CN101321628A - Labels and Label Printers with Release Paper - Google Patents

Labels and Label Printers with Release PaperDownload PDFInfo

- Publication number

- CN101321628A CN101321628ACNA200680045125XACN200680045125ACN101321628ACN 101321628 ACN101321628 ACN 101321628ACN A200680045125X ACNA200680045125X ACN A200680045125XACN 200680045125 ACN200680045125 ACN 200680045125ACN 101321628 ACN101321628 ACN 101321628A

- Authority

- CN

- China

- Prior art keywords

- label

- information

- printed

- release paper

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Labeling Devices (AREA)

- Handling Of Continuous Sheets Of Paper (AREA)

- Accessory Devices And Overall Control Thereof (AREA)

- Controlling Rewinding, Feeding, Winding, Or Abnormalities Of Webs (AREA)

- Printers Characterized By Their Purpose (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及带剥离纸的标签和向该标签个体进行打印的标签打印机。The present invention relates to a label with release paper and a label printer for printing on the label itself.

具体来说,本发明是将与标签个体有关的信息在剥离纸的一面进行条形码打印,根据该条形码信息实现规定的控制的带剥离纸的标签,可用于显示能够打印条形码信息的标签个体的剩余张数或用作标签个体相对于打印设计的打印控制信息。Specifically, the present invention prints a barcode on one side of the release paper with information related to the individual label, and the label with release paper that achieves specified control based on the barcode information can be used to display the remainder of the individual label that can print the barcode information. Sheet count or used as print control information for individual labels relative to the print design.

背景技术Background technique

在以各种商品的标签为首的超市等食品卖场中的商品的标签、发货票、现品票、产品制造商等中的产品标签等所有的产业领域中,作为日常业务而被称作标签打印机的、在标签(标签个体)上进行打印的打印机很活跃。It is called labeling as a daily business in all industrial fields, including product labels in food stores such as supermarkets, shipping receipts, product labels, and product labels in product manufacturers, including labels for various products. A printer that prints on a label (label individual) is active.

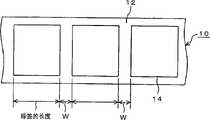

在该标签打印机中使用的标签通常使用带剥离纸的标签。图9用于表示带剥离纸的标签10的一例,其在呈带状的剥离纸(衬纸)12的一面例如表面上,在一列上隔开规定间隔(标签间隔)W而粘贴有多张标签个体14。Labels used in this label printer usually use labels with release paper. 9 shows an example of a

带剥离纸的标签10通常卷绕成滚筒状,以缠绕在包装纸的状态购买。在包装纸上,通常显示有标签张数(能够打印的张数)。关于标签打印机,在其显示部附加有能够显示标签张数的功能,关于这种带显示功能的标签打印机,可通过输入打印在包装纸上的标签张数,确认用设置的带剥离纸的标签10打印的标签张数有几张。The

但是,在该方法中由于有可能发生标签张数的输入错误,因而考虑在剥离纸12的背面打印标签张数信息的带剥离纸的标签。However, in this method, since an input error of the number of labels may occur, a label with a release paper in which the information on the number of labels is printed on the back of the

该带剥离纸的标签,在剥离纸的背面标签的能够打印的张数信息,作为识别信息而从剥离纸的始端至末端为止以规定间隔进行打印。在标签打印机中,通过读取并显示该能够打印的张数信息,能够确认可打印的标签张数。In this label with release paper, information on the number of printable sheets of the label on the back side of the release paper is printed at predetermined intervals from the beginning to the end of the release paper as identification information. In the label printer, the number of printable labels can be confirmed by reading and displaying the number of printable sheets.

但是,为了每次在标签进行打印处理时,将可打印的张数更新后显示,在分别与标签粘贴位置相对的剥离纸的背面的位置,必须要将内容不同的识别信息作为可打印的张数信息而依次打印。However, in order to update and display the number of printable sheets each time the label is printed, it is necessary to set identification information with different contents as printable sheets at the positions on the back of the release paper that face the label attachment positions. The information is printed sequentially.

为此从剥离纸的始端至末端为止需要间歇性地打印与剩余张数有关的识别信息,因而对剥离纸的打印处理烦琐,并且导致带剥离纸的标签的成本上升。For this reason, it is necessary to intermittently print identification information on the number of remaining sheets from the beginning to the end of the release paper, which makes the printing process on the release paper cumbersome and increases the cost of the label with the release paper.

为了至少实现成本降低,例如考虑对应每规定张数打印与剩余张数有关的识别信息,但即使在这种情况下,相对于几米长的剥离纸的全长与标签粘贴位置相关而对应规定间隔进行打印时伴随非常烦琐的作业,从而不能期待充分的成本降低。In order to achieve at least cost reduction, for example, it is considered to print identification information related to the remaining number of sheets corresponding to every predetermined number of sheets, but even in this case, the entire length of the release paper with a length of several meters depends on the label attachment position and corresponds to a predetermined interval. Printing involves very cumbersome work, and thus sufficient cost reduction cannot be expected.

另一方面,在上述标签个体14上,有在其一部分打印预定的信息的类型和不打印任何信息的类型。预先打印的规定的信息为个别识别信息。作为个别识别信息,例如可考虑如图10A、图10B一样商品的提供者(制造商、销售商等)的法人名、其住所、电话号码等商品的提供者一侧的信息。On the other hand, the

个别识别信息的打印位置,可考虑如图10A一样标签个体14的下侧的一部分或如图10B一样上侧的一部分。因此,标签个体14的打印部位(打印区域)14a以外的部位(区域)14b成为可打印的区域(打印区域)14b。As for the printing position of the individual identification information, a part of the lower side of the

打印在打印区域14a上的个别识别信息,如图10A、图10B一样,通常打印成可从其左侧读取。在打印区域14b上打印有包装后商品的商品名、原材料名、品尝期限等与该商品有关的信息(打印设计信息)。The individual identification information printed on the print area 14a is usually printed so as to be read from the left side thereof, as in FIGS. 10A and 10B. In the

打印设计信息,可通过标签打印机所具有的操作键来输入,但由于限制输入信息,因而通常使用个人计算机等终端装置来生成。The print design information can be input through the operation keys of the label printer, but since input information is limited, it is usually generated using a terminal device such as a personal computer.

打印设计信息的生成例如图11A和图12A所示。The generation of print design information is shown, for example, in FIGS. 11A and 12A.

在生成用于打印到标签个体14上的设计的情况下,考虑图10A、图10B所示的打印区域14a位于标签个体14d哪个位置。图11A是打印区域14a存在于标签个体14的下侧时的设计例,图12A是相反地存在于上侧时的设计例。When generating a design for printing on the

在发挥打印用终端装置的功能的个人计算机的显示器画面S,显示相当于标签个体14的尺寸的轮廓60,并且在图11A的情况下轮廓60下侧的区域62确保为打印禁止区域,在图12A的情况下其上侧的一部分区域62确保为打印禁止区域。On the monitor screen S of a personal computer that functions as a terminal device for printing, an

打印禁止区域62相当于标签个体14的打印区域14a,除此以外的区域64确保为打印区域,在终端装置输入所需要的打印信息(打印设计信息),以收敛于该打印区域64(与图10A、图10B的打印区域14b相同)。所输入的打印设计信息,或保存在终端装置内,或存储在外部存储器中。所生成的打印设计信息可以直接发送到标签打印机而保存在标签打印机中,也可以在标签打印机安装外部存储器,保存打印设计信息。The print prohibited

作为粘贴剥离纸12的标签个体14的粘贴方向,可考虑图11B、图11C或图12B、图12C。在如图11A一样生成打印设计信息的情况下,考虑如图11B一样使打印区域14a位于下侧(相对于标签移动方向靠后的一侧)地将标签个体14粘贴(排列)在剥离纸12上的情况和如图11C一样使打印区域14a位于上侧(相对于标签移动方向靠前的一侧)地粘贴的情况。FIG. 11B, FIG. 11C or FIG. 12B, FIG. 12C can be considered as a sticking direction of the label individual 14 to which the

并且,在如图12A一样生成打印设计信息的情况下,可考虑如图12B一样使打印区域14a位于上侧地排列标签个体14的情况和如图12C一样使打印区域14a位于下侧的排列的情况。And, in the case of generating the print design information as in FIG. 12A , it is conceivable to arrange the

因此,在如图11B所示地使打印区域14a位于下侧地将标签个体14粘贴在剥离纸12上的带剥离纸的标签10上打印打印设计信息的情况下,将在终端装置生成的打印设计信息直接输出而打印时,能够不与打印区域14a重叠地打印打印设计信息。Therefore, when printing design information on the

但是,在如图11C的情况下,将打印设计信息直接输出而打印时,以与打印在打印区域14a内的信息重叠的状态打印打印设计信息。在这种情况下,必须要将打印设计信息反转而打印。However, in the case of FIG. 11C , when the print design information is directly output and printed, the print design information is printed overlapping with the information printed in the print area 14 a. In this case, it is necessary to reverse the print design information and print.

如上所述,在图12B的情况下,即使将打印设计信息直接输出而打印,可根据与图12A的关系不与打印区域14a重叠地打印打印设计信息。As described above, in the case of FIG. 12B , even if the print design information is directly output and printed, the print design information can be printed without overlapping the print area 14 a according to the relationship with FIG. 12A .

在如图12C的情况下,将打印设计信息直接输出而打印时,以相对于打印在打印区域14a内的信息重叠的状态打印打印设计信息。因此,在这种情况下,也必须要将打印设计信息反转而打印。In the case of FIG. 12C , when the print design information is directly output and printed, the print design information is printed in a state of being superimposed on the information printed in the print area 14 a. Therefore, also in this case, it is necessary to reverse and print the print design information.

由此,在利用所生成的打印设计信息在标签个体上打印的情况下,需要考虑打印在标签个体上的打印区域14a的打印位置。Therefore, when printing on an individual label using the generated print design information, it is necessary to consider the print position of the print area 14 a printed on the individual label.

发明内容Contents of the invention

本发明是为了解决上述以往问题而作出的,将与标签个体有关的信息在剥离纸的一面进行条形码打印。可通过将该条形码信息用于显示能够打印的剩余张数或用作相对于对标签个体的打印设计信息的打印控制信息,实现成本降低、正常打印等。The present invention was made to solve the above-mentioned conventional problems, and the information related to the individual label is printed with a barcode on one side of the release paper. Cost reduction, normal printing, and the like can be realized by using this barcode information to display the remaining number of sheets that can be printed or as print control information with respect to print design information for individual labels.

为了解决上述课题,权利要求1所述的带剥离纸的标签,其特征在于,包括:标签个体,粘贴在剥离纸的一面;和条形码,在上述剥离纸的另一面从其始端开始以规定长度打印,显示上述标签个体的相关信息;在上述相关信息中包含与粘贴在上述剥离纸上的上述标签个体的可打印张数有关的信息或显示打印在上述标签个体上的打印部位的打印控制信息。In order to solve the above-mentioned problems, the label with a release paper according to

并且,权利要求2所述的标签打印机,其特征在于,包括:条形码传感器,读取打印在标签用剥离纸的一面上的条形码信息;和控制部,根据上述条形码信息进行显示控制或打印控制。The label printer according to claim 2, further comprising: a barcode sensor for reading barcode information printed on one side of the label release paper; and a control unit for performing display control or printing control based on the barcode information.

并且在本发明中,在剥离纸的一个面(例如表面)上以规定的间隔粘贴有多个标签个体。在另一个面(背面)上,在剥离纸的始端的一部分打印有条形码。Furthermore, in the present invention, a plurality of individual labels are attached at predetermined intervals to one surface (for example, the surface) of the release paper. On the other side (back side), a barcode is printed on a part of the beginning of the release paper.

条形码信息用于显示能够打印的标签个体的剩余张数或用作相对于对标签个体的打印设计信息的打印控制信息。The barcode information is used to display the remaining number of individual label sheets that can be printed or as print control information with respect to the print design information for the individual label items.

由此,显示粘贴在剥离纸上的标签个体的总数、即可打印张数(最大张数)的信息、打印时的打印设计信息等信息作为条形码信息插入,但实际上此外还包含与标签个体有关的各种信息,例如标签个体的尺寸、标签纸的种类、打印浓度等与标签个体有关的相关信息。Thus, information such as the total number of individual labels attached to the release paper, the number of printable sheets (maximum number of sheets), and the print design information at the time of printing are inserted as barcode information. Various related information, such as the size of the individual label, the type of label paper, the printing density and other relevant information related to the individual label.

条形码信息从剥离纸的始端打印规定的长度(例如,作为标签个体数为3~5张的量)。The barcode information is printed for a predetermined length from the beginning of the release paper (for example, 3 to 5 sheets as the number of individual labels).

在标签打印机中,转移至打印模式之前,准备进行条形码信息的读取的读取模式。在读取模式中空送剥离纸。以规定张数标签的量(2~3张的量)空送剥离纸的同时读取条形码信息,并在内部存储器保存该信息。即使在将剥离纸返回原来位置(打印初始位置)时也进行条形码信息的读取处理。In the label printer, the reading mode prepares to read barcode information before shifting to the printing mode. Skip feed release paper in read mode. Read the barcode information while idling the release paper for the specified number of labels (2 to 3 sheets), and store the information in the internal memory. Even when the release paper is returned to the original position (printing initial position), the reading process of the barcode information is performed.

比较2次读取的可打印张数信息。比较结果一致时将该信息显示在显示部中。对标签个体的打印处理结束时进行可打印张数的更新处理。通过显示减算处理结果,能够知道之后能够打印几张或已经打印了几张标签个体。还可以显示打印张数。Compare the number of printable sheets information of the two readings. When the comparison results match, the information is displayed on the display unit. When the printing process for individual labels is completed, the process of updating the number of printable sheets is performed. By displaying the subtraction processing result, it is possible to know how many individual label sheets can be printed later or how many individual label sheets have already been printed. The number of printed sheets can also be displayed.

检测到粘贴在剥离纸末端的标签个体时,进行需要更换带剥离纸的标签(卷筒纸)的显示,以催促更换卷筒纸。When an individual label attached to the end of the release paper is detected, a display indicating that the label (roll paper) with release paper needs to be replaced is performed to prompt replacement of the roll paper.

并且在该条形码信息中,包含显示打印在标签个体上的打印部位的位置信息(打印控制信息)。显示该打印部位的位置信息,可将打印设计信息直接输出后进行打印或反转后用作打印的控制信息。In addition, this barcode information includes positional information (print control information) indicating the printing position printed on the individual label. The position information of the printing part is displayed, and the printing design information can be directly output and printed or reversed and used as printing control information.

在标签打印机中,打印设计信息保存在标签打印机的存储器中。打印设计信息中包含下述位置信息,该位置信息显示设计时设定打印禁止区域的情况下该打印禁止区域位于标签个体的上侧还是下侧。In a label printer, print design information is stored in a memory of the label printer. The print design information includes position information indicating whether the print-prohibited area is located on the upper side of the individual label when the print-prohibited area is set during design.

保存由读取传感器读取的条形码信息中的、显示标签个体的打印部位的位置信息。显示该打印部位的位置信息为相对于标签个体的位置信息(例如,显示打印部位在上侧还是下侧等的二进制信息)。Among the barcode information read by the reading sensor, the position information indicating the printing position of the individual label is stored. The positional information indicating the printed portion is positional information relative to the individual label (for example, binary information indicating whether the printed portion is on the upper side or the lower side, etc.).

进行所保存的显示打印部位的位置信息和包含在打印设计信息中的位置信息的比较处理。在一致的情况下,将打印设计信息直接输出而进行打印。在不一致的情况下,将打印设计信息反转输出而进行打印。通过自动进行该打印控制处理,能够防止与打印的信息区域重叠而打印打印设计信息的情况。A comparison process is performed between the stored position information indicating the print location and the position information included in the print design information. If they match, the print design information is directly output and printed. If they do not match, the print design information is reversed and output and printed. By automatically performing this print control process, it is possible to prevent printing of the print design information overlapping with the printed information area.

在本发明中,提供一种带剥离纸的标签,在剥离纸的一个面上,从剥离纸的始端打印具有与标签个体有关的信息(标签粘贴张数、打印控制信息)的规定长度的条形码。In the present invention, a label with a release paper is provided. On one side of the release paper, a barcode of a predetermined length having information related to the individual label (number of labels attached, printing control information) is printed from the beginning of the release paper. .

并且,在本发明中提供一种标签打印机,具有根据打印在剥离纸上的标签关联信息进行显示控制或打印控制的控制部。Furthermore, the present invention provides a label printer including a control unit that performs display control or print control based on label-related information printed on release paper.

条形码信息为标签个体的可打印张数(标签粘贴张数)时,能够显示可打印张数。When the barcode information is the printable number of individual labels (the number of labels attached), the printable number can be displayed.

由于此时的条形码信息从剥离纸的始端打印规定长度,因而条形码的打印处理非常简单,打印成本也低。因此,能够以低成本提供带剥离纸的标签。Since the barcode information at this time is printed for a predetermined length from the beginning of the release paper, the printing process of the barcode is very simple and the printing cost is also low. Therefore, it is possible to provide a label with a release paper at low cost.

并且,在条形码信息包含显示打印在标签个体上的打印部位的信息时,通过相当于包含在打印设计信息中的打印禁止区域的位置信息与其进行比较的同时进行打印控制,能够可靠地防止与打印的信息区域重叠而打印打印设计信息的情况。由于还自动地进行打印控制处理,从而能够防止人为错误。And, when the barcode information includes information showing the printing position printed on the individual label, by comparing the position information corresponding to the print prohibition area included in the print design information and performing printing control, it is possible to reliably prevent the printing from being printed. The case where the information area of the printout overlaps and the print design information is printed. Since the print control process is also performed automatically, human error can be prevented.

附图说明Description of drawings

图1是表示本发明的标签打印机的一例的主要部分的系统图。FIG. 1 is a system diagram showing main parts of an example of the label printer of the present invention.

图2是表示打印头和标签检测机构的配置关系的侧视图。Fig. 2 is a side view showing the arrangement relationship between a print head and a label detection mechanism.

图3是表示打印头和标签检测机构的配置关系的俯视图。Fig. 3 is a plan view showing the arrangement relationship between a print head and a label detection mechanism.

图4A是表示本发明的带剥离纸的标签的构成例的表面的图。Fig. 4A is a view showing the surface of a configuration example of a label with a release paper according to the present invention.

图4B是表示图4A所示的带剥离纸的标签的背面的构成例的图。Fig. 4B is a diagram showing a configuration example of the back side of the release paper-attached label shown in Fig. 4A .

图5A是表示本发明的带剥离纸的标签的另一构成例的表面的图。Fig. 5A is a view showing the surface of another configuration example of the label with release paper of the present invention.

图5B是表示图5A所示的带剥离纸的标签的背面的构成例的图。Fig. 5B is a diagram showing a configuration example of the back side of the release paper-attached label shown in Fig. 5A .

图6是表示可打印的张数的检测处理例的流程图。6 is a flowchart showing an example of detection processing of the number of printable sheets.

图7是表示余量显示处理例的流程图。FIG. 7 is a flowchart showing an example of remaining amount display processing.

图8是表示打印控制处理例的流程图。FIG. 8 is a flowchart showing an example of print control processing.

图9是表示带剥离纸的标签的现有例的图。Fig. 9 is a diagram showing a conventional example of a label with release paper.

图10A是表示对标签个体的打印例的图。FIG. 10A is a diagram showing an example of printing on individual labels.

图10B是表示对标签个体的打印例的图。FIG. 10B is a diagram showing an example of printing on individual labels.

图11A是表示打印信息的设计例的图。FIG. 11A is a diagram showing a design example of print information.

图11B是打印信息的设计和标签个体的关系的图(其一)。FIG. 11B is a diagram (Part 1) showing the relationship between the design of print information and individual labels.

图11C是打印信息的设计和标签个体的关系的图(其二)。FIG. 11C is a diagram (Part 2) showing the relationship between the design of print information and individual labels.

图12A是表示打印信息的另一设计例的图。Fig. 12A is a diagram showing another design example of print information.

图12B是打印信息的设计和标签个体的关系的图(其一)。Fig. 12B is a diagram (Part 1) showing the relationship between the design of print information and individual labels.

图12C是打印信息的设计和标签个体的关系的图(其二)。Fig. 12C is a diagram (Part 2) showing the relationship between the design of print information and individual labels.

具体实施方式Detailed ways

接着,利用附图详细说明本发明的带剥离纸的标签和标签打印机的实施例。Next, embodiments of a label with a release paper and a label printer according to the present invention will be described in detail using the drawings.

(实施例1)(Example 1)

实施例1以在条形码信息中包含可打印的张数信息的时刻作为中心进行说明。

图1是本发明的标签打印机20的主要部分的系统图。图4A、图4B和图5A、图5B表示本发明的带剥离纸的标签10的主要部分的例子。首先,参照图4A、图4B和图5A、图5B对带剥离纸的标签10进行说明。FIG. 1 is a system diagram of main parts of a

带剥离纸的标签10由剥离纸12和在其一面的该例中粘贴在表面12a上的多个标签个体14构成。剥离纸12是呈带状的衬纸,在该例中可使用半透明的薄膜。The release paper-attached

标签个体14是感热纸,准备品质不同的多个种类的感热纸。在这里,包含优质感热纸、光泽感热纸、热转印用铜版纸等。涂敷有双面粘接剂的该标签个体14粘帖在剥离纸12上。标签个体14通过起模来生成。因此,标签个体14隔开一定间隔W而排列在剥离纸12的长度方向上。The

在该例中,标签个体14的尺寸只准备1种。根据要粘贴的商品产生要打印在标签个体14上的信息量的过多,可通过要打印的线数量、打印间隔等调整信息量的过多。由于标签个体14为1种,因而在后文描述的标签打印机上设置带剥离纸的标签10时,在打印完最终的标签个体14之前,不更换带剥离纸的标签10。即,用尽。当然,不限于这种使用例。In this example, only one size of

在该例中,在标签个体14的一部分确保打印区域14a,在此预先打印个别信息。在图4A的情况下,在标签个体14的下侧确保打印区域14a,在此打印规定的信息。规定信息是个别识别信息,例如可考虑如商品的提供者(制造商、销售商等)的法人名、其住所、电话号码等商品的提供者一侧的信息。打印在打印区域14a上的信息,如图10A、图10B一样,通常打印成可从其左侧读取。In this example, a print area 14a is reserved for a part of the

打印区域14a以外的区域14b成为实际上能够打印的打印区域。在打印区域14b上打印有包装后商品的商品名、原材料名、品尝期限等与该商品有关的信息(打印设计信息)。The

另一方面,在剥离纸12的另一面(背面)12b的大致中央部,沿着其长度方向如图4B所示地以规定的间隔打印有条形码82。条形码82从剥离纸12的始端打印规定长度L。作为规定长度L,可设定为任意长度,在该例中根据标签个体数量以相当于3~5张的量的长度打印条形码82。其在规定长度L内,相当于打印2~3个条形码82的情况。由于包含在条形码82中的信息全部相同,因而以相同的图案打印。由于以相同图案的打印和条形码82的打印长度较短,因而打印成本低廉。因此,可达成带剥离纸的标签10的低成本化。On the other hand, barcodes 82 are printed at predetermined intervals along the longitudinal direction of the

条形码,当然也可以从剥离纸的始端打印纸末端。在这种情况下,条形码信息对应标签的种类打印固定信息。由于对带剥离纸的标签的条形码信息的打印以进行轮转式打印,因而能够以低廉的打印成本制造。Barcodes, of course, can also be printed from the beginning of the release paper to the end of the paper. In this case, the barcode information is printed with fixed information corresponding to the type of label. Since the printing of the barcode information of the label with release paper is performed in rotary printing, it can be manufactured at a low printing cost.

并且,在该例中,在条形码82之前打印识别信息80。识别信息80可用作用于预先识别条形码82的存在的标记。作为识别信息80可使用特定的图形、文字、记号等。也可以根据情况,使用能够识别带剥离纸的标签10的提供者(制造商、销售商)的标识语等,在这种情况下还发挥显示该带剥离纸的标签10为正品的标识功能。Also, in this example, the

条形码82可考虑排列棒状标识的一维条形码、二维条形码(二维码)等。在信息量较少的情况下用一维条形码就充分。条形码82中包含二进制的各种信息。各种信息仅说明一例,为标签个体的尺寸、标签用纸的种类等。除了这些信息以外,包含粘贴在剥离纸12上的标签个体14的粘贴张数(可打字的张数)、显示打印在标签个体14上的打印部位(打印区域14a)的位置信息(打印控制信息)。As the

该位置信息是用于区别打印区域14a存在于标签个体14的上侧还是存在于其下侧的信息。因此,可处理为简单的二进制信息。例如打印区域14a存在于上侧时,作为位置信息可使用“00”,在下侧时可使用“11”。This positional information is information for distinguishing whether the printed area 14 a exists on the upper side of the

可打印的张数是所提供的带剥离纸的标签10上的标签个体14的最大张数。可打印的张数可在50~200张左右的范围内准备多种。相当于该可打印的张数的信息包含在条形码信息中。The number of printable sheets is the maximum number of

图5A、图5B是带剥离纸的标签10的另一例子与图4A、图4B的不同点仅是打印区域14a的位置,如图5A,此时的打印区域14a成为标签个体14的上侧的规定区域。在该例的情况下,在剥离纸12的背面12b,跨越比剥离纸12的始端长规定长度L的长度,分别以规定间隔打印识别信息80和条形码82。Fig. 5A and Fig. 5B are another example of the

利用这样构成的带剥离纸的标签10打印规定的信息。Predetermined information is printed on the release paper-attached

图1是表示本发明的标签打印机20的一例的主要部分的系统図,具有标签的余量显示功能、相对于带剥离纸的标签10的打印控制功能。1 is a system diagram showing the main parts of an example of a

在图1中,通过马达,在该例中通过步进马达22驱动压纸卷筒24,如图2和图3所示,相对于被压纸卷筒24压接的带剥离纸的标签10向规定方向a以规定速度赋予移动力。带剥离纸的标签10通过步进马达22以每1节距依次送纸。In FIG. 1 , the

在压纸卷筒24上介于带剥离纸的标签10压接有打印头(在该例中为呈线状的感热头)26,通过向打印头26供给打印设计信息,向标签个体14打印打印设计信息。On the

在比打印头26靠前规定间隔La的位置配置有标签个体14的检测机构30。作为检测机构30,可使用穿透型的检测机构。因此,如图2图示,夹着带剥离纸的标签10在一方配置有发端元件(发光二极管等)30a,在另一方配置受光元件(受光二极管)30b而构成标签个体14的检测机构30。由于穿透率不同而可检测标签个体14的粘贴位置。The

在靠近检测机构30的位置且比检测机构30靠前的位置,配置有条形码传感器34。条形码传感器34与该剥离纸12隔开规定间隙而配置在剥离纸12的背面12b侧。因此,条形码传感器34可使用反射型传感器。反射性传感器也使用发光元件和受光元件收容在相同管体内的传感器,可根据反射率不同而读取条形码信息。在剥离纸12中使用的条形码82为二维条形码的情况下,作为检测机构30可使用扫描仪。A

由于在剥离纸12的背面12b打印有条形码82等,因而如图4B或图5B所示,条形码传感器配置在能够检测条形码82的大致中央部附近的位置(中央部附近)上。相对于此,检测机构30(30a、30b)如图4A或图5A所示,配置在不检测条形码82和打印区域14a,而仅能够检测标签个体14的位置上。例如,检测机构30配置在标签个体14的右端部附近。因此,打印区域14a稍微靠左而设置。条形码传感器34,也可以配置在比检测机构30靠后的位置上。Since the

在标签打印机20上,在比打印头26靠下游的出口侧配置有带剥离纸的标签10,更具体来说配置有切断剥离纸12的切割机构32。切割机构32配置有上刃32a和下刃32b,以夹住带剥离纸的标签10,通过上刃32a、下刃32b中的任一方或双方上下移动而进行剥离纸12的切断处理。In the

上述的相对于带剥离纸的标签10的一系列的打印处理,在数据处理部40的控制下进行。数据处理部40可使用计算机,以进行标签打印机20的整体控制的CPU42为首,由存储进行打印处理时所需的控制程序的存储机构(ROM)44和工作用存储机构(RAM)45等构成数据处理部40。在该数据处理部40中,上述打印处理时,还同时进行控制打印位置的处理。The above-described series of printing processes for the

并且,由受光元件30b得到的传感器输出功率供给到I-V转换部46而进行电流电压转变后,由设在数据处理部40中的二值化处理部48进行二值化。同样,还设有相对于由条形码传感器34取得的传感器输出功率的I-V转换部47,该输出功率由设在数据处理部40中的二值化处理部49进行二值化。Then, the sensor output power obtained by the

由数据处理部40生成的打印数据介于打印数据输出部50供给到打印头26。此时,在数据处理部40生成相对于步进马达22的驱动信号(线驱动信号),与该驱动信号同步地对压纸卷筒24进行旋转驱动而对应每1线进行打印处理。相对于带剥离纸的标签10的切割处理信号也由数据处理部40生成,但省略对其详细说明。The print data generated by the

在数据处理部40中,使用于输入打印数据等的输入部(键盘)52、显示输入打印数据的显示部(LCD等)54、存储所输入的打印数据等的存储机构56、在切割标签等时使用的灯、烽鸣器等警报机构58相关。In the

存储机构56可利用闪存、卡片状存储元件等可装拆的可移动存储机构等。在将可移动存储机构用作存储机构56的情况下,其存储信息也可以用作打印信息。在数据处理部40中进而在该例中设有USB端子72,可进行与生成打印设计信息的终端装置70之间的信息的收发。The

由此在CPU构成的该数据处理部40中,可执行二值化处理、标签个体14的端面检测处理、标签移动控制处理、标签个体的余量显示处理等。因此可知该数据处理部40还发挥剩余张数控制部的功能。Thus, in the

另外,如上所述,在条形码信息中,还包含显示所设定的标签的可打印张数(标签粘贴张数)的信息。读取该可打印张数的信息并显示能够实际打印的可打印张数,并且向标签个体14进行打印处理的同时进行能够打印的可打印张数的更新处理。因此,在标签打印机20中,在转移至打印模式之前,换言之,在将新品的带剥离纸的标签10设在打印机主体上的阶段,可执行用于读取条形码的读取模式。In addition, as described above, the barcode information also includes information indicating the number of printable sheets of the set label (the number of sheets to be attached to the label). The information on the number of printable sheets is read to display the number of printable sheets that can be actually printed, and the update processing of the number of printable sheets that can be printed is performed while printing is performed on the

条形码信息的读取模式,将剥离纸12空送规定长度的同时读取条形码82的信息。返回剥离纸12,返回设置的初始状态时也读取条形码信息。因此,设置带剥离纸的标签10时,可自动执行如图6所示的可打印张数的检测处理。In the reading mode of the barcode information, the information of the

参照图6进行说明。首先,检查新品的带剥离纸的标签(卷筒纸)10是否设置或是否更换(步骤90)。带剥离纸的标签10的设置或更换,可通过检测打印机主体的卷筒纸收容盖(未图示)的开闭来实现。下面以设置带剥离纸的标签10时作为基准进行说明。Description will be made with reference to FIG. 6 . First, it is checked whether a new label (rolled paper) 10 with release paper is installed or replaced (step 90). The installation or replacement of the

设置带剥离纸的标签10时,将剥离纸12空送规定长度的同时进行条形码82的读取(步骤91)。When setting the

以标签个体14作为基准时,将剥离纸12空送规定张数的量(例如3~5张的量)。该规定张数的量对应2~3个条形码82的量。空送剥离纸12的同时读取条形码信息,从该条形码信息提取显示作为标签的可打印张数的标签粘贴张数的信息,该信息保存在内部存储器(存储机构)56中(步骤92)。When the

空送结束时,本次进行将剥离纸12返回到原来位置(打印初始位置)的逆送处理,在该逆送处理中还进行条形码信息的读取处理(步骤93、94)。When the skip feed is completed, reverse feed processing for returning the

比较读取2次的可打印张数信息(步骤95)。比较结果一致时保存该信息,并且将粘接的标签个体的打印张数显示在显示部5中(步骤96)。然后,转移至打印模式的待机状态(步骤97)。The information on the number of printable sheets read twice is compared (step 95). If the comparison results match, the information is saved, and the number of printed sheets of the bonded individual labels is displayed on the display unit 5 (step 96). Then, it shifts to the standby state of the printing mode (step 97).

相对于此,在2次的可打印张数信息不一致时,再次进行条形码82的读取处理及其比较处理。该再次处理进行2~3次左右。作为缺省值设置为“2”时,判断再次处理是否为第二次(步骤95、98),不是第二次时,转移至步骤91,进行上述读取处理时比较处理,可是不一致时,进行错误显示(步骤98、99)。错误显示可考虑如“将重新放置卷筒纸”一样的信息。进行错误显示后转移至打印模式的待机状态,由此结束粘贴的标签的可打印张数的检测控制处理(步骤99、97)。On the other hand, when the two pieces of printable sheet number information do not match, the reading process of the

处于打印模式时,确认打印设计信息的存在,进行指定的标签个体张数的量的打印处理。与此同步地进行标签个体的余量显示处理。该余量显示处理是由此能够实际打印的可打印张数的更新处理。In the printing mode, the existence of the print design information is confirmed, and the printing process is performed for the designated number of individual label sheets. Simultaneously with this, the remaining amount display processing of individual tags is performed. This remaining amount display processing is thus an update processing of the number of printable sheets that can actually be printed.

图7表示该余量显示处理例。首先,作为初始值显示作为标签的粘贴张数的可打印张数(初始值)(步骤101)。接着,检查标签打印处理,对标签个体14进行打印处理时(步骤102),与该打印处理同步地进行更新处理,以更新此后可实际打印的可打印张数(步骤103)。该更新处理是可打印张数的减算处理。作为减算处理是在使用计数器的情况下,将可打印张数设为初始值后的递减计数处理。FIG. 7 shows an example of this remaining amount display processing. First, the number of printable sheets (initial value) which is the number of attached sheets of labels is displayed as an initial value (step 101). Next, the label printing process is checked, and when the

通过该更新处理,能够知道此后能够打印几张或已经打印了几张标签个体。可通过在显示部54显示打印的张数或同时直接显示可打印张数的初始值,简单地确认打印完的标签张数等。Through this updating process, it is possible to know how many individual label sheets can be printed thereafter or how many individual label sheets have already been printed. By displaying the number of printed sheets on the

检测到对最终的标签个体14进行打印时(步骤104),可打印张数显示为“0”,显示要更换带剥离纸的标签(卷筒纸)10而结束余量显示处理(步骤105)。作为催促更换的显示,例如可考虑如“请更换带剥离纸的标签”之类的显示。When it is detected that the

在上述(实施例1)中,对设置新品的带剥离纸的标签10后的可打印张数的显示处理进行了说明。使用完带剥离纸的标签10时,从打印机主体拆下,更换为新品。此时,清除(清零)存储机构56的可打印张数信息,并且重置在显示部54显示的显示内容,由此可进行与上述相同的显示处理。这是因为有可设置张数不同的带剥离纸的标签的可能性。In the above (Example 1), the display process of the number of printable sheets after setting the new release paper-attached

另外,打印在剥离纸12上的条形码82为二维条形码的情况下,作为标签个体14的检测机构30可使用扫描仪。In addition, when the

在(实施例1)中,对使用不同种类的带剥离纸的标签的情况进行了说明,但在设置尺寸不同的带剥离纸的标签时也能够进行相同的可打印张数和余量显示处理。In (Example 1), the case where a different type of label with release paper was used was described, but the same process of displaying the number of printable sheets and the remaining amount can also be performed when setting labels with release paper of different sizes .

并且,有设置已经使用到中途的、不是新品的带剥离纸的标签的情况。由于在这种情况下不能从条形码读取与可打印张数的余量有关的信息,因而催促用户使用输入部52输入要设置的带剥离纸的标签10的卷筒直径。将卷筒纸的芯部的直径预先保存在存储机构56中。在数据处理部40中根据所输入的卷筒直径和芯部的直径计算出可打印张数,并显示该可打印张数。这是因为判断卷筒直径时,可由此大致计算出能够打印的标签个体14的张数。重置之前显示的余量显示。In addition, there is a case where a label with a release paper that has been used halfway and is not a new product is installed. In this case, since information about the remaining number of printable sheets cannot be read from the barcode, the user is urged to use the

在基于卷筒直径显示余量的情况下,在显示部54显示的可打印张数和余量显示张数与显示为概算值的信息一起显示。例如,通过在显示数值前或后显示如“大致”之类的文字,以引起用户的注意。进行这种处理时,即使是已经使用的带剥离纸的标签,也不会将其概算值误认为剩余张数。When the remaining amount is displayed based on the roll diameter, the number of printable sheets and the number of remaining display sheets displayed on the

(实施例2)(Example 2)

实施例2以作为条形码信息包含打印控制信息的时刻作为中心进行说明。Embodiment 2 will be described centering on the time when print control information is included as barcode information.

打印设计信息,如上所述,使用打印终端装置预先设计待打印到打印区域14b的信息,在打印设计信息中还包含如图11A、图12A所示的打印禁止区域62位于标签个体14的上侧还是下侧的位置信息(打印控制信息)。Printing design information, as mentioned above, use the printing terminal device to pre-design the information to be printed on the

该位置信息是与打印在标签个体14上的打印区域14a的位置信息相同的二维信息,作为打印设计信息的一部分而输入。与打印区域14a的位置信息相同地,上侧为打印禁止区域62时作为位置信息将“00”作为目标,下侧为打印禁止区域62时作为位置信息将“11”作为目标。打印设计信息保存在存储机构56中。This positional information is the same two-dimensional information as the positional information of the print area 14a printed on the

由此,在CPU构成的数据处理部40中,还进行相对于标签的打印控制处理。Accordingly, in the

由于如上所述地设计打印信息时的打印禁止区域62和实际标签个体14中的打印区域14a的关系不固定,因而可进行打印区域在哪里的判断和与此对应的打印设计信息的反转处理。参照图8的流程图对该打印控制处理进行说明。Since the relationship between the

在图8中,首先读取作为打印对象的标签10中的相当于设计上的打印禁止区域62的位置信息并将其保存(步骤190)。接着,在打印准备期间读取条形码82,提取所读取的条形码信息中的相当于标签个体14的打印区域14a的位置信息并将其保存(步骤191、192)。另外,在打印准备期间取得用于进行打印控制的信息,经过打印准备期间时进行将带剥离纸的标签10返回原来位置的处理,处于打印模式的待机状态。In FIG. 8 , first, position information corresponding to the designed print-prohibited

在打印准备期间进行相当于打印禁止区域的位置信息和相当于打印区域14a的位置信息的比较处理(步骤193)。比较处理的结果,位置信息一致时,在开始打印模式的阶段,直接将打印设计信息打印在标签个体14的打印区域14b中(步骤194、195)。图11A、图11B的关系或图12A、图12B的关系相当于此。A comparison process of the position information corresponding to the print prohibited area and the position information corresponding to the print area 14a is performed during the print preparation (step 193). As a result of the comparison process, if the positional information matches, the printing design information is printed directly on the

相对于此,在位置信息不一致时,使打印设计信息反转而打印在打印区域14b中。图11A、图11C的关系或图12A、图12C的关系相当于此。因此,即使存在打印区域14a,也能够将打印设计信息准确地打印在打印区域14b中,能够可靠地防止对打印区域14a的信息的重写。On the other hand, when the position information does not match, the print design information is reversed and printed in the

在打印处理结束的阶段,判断为对标签个体14的打印处理结束,在继续进行的情况下,以由步骤195或步骤196中选择的打印控制模式继续对标签个体14进行打印(步骤197、198)。检查结束按钮的操作,确认打印处理的结束意思,或弄清对标签个体14的最终打印处理的结束时,该打印控制处理结束(步骤197)。At the stage where the printing process ends, it is judged that the printing process to the

由于上述实施例只是本发明的一例,因而在不脱离本发明的思想的前提下,可进行各种变形、变更。Since the above-mentioned embodiment is only an example of the present invention, various modifications and changes can be made without departing from the spirit of the present invention.

工业实用性Industrial Applicability

本发明可适用于在物流业、产品制造商、超市等中使用的标签打印机。The present invention is applicable to label printers used in the logistics industry, product manufacturers, supermarkets, and the like.

Claims (7)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP346080/2005 | 2005-11-30 | ||

| JP2005346080AJP2007144955A (en) | 2005-11-30 | 2005-11-30 | Label with release paper and label printer |

| JP346081/2005 | 2005-11-30 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN101321628Atrue CN101321628A (en) | 2008-12-10 |

Family

ID=38206915

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA200680045125XAPendingCN101321628A (en) | 2005-11-30 | 2006-11-29 | Labels and Label Printers with Release Paper |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP2007144955A (en) |

| CN (1) | CN101321628A (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102371779A (en)* | 2010-08-23 | 2012-03-14 | 致伸科技股份有限公司 | Printing device with marking function |

| CN104129538A (en)* | 2014-07-22 | 2014-11-05 | 广州达意隆包装机械股份有限公司 | Method and device for prompting membrane volume status of membrane charter |

| CN104444520A (en)* | 2014-10-28 | 2015-03-25 | 东莞市安德标签材料有限公司 | Non-setting adhesive coating dividing and cutting machine |

| CN107656710A (en)* | 2017-08-30 | 2018-02-02 | 深圳市盛路物联通讯技术有限公司 | Data Migration Method of printing and relevant device |

| CN110196700A (en)* | 2019-06-06 | 2019-09-03 | 宜春宜联科技有限公司 | Processing method, the device and system of printer print amount |

| US10703087B2 (en) | 2016-03-01 | 2020-07-07 | Hewlett-Packard Development Company, L.P. | Template generation |

| CN111746148A (en)* | 2019-03-26 | 2020-10-09 | 东芝泰格有限公司 | Labeling systems and label printers |

| CN112997233A (en)* | 2018-09-28 | 2021-06-18 | 兄弟工业株式会社 | Medium |

| CN115139667A (en)* | 2021-03-30 | 2022-10-04 | 精工爱普生株式会社 | Information processing device, tape printing system, method for controlling information processing device, and recording medium |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5082755B2 (en)* | 2007-10-22 | 2012-11-28 | セイコーエプソン株式会社 | Recording medium detection method and label printer |

| DE102013007134A1 (en) | 2013-04-25 | 2014-10-30 | Bizerba Gmbh & Co Kg | Printer and print medium |

| JP6977442B2 (en)* | 2017-09-21 | 2021-12-08 | ブラザー工業株式会社 | Tape cassettes and tape rolls |

| KR102379435B1 (en)* | 2017-12-28 | 2022-03-28 | 주식회사 빅솔론 | Label printer |

| JP7288599B2 (en)* | 2019-03-28 | 2023-06-08 | ブラザー工業株式会社 | Printer and Consumables Management System |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6264571A (en)* | 1985-09-17 | 1987-03-23 | Toshiba Corp | thermal recording device |

| JPH09240121A (en)* | 1996-03-13 | 1997-09-16 | Suzuka Fuji Xerox Kk | Label roll and label printer |

| JPH1056604A (en)* | 1996-08-07 | 1998-02-24 | Olympus Optical Co Ltd | Electronic camera with built-in printer and medium to be recorded |

- 2005

- 2005-11-30JPJP2005346080Apatent/JP2007144955A/enactivePending

- 2006

- 2006-11-29CNCNA200680045125XApatent/CN101321628A/enactivePending

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102371779A (en)* | 2010-08-23 | 2012-03-14 | 致伸科技股份有限公司 | Printing device with marking function |

| CN104129538A (en)* | 2014-07-22 | 2014-11-05 | 广州达意隆包装机械股份有限公司 | Method and device for prompting membrane volume status of membrane charter |

| CN104129538B (en)* | 2014-07-22 | 2016-05-18 | 广州达意隆包装机械股份有限公司 | Film chartered plane film volume state reminding method |

| CN104444520A (en)* | 2014-10-28 | 2015-03-25 | 东莞市安德标签材料有限公司 | Non-setting adhesive coating dividing and cutting machine |

| US10703087B2 (en) | 2016-03-01 | 2020-07-07 | Hewlett-Packard Development Company, L.P. | Template generation |

| CN107656710A (en)* | 2017-08-30 | 2018-02-02 | 深圳市盛路物联通讯技术有限公司 | Data Migration Method of printing and relevant device |

| CN112997233A (en)* | 2018-09-28 | 2021-06-18 | 兄弟工业株式会社 | Medium |

| CN112997233B (en)* | 2018-09-28 | 2023-04-04 | 兄弟工业株式会社 | Medium |

| CN111746148A (en)* | 2019-03-26 | 2020-10-09 | 东芝泰格有限公司 | Labeling systems and label printers |

| CN111746148B (en)* | 2019-03-26 | 2022-02-18 | 东芝泰格有限公司 | Labeling systems and label printers |

| CN110196700A (en)* | 2019-06-06 | 2019-09-03 | 宜春宜联科技有限公司 | Processing method, the device and system of printer print amount |

| CN115139667A (en)* | 2021-03-30 | 2022-10-04 | 精工爱普生株式会社 | Information processing device, tape printing system, method for controlling information processing device, and recording medium |

| CN115139667B (en)* | 2021-03-30 | 2023-09-15 | 精工爱普生株式会社 | Information processing apparatus, tape printing system, control method for information processing apparatus, and recording medium |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2007144955A (en) | 2007-06-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101321628A (en) | Labels and Label Printers with Release Paper | |

| JP5347812B2 (en) | Label with release paper, label printer, and label printing method | |

| WO2007064035A1 (en) | Peel-off paper-attached label and label printer | |

| JP2013095048A (en) | Tape printing apparatus | |

| CN101322167B (en) | Label with peeling paper, and label printer | |

| WO2007063917A1 (en) | Label with release paper and label printer | |

| US20120014734A1 (en) | Printer and roll | |

| JP5113604B2 (en) | Printing apparatus and printing method | |

| JP4930557B2 (en) | Label with release paper and label printer | |

| JP4537746B2 (en) | Print issuing device and print issuing method | |

| JP2007144956A (en) | Label with release paper and label printer | |

| JP7293896B2 (en) | label printer, program | |

| JP5055755B2 (en) | Label with release paper and label printer | |

| JP5619564B2 (en) | Verification device | |

| JP5757743B2 (en) | Verification device | |

| JP2006056009A (en) | Printer setting method and printer | |

| JP2005178093A (en) | Printer, recording paper information reading method, detection method of remaining amount of recording paper and recording paper roll | |

| US20110135367A1 (en) | Tape printer, method for controlling tape printer, and computer program product | |

| JP2007144954A (en) | Label with release paper and label printer | |

| JPH0634250B2 (en) | Printing device for labels, tags, etc. | |

| US20240253922A1 (en) | Media Processing Device Configured to Reduce Media Waste | |

| JP6160343B2 (en) | Printing tape | |

| JP5749036B2 (en) | Verification device | |

| JP2005047087A (en) | Label printer | |

| JP6160344B2 (en) | Printing tape and tape printer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Open date:20081210 |