CN101209771B - Refrigerated container safety intelligent detecting system - Google Patents

Refrigerated container safety intelligent detecting systemDownload PDFInfo

- Publication number

- CN101209771B CN101209771BCN200610063741XACN200610063741ACN101209771BCN 101209771 BCN101209771 BCN 101209771BCN 200610063741X ACN200610063741X ACN 200610063741XACN 200610063741 ACN200610063741 ACN 200610063741ACN 101209771 BCN101209771 BCN 101209771B

- Authority

- CN

- China

- Prior art keywords

- module

- unit

- refrigerated container

- intelligent terminal

- detection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000001514detection methodMethods0.000claimsabstractdescription109

- 238000004891communicationMethods0.000claimsabstractdescription68

- 238000012545processingMethods0.000claimsdescription35

- 238000000034methodMethods0.000claimsdescription11

- 238000004378air conditioningMethods0.000claimsdescription7

- 238000003745diagnosisMethods0.000claimsdescription7

- 230000008569processEffects0.000claimsdescription7

- 230000007613environmental effectEffects0.000abstractdescription15

- 230000006870functionEffects0.000description34

- 238000007726management methodMethods0.000description24

- 238000012544monitoring processMethods0.000description23

- CURLTUGMZLYLDI-UHFFFAOYSA-NCarbon dioxideChemical compoundO=C=OCURLTUGMZLYLDI-UHFFFAOYSA-N0.000description14

- 238000006243chemical reactionMethods0.000description9

- VGGSQFUCUMXWEO-UHFFFAOYSA-NEtheneChemical compoundC=CVGGSQFUCUMXWEO-UHFFFAOYSA-N0.000description7

- 239000005977EthyleneSubstances0.000description7

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000description7

- 229910002092carbon dioxideInorganic materials0.000description7

- 239000001569carbon dioxideSubstances0.000description7

- 239000007789gasSubstances0.000description7

- 239000001301oxygenSubstances0.000description7

- 229910052760oxygenInorganic materials0.000description7

- 230000005540biological transmissionEffects0.000description5

- 238000010586diagramMethods0.000description5

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000description4

- 238000007789sealingMethods0.000description4

- 230000008859changeEffects0.000description3

- 235000013305foodNutrition0.000description3

- 241000894006BacteriaSpecies0.000description2

- 238000001816coolingMethods0.000description2

- 238000013523data managementMethods0.000description2

- 238000013461designMethods0.000description2

- 230000006866deteriorationEffects0.000description2

- 238000001914filtrationMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 229910052757nitrogenInorganic materials0.000description2

- 229910001030Iron–nickel alloyInorganic materials0.000description1

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000description1

- 229910000831SteelInorganic materials0.000description1

- 230000009471actionEffects0.000description1

- 230000003321amplificationEffects0.000description1

- 238000004458analytical methodMethods0.000description1

- 239000010836blood and blood productSubstances0.000description1

- 229940125691blood productDrugs0.000description1

- 230000003750conditioning effectEffects0.000description1

- 238000010276constructionMethods0.000description1

- 238000013480data collectionMethods0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000006073displacement reactionMethods0.000description1

- 229940079593drugDrugs0.000description1

- 239000003814drugSubstances0.000description1

- 238000005187foamingMethods0.000description1

- 235000012055fruits and vegetablesNutrition0.000description1

- 230000004927fusionEffects0.000description1

- 238000007499fusion processingMethods0.000description1

- 230000008676importEffects0.000description1

- 230000010354integrationEffects0.000description1

- 229910052744lithiumInorganic materials0.000description1

- 230000007774longtermEffects0.000description1

- 239000011159matrix materialSubstances0.000description1

- 230000007246mechanismEffects0.000description1

- QSHDDOUJBYECFT-UHFFFAOYSA-NmercuryChemical compound[Hg]QSHDDOUJBYECFT-UHFFFAOYSA-N0.000description1

- 229910052753mercuryInorganic materials0.000description1

- 244000005700microbiomeSpecies0.000description1

- 238000012806monitoring deviceMethods0.000description1

- 230000006855networkingEffects0.000description1

- 238000003199nucleic acid amplification methodMethods0.000description1

- 235000015097nutrientsNutrition0.000description1

- 230000001105regulatory effectEffects0.000description1

- 239000010959steelSubstances0.000description1

Images

Landscapes

- Arrangements For Transmission Of Measured Signals (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及集装箱,尤其涉及集装箱的安全监测装置。The invention relates to a container, in particular to a container safety monitoring device.

背景技术Background technique

目前,进出口集装箱的货物品种越来越多,其中药品、血液制品、冷冻冷藏保鲜食品所占的比例呈几何数增长,这些货物在中转时均需要靠冷藏箱进行装运。同时,农副产品流通的数量和品种在逐步增多,由于富含营养,极易繁殖有害细菌/微生物而腐败变质,或者由于蔬果的过度成熟,降低丁抵抗细菌的能力,或者因生命终结而腐烂,为保证其品质不改变,大多数农副产品必须储存在适合该产品长期保存的环境中,如:必要的温度、湿度,及空气中氧气和二氧化碳气体的含量,这也是冷藏集装箱越来越广泛得到应用的一方面。但是,每年因为集装箱内部运输货物腐烂变质而造成的损失保守估计超过10000亿美圆,有7%的货物是在运输途中因为监管不善而毁损的。At present, there are more and more types of goods in import and export containers, among which the proportion of medicines, blood products, and frozen and refrigerated fresh-keeping foods is increasing geometrically. These goods need to be shipped in refrigerated containers during transit. At the same time, the quantity and variety of agricultural and sideline products are gradually increasing. Because they are rich in nutrients, they are very easy to breed harmful bacteria/microorganisms and deteriorate, or due to the over-ripe fruits and vegetables, the ability to resist bacteria is reduced, or they rot due to the end of life. In order to ensure that its quality does not change, most agricultural and sideline products must be stored in an environment suitable for long-term storage of the product, such as: necessary temperature, humidity, and the content of oxygen and carbon dioxide in the air, which is why refrigerated containers are becoming more and more widely used one aspect of the application. However, it is conservatively estimated that the loss caused by the rot and deterioration of the goods transported in the container exceeds 1 trillion US dollars every year, and 7% of the goods are damaged due to poor supervision during transportation.

同时,由于冷藏集装箱在货物装填完毕,集装箱封箱后,快速制冷的过程中集装箱内部由于空气冷却而形成相对大气压力的负压,负压会导致箱体变形,箱门开启困难等问题,从而影响到集装箱的使用寿命。At the same time, since the refrigerated container is filled with goods, after the container is sealed, the interior of the container will form a negative pressure relative to the atmospheric pressure due to air cooling during the rapid cooling process. The negative pressure will cause deformation of the box body and difficulty in opening the door. affect the service life of the container.

另外,目前国际反恐和货运安全,都要求对集装箱进行全供应链监测,以防止集装箱内部货物偷盗和集装箱门的开法开启的恐怖和危险事件的发生。In addition, the current international anti-terrorism and freight security require the monitoring of the entire supply chain of the container to prevent the occurrence of terrorist and dangerous incidents such as theft of goods inside the container and the opening of the container door.

此外,目前的集装箱信息采集板与数据采集中心之间的数据采集方式都是通过四芯接口、串口通讯和电力载波通讯三种有线数据传输方式,组网的灵活性非常差,可扩充性差,成本高。In addition, the current data collection methods between the container information collection board and the data collection center are all through three wired data transmission methods: four-core interface, serial port communication and power carrier communication. The flexibility of networking is very poor, and the scalability is poor. high cost.

发明内容Contents of the invention

本发明旨在克服现有技术的不足,而从改善内部环境监控手段入手以减少损失;从改善内部压力探测与调整入手以提高集装箱的使用寿命;从改善对集装箱的启动情况进行探测入手以识别集装箱门的授权和非授权开启情况,甄别集装箱安全与否;从构建无线通讯手段,以降低成本,提高监测组网扩充的灵活性。The present invention aims to overcome the deficiencies of the prior art, and start from improving the means of internal environment monitoring to reduce losses; start from improving internal pressure detection and adjustment to increase the service life of the container; start from improving the detection of the start-up of the container to identify The authorized and unauthorized opening of the container door can identify whether the container is safe or not; from the construction of wireless communication means to reduce costs and improve the flexibility of monitoring network expansion.

为了实现上述目的,本发明生产制造一种冷藏集装箱安全智能检测系统,包括至少一冷藏集装箱和与该些冷藏集装箱通讯连接的后台信息系统,所述冷藏集装箱包括:In order to achieve the above object, the present invention manufactures a refrigerated container safety intelligent detection system, which includes at least one refrigerated container and a background information system that communicates with these refrigerated containers, and the refrigerated container includes:

至少一用以探测箱体内温湿度和气体浓度的环境探测单元;at least one environmental detection unit for detecting the temperature, humidity and gas concentration in the box;

一箱门状态探测单元;和,a door state detection unit; and,

一智能终端单元;an intelligent terminal unit;

所述后台信息系统包括至少一本地的/远程的计算机或机组;The background information system includes at least one local/remote computer or group;

所述智能终端单元与该些计算机或机组通讯连接;The intelligent terminal unit is communicatively connected with these computers or the unit;

所述智能终端单元与环境探测单元和箱门状态探测单元通讯连接;The intelligent terminal unit communicates with the environment detection unit and the box door state detection unit;

所述智能终端单元,将收集到的、由环境探测单元和箱门状态探测单元提供的信息,上传给所述后台信息系统供其判断所述冷藏集装箱内部货物存储环境状态是否适宜和所述冷藏集装箱本身状态是否安全。The intelligent terminal unit uploads the collected information provided by the environment detection unit and the door state detection unit to the background information system for it to judge whether the storage environment state of the goods inside the refrigerated container is suitable for the refrigerated container. Whether the status of the container itself is safe.

所述冷藏集装箱还包括:The refrigerated container also includes:

一压力探测与控制单元;a pressure detection and control unit;

所述智能终端单元与该压力探测与控制单元通讯连接;The intelligent terminal unit communicates with the pressure detection and control unit;

所述智能终端单元,根据收集到的、由该压力探测与控制单元提供的信息,向该压力探测与控制单元发送命令以调节冷藏集装箱箱体内部的压力。The intelligent terminal unit sends commands to the pressure detection and control unit to adjust the pressure inside the refrigerated container according to the collected information provided by the pressure detection and control unit.

所述冷藏集装箱还包括:The refrigerated container also includes:

一气调系统;an air conditioning system;

所述智能终端单元收集由环境探测单元、箱门状态探测单元和内部气体压力探测与控制单元提供的信息,并根据该些信息对该气调系统进行控制以调节箱体内部环境。The intelligent terminal unit collects information provided by the environment detection unit, the door state detection unit and the internal gas pressure detection and control unit, and controls the air conditioning system according to the information to adjust the internal environment of the box.

所述冷藏集装箱还包括:The refrigerated container also includes:

一冷机信号采集与故障诊断单元;A cold machine signal acquisition and fault diagnosis unit;

所述智能终端单元与该冷机信号采集与故障诊断单元通讯连接;The intelligent terminal unit is communicatively connected with the cold machine signal acquisition and fault diagnosis unit;

所述智能终端单元,将收集到的、由冷机信号采集与故障诊断单元提供的信息,上传给所述后台信息系统供其判断所述冷藏集装箱内部冷机状态是否正常。The intelligent terminal unit uploads the collected information provided by the chiller signal acquisition and fault diagnosis unit to the background information system for it to judge whether the internal chiller state of the refrigerated container is normal.

所述环境探测单元,包括环境探测传感模块、传感接口模块、数据处理控制模块、信息存储模块、扩展接口模块、总线通信控制接口模块和电源管理模块;通过各种传感器将冷藏集装箱内的温度、湿度、氧气浓度、二氧化碳浓度、乙烯浓度、氮气浓度等物理量转换成相应的电子信号,并且通过传感接口模块将各种信号上传给数据控制处理模块。The environment detection unit includes an environment detection sensor module, a sensor interface module, a data processing control module, an information storage module, an expansion interface module, a bus communication control interface module and a power management module; Physical quantities such as temperature, humidity, oxygen concentration, carbon dioxide concentration, ethylene concentration, and nitrogen concentration are converted into corresponding electronic signals, and various signals are uploaded to the data control processing module through the sensor interface module.

所述箱门状态探测单元,通过电容、电感、位移传感器等探测集装箱门开关情况,在一具体实施中,包括磁场强度设定模块、霍尔传感模块、数据处理控制模块、信息存储模块、无线通信模块、扩展接口模块和电源管理模块;箱门的开关过程中磁场强度设定模块的磁场强度发生变化,使霍尔传感模块产生不同的信号,输出信号经过处理后用作箱门开关状态的判断信号。The door state detection unit detects the opening and closing of the container door through capacitance, inductance, displacement sensors, etc. In a specific implementation, it includes a magnetic field strength setting module, a Hall sensor module, a data processing control module, an information storage module, Wireless communication module, expansion interface module and power management module; the magnetic field strength of the magnetic field strength setting module changes during the opening and closing of the box door, so that the Hall sensor module generates different signals, and the output signal is used as a box door switch after processing status signal.

所述压力探测与控制单元,包括微型电动球阀以及压力探测模块、数据处理控制模块、总线通信控制接口模块和电源管理模块,通过压力探测传感器探测集装箱内部的气体压力,根据监测的内部压力情况,通过智能终端单元发送命令调节压力探测与控制单元的微型电动球阀使冷箱内压力与外面环境压力基本平衡,避免产生负压影响箱体。The pressure detection and control unit includes a miniature electric ball valve, a pressure detection module, a data processing control module, a bus communication control interface module, and a power management module. The pressure detection sensor detects the gas pressure inside the container. According to the monitored internal pressure, The micro electric ball valve of the pressure detection and control unit is adjusted by sending commands through the intelligent terminal unit to basically balance the pressure inside the cold box with the external environment pressure, and avoid negative pressure affecting the box.

所述智能终端单元,包括总线通信控制接口模块、终端处理器模块、LCD显示模块、无线通信模块、PLC控制接口模块和电源模块,实现集装箱数据的集成与处理并将数据上传到后台信息系统。The intelligent terminal unit includes a bus communication control interface module, a terminal processor module, an LCD display module, a wireless communication module, a PLC control interface module and a power supply module to realize the integration and processing of container data and upload the data to the background information system.

所述智能终端单元,还包括一GPS模块,所述终端处理器模块通过该GPS模块获取定位信息。The intelligent terminal unit further includes a GPS module, and the terminal processor module acquires positioning information through the GPS module.

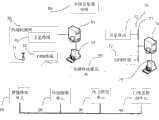

所述后台信息系统负责对智能终端单元上传数据的处理,实现对冷藏集装箱的本地/远程监测与控制,包括局域监测网和广域监测网。局域监测网是在一定范围内,如:码头、港口、堆场,通过一种无线数传输方式,在局域数据监测管理中心与各智能冷箱终端之间进行数据通讯,实现对局域范围内的冷藏集装箱监测;广域监测网是通过在局域终端配置GPRS终端或全球卫星通讯终端,实现广域,如:中国,甚至全球范围内的冷藏集装箱监测。The background information system is responsible for processing the data uploaded by the intelligent terminal unit, realizing local/remote monitoring and control of the refrigerated container, including a local area monitoring network and a wide area monitoring network. The local area monitoring network is within a certain range, such as: docks, ports, and storage yards. Through a wireless data transmission method, data communication is carried out between the local area data monitoring management center and each intelligent cold box terminal to realize local monitoring. Wide-area monitoring of refrigerated containers within a wide area; the wide-area monitoring network realizes monitoring of refrigerated containers in a wide area, such as China, or even around the world, by configuring GPRS terminals or global satellite communication terminals at local terminals.

与现有技术相比,本发明的冷藏集装箱安全智能检测系统,可提高货运效率,增强货运安全。Compared with the prior art, the refrigerated container safety intelligent detection system of the present invention can improve freight efficiency and enhance freight safety.

附图说明Description of drawings

图1是本发明的冷藏集装箱安全智能检测系统实施例原理示意;Fig. 1 is a schematic diagram of the embodiment principle of the refrigerated container safety intelligent detection system of the present invention;

图2是本发明实施例中所述冷藏集装箱结构示意;Fig. 2 is the structural representation of the refrigerated container described in the embodiment of the present invention;

图3是本发明实施例中所述智能终端单元结构示意;Fig. 3 is a schematic diagram of the structure of the intelligent terminal unit in the embodiment of the present invention;

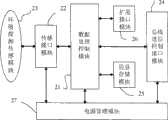

图4是本发明实施例中所述环境探测单元结构示意;Fig. 4 is a schematic structural diagram of the environment detection unit described in the embodiment of the present invention;

图5是本发明实施例中所述压力探测与控制单元结构示意;Fig. 5 is a schematic structural diagram of the pressure detection and control unit described in the embodiment of the present invention;

图6是本发明实施例中所述箱门状态探测单元结构示意。Fig. 6 is a schematic structural diagram of the box door state detection unit in the embodiment of the present invention.

具体实施方式Detailed ways

以下结合附图,对本发明予以进一步地详尽阐述。The present invention will be further elaborated below in conjunction with the accompanying drawings.

本发明的基本思路在于:Basic thinking of the present invention is:

通过在每一集装箱内部,如顶部六个位置分布式布置上探测模块,探测模块集成有温度、湿度、气体浓度探测传感器,每隔一定的时间间隔,如5分钟,采集一次信号,监测集装箱内部温度、湿度、氧气浓度、乙烯浓度、二氧化碳浓度等,乙烯浓度准确反映食品品质恶化的程度和速度,通过对冷藏集装箱内部环境的准确监测,实时信号采集与报警,从而实现对内部货物品质的实时监管,内部环境和气体浓度探测模块信号统一集成到冷藏集装箱的智能终端,智能终端将采集到的集装箱数据进行分析处理,并同时与气调系统连接,通过气调系统,实时主动调节内部氧气、二氧化碳、乙烯、氮气等的浓度,来确保货物品质安全;By distributing detection modules inside each container, such as six positions on the top, the detection module is integrated with temperature, humidity, and gas concentration detection sensors, and collects signals at regular intervals, such as 5 minutes, to monitor the interior of the container Temperature, humidity, oxygen concentration, ethylene concentration, carbon dioxide concentration, etc. The ethylene concentration accurately reflects the degree and speed of food quality deterioration. Through accurate monitoring of the internal environment of the refrigerated container, real-time signal collection and alarm, so as to realize real-time internal cargo quality Supervision, internal environment and gas concentration detection module signals are integrated into the smart terminal of the refrigerated container. The smart terminal analyzes and processes the collected container data and connects with the air conditioning system at the same time. Through the air conditioning system, the internal oxygen, The concentration of carbon dioxide, ethylene, nitrogen, etc., to ensure the quality and safety of goods;

通过集装箱门开关探测模块监测门的开关状态,并将门开关状态的信号集成到智能终端;Monitor the opening and closing status of the door through the container door opening and closing detection module, and integrate the signal of the door opening and closing status into the smart terminal;

通过压力探测与控制单元监测内部压力情况,并将压力信号集成到智能终端,通过智能终端基于采集的压力信息来调节和控制压力探测与控制单元电动球阀的动作来调节箱内压力,实现箱内外压力的基本平衡;The internal pressure is monitored by the pressure detection and control unit, and the pressure signal is integrated into the smart terminal. Based on the collected pressure information, the smart terminal is used to adjust and control the action of the electric ball valve of the pressure detection and control unit to adjust the pressure in the box to realize the inside and outside of the box. Basic balance of pressure;

冷藏集装箱箱体上的智能终端与监测中心之间采用无线数据传输,通过WLAN、GPRS、GSM、卫星等方式将数据上传到监测中心;Wireless data transmission is adopted between the intelligent terminal on the refrigerated container and the monitoring center, and the data is uploaded to the monitoring center through WLAN, GPRS, GSM, satellite, etc.;

并通过在冷藏集装箱智能终端中集成GPS模块,从而实现冷藏集装箱内部温湿度环境和气体环境以及门开关状态的远程监测,确保冷藏集装箱的货物品质安全,实现冷链物流的透明化实时化,实现货运安全和国际反恐。And by integrating the GPS module in the smart terminal of the refrigerated container, the remote monitoring of the temperature and humidity environment and gas environment inside the refrigerated container and the state of the door switch can be realized to ensure the quality and safety of the goods in the refrigerated container, realize the transparency and real-time of cold chain logistics, and realize Freight security and international anti-terrorism.

本发明的冷藏集装箱安全智能检测系统实施例,如图1和图2所示,由环境探测单元20,压力探测与控制单元30,箱门状态探测单元40,智能终端单元10,局域检测网50,无线移动电话通讯网60,广域检测网70和全球卫星通讯网80等构成。The embodiment of the refrigerated container safety intelligent detection system of the present invention, as shown in Figure 1 and Figure 2, consists of an

局域检测网50包括WLAN通讯模块51,GPRS终端52,卫星通讯终端52,数据监测管理中心54和用户终端55等;The

广域检测网70包括GPRS终端71,卫星通讯终端72,数据监测管理中心73和用户终端74等;Wide

局域数据监测管理中心54是电子安全物流的一个本地数据管理控制中心,广域数据监测管理中心73则是电子安全物流的一个远程数据管理控制中心,它们均主要为管理数据库系统和系统软件提供运行的平台,提供INTERNET的接入服务,以及提供同智能终端单元10的数据通信。The local area data monitoring and

局域数据监测管理中心54和/或广域数据监测管理中心73可以根据不同的管理服务情况来选择设备的配置,可选的设备配置主要有PC机级、工作站级、服务器级。The local area data

软件方面,环境探测单元20、压力探测与控制单元30、箱门状态探测单元40、智能终端单元10的底层嵌入式系统功能以及内部总线和外部无线通信功能是由智能监控系统软件提供的,包括各个单元模块的顶层功能管理及数据的融合、处理、显示、控制、传送等功能,具有实用、友好的用户操作界面与管理数据库的良好接口。In terms of software, the

如图2所示,在冷藏集装箱1中,于门端2处设置箱门状态探测单元40,于箱顶设置压力探测与控制单元30,于箱尾设置冷机和气调机构3,于箱体内设置和智能终端单元10,于箱体内在有效空间范围内分布式设置若干环境探测单元20,各单元的具体描述如下:As shown in Figure 2, in a

1、智能终端单元101. Intelligent

如图3所示,包括总线通信控制接口模块13、终端处理器模块11、LCD显示模块14、无线通信模块12、PLC控制接口模块15、电源模块16和天线17等部分。主要是通过内部总线采集各个环境探测单元20提供的环境参数,并将采集到的各种参数进行数据融合处理,然后给出内部环境综合参数并通过LCD显示模块14进行显示。同时,环境综合参数通过PLC控制接口模块15上传给冷藏集装箱的PLC控制器使其对箱内环境进行相应的调节。另外,环境综合参数通过无线数据传输模块12,以WLAN、GPRS或3G等形式上传到局域监测网50,用户通过用户终端55就可从局域数据监测管理中心54实时了解在信号覆盖范围内的所有冷藏集装箱的情况。其中,As shown in FIG. 3 , it includes bus communication

总线通信控制接口模块13由总线通信控制电路和总线接口电路构成。主要实现智能终端单元10与内部总线连接、数据通信控制等功能;The bus communication

终端处理器模块11由MCU单元及相关辅助电路构成。主要实现各种数据处理、通信功能模块控制、显示功能模块控制、系统程序的存储和运行等功能。MCU单元可选用处理功能较强的ARM7系列16位微处理器或ARM9系列32位微处理器,相关辅助电路则包括系统复位、系统存储器、系统时钟、系统电源滤波等电路;The

LCD显示模块14由LCD显示电路构成。主要实现温度、湿度、压力、氧气浓度、二氧化碳浓度、乙烯浓度等参数的显示功能,便于工作人员的查询、操作等工作,可选用低功耗的字符或点阵的LCD模块;The

无线通信模块12由无线通信器件、相关辅助电路以及天线17构成。主要为智能终端单元10提供同其它设备的无线通信功能。可根据实际需要选用符合3G、GPRS或WLAN的无线通信器件;相关辅助电路以及天线17主要是对射频参数的匹配,以保证射频信号的良好可靠。The

PLC控制接口模块15由PLC控制接口电路构成。主要实现智能终端单元与PLC控制设备的数据通信功能,为PLC控制设备提供各种环境参数的控制调整数据。可根据PLC控制设备要求选定接口电路的具体方式,如RS232,UART,SPI等。The PLC

电源模块16由电源转换电路构成。主要实现电源转换功能为智能终端单元10提供获得外部电源供给的功能。智能终端单元10是同制冷机的PLC控制设备相连接的,因此它们的工作电源通过电源转换后可直接供给智能终端单元10及内部总线使用。可选用满足具体要求的DC-DC电路。The

智能终端单元10的可采用半密封结构。The

2、环境探测单元202.

如图4所示,包括环境探测传感模块23、传感接口模块22、数据处理控制模块21、信息存储模块25、扩展接口模块26、总线通信控制接口模块24和电源管理模块17等部分。主要是通过温度、湿度、压力、氧气浓度、二氧化碳浓度和乙烯浓度传感模块,对内部的食品存储环境进行探测。每5分钟采集一次信号,并通过内部总线方式将传感器采集数据上传给智能终端单元10。其中,As shown in FIG. 4 , it includes an environment

环境探测传感模块23由温湿度传感器、压力传感器和各种气体浓度传感器构成。主要通过各传感器件将冷藏集装箱内的温度、湿度、压力、氧气浓度、二氧化碳浓度、乙烯浓度等物理量转换成相应的电子信号,并且通过传感接口模块22将各种信号上传给数据控制处理模块21;The environmental

传感接口模块22由传感器信号调理电路、信号处理控制电路和接口电路构成。主要是对各种传感器产生的不同输出信号进行相关处理控制,如:放大、滤波、数字转换等,为数据处理控制模块21提供可直接处理控制的数字接口。可设计一个自定义的接口标准使所用的环境探测传感模块内的各种传感器件具备即插即用功能,以方便传感器件的定期校准需求;The

数据处理控制模块21由MCU单元及相关辅助电路构成。主要实现传感数据处理、传感接口控制、总线通信调度、信息存储管理、系统程序存储和运行等功能。MCU单元可选用Atmega系列8位微处理器,相关辅助电路包括系统复位、系统时钟、电源滤波等电路;The data

信息存储模块25主要由一个低电压可读写的串行存储单元构成,用于信息存储、查询等功能。可选用4Mb容量的存储器件;The

扩展接口模块26由JTAG、UART、可扩展的传感接口构成。主要实现编程、调试、扩展传感器件等功能。接口功能可由MCU单元提供,并根据具体要求选用不同形式的连接器;The

总线通信控制接口模块24由总线通信控制电路、总线接口电路构成。主要实现环境探测单元与内部总线连接、数据通信控制等功能。The bus communication

电源管理模块27由总线电源接口电路、DC-DC转换电路、电源管理电路构成。主要是从内部总线上获取电流并且通过相应得接口、转换及管理电路为环境探测单元20中各模块提供相应得工作电源及功耗管理功能。The

环境探测单元20可采用半密封结构。The

3、压力探测与控制单元303. Pressure detection and

如图5所示,包括微型电动球阀以及压力探测模块32、数据处理控制模块31、总线通信控制接口模块33、电源管理模块34等部分。主要是根据环境探测单元20监测得到的内部压力情况,通过智能终端单元10发送命令调节微型电动球阀使冷箱内压力与外面环境压力相同,避免产生负压影响箱体。在一个具体实施中,箱内压力调节阀采用电动阀,阀体厚度不超过76mm,箱内体积为80立方米,阀门的通气量能保证冷箱在4-5分钟的时间内箱内压力由一775mm汞柱高达到正常气压,阀体通过二次发泡的形式固定在冷箱内壁。其中,As shown in FIG. 5 , it includes a miniature electric ball valve, a

微型电动球阀以及压力探测模块32由微型电动球阀、控制输入接口、电源以及压力探测传感器构成。主要对箱体内压力进行探测,并上传给智能终端单元10,并通过接收控制命令来设定电动球阀的开关位置而进行冷藏集装箱的内部压力的调整;The miniature electric ball valve and the

数据处理控制模块31由MCU单元及控制输出接口电路构成。主要实现对压力数据进行处理判读,给出球阀控制信号输出等功能。MCU单元可选用Atmega系列8位微处理器,相关辅助电路包括系统复位、电源滤波等电路;The data

总线通信控制接口模块33由总线通信控制电路、总线接口电路构成。主要实现压力探测与控制单元与内部总线连接、数据通信控制等功能;The bus communication

电源管理模块34由总线电源接口电路、DC-DC转换电路、电源管理电路构成。主要是从内部总线上获取电流并且通过相应得接口、转换及管理电路为压力探测与控制单元中各个模块提供相应得工作电源及功耗管理功能。The

4、箱门状态探测单元404. Box door

如图6所示,包括磁场强度设定模块43、霍尔传感模块42、数据处理控制模块41、信息存储模块45、无线通信模块44、扩展接口模块47、电源管理模块46和天线48等部分。主要是在集装箱门上配置门开关探测传感设备,对箱门开关状态进行监测,当箱门之间缝隙达到一定距离时产生开关事件信息并存储,同时对未授权的开关事件进行报警。安装在门端,天线48部分伸出集装箱,通过外部手持阅读器或者固定阅读器可读取箱门状态探测器内部信息,同时,与智能终端单元10相连,从智能终端单元10亦可查询和读取到该探测单元的内部信息。其中,As shown in Figure 6, it includes a magnetic field

磁场强度设定模块43由一定强度的镍铁合金磁钢构成。主要在箱门状态探测单元外形成一定强度的磁场,当箱门的开关过程中磁场强度发生变化,使所选用的霍尔元件产生不同的信号,输出信号经过处理后用作箱门开关状态的判断信号。可采用一到两个磁钢固定在冷藏集装箱门的一端,使霍尔元件对箱门的开关产生的磁场强度变化感应最灵敏;The magnetic field

霍尔传感模块42由霍尔元件、信号处理电路构成。主要感应箱门的开关过程中磁场强度的变化,使所用的霍尔元件产生不同的信号,输出信号经过滤波、数字转换等处理后,为数据处理控制模块41提供箱门开关状态的判断信号。霍尔元件可根据具体要求选用一个或两个,比如:一个监测门开关状态、一个监测恶意侵入,同时可以被周期性休眠;The

数据处理控制模块43由MCU单元及相关辅助电路构成。主要实现数据进行处理、功能控制、系统程序存储和运行等功能。MCU单元可选用Atmega系列8位微处理器,相关辅助电路包括系统复位、电源滤波、ID标识等电路。The data

信息存储模块45主要由一个低电压可读写的串行存储单元构成,用于信息存储、查询等功能。可根据具体要求选用不同容量的存储器件。The

无线通信模块44由半双工、低功耗的无线通信器件、相关辅助电路以及天线48构成。主要为电子关封设备提供同其它设备的无线通信功能,并且具有四个可预置的工作频段、软件可调的频道、功率等功能。无线通信器件可选用CHIPCON公司的低功耗无线通信器件;相关辅助电路主要是对射频参数的匹配,以保证射频信号的良好可靠;天线可选用中集集团提供的PCB天线;The

扩展接口模块47由JTAG、UART、可扩展的传感接口构成。主要实现编程、调试、有线通信、扩展传感元件等功能。接口功能可由MCU单元提供,再根据具体要求选用不同形式的连接器。The

电源管理模块46由电源及电源管理电路构成。主要为电子关封设备提供工作电源及各电路模块的功耗管理功能。电子关封设备安装在集装箱内,因此设计中系统工作电源需用电池供电,可选用高电量的锂电池。为提高电池使用寿命,设计中采用低功耗器件、MCU单元电源管理功能及电源管理电路,以及通过管理所有电路模块的电源开关和选用合适的工作周期等方式来保证电池使用寿命达到5年以上。The

箱门状态探测单元40可采用分体结构及全密封。The door

需要说明的是,本发明的冷藏集装箱安全智能检测系统实施例,其中设置于冷藏集装箱内与智能终端单元10配合的单元并不限于上述几种,可以想象到的一个例子是:It should be noted that, in the embodiment of the refrigerated container safety intelligent detection system of the present invention, the units arranged in the refrigerated container to cooperate with the

GPS模块,用以提供冷藏集装箱的地理坐标,这个模块可以是直接设置在智能终端单元10内部,直接与智能终端单元10中终端处理器模块11连接,也可以是作为一个单元,通过总线通信控制接口模块与智能终端单元10,还可以是通过无线通信模块与智能终端单元10相连。The GPS module is used to provide the geographic coordinates of the refrigerated container. This module can be directly installed inside the

可以想象到的另一个例子是:冷机信号采集与故障诊断单元,与环境探测单元20类似,包括探测传感模块、传感接口模块、数据处理控制模块、信息存储模块、扩展接口模块、总线通信控制接口模块和电源管理模块等部分。可通过总线通信控制接口模块与智能终端单元10,用以采集冷机腔内油液品质、油液液位高度、油液温度、转轴振动、冷机腔内温度、冷机腔内噪音信号,通过信号分析和处理算法判断冷机运行状态,并对出现和故障和潜在的故障风险进行分析、诊断、和预警。上述位于冷藏集装箱内的各单元是通过总线进行通讯连接和电源支持和管理的,而其中通讯之功能,采用短距离的无线通讯手段是可以想象的到的一种替换。Another example that can be imagined is: a cold machine signal acquisition and fault diagnosis unit, similar to the

上述内容,仅为本发明的较佳实施例,并非用于限制本发明的实施方案,本领域普通技术人员根据本发明的主要构思和精神,可以十分方便地进行相应的变通或修改,故本发明的保护范围应以权利要求书所要求的保护范围为准。The above content is only a preferred embodiment of the present invention, and is not intended to limit the implementation of the present invention. Those of ordinary skill in the art can easily make corresponding modifications or modifications according to the main concept and spirit of the present invention. Therefore, this The protection scope of the invention shall be determined by the protection scope required by the claims.

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200610063741XACN101209771B (en) | 2006-12-31 | 2006-12-31 | Refrigerated container safety intelligent detecting system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN200610063741XACN101209771B (en) | 2006-12-31 | 2006-12-31 | Refrigerated container safety intelligent detecting system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101209771A CN101209771A (en) | 2008-07-02 |

| CN101209771Btrue CN101209771B (en) | 2012-07-04 |

Family

ID=39610061

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN200610063741XAExpired - Fee RelatedCN101209771B (en) | 2006-12-31 | 2006-12-31 | Refrigerated container safety intelligent detecting system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101209771B (en) |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20110291828A1 (en)* | 2010-06-01 | 2011-12-01 | Walker Timothy A | Embedded communication system for refrigerated transportation containers |

| CN102167182A (en)* | 2011-02-17 | 2011-08-31 | 上海市疾病预防控制中心 | Intelligent tracking transport case |

| CN102436231B (en)* | 2011-10-13 | 2014-07-09 | 深圳市锐能机械有限公司 | System for checking and monitoring container |

| CN103134550A (en)* | 2011-11-25 | 2013-06-05 | 上海仁哲弘誉信息技术有限公司 | Radio frequency identification device (RFID) wireless logistics temperature monitoring device |

| CN102673923B (en)* | 2012-03-31 | 2014-12-24 | 北京奥科美技术服务有限公司 | Terminal distribution cabinet with remote monitoring and controlling function, distribution cabinet system and communication method |

| CN103115645B (en)* | 2013-01-25 | 2016-04-06 | 重庆西南集成电路设计有限责任公司 | Container satellite locating and monitoring system |

| CN103176035B (en)* | 2013-03-05 | 2015-05-13 | 大连交通大学 | Online container monitoring and positioning method |

| CN104142655A (en)* | 2013-05-08 | 2014-11-12 | 中国国际海运集装箱(集团)股份有限公司 | Refrigerated transport tool monitoring system, control method thereof and refrigerated transport tool |

| CN105467912A (en)* | 2015-12-24 | 2016-04-06 | 中国农业大学 | Edible mushroom cold-chain logistics monitoring system and method |

| US10704827B2 (en)* | 2015-12-28 | 2020-07-07 | Eaton Intelligent Power Limited | Systems and methods for testing electrical connectors |

| CN105528885A (en)* | 2016-01-20 | 2016-04-27 | 澳柯玛股份有限公司 | GSM (global system for mobile communications) communication equipment for commercial cold chain |

| CN106196701B (en)* | 2016-06-28 | 2019-07-23 | 福建雪人股份有限公司 | For the refrigeration system to building site cooling supply |

| CN106379666A (en)* | 2016-08-30 | 2017-02-08 | 孟玲 | Container security system |

| CN106742719B (en)* | 2017-02-08 | 2018-11-20 | 中民新能物联股份有限公司 | A kind of intelligent storage case suitable for e-commerce |

| CN107091909B (en)* | 2017-07-05 | 2019-09-27 | 温州科技职业学院 | A kind of Intelligent data analysis and decision system and its monitoring method for preserving fruit and vegetable utilizing |

| CN107563697A (en)* | 2017-09-07 | 2018-01-09 | 信阳师范学院 | Fresh product Cold Chain Logistics detecting system and method based on Internet of Things |

| CN107748550A (en)* | 2017-11-23 | 2018-03-02 | 苏州迪芬德物联网科技有限公司 | A kind of refrigerating box power carrier monitoring system |

| CN110910057A (en)* | 2018-09-18 | 2020-03-24 | 深圳中集智能科技有限公司 | Intelligent reefer container and intelligent reefer container management platform |

| CN109343439A (en)* | 2018-12-01 | 2019-02-15 | 商丘师范学院 | An intelligent monitoring system for refrigerated trucks based on Internet of Things technology |

| CN109884946A (en)* | 2019-03-14 | 2019-06-14 | 深圳中集智能科技有限公司 | A monitoring terminal and refrigerated container |

| CN110557442A (en)* | 2019-08-19 | 2019-12-10 | 上海现代建筑设计集团工程建设咨询有限公司 | transportation frame management and control method, device and system and electronic equipment |

| CN110456717A (en)* | 2019-08-30 | 2019-11-15 | 中车长江车辆有限公司 | A kind of electronic frozen products insulated container monitoring system and method for railway cold chain transportation |

| CN111689080B (en)* | 2020-07-19 | 2024-06-07 | 深圳市新时空智能系统有限公司 | Monitoring terminal and intelligent refrigerated container |

| CN113753420A (en)* | 2021-03-31 | 2021-12-07 | 上海航益航空地面设备制造股份有限公司 | Intelligent land transportation refrigeration container |

| KR102629015B1 (en)* | 2021-09-03 | 2024-01-25 | 주식회사 지엔테크놀로지스 | Method and system for metal shielding spaces management using multiple terminals |

| CN114019549A (en)* | 2021-10-25 | 2022-02-08 | 北京时域智控技术有限公司 | A container positioning sensing system and container remote monitoring method |

| CN114237112A (en)* | 2021-12-14 | 2022-03-25 | 山东省科学院激光研究所 | An intelligent container control system and device |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4987745A (en)* | 1988-07-29 | 1991-01-29 | Transfresh Corporation | Controlled environment transportation of respiring comestibles |

| CN2295710Y (en)* | 1997-01-06 | 1998-10-28 | 孔令章 | Air conditioning preserving refrigerating container |

| US5872721A (en)* | 1990-04-11 | 1999-02-16 | Transfresh Corporation | Monitor-control systems and methods for monitoring and controlling atmospheres in containers for respiring perishables |

| CN1046999C (en)* | 1993-12-17 | 1999-12-01 | 株式会社金星社 | Method for producing vegetable freshness sensor and vegetable frfshness keeping device using such sensor |

| CN2490522Y (en)* | 2001-05-11 | 2002-05-08 | 尹新鸣 | Miniature intellegence fresh-keeping freezer capable of remote monitoring regulating |

| CN1418554A (en)* | 2001-11-14 | 2003-05-21 | 李国忱 | Resaerch and design for intelligence control of low temp., adding moisture, reducing pressure and air conditioning for retaining freshness of fruits and vegetables |

| CN1733568A (en)* | 2004-08-02 | 2006-02-15 | 中国国际海运集装箱(集团)股份有限公司 | A tank container with an electronic monitoring device |

| CN2765265Y (en)* | 2005-01-11 | 2006-03-15 | 冯天晶 | A theft-proof alarm for window and door |

| CN201002857Y (en)* | 2006-12-31 | 2008-01-09 | 中国国际海运集装箱(集团)股份有限公司 | Refrigerated container safety intelligent detection system |

- 2006

- 2006-12-31CNCN200610063741XApatent/CN101209771B/ennot_activeExpired - Fee Related

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4987745A (en)* | 1988-07-29 | 1991-01-29 | Transfresh Corporation | Controlled environment transportation of respiring comestibles |

| US5872721A (en)* | 1990-04-11 | 1999-02-16 | Transfresh Corporation | Monitor-control systems and methods for monitoring and controlling atmospheres in containers for respiring perishables |

| CN1046999C (en)* | 1993-12-17 | 1999-12-01 | 株式会社金星社 | Method for producing vegetable freshness sensor and vegetable frfshness keeping device using such sensor |

| CN2295710Y (en)* | 1997-01-06 | 1998-10-28 | 孔令章 | Air conditioning preserving refrigerating container |

| CN2490522Y (en)* | 2001-05-11 | 2002-05-08 | 尹新鸣 | Miniature intellegence fresh-keeping freezer capable of remote monitoring regulating |

| CN1418554A (en)* | 2001-11-14 | 2003-05-21 | 李国忱 | Resaerch and design for intelligence control of low temp., adding moisture, reducing pressure and air conditioning for retaining freshness of fruits and vegetables |

| CN1733568A (en)* | 2004-08-02 | 2006-02-15 | 中国国际海运集装箱(集团)股份有限公司 | A tank container with an electronic monitoring device |

| CN2765265Y (en)* | 2005-01-11 | 2006-03-15 | 冯天晶 | A theft-proof alarm for window and door |

| CN201002857Y (en)* | 2006-12-31 | 2008-01-09 | 中国国际海运集装箱(集团)股份有限公司 | Refrigerated container safety intelligent detection system |

Non-Patent Citations (1)

| Title |

|---|

| CN 201002857 Y,权利要求1-10. |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101209771A (en) | 2008-07-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101209771B (en) | Refrigerated container safety intelligent detecting system | |

| CN201002857Y (en) | Refrigerated container safety intelligent detection system | |

| CN107065710B (en) | Passive wireless cold chain transportation vehicle-mounted real-time monitoring system based on Internet of things | |

| CN202904341U (en) | Multi-parameter grain condition monitoring system based on things of internet | |

| CN206450004U (en) | Remote control system of intelligent refrigerator | |

| CN204009562U (en) | Transformer body travel position on-line monitoring system | |

| CN106990744A (en) | A kind of grain depot intelligent management device | |

| CN204375005U (en) | Agricultural product cold chain based on WSN and RFID monitoring, tracing system in transit | |

| CN203164715U (en) | Safe intelligent monitoring and control system for refrigeration storage and transportation equipment | |

| CN105353752A (en) | Internet of things household cold chain turnover box detection system and turnover method | |

| CN107677322A (en) | A kind of real-time monitoring system of Table Grape Cold Chain Logistics | |

| CN206920874U (en) | A kind of vehicle-mounted real-time monitoring system of passive and wireless cold chain transportation based on Internet of Things | |

| CN207336757U (en) | A kind of vehicle-mounted Big Dipper terminal for monitoring refrigerator carriage humiture in real time | |

| CN107544360A (en) | A kind of cold chain transportation monitoring system based on RFID | |

| CN212749900U (en) | Logistics monitoring device based on NB-IoT | |

| CN207488744U (en) | A kind of cold chain transportation monitoring system based on RFID | |

| CN204044653U (en) | Based on the frozen products insulated container information acquisition system of Zigbee networking technology | |

| CN206431676U (en) | Cold chain logistics comprehensive monitoring system | |

| CN101246076A (en) | Valve switch detector and monitoring and tracking system using the detector | |

| CN203243373U (en) | Integrated network monitoring system for logistics vehicle | |

| CN107703832A (en) | A kind of Cold Chain Logistics transport monitoring device based on electronic tag | |

| CN206863556U (en) | A kind of grain depot intelligent management device | |

| CN206411096U (en) | A kind of toxic gas on-line monitoring system | |

| CN208922132U (en) | A kind of ultrasonic solution LPG cylinder level monitoring scheme and system | |

| CN203673312U (en) | Master-slave wireless sensing node monitoring system for cold-chain logistics |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C41 | Transfer of patent application or patent right or utility model | ||

| TR01 | Transfer of patent right | Effective date of registration:20161125 Address after:518000 Guangdong city of Shenzhen province Nanshan District Nanhai Road No. 1057 technology building two Room 102 building A Patentee after:SHENZHEN CIMC SECURITY AND SMART TECHNOLOGY Co.,Ltd. Address before:No. 2 Shekou Harbour Road in Shenzhen city of Guangdong Province in 518000 Patentee before:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) Ltd. | |

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120704 | |

| CF01 | Termination of patent right due to non-payment of annual fee |