveyors of the same number are respectively installed. The automatic control equipment The item motion sensor and the controller are respectively installed on the above equipment.

所述的箱内物品推出设备由水平固定安装在第一支架上的第一气缸和垂直于水平面固定安装在第一气缸的气杠杆上的第一推板以及物品包装箱箱盖固定机构构成,第一支架固定安装在辊筒输送机的侧面并与辊筒输送机的机架横梁之间预留一狭缝,狭缝宽度大于纸箱纸板厚度,第一气缸的气杠杆上的第一推板位于辊筒输送机的输送面的上方,物品包装箱箱盖固定机构由固定安装在辊筒输送机末端且高出辊筒输送机的上平面的金属或非金属硬质条状阻挡块、由两条金属或非金属硬质第一条状块和第二条状块以及“F”形的支架形成的包装箱上翻盖狭缝构成,第一条状块和第二条状块水平平行固定安装在倒“F”形的支架一端,“F”形的支架的另一端固定安装在第一支架上,在第一条状块和第二条状块之间形成的一条大于包装箱盖厚度的狭缝位于辊筒输送机和第一支架所形成的狭缝的上方、高于包装箱上表面但低于包装箱上翻盖垂直翻起的上边缘,狭缝的两头是口朝外的两个喇叭口状以便于包装箱上翻盖在垂直翻起时能方便进入狭缝。The device for pushing out items in the box is composed of a first air cylinder fixed horizontally on the first bracket, a first push plate fixedly installed on the air lever of the first air cylinder perpendicular to the horizontal plane, and a fixing mechanism for the box cover of the article packing box, The first bracket is fixedly installed on the side of the roller conveyor and a slit is reserved between the frame beam of the roller conveyor. The width of the slit is greater than the thickness of the carton cardboard. The first push plate on the air lever of the first cylinder Located above the conveying surface of the roller conveyor, the fixing mechanism for the box cover of the article packing box is composed of a metal or non-metal hard strip-shaped block that is fixedly installed at the end of the roller conveyor and is higher than the upper plane of the roller conveyor. Two metal or non-metallic hard first strips and second strips and "F"-shaped brackets are formed by the flip slits on the packaging box. The first strip and the second strip are fixed horizontally and parallel. Installed on one end of the inverted "F"-shaped bracket, the other end of the "F"-shaped bracket is fixedly installed on the first bracket, and the strip formed between the first strip block and the second strip block is larger than the thickness of the packing box cover The slit is located above the slit formed by the roller conveyor and the first support, higher than the upper surface of the packaging box but lower than the upper edge of the vertical flip of the upper flap of the packaging box, and the two ends of the slit are two sides with the mouth facing outwards. A bell-mouth shape makes it easy for the upper cover of the packaging box to enter the slit when it is turned up vertically.

所述的物品侧向推出设备由水平固定安装在第二支架上的第二气缸和垂直于水平面固定安装在第二气缸的气杠杆上的第二推板构成,第二支架固定安装在第二段皮带输送机末端侧面,在第二段皮带输送机末端竖直安装有挡板。The article lateral push-out device is composed of a second air cylinder fixed horizontally on the second bracket and a second push plate fixedly installed on the air lever of the second air cylinder perpendicular to the horizontal plane, and the second bracket is fixedly installed on the second On the side of the end of the first section of the belt conveyor, a baffle is vertically installed at the end of the second section of the belt conveyor.

所述的箱内物品缓存平台是一块从第二段皮带输送机末端侧面支架延伸出来并与第二段皮带输送机的皮带上平面在同一水平面上的平面,箱内物品缓存平台的末端侧面安装有竖直挡板,其高度高于推出物品的总堆高。The item buffering platform in the box is a plane that extends from the side support at the end of the second section of the belt conveyor and is on the same level as the upper plane of the belt of the second section of the belt conveyor. There are vertical baffles whose height is higher than the total stack height of ejected items.

所述的物品推入设备由水平固定安装在第三支架上的第三气缸和垂直于水平面固定安装在第三气缸的气杠杆上的第三推板构成,第三支架在步进式物品输送机的对面固定安装于箱内物品缓存平台的侧面。The article pushing device is composed of a third air cylinder fixed horizontally on the third support and a third push plate fixed on the air lever of the third air cylinder perpendicular to the horizontal plane. The opposite side of the machine is fixedly installed on the side of the item buffer platform in the box.

所述的带有格栅的步进式物品输送机由步进式链板输送机或步进式链式输送机和竖直安装于输送机的链板或输送链上的一组格栅构成,格栅的高度高于所输送物品的堆高。The stepping article conveyor with a grid is composed of a stepping chain plate conveyor or a stepping chain conveyor and a group of grids vertically installed on the chain plate or conveyor chain of the conveyor , the height of the grid is higher than the pile height of the conveyed items.

所述的一组补货物品推出设备由水平固定安装在支架上的一组气缸和垂直于水平面固定安装在每一个气缸的气杠杆上的一组推板构成。The set of supplementary goods push-out equipment is composed of a set of cylinders fixed horizontally on the bracket and a set of push plates fixedly installed on the air lever of each cylinder perpendicular to the horizontal plane.

所述的自动控制设备由安装于辊筒输送末端的第一光电传感器、安装于皮带输送机末端的第二光电传感器、安装于第二段皮带输送机的末端挡板上的第三光电传感器、安装箱内物品缓存平台的竖直挡板上的第四光电传感器、与竖直挡板在同一平面上且位于带有格栅的步进式物品输送机主梁上方并在格栅顶端下方固定安装第五光电传感器、与箱内物品推出设备的第一气缸相连接的第一电磁阀、与皮带输送机的电动机相连接的第一接触器、与物品侧向推出设备的第二气缸相连接的第二电磁阀、与物品推入设备的第三气缸相连接的第三电磁阀、与步进式物品输送机的电动机相连接的第二接触器、与一组补货物品推出设备的每个气缸分别联接的电磁阀组和可编程逻辑控制器构成,第一光电传感器、第二光电传感器、第三光电传感器、第四光电传感器、第五光电传感器分别连接到可编程逻辑控制器的开关量输入端子上,第一电磁阀、第一接触器、第二电磁阀、第三电磁阀、第二接触器、电磁阀组分别连接到可编程逻辑控制器的开关量输出端子上。The automatic control equipment consists of a first photoelectric sensor installed at the end of the roller conveying, a second photoelectric sensor installed at the end of the belt conveyor, a third photoelectric sensor installed on the end baffle of the second section of the belt conveyor, Install the fourth photoelectric sensor on the vertical baffle of the item buffer platform in the box, on the same plane as the vertical baffle and above the main beam of the stepping type article conveyor with grid and fixed below the top of the grid Install the fifth photoelectric sensor, the first solenoid valve connected with the first cylinder of the item push-out device in the box, the first contactor connected with the motor of the belt conveyor, and the second cylinder of the item side push-out device The second solenoid valve, the third solenoid valve connected with the third cylinder of the article pushing device, the second contactor connected with the motor of the stepping article conveyor, and each The electromagnetic valve group and the programmable logic controller which are respectively connected to two cylinders are composed, and the first photoelectric sensor, the second photoelectric sensor, the third photoelectric sensor, the fourth photoelectric sensor and the fifth photoelectric sensor are respectively connected to the switches of the programmable logic controller. On the quantity input terminal, the first solenoid valve, the first contactor, the second solenoid valve, the third solenoid valve, the second contactor and the solenoid valve group are respectively connected to the switching quantity output terminal of the programmable logic controller.

所述的第二段皮带输送机的运行速度是第二段皮带输送机的1.2倍~2倍。The operating speed of the second belt conveyor is 1.2 to 2 times that of the second belt conveyor.

本发明具有的有益的效果是:The beneficial effects that the present invention has are:

通过本发明所提供配送中心配货线自动补货系统,能够与分拣配货线配合应用,使配送中心在应用分拣配货线的时候,自动完成物品到分拣配货线的补货,大大提高分拣配货线的运行效率,减轻配送中心操作人员的劳动强度,提高配货操作准确度和工作效率,加强配送中心的配送能力。The distribution center distribution line automatic replenishment system provided by the present invention can be used in conjunction with the sorting and distribution line, so that the distribution center can automatically complete the replenishment of items to the sorting and distribution line when the sorting and distribution line is applied , Greatly improve the operating efficiency of the sorting and distribution line, reduce the labor intensity of the distribution center operators, improve the accuracy and work efficiency of the distribution operation, and strengthen the distribution capacity of the distribution center.

附图说明Description of drawings

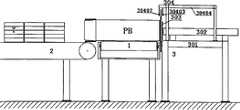

图1是配送中心配货线自动补货系统的构成示意图。Figure 1 is a schematic diagram of the composition of the automatic replenishment system for the distribution line of the distribution center.

图2是箱内物品推出设备及物品包装箱固定机构构成示意图。Fig. 2 is a schematic diagram of the composition of the device for pushing out items in the box and the fixing mechanism for the box for the items.

图3是物品侧向推出设备和物品缓存平台构成示意图。Fig. 3 is a schematic diagram of the configuration of the item lateral pushing device and the item buffering platform.

图中:1、辊筒输送机,2、第一段皮带输送机,3、箱内物品推出设备,4、第二段皮带输送机,5、物品侧向推出设备,6、箱内物品缓存平台,7、步进式物品输送机,8、物品推入设备,9、一组补货物品推出设备,10、一组配货缓存输送机,11、配货线主输送机,12、自动控制设备。In the figure: 1. Roller conveyor, 2. The first section of belt conveyor, 3. The equipment for pushing out items in the box, 4. The second section of belt conveyor, 5. The equipment for sideways pushing out items, 6. The buffer for items in the box Platform, 7. Stepping item conveyor, 8. Item pushing equipment, 9. A set of supplementary item pushing equipment, 10. A set of distribution buffer conveyor, 11. Main conveyor of distribution line, 12. Automatic controlling device.

具体实施方式Detailed ways

下面结合附图和实施例对本发明作进一步说明。The present invention will be further described below in conjunction with drawings and embodiments.

如图1所示,本发明在辊筒输送机1的一端的两侧并与辊筒输送机1在同一水平面上且垂直于辊筒输送机1运转方向,分别固定安装有输送箱内物品的皮带输送机2和箱内物品推出设备3,远离辊筒输送机1一侧的第一段皮带输送机2的一端连接安装第二段皮带输送机4,在第二段皮带输送机4两侧面分别安装有物品侧向推出设备5和箱内物品缓存平台6,在第二段皮带输送机4的末端和箱内物品缓存平台6并垂直于第二段皮带输送机4运动方向安装有带有格栅的步进式物品输送机7,相对于步进式物品输送机7在箱内物品缓存平台6的另一侧安装有物品推入设备8,在步进式物品输送机7的两侧分别对应安装有一组补货物品推出设备9和一组相同数量的配货缓存输送机10,自动控制设备12中的物品运动传感器和控制器分别安装在上述设备上。滚筒输送机1也可以采用皮带输送机。上述第二段皮带输送机4的运行速度是第一段皮带输送机2的1.1倍~2倍。As shown in Figure 1, the present invention is on both sides of one end of the

如图1和图2所示,所述的箱内物品推出设备3由水平固定安装在第一支架301上的第一气缸302和垂直于水平面固定安装在第一气缸302的气杠杆上的第一推板303以及物品包装箱箱盖固定机构304构成,第一支架301固定安装在辊筒输送机1的侧面并与辊筒输送机1的机架横梁之间预留一狭缝,狭缝宽度大于纸箱纸板厚度,第一气缸302的气杠杆上的第一推板303位于辊筒输送机1的输送面的上方,物品包装箱箱盖固定机构304由固定安装在辊筒输送机1末端且高出辊筒输送机1的上平面的金属或非金属硬质条状阻挡块30401、由两条金属或非金属硬质第一条状块30402和第二条状块30403以及“F”形的支架30404形成的包装箱上翻盖狭缝构成,第一条状块30402和第二条状块30403水平平行固定安装在倒“F”形的支架30404一端,“F”形的支架30404的另一端固定安装在第一支架301上,在第一条状块30402和第二条状块30403之间形成的一条大于包装箱盖厚度的狭缝位于辊筒输送机1和第一支架301所形成的狭缝的上方、高于包装箱上表面但低于包装箱上翻盖垂直翻起的上边缘,狭缝的两头是口朝外的两个喇叭口状以便于包装箱上翻盖在垂直翻起时能方便进入狭缝。As shown in Figures 1 and 2, the described box-in-

如图1和图3所示,所述的物品侧向推出设备5由水平固定安装在第二支架501上的第二气缸502和垂直于水平面固定安装在第二气缸502的气杠杆上的第二推板503构成,第二支架501固定安装在第二段皮带输送机4末端侧面,在第二段皮带输送机4末端竖直安装有挡板401。As shown in Fig. 1 and Fig. 3, the described article lateral push-out device 5 is composed of the

如图1和图3所示,所述的箱内物品缓存平台6是一块从第二段皮带输送机4末端侧面支架延伸出来并与第二段皮带输送机4的皮带上平面在同一水平面上的平面601,箱内物品缓存平台6的末端侧面安装有竖直挡板602,其高度高于推出物品的总堆高。As shown in Figures 1 and 3, the

如图1所示,所述的物品推入设备8由水平固定安装在第三支架801上的第三气缸802和垂直于水平面固定安装在第三气缸802的气杠杆上的第三推板803构成,第三支架801在步进式物品输送机7的对面固定安装于箱内物品缓存平台6的侧面。As shown in Figure 1, the article pushing device 8 is composed of a third air cylinder 802 fixedly installed on the third support 801 horizontally and a third push plate 803 fixedly installed on the air lever of the third air cylinder 802 perpendicular to the horizontal plane In this configuration, the third bracket 801 is fixedly installed on the side of the

如图1所示,所述的带有格栅的步进式物品输送机7由步进式链板输送机或步进式链式输送机701和竖直安装于输送机的链板或输送链上的一组格栅702构成,格栅702的高度高于所输送物品的堆高。As shown in Figure 1, the described stepping article conveyor 7 with a grid is composed of a stepping chain conveyor or a stepping chain conveyor 701 and a chain plate or a chain conveyor installed vertically on the conveyor. A set of grids 702 on the chain is formed, the height of the grids 702 being higher than the stack height of the conveyed items.

如图1所示,所述的一组补货物品推出设备9由水平固定安装在支架901上的一组气缸902和垂直于水平面固定安装在每一个气缸902的气杠杆上的一组推板903构成。As shown in Fig. 1, described one group of replenishment product push-out equipment 9 is fixed by a group of cylinder 902 that is horizontally fixedly installed on the bracket 901 and a group of push plate that is vertically fixedly installed on the gas lever of each cylinder 902 903 constitute.

如图1所示,所述的自动控制设备12由安装于辊筒输送机1末端的第一光电传感器1201、安装于皮带输送机2末端的第二光电传感器1203、安装于第二段皮带输送机4的末端挡板401上的第三光电传感器1205、安装箱内物品缓存平台6的竖直挡板602上的第四光电传感器1207、与竖直挡板602在同一平面上且位于带有格栅的步进式物品输送机7主梁上方并在格栅702顶端下方固定安装第五光电传感器1209、与箱内物品推出设备3的第一气缸302相连接的第一电磁阀1202、与皮带输送机2的电动机相连接的第一接触器1204、与物品侧向推出设备5的第二气缸502相连接的第二电磁阀1206、与物品推入设备8的第三气缸802相连接的第三电磁阀1208、与步进式物品输送机7的电动机相连接的第二接触器1210、与一组补货物品推出设备9的每个气缸902分别联接的电磁阀组1211和可编程逻辑控制器1212构成,第一光电传感器1201、第二光电传感器1203、第三光电传感器1205、第四光电传感器1207、第五光电传感器1209分别连接到可编程逻辑控制器1212的开关量输入端子上,第一电磁阀1202、第一接触器1204、第二电磁阀1206、第三电磁阀1208、第二接触器1210、电磁阀组1211分别连接到可编程逻辑控制器1212的开关量输出端子上。As shown in Figure 1, the automatic control device 12 is conveyed by the first photoelectric sensor 1201 installed at the end of the

该配送中心配货线自动补货系统的工作原理为:The working principle of the automatic replenishment system of the distribution center distribution line is as follows:

当装载有物品T的纸箱PB由输送机1输送到操作位时,操作员将纸箱PB两头的箱盖打开,并将纸箱PB朝向气缸推板303一端的上下左右四个箱盖分别朝上下左右方向翻开,并使向上翻开的箱盖进入物品包装箱箱盖固定机构304的两条状块30402和30403之间的狭缝,使向下翻开的箱盖进入滚筒输送机1的机架与气缸支架301之间的狭缝。在滚筒输送机1的末端安装有第一光电传感器1201,第一光电传感器1201连接到可编程逻辑控制器1212的开关量输入端子,箱内物品推出设备3的气缸302通过第一电磁阀1202连接到可编程逻辑控制器1212的开关量输出端子上,在纸箱箱盖被翻开进入狭缝并继续向前运动到滚筒输送机1末端的条状阻挡块30401时,纸箱PB停止运动,同时触发第一光电传感器1201,第一光电传感器1201将触发信号传送到可编程逻辑控制器1212,可编程逻辑控制器1212经开关量输出端子发出信号到第一电磁阀1202,由第一电磁阀1202控制气缸302推出,气缸302带动推板303将纸箱内物品从纸箱PB中推出到皮带输送机2上,由于皮带输送机2经第一接触器1204连接到可编程逻辑控制器1212的开关量输出端子,在可编程逻辑控制器1212收到第一光电传感器1201的触发信号时,发出控制信号使第一接触器1204吸合,从而使皮带输送机2运转,箱内物品T被推出到皮带输送机2上后,被皮带输送机2带着向前运动。同时可编程逻辑控制器1212发出控制信号控制第一电磁阀1202驱动气缸302复位。When the carton PB loaded with articles T is transported to the operating position by the

箱内物品T不断被从纸箱中推出到皮带输送机2上时,在皮带输送机2形成输送队列。在皮带输送机2的末端连接安装第二段皮带输送机4,由于第二段皮带输送机4的速度大于皮带输送机2,故当物品T接触到第二段皮带输送机4时,该物品运行速度加快,因此与它后面的物品拉开一个间距,在皮带输送机2的末端安装有第二光电传感器1203,当有物品被输送到皮带输送机2的末端时,第二光电传感器1203被触发,第二光电传感器1203的触发信号传送到可编程逻辑控制器1212,当该物品离开第二光电传感器1203后,第二光电传感器1203的触发信号复位,该复位信号传送到可编程逻辑控制器1212中记录,经过两物品之间的间距之后,后面物品被输送到皮带输送机2的末端,第二光电传感器1203再次被触发,可编程逻辑控制器1212收到该触发信号后即发出控制信号使皮带输送机2停止运转,于是后面物品停止前行,而前面物品T在第二皮带输送机4的输送下继续向前运动。When the articles T in the box are continuously pushed out from the carton onto the

在第二皮带输送机4的末端挡板401上安装有第三光电传感器1205。当前面的物品T在第二皮带输送机4的输送下继续向前运动,直到碰到第二皮带输送机4末端挡板401才停止,与此同时前面的物品T触发第三光电传感器1205,第三光电传感器1205的触发信号传送到可编程逻辑控制器1212,可编程逻辑控制器1212即控制物品侧向推出设备5的气缸502推出。在气缸502的推出方向,从第二段皮带输送机4的末端侧面延伸安装有箱内物品缓存平台6。箱内物品缓存平台6的末端侧面安装有竖直挡板602,其高度高于推出物品T的总堆高,在竖直挡板602上安装有第四光电传感器1207。当箱内物品T碰到缓存平台6的竖直挡板602时,竖直挡板602上的第四光电传感器1207被触发,第四光电传感器1207的触发信号传送到可编程逻辑控制器1212,可编程逻辑控制器1212即控制物品侧向推出设备5的气缸502停止推进并复位。然后,可编程逻辑控制器1212控制启动皮带输送机2运转,继续将后面物品输送到第二皮带输送机4。A third photoelectric sensor 1205 is installed on the

在第二皮带输送机4运转方向的末端、垂直于第二段皮带输送机4,安装有带有格栅的步进式物品输送机7,步进式物品输送机7也与箱内物品缓存平台6相邻接。在箱内物品缓存平台6与第二皮带输送机4的安装侧的另一个相邻侧,安装有物品推入设备8,物品推入设备8安装在物品缓存平台6相对于步进式物品输送机7的一侧。当物品T被侧向推出设备8推到物品缓存平台6并触发第四光电传感器1207,而且物品侧向推出设备5的气缸502停止推进并开始复位时,可编程逻辑控制器1212通过第三电磁阀1208控制物品推入设备8的气缸802推出,将物品T从缓存平台6上推入步进式物品输送机7的格栅702之间。物品T推入格栅702完成后,物品推入设备8的气缸802立即复位。At the end of the running direction of the

在步进式物品输送机7运转方向的下游,在步进式物品输送机7的两侧分别对应安装有一组补货物品推出设备9和一组配货缓存输送机10。在带有格栅的步进式物品输送机7的主梁上方、与箱内物品缓存平台6的竖直挡板601在同一平面上、在格栅702顶端的下方位置固定安装有第五光电传感器1209。第二接触器1210与步进式物品输送机7的电动机相连接。步进式物品输送机7运转时,带动处于输送机7的上平面的格栅702向前水平移动,当步进式物品输送机7的某个格栅702移动到箱内物品缓存平台6的竖直挡板602的同一平面上时,该格栅702触发第五光电传感器1209,触发信号传送到可编程逻辑控制器1212,可编程逻辑控制器1212控制第二接触器1210从闭合状态翻转为打开状态,步进式物品输送机7停止运行,这时格栅702与缓存平台6的竖直挡板601位于同一平面,为物品T从缓存平台6上推入步进式物品输送机7的两个格栅702之间做好准备。在第四光电传感器1207被触发时,物品T被推入设备8的气缸802从缓存平台6上推入到步进式物品输送机7的格栅702之间。物品推入设备8的气缸802复位后,可编程逻辑控制器1212控制步进式物品输送机7向前运行一步,第五光电传感器1209又被触发,步进式物品输送机7做好接收下一物品的准备。经过一步步的运行,物品被步进式物品输送机7输送到相应的补货物品推出设备9和配货缓存输送机10之间,可编程逻辑控制器1212根据第五光电传感器1209触发的次数,计算出该物品是否已经进入指定位置,若该物品已经进入指定位置,则可编程逻辑控制器1212通过电磁阀组1211中对应的电磁阀控制相应的补货物品推出设备9的气缸组902中相应的气缸将物品推出到对应的配货缓存输送机组10中对应的缓存输送机上。在配货时,配货缓存输送机组10中的物品通过配货线主输送机11完成配货和输送。Downstream of the running direction of the stepping article conveyor 7 , a group of supplementary article pushing devices 9 and a group of distribution buffer conveyors 10 are respectively installed on both sides of the stepping article conveyor 7 . Above the main beam of the stepping article conveyor 7 with a grid, on the same plane as the

在本实施例中,辊筒输送机1、皮带输送机2、箱内物品推出设备3、第二段皮带输送机4、物品侧向推出设备5、步进式物品输送机7、物品推入设备8、物品推出设备9中的电动机和气缸等设备零部件均可采用常规产品,物品运动传感器可以采用常规的光电开关、接近开关等,PLC可编程逻辑控制器可以使用由西门子公司生产的S7-200系列可编程逻辑控制器,比如S7-226或S7-224;物品缓存平台6可以采用金属或木制结构。In this embodiment, the

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNA200810120970XACN101357716A (en) | 2008-09-09 | 2008-09-09 | Distribution center distribution line automatic replenishment system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNA200810120970XACN101357716A (en) | 2008-09-09 | 2008-09-09 | Distribution center distribution line automatic replenishment system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101357716Atrue CN101357716A (en) | 2009-02-04 |

Family

ID=40330341

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA200810120970XAPendingCN101357716A (en) | 2008-09-09 | 2008-09-09 | Distribution center distribution line automatic replenishment system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101357716A (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101723170B (en)* | 2009-11-12 | 2011-11-09 | 浙江大学城市学院 | Self-propelled replenish truck system of cargo allocation line of distribution center |

| CN102553829A (en)* | 2010-12-07 | 2012-07-11 | 天海欧康科技信息(厦门)有限公司 | Vertical sorter structure |

| CN103264863A (en)* | 2013-05-31 | 2013-08-28 | 浙江省烟草公司绍兴市公司 | Automatic replenishing system and replenishing method |

| CN104192587A (en)* | 2014-08-26 | 2014-12-10 | 武汉蓝海燕智能装车设备有限公司 | Distribution device for bagged cement loading stacking main machine |

| CN108596540A (en)* | 2018-04-23 | 2018-09-28 | 北京京东尚科信息技术有限公司 | Replenishing method and device, computer readable storage medium, electronic equipment |

| CN109250377A (en)* | 2017-07-11 | 2019-01-22 | 浙江国自机器人技术有限公司 | Replenishing method and actuating station and control terminal |

| CN109335576A (en)* | 2018-08-28 | 2019-02-15 | 上海畅联国际物流股份有限公司 | A kind of cargo goes out Input System |

| CN113478129A (en)* | 2021-07-13 | 2021-10-08 | 东创智造(浙江)有限公司 | End cover lead welding equipment |

- 2008

- 2008-09-09CNCNA200810120970XApatent/CN101357716A/enactivePending

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101723170B (en)* | 2009-11-12 | 2011-11-09 | 浙江大学城市学院 | Self-propelled replenish truck system of cargo allocation line of distribution center |

| CN102553829A (en)* | 2010-12-07 | 2012-07-11 | 天海欧康科技信息(厦门)有限公司 | Vertical sorter structure |

| CN103264863A (en)* | 2013-05-31 | 2013-08-28 | 浙江省烟草公司绍兴市公司 | Automatic replenishing system and replenishing method |

| CN103264863B (en)* | 2013-05-31 | 2015-11-18 | 浙江省烟草公司绍兴市公司 | A kind of automatic replenishment and replenishing method |

| CN104192587A (en)* | 2014-08-26 | 2014-12-10 | 武汉蓝海燕智能装车设备有限公司 | Distribution device for bagged cement loading stacking main machine |

| CN104192587B (en)* | 2014-08-26 | 2016-09-28 | 武汉蓝海燕智能装车设备有限公司 | The distributor of piling main frame is loaded for bagged cement |

| CN109250377A (en)* | 2017-07-11 | 2019-01-22 | 浙江国自机器人技术有限公司 | Replenishing method and actuating station and control terminal |

| CN108596540A (en)* | 2018-04-23 | 2018-09-28 | 北京京东尚科信息技术有限公司 | Replenishing method and device, computer readable storage medium, electronic equipment |

| CN109335576A (en)* | 2018-08-28 | 2019-02-15 | 上海畅联国际物流股份有限公司 | A kind of cargo goes out Input System |

| CN113478129A (en)* | 2021-07-13 | 2021-10-08 | 东创智造(浙江)有限公司 | End cover lead welding equipment |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101357716A (en) | Distribution center distribution line automatic replenishment system | |

| CN107790393B (en) | An automatic sorting system for goods | |

| CN201272631Y (en) | Distribution line automatic replenishment system for delivery center | |

| CN104128313B (en) | Overpass type sorting apparatus and method thereof | |

| CN101863385A (en) | An automatic depalletizing process for cigarettes in storage | |

| CN204297213U (en) | A kind of automobile loose mail packaging and sorting manufacturing line | |

| CN105173500A (en) | Tobacco stereoscopic warehouse conveyor and conveying method thereof | |

| CN108674746A (en) | Automate boxing apparatus | |

| CN106743018A (en) | It is a kind of based on the Automated Sorting System and technique that replenish in real time with the intensive caching of bar cigarette | |

| CN105599998A (en) | Automatic boxing device for cheese packaging line | |

| CN102152960B (en) | Finished cigarette warehousing random inspection method and system | |

| CN107487482A (en) | A kind of furniture board selects plate converging system | |

| CN209758208U (en) | A multi-intensive shuttle warehouse online sorting hoist | |

| CN207312388U (en) | Conveyer system applied to tiered warehouse facility into shipment | |

| CN206327618U (en) | Boxing apparatus is entered in a kind of full-automatic side | |

| CN209427657U (en) | artifact caching facility | |

| CN107628323A (en) | A kind of automatic packaging and storage production line of carton | |

| KR101603419B1 (en) | Three-sided wrapped food accumulator | |

| CN107618893B (en) | Flexible material distributing and stacking system | |

| CN209455621U (en) | Pallet conveying equipment | |

| CN205256751U (en) | Carton packing auxiliary conveyor device | |

| CN117104830A (en) | Automatic tobacco bale posture adjustment system | |

| CN204416652U (en) | A kind of magnetic belt automatic board-stacking machine | |

| CN216360179U (en) | An intelligent warehouse robot | |

| CN205060608U (en) | Tobacco stereoscopic warehouse conveyer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Open date:20090204 |