CN101255077B - An aerobic composting reactor - Google Patents

An aerobic composting reactorDownload PDFInfo

- Publication number

- CN101255077B CN101255077BCN2008101031340ACN200810103134ACN101255077BCN 101255077 BCN101255077 BCN 101255077BCN 2008101031340 ACN2008101031340 ACN 2008101031340ACN 200810103134 ACN200810103134 ACN 200810103134ACN 101255077 BCN101255077 BCN 101255077B

- Authority

- CN

- China

- Prior art keywords

- tank body

- tank

- compost reactor

- reactor

- sensor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000009264compostingMethods0.000titleabstractdescription27

- 238000003756stirringMethods0.000claimsabstractdescription33

- 238000009423ventilationMethods0.000claimsabstractdescription26

- 238000012544monitoring processMethods0.000claimsabstractdescription8

- 239000002361compostSubstances0.000claimsdescription20

- 238000009413insulationMethods0.000claimsdescription5

- 239000000463materialSubstances0.000abstractdescription14

- 238000005070samplingMethods0.000abstractdescription6

- 238000000855fermentationMethods0.000abstractdescription5

- 230000004151fermentationEffects0.000abstractdescription5

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000abstractdescription5

- 238000005054agglomerationMethods0.000abstractdescription3

- 230000002776aggregationEffects0.000abstractdescription3

- 238000007599dischargingMethods0.000abstractdescription3

- 230000008020evaporationEffects0.000abstractdescription3

- 238000001704evaporationMethods0.000abstractdescription3

- 206010021143HypoxiaDiseases0.000abstractdescription2

- 230000007954hypoxiaEffects0.000abstractdescription2

- 230000035699permeabilityEffects0.000abstractdescription2

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000description8

- 229910052760oxygenInorganic materials0.000description8

- 239000001301oxygenSubstances0.000description8

- 238000012360testing methodMethods0.000description7

- 238000000034methodMethods0.000description6

- 239000003638chemical reducing agentSubstances0.000description4

- 238000011160researchMethods0.000description3

- 238000000354decomposition reactionMethods0.000description2

- 230000000694effectsEffects0.000description2

- 238000010438heat treatmentMethods0.000description2

- 230000006872improvementEffects0.000description2

- 239000012774insulation materialSubstances0.000description2

- 244000005700microbiomeSpecies0.000description2

- 239000000203mixtureSubstances0.000description2

- 229920002635polyurethanePolymers0.000description2

- 239000004814polyurethaneSubstances0.000description2

- 230000008569processEffects0.000description2

- 239000002994raw materialSubstances0.000description2

- 239000000523sampleSubstances0.000description2

- 239000002699waste materialSubstances0.000description2

- 239000004793PolystyreneSubstances0.000description1

- 244000052616bacterial pathogenSpecies0.000description1

- 230000008859changeEffects0.000description1

- 238000006243chemical reactionMethods0.000description1

- 238000013480data collectionMethods0.000description1

- 230000007812deficiencyEffects0.000description1

- 230000010259detection of temperature stimulusEffects0.000description1

- 238000005516engineering processMethods0.000description1

- 230000007613environmental effectEffects0.000description1

- 238000002474experimental methodMethods0.000description1

- 239000006260foamSubstances0.000description1

- 239000011521glassSubstances0.000description1

- 230000017525heat dissipationEffects0.000description1

- 238000002156mixingMethods0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 239000005416organic matterSubstances0.000description1

- 229920002223polystyrenePolymers0.000description1

- 230000002265preventionEffects0.000description1

- 238000004886process controlMethods0.000description1

- 239000002689soilSubstances0.000description1

- 239000007787solidSubstances0.000description1

- 239000002910solid wasteSubstances0.000description1

- 239000004575stoneSubstances0.000description1

- 238000006467substitution reactionMethods0.000description1

- 230000007306turnoverEffects0.000description1

- 210000002268woolAnatomy0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/40—Bio-organic fraction processing; Production of fertilisers from the organic fraction of waste or refuse

Landscapes

- Processing Of Solid Wastes (AREA)

- Fertilizers (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及固体发酵领域,具体涉及一种好氧堆肥反应器。The invention relates to the field of solid fermentation, in particular to an aerobic composting reactor.

背景技术Background technique

随着固体废弃物的排放量不断增长,废弃物的处理成了关系生态环境的一大问题,作为废弃物的一种处理方法,堆肥技术越来越受到重视,相应的堆肥设备发展迅速。好氧堆肥反应器系统具有堆体温度高、发酵时间短、有机物分解彻底、有效防止病原菌的传播和异味散发的优点。堆肥设备的不同主要体现在通风方式、有无搅拌及外形特点这几方面。With the increasing discharge of solid waste, the disposal of waste has become a major issue related to the ecological environment. As a treatment method for waste, composting technology has received more and more attention, and the corresponding composting equipment has developed rapidly. The aerobic composting reactor system has the advantages of high compost temperature, short fermentation time, thorough decomposition of organic matter, and effective prevention of the spread of pathogenic bacteria and odor emission. The difference of composting equipment is mainly reflected in the aspects of ventilation mode, whether there is stirring or not, and appearance characteristics.

除了工厂化的堆肥设备外,应用于实验室中的堆肥装置,用来研究堆肥过程及变化的实例也越来越多,这种装置按规模大小分为小试、中试和体积更大的试验装置,体积在10-100L范围的为小试装置,由于比表面积越小,散热也越快,所以中试型在条件上更加接近工厂中的堆肥设备。目前国内的堆肥研究,一般采用小型试验装置及简单的控制较多,对于制作体积大,如在1000L以上的装置的研究较少。并且,在堆肥装置内,对于几项重要的物理参数--温度、水分和O2含量研究的不多,特别是水分和O2含量的监测。In addition to factory composting equipment, there are more and more examples of composting devices used in laboratories to study the composting process and changes. Such devices are divided into small-scale tests, pilot tests and larger volumes according to their scale. The test device is a small test device with a volume in the range of 10-100L. Because the smaller the specific surface area, the faster the heat dissipation, so the pilot test type is closer to the composting equipment in the factory in terms of conditions. At present, domestic compost research generally uses small-scale test devices and simple controls, and there are few studies on devices with large volumes, such as devices above 1000L. Moreover, in the composting plant, there are not many studies on several important physical parameters - temperature, moisture and O2 content, especially the monitoring of moisture and O2 content.

在堆肥反应器内进行堆肥容易产生一些问题,例如物料均匀性差,通气不均衡,造成局部厌氧、结块,物料发酵不完全,进出料困难等。Composting in a composting reactor is prone to some problems, such as poor material uniformity, unbalanced ventilation, local anaerobic, agglomeration, incomplete fermentation of materials, and difficulty in feeding and discharging materials.

发明内容Contents of the invention

针对上述不足,本发明提供了一种好氧堆肥反应器,其能够对堆肥环境进行监测和调节。In view of the above deficiencies, the present invention provides an aerobic composting reactor, which can monitor and adjust the composting environment.

为实现上述目的,本发明提供的堆肥反应器包括罐体,所述罐体顶部具有进料口和排风口,罐体底部具有出料口,所述罐体内具有搅拌装置以及一个或多个温度传感器、一个或多个水分传感器和一个或多个O2传感器,所述搅拌装置由电机驱动,所述罐体壁上具有一个或多个通风管,所述通风管上具有通风孔与罐体内相通,所述通风管与风机相连。In order to achieve the above object, the composting reactor provided by the present invention includes a tank body, the top of the tank body has an inlet and an air outlet, the bottom of the tank body has a discharge port, and the tank body has a stirring device and one or more temperature sensor, one or more moisture sensors and one or moreO2 sensors, the stirring device is driven by a motor, and one or more ventilation pipes are provided on the wall of the tank body, and the ventilation pipes have ventilation holes and tank The body communicates, and the ventilation pipe is connected with the fan.

本发明反应器可设置成卧式,在罐体底部设置一底座,并在底座上安装支架,用于固定罐体。在所述底座上还可安装脚轮,以便移动反应器。The reactor of the present invention can be arranged as a horizontal type, and a base is arranged at the bottom of the tank body, and a bracket is installed on the base for fixing the tank body. Casters can also be installed on the base to move the reactor.

上述搅拌装置包括搅拌轴以及一个或多个连接在搅拌轴上的搅拌桨,搅拌轴由电机驱动转动,可在电机与搅拌轴之间设置一减速机,用于调节搅拌轴的转速。The stirring device above includes a stirring shaft and one or more stirring paddles connected to the stirring shaft. The stirring shaft is driven by a motor, and a speed reducer can be arranged between the motor and the stirring shaft to adjust the rotating speed of the stirring shaft.

上述通风管与风机之间可依次连接一流量计和一阀门,用于监测和调节气流量。所述阀门可为电子阀门,所述风机可通过一时间继电器控制其开关时间。上述罐体顶部两端还设有取样口,可在其中1取样口处设置一排风扇,以便及时带走多余水分。A flow meter and a valve can be connected sequentially between the ventilation pipe and the fan for monitoring and adjusting the air flow. The valve can be an electronic valve, and the fan can be controlled on and off by a time relay. There are also sampling ports at both ends of the top of the tank, and a row of fans can be set at one of the sampling ports to take away excess water in time.

通过对温度传感器、水分传感器和O2传感器的数据采集可以实现对温度、水分和O2的检测。并且,可以通过一数据采集器将上述传感器输出的信号采集到计算机中,可实现对数据的实时记录、存储和调用,时刻了解堆肥中温度、水分及O2含量的变化情况,从而为堆肥的过程控制提供了良好的环境。The detection of temperature, moisture andO2 can be realized through the data collection of temperature sensor, moisture sensor andO2 sensor. Moreover, the signals output by the above sensors can be collected into the computer through a data collector, which can realize real-time recording, storage and calling of the data, and keep abreast of the changes in temperature, moisture andO2 content in the compost, so as to provide more information for composting. Process control provides a good environment.

上述反应器的罐体外壁还可包被一层保温层,以防止温度的散失。保温材料可以是聚苯乙烯、聚氨酯和泡沫石棉。经试验表明,反应器在外界温度低于零度的条件下,仍能维持温度上升,达到高温期,并持续一周左右。此外,在保温层内或保温层外还可设置加热装置,用于调节罐体内的温度。The outer wall of the tank of the above-mentioned reactor can also be coated with a layer of insulation layer to prevent the loss of temperature. Insulation materials can be polystyrene, polyurethane and foam stone wool. Tests have shown that the reactor can still maintain a temperature rise when the external temperature is lower than zero, reaching a high temperature period, which lasts for about a week. In addition, a heating device can also be arranged inside or outside the insulation layer to adjust the temperature in the tank.

本发明堆肥反应器,能够使物料混匀,改善通气性,水分易蒸发,物料发酵充分,不存在局部缺氧或结块,进出料容易,风机可以实现人为控制,并且可以在线监测和管理数据,随时调用分析数据,是研究好氧堆肥过程的良好反应器。The composting reactor of the present invention can make materials evenly mixed, improve air permeability, easy evaporation of water, sufficient fermentation of materials, no local hypoxia or agglomeration, easy feeding and discharging of materials, manual control of fans, and online monitoring and management of data , call analysis data at any time, it is a good reactor for studying aerobic composting process.

附图说明Description of drawings

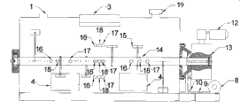

图1是本发明反应器的结构示意图;Fig. 1 is the structural representation of reactor of the present invention;

图2是图1的左侧视图;Fig. 2 is the left side view of Fig. 1;

图3是在线监测系统的流程图。Figure 3 is a flowchart of the online monitoring system.

图中:1.取样口;2.排气口;3.加料口;4.出料口;5.脚轮;6.底座;7.支架;8.风机;9.阀门;10.流量计;11.通风管;12.电机;13.减速机;14.搅拌轴;15.搅拌桨;16.水分传感器;17.温度传感器;18.O2传感器;19.排风扇。In the figure: 1. Sampling port; 2. Exhaust port; 3. Feeding port; 4. Material outlet; 5. Casters; 6. Base; 7. Bracket; 8. Fan; 11. Ventilation pipe; 12. Motor; 13. Reducer; 14. Stirring shaft; 15. Stirring paddle; 16. Moisture sensor; 17. Temperature sensor; 18. O2 sensor; 19. Exhaust fan.

具体实施方式Detailed ways

下面结合附图进一步说明本发明。应当理解,以下实施例仅用于说明本发明,而不能限制本发明的范围。在不背离本发明精神和实质的情况下,本领域技术人员仍可对具体的结构、装置或材料作各种各样的替换或修改,然而,这些仍然属于本发明的范围。Further illustrate the present invention below in conjunction with accompanying drawing. It should be understood that the following examples are only used to illustrate the present invention, but not to limit the scope of the present invention. Without departing from the spirit and essence of the present invention, those skilled in the art can still make various substitutions or modifications to specific structures, devices or materials, however, these still belong to the scope of the present invention.

实施例1Example 1

参见图1和图2,本发明反应器包括堆肥罐体、通风系统、搅拌系统及各种传感器等。本例中,罐体呈圆柱形,卧式。Referring to Fig. 1 and Fig. 2, the reactor of the present invention includes a compost tank, a ventilation system, a stirring system and various sensors. In this example, the tank body is cylindrical and horizontal.

所述罐体顶部设有取样口1(两个,分别位于罐体顶部的两端)、排气口2以及加料口3,在所述罐体底部设有出料口4。在所述罐体下设有底座6,底座6上安装有罐体支架7,罐体支架7支撑在罐体两端的中心轴上,罐体通过底座6以及支架7得以固定,在底座6底面安装有脚轮5,以增加其移动性。The top of the tank is provided with a sampling port 1 (two, located at both ends of the top of the tank), an

所述通风系统由依次用导管连接的风机8、阀门9、流量计10(可采用玻璃转子流量计)与通风管11组成,所述通风管有三支,分别位于罐体底部以及两个侧面,位于侧面的通风管可位于罐体的中下部(位于罐体中心轴以下的部位),并且对称设置,这样可有利于通风。通风管上具有若干个通气孔,均匀分布,并与罐体内部(罐腔)相通。空气通过风机8鼓入罐体内,通过流量计10可以显示通风量,根据需要可以通过阀门9来调节通风量。所述风机可以与一时间继电器相连,通过继电器开控制风机的开关,达到定时开关的作用。在取样口1设置一排风扇19(排风扇可采用离心式风机,功率4.5KW),能增强通风系统的性能,带走罐体内的多余水分。The ventilation system is composed of

上述搅拌装置,包括搅拌轴14和安装在搅拌轴14上的搅拌桨15,搅拌轴14由电机12驱动,在电机12和搅拌轴14之间设置有一减速机13,电机12驱动减速机13转动,经减速后,搅拌轴14可获得较低的转速,以适应反应器的搅拌需求。本例中搅拌桨15共设置6片,等距离分布在搅拌轴上,搅拌浆与搅拌浆间的夹角为60度,搅拌桨的长短可以不一致,并且可在搅拌桨的端部或者其它部位设有突起,以增加搅拌效果。启动电机后,搅拌装置能同时、不同角度地对物料进行翻转,充分混合均匀。Above-mentioned stirring device comprises stirring

在上述罐体内设有温度传感器16、水分传感器17以及氧传感器18,传感器可设置在转动轴以及罐体内壁上,本例中各种传感器各设置5各,其中每种三个分别等距位于转动轴上,另两个则对称地位于中心轴的垂直方向上。传感器的分布尽量使得其能反应罐内整体环境情况。A

采用的传感器可为:The sensors used can be:

温度传感器:温度热电阻PT-100,5只Temperature sensor: temperature thermal resistance PT-100, 5 pieces

氧传感器:MF010-0-LC氧气传感器Oxygen sensor: MF010-0-LC oxygen sensor

水分传感器:用于测定土壤水分的FDR-406,三根探针,可以测得插孔处(即传感器所在位置)的堆肥材料水分值,若需测量堆体内部水分值,可将堆肥样品取出,放入烧杯中,将传感器插入堆肥样中,测得水分值。Moisture sensor: FDR-406 for measuring soil moisture, with three probes, can measure the moisture value of the compost material at the jack (that is, where the sensor is located). Take it out, put it into a beaker, insert the sensor into the compost sample, and measure the moisture value.

作为一种改进,可以在罐体的外壁上包被一层保温层,例如1m3的罐体外面覆盖一层50mm厚的聚氨酯保温材料,经实验表明在低于零度的环境下仍然维持温度上升,达到高温期,并持续一周左右。As an improvement, a layer of insulation can be coated on the outer wall of the tank. For example, a1m3 tank is covered with a layer of 50mm thick polyurethane insulation material. Experiments show that the temperature can still be maintained in a sub-zero environment. , reaches a high temperature period, and lasts for about a week.

作为一种改进,还可以在保温层内或保温层外设置加热装置,用于调节罐体内的温度。As an improvement, a heating device can also be provided inside or outside the insulation layer to adjust the temperature in the tank.

参见图3,是在线监测系统的流程图。传感器的输出信号被数据采集器接收,送到微电脑系统,打开特定的软件程序,能够显示正在工作中的各个传感器的数据,根据数据,调节时间继电器,控制风机的开关时间。监测数据可以保存成Excel格式,做其它分析用。Referring to Figure 3, it is a flow chart of the online monitoring system. The output signal of the sensor is received by the data collector, sent to the microcomputer system, and a specific software program is opened to display the data of each sensor in operation. According to the data, the time relay is adjusted to control the switching time of the fan. The monitoring data can be saved in Excel format for other analysis.

把堆肥原料进行配比混合后,将其装入堆肥实验装置中,加盖进料口,风机开始工作,利用时间控制法调节通风时间,也可完全由人工来控制风机的开与关。利用时间控制是指时间继电器是双设定数显时间继电器,在堆肥的第一个阶段,原料加入时的温度很低,在未达到高温期以前,设定通风时间为开5min,停1h,为初期堆肥内部的好氧微生物提供氧气,微生物的分解活动放出能量,堆体温度迅速上升,在堆肥第2d温度可上升到55℃,为加大水分的散发,保证温度维持在65℃左右,通风时间改为开5min,停30min,在高温期最高温度可达67℃,并且可以持续一周时间,搅拌装置在高温期,保持每2d搅拌一次,使物料充分混合均匀,并加快水分的蒸发。当反应逐渐减慢时,堆肥温度也会降低,再改变通风时间,通以适当的氧气,保证堆肥最终腐熟。After mixing the compost raw materials, put them into the composting experimental device, cover the feed inlet, the fan starts to work, and use the time control method to adjust the ventilation time, or completely control the fan on and off manually. The use of time control means that the time relay is a dual-setting digital display time relay. In the first stage of composting, the temperature when the raw materials are added is very low. Before the high temperature period is reached, the ventilation time is set to open for 5 minutes and stop for 1 hour. Provide oxygen for the aerobic microorganisms in the initial composting, the decomposition activities of the microorganisms release energy, the temperature of the compost rises rapidly, and the temperature can rise to 55°C on the second day of composting. In order to increase the distribution of water, the temperature is maintained at about 65°C. The ventilation time is changed to open for 5 minutes and stop for 30 minutes. In the high temperature period, the maximum temperature can reach 67°C, and it can last for a week. When the stirring device is in the high temperature period, keep stirring once every 2 days to fully mix the materials and speed up the evaporation of water. When the reaction gradually slows down, the temperature of the compost will also decrease, and then change the ventilation time to supply proper oxygen to ensure the final maturity of the compost.

堆肥装置可以记录温度、水分和氧气含量值,在进行时间控制之外,也可以人为根据氧气含量以及温度的数据,采用另外的控制方法,并且可以对氧气的消耗,堆肥的需氧情况等作进一步研究,为后续的实验研究提供了更大的空间。The composting device can record the temperature, moisture and oxygen content values. In addition to time control, other control methods can also be used artificially based on the data of oxygen content and temperature, and the consumption of oxygen and the aerobic conditions of the compost can be adjusted. Further research provides a larger space for subsequent experimental research.

Claims (8)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2008101031340ACN101255077B (en) | 2008-03-31 | 2008-03-31 | An aerobic composting reactor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2008101031340ACN101255077B (en) | 2008-03-31 | 2008-03-31 | An aerobic composting reactor |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101255077A CN101255077A (en) | 2008-09-03 |

| CN101255077Btrue CN101255077B (en) | 2010-12-08 |

Family

ID=39890243

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2008101031340AActiveCN101255077B (en) | 2008-03-31 | 2008-03-31 | An aerobic composting reactor |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101255077B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106977241A (en)* | 2017-04-10 | 2017-07-25 | 中海油能源发展股份有限公司北京安全环保工程技术研究院 | A kind of aerobic compost reactor |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101481271B (en)* | 2009-02-09 | 2012-07-25 | 万若(北京)环境工程技术有限公司 | Oxygen temperature on-line detected and controlled composting method |

| CN101928162A (en)* | 2009-04-02 | 2010-12-29 | 邵海锋 | Static aerobic fermentation drying tower and application |

| CN101614630B (en)* | 2009-06-11 | 2011-04-27 | 福建师范大学 | An Accelerated Reactor Using Sludge Composting to Accelerate the Performance Aging of Plastic Films |

| CN101830745B (en)* | 2010-05-10 | 2012-10-03 | 中国农业大学 | Device and method for simulating aerobic composting process |

| CN102757270B (en)* | 2011-04-26 | 2014-06-18 | 湖南深拓智能设备股份有限公司 | Horizontally-arranged cylinder rolling type aerobic fermentation apparatus with heat exchange function |

| MX2014011530A (en)* | 2012-04-26 | 2015-01-16 | Procter & Gamble | Composting appliance. |

| CN102976798A (en)* | 2012-12-27 | 2013-03-20 | 苏州顶裕节能设备有限公司 | Biolysis treater of animal dung |

| CN103008333B (en)* | 2012-12-31 | 2015-09-02 | 江苏大学 | A kind of broken last utilization of waste as resource outfit of stalk and matrixing method |

| CN103214290B (en)* | 2013-04-23 | 2014-08-20 | 中国农业大学 | Intelligent aerobic composting reactor system |

| CN103304288B (en)* | 2013-05-14 | 2016-04-06 | 深圳市三盛环保科技有限公司 | A kind of organic materials fertilize preparation machine and fertilizer manufacture |

| CN104003764B (en)* | 2014-06-03 | 2016-08-17 | 天津市农业资源与环境研究所 | A kind of installation for fermenting for feces of livestock and poultry quick composting and using method thereof |

| CN105424094B (en)* | 2015-12-23 | 2018-07-03 | 黑龙江省农业科学院土壤肥料与环境资源研究所 | One kind cold ground aerobic composting fermentation envirment factor remote monitoring system |

| CN109553446A (en)* | 2017-09-27 | 2019-04-02 | 天津科技大学 | A kind of small-sized temperature controlled Blue alga compost device |

| CN108299038B (en)* | 2018-03-13 | 2021-04-06 | 广东省顺原满农业科技发展有限公司 | Process for preparing fertilizer from potassium-rich organic fertilizer |

| CN109678571B (en)* | 2019-01-30 | 2021-10-29 | 东南大学 | Heated drum type aerobic composting reactor |

| CN109682714B (en)* | 2019-02-02 | 2023-11-10 | 农业部规划设计研究院 | Pile body resistance measuring device and resistance coefficient obtaining method |

| CN116161995A (en)* | 2023-03-01 | 2023-05-26 | 德州市园林绿化服务中心 | Preparation system and method of biological matrix |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1256649A (en)* | 1998-02-23 | 2000-06-14 | Tlv有限公司 | Fermentation treating equipment for organic waste |

| CN1406884A (en)* | 2001-08-22 | 2003-04-02 | 上海莱利生化环境技术有限公司 | Organic food refuse processing apparatus by biochemical process |

| CN101148373A (en)* | 2007-08-30 | 2008-03-26 | 福建师范大学 | A sludge aerobic composting reactor |

- 2008

- 2008-03-31CNCN2008101031340Apatent/CN101255077B/enactiveActive

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1256649A (en)* | 1998-02-23 | 2000-06-14 | Tlv有限公司 | Fermentation treating equipment for organic waste |

| CN1406884A (en)* | 2001-08-22 | 2003-04-02 | 上海莱利生化环境技术有限公司 | Organic food refuse processing apparatus by biochemical process |

| CN101148373A (en)* | 2007-08-30 | 2008-03-26 | 福建师范大学 | A sludge aerobic composting reactor |

Non-Patent Citations (3)

| Title |

|---|

| 廖春燕等.固态发酵生物反应器.《微生物学通报》.2005,第32卷(第1期),99-103.* |

| 张锐.好氧堆肥反应器系统研究进展.《中国农业工程学会2005年学术年会论文集》.2005,246-252.* |

| 张锐等.好氧堆肥反应器系统在 废弃物处理中的应用.《农机化研究》.2006,(第10期),173-175.* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106977241A (en)* | 2017-04-10 | 2017-07-25 | 中海油能源发展股份有限公司北京安全环保工程技术研究院 | A kind of aerobic compost reactor |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101255077A (en) | 2008-09-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101255077B (en) | An aerobic composting reactor | |

| CN106701563B (en) | Automatic Control multifunctional solid fermentor | |

| CN103214290B (en) | Intelligent aerobic composting reactor system | |

| CN203960069U (en) | A kind of aerobic compost reactor | |

| CN102603382A (en) | Organic waste aerobic composting test device | |

| CN203782051U (en) | Organic solid waste aerobic composting experiment device | |

| CN101830745B (en) | Device and method for simulating aerobic composting process | |

| JP7633681B2 (en) | system | |

| CN107716522B (en) | Aerobic fermentation device and aerobic fermentation system adopting same | |

| CN103664270A (en) | Full-automatic aerobic composting test equipment | |

| CN103911282A (en) | Fermentation apparatus | |

| JP2018172272A (en) | Composting apparatus and control method thereof | |

| CN102286361B (en) | Biomass fermentation reaction device and application | |

| CN207130031U (en) | A kind of goat plant sewage-treatment plant | |

| KR102050846B1 (en) | Fermentation control system and fermentation equipment using thereof | |

| CN208667522U (en) | Box aerobic fermentation reactor | |

| KR100888618B1 (en) | Management control device of powdered fermenter | |

| CN220766963U (en) | Constant-temperature aerobic fermentation device for experiments | |

| CN117049902B (en) | Organic waste bionic fermentation box and accurate monitoring and regulating method for fermentation process | |

| CN207463797U (en) | A kind of aerobic fermentation device and the aerobic fermentation system using this device | |

| CN219058846U (en) | UNICOM formula multisystem aerobic composting fermentation case | |

| CN208898763U (en) | Multifunctional composting reactor with adjustable moisture content | |

| CN208378746U (en) | The vertical Rapid Fermentation tower of excrement | |

| CN110127841A (en) | A kind of integrated effluent disposal system | |

| CN209081899U (en) | A kind of high solid content material anaerobic fermentation heat transfer performance test platform |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| EE01 | Entry into force of recordation of patent licensing contract | Assignee:Beijing LongAge Amms Biological Technology Co., Ltd. Assignor:Li Ji Contract record no.:2012990000225 Denomination of invention:Aerobic compost reactor Granted publication date:20101208 License type:Exclusive License Open date:20080903 Record date:20120412 | |

| C41 | Transfer of patent application or patent right or utility model | ||

| TR01 | Transfer of patent right | Effective date of registration:20151207 Address after:100193 west campus, No. 2, Old Summer Palace West Road, Beijing, Haidian District Patentee after:China Agricultural University Address before:100094 School of resources and environment, China Agricultural University, 2 West Old Summer Palace Road, Beijing, Haidian District Patentee before:Li Ji |