CN101163440B - Three-dimensional adhesive device with embedded microelectronic system - Google Patents

Three-dimensional adhesive device with embedded microelectronic systemDownload PDFInfo

- Publication number

- CN101163440B CN101163440BCN2006800137188ACN200680013718ACN101163440BCN 101163440 BCN101163440 BCN 101163440BCN 2006800137188 ACN2006800137188 ACN 2006800137188ACN 200680013718 ACN200680013718 ACN 200680013718ACN 101163440 BCN101163440 BCN 101163440B

- Authority

- CN

- China

- Prior art keywords

- adhesive

- adhesive device

- binding agent

- parts

- microelectronics system

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/68—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient

- A61B5/6801—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be attached to or worn on the body surface

- A61B5/683—Means for maintaining contact with the body

- A61B5/6832—Means for maintaining contact with the body using adhesives

- A61B5/6833—Adhesive patches

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/41—Detecting, measuring or recording for evaluating the immune or lymphatic systems

- A61B5/411—Detecting or monitoring allergy or intolerance reactions to an allergenic agent or substance

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Medical Informatics (AREA)

- Biophysics (AREA)

- Pathology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Physics & Mathematics (AREA)

- Molecular Biology (AREA)

- Surgery (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Immunology (AREA)

- Vascular Medicine (AREA)

- Adhesives Or Adhesive Processes (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及主要用于监视生理或神经条件的微电子系统。更特别地,本发明涉及被嵌入三维粘合剂器件中的侵入式和非侵入式微电子系统,该三维粘合剂器件可被附着到哺乳动物的表面上,该表面适当地为皮肤。该微电子系统适当地利用无线通信并可用于测量ECG(心电图)、EMG(肌电图)、EEG(脑电图)、血糖、脉搏、血压、pH值和氧。The present invention relates to microelectronic systems primarily for monitoring physiological or neurological conditions. More particularly, the present invention relates to invasive and non-invasive microelectronic systems embedded in a three-dimensional adhesive device that can be attached to a mammalian surface, suitably skin. The microelectronic system suitably utilizes wireless communication and can be used to measure ECG (electrocardiogram), EMG (electromyography), EEG (electroencephalogram), blood glucose, pulse, blood pressure, pH and oxygen.

背景技术Background technique

感测系统通过压敏粘合剂向皮肤的附着被很好地建立。因此,AMBU A/S,DK具有大量的用于测量ECG的产品,这些产品通过泡沫粘合剂、微孔粘合剂或水凝胶粘合剂附着到皮肤上。这些传感器一般通过导线连接到监视设备上。The sensing system is well established by attachment of pressure sensitive adhesives to the skin. Therefore, AMBU A/S, DK has a large number of products for measuring ECG which are attached to the skin by foam adhesives, microporous adhesives or hydrogel adhesives. These sensors are generally connected to monitoring equipment by wires.

在WO 03/065926A2中,Ozgus等人公开了具有柔软并且较薄的集成电路的可佩带的生物监视器。该专利申请提出通过使用薄层粘合剂或粘合剂垫料附着到皮肤上而实现高舒适度佩带的方式。但是,使用的粘合剂是吸留的。该申请还说明了用于无线数据收集的传感器模块,该传感器模块具有包含电路的薄硅板和作为多个层被嵌入传感器模块内的柔性电源。In WO 03/065926A2, Ozgus et al. disclose a wearable biomonitor with flexible and thinner integrated circuits. This patent application proposes a way of achieving a high wearing comfort by attaching to the skin using a thin layer of adhesive or an adhesive pad. However, the adhesive used is occlusive. The application also describes a sensor module for wireless data collection with a thin silicon plate containing circuitry and a flexible power source embedded as multiple layers within the sensor module.

在US 5054488中,Mus等人公开了用于产生代表生理条件的电信号的光电子传感器。传感器可通过聚酯衬里上的双侧压敏粘合剂被附着到身体上。In US 5054488, Mus et al. disclose optoelectronic sensors for generating electrical signals representative of physiological conditions. The sensor can be attached to the body by double sided pressure sensitive adhesive on the polyester liner.

在US 5458124中,Stanko等人公开了通过双侧压敏粘合剂被附着到身体上的心电图电极。In US 5458124, Stanko et al. disclose electrocardiogram electrodes that are attached to the body by a double sided pressure sensitive adhesive.

在US 6372951中,Ter-Ovanesyan等人公开了在操作上连接到通过粘合剂补片与佩带者配合的一次性物品上的传感器。各种各样的身体粘合成分可被使用。In US 6372951, Ter-Ovanesyan et al. disclose sensors operatively attached to a disposable item that is fitted to the wearer by an adhesive patch. A wide variety of body bonding compositions can be used.

在US 6385473中,Haines等人公开了用水解胶体粘合剂的两个条带附着到哺乳动物对象身体上的层叠的传感器器件。层叠结构也包含与水解胶体粘合剂接触的水凝胶。器件的寿命规定为24小时。In US 6385473, Haines et al. disclose a laminated sensor device attached to the body of a mammalian subject with two strips of hydrocolloid adhesive. The laminated structure also comprises a hydrogel in contact with a hydrocolloid binder. The lifetime of the device is specified as 24 hours.

在WO 99/59465中,Feierbach等人公开了用于监视病人的生理条件的装置。该装置包括具有用于附着到病人身上的远端侧的补片。该装置还可包含可与所述补片耦合的电子外壳。在一个实施例中,装置的表面可预先形成为符合身体部位的轮廓。承载电子外壳的补片可以较软并提供自然的感觉,并且可由乳胶、硅或其它的涂胶的织物制成。如该专利的图2B和图8所示,具有电子外壳的补片的上表面可具有平滑的凸面形状。补片通过粘合剂与病人的皮肤耦合。这种粘合剂可以是由3M制造的水解胶体皮肤保护粘合剂。由此,该专利申请教导使用用于附着传感器的水解胶体粘合剂衬里,该传感器具有任选地以预先形成的形状配合身体的轮廓的平滑并且较软的衬背。In WO 99/59465, Feierbach et al. disclose a device for monitoring the physiological condition of a patient. The device includes a patch having a distal side for attachment to a patient. The device may also include an electronics housing couplable to the patch. In one embodiment, the surface of the device may be preformed to conform to the contours of the body part. The patch carrying the electronics housing can be soft and provide a natural feel, and can be made of latex, silicon, or other rubberized fabric. As shown in Figures 2B and 8 of that patent, the upper surface of the patch with the electronics housing may have a smooth convex shape. The patch is coupled to the patient's skin by an adhesive. Such an adhesive may be a hydrocolloid skin protection adhesive manufactured by 3M. Thus, this patent application teaches the use of a hydrocolloid adhesive liner for attaching a sensor with a smooth and relatively soft backing, optionally in a pre-formed shape to fit the contours of the body.

在美国申请2003/0009097A1中,Sheraton等人公开了这样一种传感器,即,该传感器具有水凝胶导电中心皮肤接触部分和围绕该中心部分的用于粘合传感器的水解胶体粘合剂部分,并且,在所述组合的盘上,导电端子与导线连接。这种结构进一步被粘合到端子上的叠层膜层和粘合剂的周缘保护。该专利申请教导使用用于将传感器附着到皮肤上的水解胶体粘合剂并强调制成非常薄和柔软的电极的方面。在组合使用水解胶体粘合剂和水凝胶的意义上,该专利申请是独特的。对于任何实际的目的,所公开的结构将是没有用处的,因为来自水凝胶的水分将迁移到水解胶体粘合剂内并随着时间破坏它。In U.S. Application 2003/0009097A1, Sheraton et al. disclose a sensor having a hydrogel conductive central skin contact portion and a hydrocolloid adhesive portion surrounding the central portion for bonding the sensor, And, on the combined pad, the conductive terminals are connected with the wires. This structure is further protected by the perimeter of the laminate film and adhesive bonded to the terminals. This patent application teaches the use of hydrocolloid adhesives for attaching the sensors to the skin and emphasizes the aspect of making electrodes very thin and flexible. This patent application is unique in the sense that hydrocolloid binders and hydrogels are used in combination. For any practical purpose, the disclosed structure would be useless, as the moisture from the hydrogel would migrate into the hydrocolloid adhesive and destroy it over time.

在生理条件的监视器件方面的最新的进展是无线类型。除了能够以侵入或非侵入的方式监视生理条件并潜在地与基准相比较以外,它们能够处理数据并将它们发送给便携式器件。事实上,可附着的器件本身也可例如通过使用光发射、音频报警或另外的警告信号用作警报器。The latest advances in physiological condition monitoring devices are of the wireless type. In addition to being able to monitor physiological conditions in an invasive or non-invasive manner and potentially compare to a baseline, they are able to process the data and send them to a portable device. In fact, the attachable device itself can also be used as an alarm, for example by using light emission, an audio alarm or another warning signal.

当监视人体的生理或神经条件时,附着的微电子系统配戴起来尽可能舒适是十分重要的,特别是当携带器件的人不是卧床不起的并表示正常的身体活动或者甚至类似在运动或运动医学中表示过量的身体活动时尤其如此。优选用户应感觉不到附着的微电子系统,并且优选监视应保持秘密的。但是,在这方面,已知的微电子系统如下所述存在几种主要的缺点。When monitoring physiological or neurological conditions in the human body, it is important that the attached microelectronic system is as comfortable to wear as possible, especially when the person carrying the device is not bedridden and exhibits normal physical activity or even something similar in sports or This is especially true when excessive physical activity is indicated in sports medicine. Preferably the user should not feel the attached microelectronic system, and preferably monitoring should remain secret. In this respect, however, known microelectronic systems suffer from several major disadvantages as described below.

通过吸留的压敏粘合剂附着到皮肤上常由于水分的吸留并由于诸如来自压敏粘合剂聚合物系统、例如来自例如丙烯酸粘合剂的单体的刺激物导致皮肤刺激。刺激可以为发痒和红斑的形式,并且,当粘合剂器件被长时间附着时特别可能发展。吸留还可增加产生对于粘合剂成分的过敏性反应的风险。解决吸留的负面影响的一种常用的方式是使用微孔带,但这种微孔带基本是二维的并且较薄并且不保护微电子系统免受由于与衣服等摩擦导致的剪切力。Adhesion of pressure sensitive adhesives by occlusion to the skin often results in skin irritation due to occlusion of moisture and due to irritants such as from monomers from the pressure sensitive adhesive polymer system, for example from eg acrylic adhesives. Irritation can be in the form of itching and erythema, and is particularly likely to develop when the adhesive device is attached for an extended period of time. Occlusion can also increase the risk of developing an allergic reaction to the adhesive components. A common way to address the negative effects of occlusion is to use microporous tapes, but such tapes are essentially two-dimensional and thin and do not protect microelectronic systems from shear forces due to friction with clothing, etc. .

在以上的参照文献中,器件作为大块部分通过承载微电子系统的薄的平面粘合剂层被附着到皮肤上,从而导致携带器件的病人或其他人由于坚硬或与衣服摩擦而感觉不舒服,并增加无意中从皮肤脱开的风险。当这种器件要被长时间使用时,减小由于皮肤刺激或携带大块器件的不方便导致的任何类型的不适是十分重要的。并且,粘合剂器件保持固定到皮肤上直到被故意取下对于信号检测来说是关键的。In the above references, the device is attached to the skin as a bulk by a thin planar adhesive layer carrying the microelectronics, causing discomfort to the patient or other person carrying the device due to stiffness or friction with clothing , and increases the risk of inadvertent detachment from the skin. When such devices are to be used for extended periods of time, it is important to minimize any type of discomfort due to skin irritation or the inconvenience of carrying bulky devices. Also, it is critical for signal detection that the adhesive device remains fixed to the skin until intentionally removed.

器件的适当的粘合需要平面粘合剂的相当厚的层。但是,相当厚的层可表现出在边缘上粘合到衣服或亚麻布上的趋势,并且,通过这样做,会产生滚动和脱开的倾向。Proper bonding of devices requires a fairly thick layer of planar adhesive. However, relatively thick layers may exhibit a tendency to bond to the garment or linen at the edges and, in doing so, have a tendency to roll and unravel.

许多传感器通过导线与监视系统连接。这种系统的不利之处在于,由于导线被附着到身体上的传感器上并与监视系统连接,因此病人不能自由移动。每当病人希望移动时,他必须非常仔细以避免移去附着到传感器上的导线中的任一个,并且他必须进一步拾取监视系统并随身携带它。Many sensors are wired to the monitoring system. The downside of this system is that the patient cannot move freely because the wires are attached to the sensors on the body and connected to the monitoring system. Whenever the patient wishes to move, he must be very careful not to remove any of the wires attached to the sensors, and he must further pick up the monitoring system and carry it with him.

上述参考文献中都没有如本发明那样说明模压或铸造成其中嵌入微电子系统的三维粘合剂体的、由任选包含热塑性压敏粘合剂和/或化学固化压敏粘合剂的水解胶体组成的身体传感器器件。None of the above references describe hydrolysis of molded or casted three-dimensional adhesive bodies, optionally comprising thermoplastic pressure sensitive adhesives and/or chemically cured pressure sensitive adhesives, as in the present invention. Body sensor devices composed of colloids.

关于器件的粘合剂部分,克服上述缺点中的一些的已知的传感器制造起来不象本发明的粘合剂器件那样简单和便宜。With regard to the adhesive part of the device, known sensors that overcome some of the above-mentioned disadvantages are not as simple and cheap to manufacture as the adhesive device of the present invention.

其中嵌入微电子系统的本发明的粘合剂器件制造起来相对容易,并且,除了覆盖层和任选的释放层以外,器件不需要任何其它的层,因此在商业上是十分有吸引力的。Adhesive devices of the present invention in which microelectronic systems are embedded are relatively easy to manufacture and are commercially very attractive since the devices do not require any additional layers other than a cover layer and an optional release layer.

嵌入微电子部件时,还可更好地避免机械损伤和水分从周围环境的渗透。When embedding microelectronic components, mechanical damage and penetration of moisture from the surrounding environment are also better protected.

并且,当前许多类型的电子器件被临时附着到不同的表面上。特别是在医疗护理中,为了例如检测不同的生物医学信号或从病人取回样品,诸如探针和传感器的不同类型的医疗器件被附着到皮肤的不同区域上。这些医疗器件常仅被附着有限的时间直到疾病被诊断或病人的健康得到改善。但是,一些慢性疾病可能需要定期监视,例如当病人在休眠中时,或者,在一些情况下,希望日夜进行恒定的监视。被附着到病人的皮肤上的医疗器件可适于检测许多类型的信号,它例如是用于检测诸如肌电图(EMG)信号、心电图(ECG)信号、脑电图(EEG)信号的一种或更多种信号的传感器。Also, many types of electronic devices are currently temporarily attached to various surfaces. Especially in medical care, different types of medical devices such as probes and sensors are attached to different areas of the skin in order to eg detect different biomedical signals or retrieve a sample from a patient. These medical devices are often only attached for a limited time until the disease is diagnosed or the patient's health improves. However, some chronic diseases may require periodic monitoring, such as when the patient is dormant, or, in some cases, constant monitoring day and night is desired. A medical device attached to a patient's skin can be adapted to detect many types of signals, it is for example one for detecting signals such as electromyogram (EMG) signals, electrocardiogram (ECG) signals, electroencephalogram (EEG) signals or sensors for more signals.

这些医疗器件可被分成至少三种一般的元件:用于测量诸如生物信号的希望的值的微电子元件;用于将微电子元件附着到表面上的粘合剂;和用于向微电子电路的至少一部分供电的电源。These medical devices can be divided into at least three general components: microelectronic components for measuring desired values such as biological signals; adhesives for attaching microelectronic components to surfaces; at least a portion of the power supply.

不同的元件具有不同的寿命,但是,由于元件一般被组装到一个不可分的单元中,因此在使用后它们被一起处理掉。但是,当单独地察看各元件时,可以理解,它们具有不同的寿命。因此,粘合剂元件一般仅为一次性使用。电源可在一些情况下根据电池的应用和尺寸被再使用几次。但是,微电子元件可被再使用许多次,由此在仅使用一次后就处理掉使其成为昂贵的元件。Different components have different lifetimes, however, since components are generally assembled into an inseparable unit, they are disposed of together after use. However, when the elements are viewed individually, it can be understood that they have different lifetimes. Accordingly, the adhesive elements are generally only for one-time use. The power supply may in some cases be reused several times depending on the application and size of the battery. However, microelectronic components can be reused many times, thus making them expensive components to dispose of after only one use.

因此,为了提高医疗器件的成本效率,需要能够重新使用在使用后仍可工作的元件。Therefore, in order to improve the cost efficiency of medical devices, there is a need to be able to reuse components that are still functional after use.

US 2002/0180605公开了一种监视生理特性的方法。所公开的方法可包含以下的连续的步骤:从传感器模块去除粘合剂垫,以及,在数据已从传感器模块被转移到接收器模块后,在用于消毒的高压灭菌器中加热传感器模块。US 2002/0180605 discloses a method of monitoring physiological properties. The disclosed method may comprise the sequential steps of removing the adhesive pad from the sensor module and, after the data has been transferred from the sensor module to the receiver module, heating the sensor module in an autoclave for sterilization .

发明内容Contents of the invention

因此,本发明涉及一种包含微电子感测系统的三维粘合剂器件,其特征在于,Therefore, the present invention relates to a three-dimensional adhesive device comprising a microelectronic sensing system, characterized in that,

(a)具有上表面和底表面的由压敏粘合剂制成的三维粘合剂体;(a) a three-dimensional adhesive body made of a pressure sensitive adhesive having an upper surface and a bottom surface;

(b)被嵌入压敏粘合剂的体部中的微电子系统;(b) a microelectronic system embedded in a body of pressure sensitive adhesive;

(c)被附着到上表面上的一个或更多个覆盖层;和(c) one or more covering layers attached to the upper surface; and

(d)任选地,可释放地附着到粘合剂器件的底表面上的释放衬里。(d) Optionally, a release liner releasably attached to the bottom surface of the adhesive device.

适当地,微电子系统是微电子感测系统。该微电子感测系统适当地能够感测诸如压力、振动、声音、电活动(例如,从肌肉活动)、张力、血流、水分、温度、酶活性、细菌、pH值、血糖、导电率、电阻、电容、电感或其它化学、生物化学、生物学、机械或电气输入的物理输入。Suitably the microelectronic system is a microelectronic sensing system. The microelectronic sensing system is suitably capable of sensing information such as pressure, vibration, sound, electrical activity (e.g., from muscle activity), tension, blood flow, moisture, temperature, enzyme activity, bacteria, pH, blood glucose, conductivity, Physical input of resistance, capacitance, inductance or other chemical, biochemical, biological, mechanical or electrical input.

附图说明Description of drawings

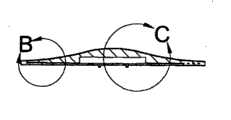

图1表示根据本发明的粘合剂器件的典型表示的形状的模具断面。CT是器件的最大厚度,PT是器件的周缘的厚度。Figure 1 shows a mold section in the shape of a typical representation of an adhesive device according to the invention. CT is the maximum thickness of the device, and PT is the thickness of the periphery of the device.

图2示出嵌入/集成到三维(3D)粘合剂中的微电子系统。缩放框表示图3、图4、图5、图6、图7、图8、图9、图10、图11和图12所示的粘合剂器件的一部分。Figure 2 shows a microelectronic system embedded/integrated into a three-dimensional (3D) adhesive. The zoom box represents a portion of the adhesive device shown in FIGS. 3 , 4 , 5 , 6 , 7 , 8 , 9 , 10 , 11 and 12 .

图3示出完全集成到粘合剂体内的微电子系统(影线框)。Figure 3 shows the microelectronic system fully integrated into the adhesive body (hatched box).

图4示出微电子系统的多个部分可在不同的位置被集成到粘合剂器件内,使得这些部分之间具有适当的机械或电气互连。Figure 4 shows that multiple parts of a microelectronic system can be integrated into an adhesive device at different locations with appropriate mechanical or electrical interconnections between the parts.

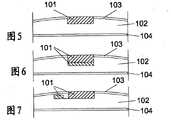

图5示出被施加到粘合剂体内的凹槽中的微电子系统。凹槽是皮肤固定区的远端。微电子系统可任选地是可互换的或可再使用的。Figure 5 shows a microelectronic system applied into a groove within an adhesive body. The groove is the distal end of the skin fixation zone. Microelectronic systems are optionally interchangeable or reusable.

图6示出上部可互换或可再使用并且下部被永久集成到粘合剂体内的微电子系统。Figure 6 shows a microelectronic system where the upper part is interchangeable or reusable and the lower part is permanently integrated into the adhesive body.

图7示出微电子系统的多个部分可在不同的位置位于粘合剂器件内,使得这些部分之间具有适当的机械或电气互连。Figure 7 shows that various parts of a microelectronic system can be located within the adhesive device at different locations with appropriate mechanical or electrical interconnections between the parts.

图8示出被嵌入/施加到粘合剂体的粘合剂侧的凹槽内的微电子系统。Figure 8 shows a microelectronic system embedded/applied into a groove on the adhesive side of the adhesive body.

图9示出具有下部可互换或可再使用并且上部被永久集成到粘合剂体内的微电子系统的器件。Figure 9 shows a device with a microelectronic system whose lower part is interchangeable or reusable and whose upper part is permanently integrated into the adhesive body.

图10示出一些微电子部件(小影线框)在制造过程中被集成到粘合剂体内并且一些微电子部件在以后被施加由此建立必要的机械/电气连接的系统。Figure 10 shows a system in which some microelectronic components (small hatched boxes) are integrated into the adhesive body during the manufacturing process and some microelectronic components are applied later thereby establishing the necessary mechanical/electrical connections.

图11示出被嵌入粘合剂内的微电子系统,该系统从粘合剂体的远端侧和皮肤固定侧均是可施加和可达到的。Figure 11 shows a microelectronic system embedded within an adhesive that is both applicable and accessible from both the distal side of the adhesive body and the skin-fixed side.

图12示出微电子系统由两个部分组装的系统,这两个部分中的一个或每一个可以是可互换的或可再使用的。Figure 12 shows a system in which the microelectronic system is assembled from two parts, one or each of which may be interchangeable or reusable.

在本发明的所有以上结构中,不管上表面上是否存在微电子系统的部件,上表面均保持平滑。可以通过微电子部件的适当构建、封装等实现这一点。In all the above structures of the present invention, the upper surface remains smooth regardless of the presence or absence of components of the microelectronic system on the upper surface. This can be achieved through appropriate construction, packaging, etc. of the microelectronic components.

图8、图9、图10、图11和图12所示的结构特别适于包含例如应具有皮肤接点的电极的元件的微电子系统。The structures shown in Figures 8, 9, 10, 11 and 12 are particularly suitable for microelectronic systems comprising elements such as electrodes which should have skin contacts.

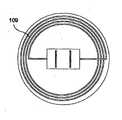

图13~18示出本发明的实施例,这里,天线、中央处理单元、电池和电极被嵌入粘合剂器件内。图13示出器件的二维形状,由A-A指示断面。在图15中,第三维被示为断面A-A。从器件的边缘的圆B在图16中被进一步放大,并且中心的圆C类似地在图17中被放大。图14示出位于粘合剂器件的外部并与微电子系统的中心部分连接的天线的位置。图16更详细地表示被平放嵌入粘合剂内的天线的构建。图1 7表示具有电池、CPU和伸出粘合剂的电极的微电子系统的中心部分的位置。电池和CPU被包封在透明的硅酮橡胶内。最后,图18以三维模式示出粘合剂器件。Figures 13-18 show an embodiment of the invention where the antenna, central processing unit, battery and electrodes are embedded within the adhesive device. Figure 13 shows the two-dimensional shape of the device, with sections indicated by A-A. In Figure 15, the third dimension is shown as section A-A. Circle B from the edge of the device is further enlarged in FIG. 16 , and circle C in the center is similarly enlarged in FIG. 17 . Figure 14 shows the location of the antenna located on the outside of the adhesive device and connected to the central part of the microelectronic system. Figure 16 shows in more detail the construction of the antenna laid flat within the adhesive. Figure 17 shows the location of the central part of the microelectronic system with the battery, CPU and electrodes protruding from the adhesive. The battery and CPU are encapsulated in transparent silicone rubber. Finally, Figure 18 shows the adhesive device in three dimensions.

图19表示在透视分解图中看到的根据本发明的传感器组件的一个实施例。Figure 19 shows an embodiment of a sensor assembly according to the invention seen in a perspective exploded view.

图20表示沿图19中的线XX-XX的断面图中的传感器组件的实施例。FIG. 20 shows an embodiment of a sensor assembly in a cross-sectional view along line XX-XX in FIG. 19 .

图21表示从底端看到的传感器组件的实施例。Figure 21 shows an embodiment of the sensor assembly seen from the bottom.

图22a和图22b表示根据本发明的器件的另一实施例,其中,图22b以放大图表示图22a的一部分。Figures 22a and 22b show another embodiment of a device according to the invention, wherein Figure 22b shows a part of Figure 22a in an enlarged view.

图23表示在透视图中看到的根据本发明的器件的另一实施例。Fig. 23 shows another embodiment of a device according to the invention seen in a perspective view.

图24表示沿图23中的线XXIV-XXIV的断面图中的根据本发明的器件的实施例。FIG. 24 shows an embodiment of a device according to the invention in a cross-sectional view along line XXIV-XXIV in FIG. 23 .

具体实施方式Detailed ways

本发明涉及具有被嵌入由压敏粘合剂制成的粘合剂体中的微电子系统的粘合剂器件。The present invention relates to an adhesive device having a microelectronic system embedded in an adhesive body made of pressure sensitive adhesive.

以下,当限定例如粘合剂体或器件的元件时使用的术语“三维”是指当在断面中观察时轮廓变化相当大的元件。因此,例如,三维粘合剂体将具有最大厚度和最小厚度。根据本发明,最大厚度将为最小厚度的至少两倍。在优选实施例中,粘合剂器件的外边缘或周缘的厚度小于传感器的最厚部分(一般为中心部分)的厚度的一半。Hereinafter, the term "three-dimensional" used when defining an element such as an adhesive body or a device refers to an element whose profile changes considerably when viewed in cross-section. Thus, for example, a three-dimensional adhesive body will have a maximum thickness and a minimum thickness. According to the invention, the maximum thickness will be at least twice the minimum thickness. In a preferred embodiment, the thickness of the outer edge or periphery of the adhesive means is less than half the thickness of the thickest part of the sensor (typically the central part).

与术语“三维”相反,当限定元件时使用的术语“二维”是指具有一般平整的表面的元件。因此,二维粘合剂体的最大厚度小于粘合剂体的最小厚度的两倍。In contrast to the term "three-dimensional", the term "two-dimensional" is used when defining an element to refer to an element having a generally planar surface. Thus, the maximum thickness of the two-dimensional adhesive body is less than twice the minimum thickness of the adhesive body.

如这里使用的那样,关于微电子系统或其部件,术语“嵌入”意味着粘合剂体的压敏粘合剂部分或全部包围微电子系统的全部或一些部件。因此,术语“嵌入”包含系统或部件的所有边被粘合剂体的粘合剂覆盖的情况,并且还包含这样一种情况,即,嵌入的物品不是所有各边都被粘合剂体的粘合剂覆盖,例如,物品被放在粘合剂体中的凹槽或空腔中并且是可从外面到达的。As used herein, the term "embedded" with reference to a microelectronic system or a component thereof means that the pressure sensitive adhesive of the adhesive body partially or fully surrounds all or some components of the microelectronic system. Thus, the term "embedded" includes the situation where all sides of the system or part are covered by the adhesive of the adhesive body, and also includes the situation where the embedded item is not covered by the adhesive body on all sides. Adhesive covers, for example, items are placed in recesses or cavities in the adhesive body and are accessible from the outside.

“嵌入”是用于说明微电子系统位于粘合剂体内的方式的一般术语,而术语“集成”意味着微电子系统或其特定部件在所有各边上都被粘合剂覆盖,并且,当微电子系统仅被部分覆盖时使用术语“施加”。"Embedded" is the general term used to describe the manner in which the microelectronic system is located within the body of the adhesive, while the term "integrated" means that the microelectronic system or specific parts thereof are covered by the adhesive on all sides and, when The term "applied" is used when the microelectronic system is only partially covered.

在所有各边上集成和覆盖还包含这样一种情况,即,集成的部件例如以电气或其它的方式连接到嵌入粘合剂体内的另一部件上。Integrating and covering on all sides also includes the case where an integrated component is connected, for example electrically or otherwise, to another component embedded in an adhesive body.

如这里使用的那样,微电子“感测”系统意味着包含具有能够检测生理或神经条件的元件的换能器的微电子系统。As used herein, a microelectronic "sensing" system means a microelectronic system that includes transducers with elements capable of detecting physiological or neurological conditions.

如这里使用的那样,通孔意味着在粘合剂体的上表面上具有开口并且在粘合剂体的底表面上具有开口的穿过粘合剂体的孔。优选地,通孔在粘合剂体的上表面上具有一个开口并在底表面上具有一个开口。通孔可具有任意适当的形状。As used herein, through hole means a hole through the adhesive body having an opening on the upper surface of the adhesive body and an opening on the bottom surface of the adhesive body. Preferably, the through hole has one opening on the upper surface of the adhesive body and one opening on the bottom surface. The vias may have any suitable shape.

粘合剂器件的“厚度”意味着可在上表面上的特定点到底表面上的点之间画出的最短线或可在底表面上的特定点到上表面上的点之间画出的最短线的长度。The "thickness" of an adhesive device means the shortest line that can be drawn between a specific point on the top surface or between a specific point on the bottom surface and a point on the top surface. The length of the shortest line.

对于本发明,表达“皮肤”被用于表示哺乳动物的外表面。For the purposes of the present invention, the expression "skin" is used to denote the external surface of a mammal.

如上所述,很惊奇地发现,微电子部分被嵌入三维形状的压敏粘合剂体中的无线微电子系统解决已知的传感器器件的问题。As stated above, it has surprisingly been found that a wireless microelectronic system in which the microelectronic parts are embedded in a three-dimensionally shaped body of pressure sensitive adhesive solves the problems of known sensor devices.

由于三维压敏粘合剂的性能,产生对微电子系统的最佳保护。粘合剂向皮肤表面提供密封,并且,由于粘合剂器件顶端的聚合物覆盖层,因此粘合剂器件得到保护免受外面的液体影响。并且,粘合剂保护嵌入的微电子部分免受机械损伤。Due to the properties of the three-dimensional pressure-sensitive adhesive, an optimal protection of microelectronic systems results. The adhesive provides a seal to the skin surface and, due to the polymer cover layer on top of the adhesive device, the adhesive device is protected from external liquids. Also, the adhesive protects the embedded microelectronics from mechanical damage.

根据本发明的粘合剂体由三维形状的压敏粘合剂制成,从粘合剂体的中心到边缘具有变化的厚度,并适当地在粘合剂体最厚的位置具有嵌入粘合剂体内的微电子感测系统。The adhesive body according to the invention is made of a three-dimensionally shaped pressure sensitive adhesive having a varying thickness from the center to the edge of the adhesive body and suitably having an inset bond where the adhesive body is thickest Microelectronic sensing system inside the agent.

具有这种形状并适当地具有斜面边缘的器件提供与皮肤的平滑界面。粘合剂器件将提供柔和的感觉并且将不趋于与衣服和亚麻布发生摩擦。特殊的优点在于,粘合剂器件将不容易由于笨重和边缘的粘性无意中脱落。这对于器件的真正功能是十分重要的。Devices of this shape, suitably with beveled edges, provide a smooth interface with the skin. The adhesive device will provide a soft feel and will not tend to rub against clothing and linens. A particular advantage is that the adhesive device will not easily come off unintentionally due to the bulkiness and stickiness of the edges. This is very important for the true function of the device.

并且,由于粘合剂体具有作为将器件固定到皮肤的手段、微电子系统的保护手段和用于将器件成形为方便的形状的手段的三重功能,因此粘合剂器件的结构十分简便。该结构在三维器件的组装中需要较少的部件和工艺步骤,因此成本不高并且更易于制造。Also, since the adhesive body has a triple function as a means to fix the device to the skin, a means to protect the microelectronic system, and a means to shape the device into a convenient shape, the structure of the adhesive device is very simple. The structure requires fewer parts and process steps in the assembly of the three-dimensional device and is therefore less expensive and easier to manufacture.

根据本发明的一个实施例,三维粘合剂体具有适于粘合到哺乳动物的体表面上的基本上平整的底表面和平滑的上表面。粘合剂器件适当地在体部的中心部分最厚并在体部的边缘最薄。According to one embodiment of the present invention, the three-dimensional adhesive body has a substantially planar bottom surface and a smooth upper surface adapted to adhere to a mammalian body surface. The adhesive means is suitably thickest at the central portion of the body and thinnest at the edges of the body.

优选地,上表面具有平滑的凸形表面,但它原则上可采取任何形式。Preferably, the upper surface has a smooth convex surface, but it may in principle take any form.

粘合剂器件的外边缘或周缘必须被成形为厚度小于传感器的最厚部分(一般为中心部分)的厚度的一半。The outer edge or perimeter of the adhesive device must be formed to a thickness less than half the thickness of the thickest part of the sensor (typically the central part).

因此,在本发明的另一实施例中,粘合剂器件在边缘上的厚度小于粘合剂器件在其最厚位置上的厚度的50%,适当地,边缘上的厚度小于粘合剂器件在其最厚位置上的厚度的25%,优选地,边缘上的厚度小于粘合剂器件在其最厚位置上的厚度的10%,并且,最优选地,边缘上的厚度小于粘合剂器件在其最厚位置上的厚度的5%。Therefore, in another embodiment of the invention, the thickness of the adhesive device at the edge is less than 50% of the thickness of the adhesive device at its thickest point, suitably the thickness at the edge is less than 50% of the thickness of the adhesive device at its thickest point. 25% of the thickness at its thickest point, preferably less than 10% of the thickness of the adhesive device at its thickest point on the edge, and, most preferably, less than the thickness on the edge of the adhesive 5% of the thickness of the device at its thickest point.

粘合剂器件在边缘上的厚度一般小于0.4mm。在一个实施例中,该厚度可以为0.01~0.4mm。适当地,粘合剂器件在边缘上的厚度大于0.05mm,优选为0.05~0.4mm。The thickness of the adhesive device on the edges is generally less than 0.4 mm. In one embodiment, the thickness may be 0.01-0.4 mm. Suitably, the thickness of the adhesive means at the edges is greater than 0.05 mm, preferably 0.05 to 0.4 mm.

一般地,粘合剂器件的厚度为0.5~15mm,更适当地,在一般但不必地在粘合剂体的中心处最厚的情况下为1~5mm。Typically, the thickness of the adhesive device is 0.5 to 15mm, more suitably 1 to 5mm where it is typically but not necessarily thickest in the center of the adhesive body.

适当地,粘合剂器件的底表面和从底表面的周边的任意点到上表面处粘合剂体最厚位置上的点画出的线之间的角度小于60度,优选小于45度,并且最优选小于30度。Suitably, the angle between the bottom surface of the adhesive device and a line drawn from any point on the periphery of the bottom surface to a point on the upper surface where the body of adhesive is thickest is less than 60 degrees, preferably less than 45 degrees, And most preferably less than 30 degrees.

粘合剂体的外边缘可适当被成形为具有或没有瓣或凸起的圆形或椭圆形,或者它可以成形为矩形或三角形以获得尽可能方便和安全的器件。The outer edge of the body of adhesive may suitably be shaped as a circle or oval with or without petals or protrusions, or it may be shaped as a rectangle or a triangle to obtain a device as convenient and safe as possible.

一般地,粘合剂体的周缘将包含粘合剂体的粘合剂。但是,可存在微电子系统或其部件被放在周缘内/或上的实施例,由此,周缘不只包含粘合剂体的粘合剂。Typically, the perimeter of the adhesive body will contain the adhesive of the adhesive body. However, there may be embodiments where the microelectronic system or components thereof are placed within and/or on the perimeter, whereby the perimeter does not contain only the adhesive of the adhesive body.

制成三维粘合剂体的压敏粘合剂适当地为可塑的热塑性或化学固化的压敏粘合剂,该压敏粘合剂具有使得粘合剂器件能够符合身体部位的曲率同时即使在移动条件下也保持其粘合性能的柔性。The pressure sensitive adhesive from which the three-dimensional adhesive body is made is suitably a malleable thermoplastic or chemically cured pressure sensitive adhesive having a curvature which enables the adhesive device to conform to the body part while even in Flexibility to maintain its adhesive properties also under moving conditions.

适当地,制成粘合剂体的压敏粘合剂是基于聚合物的粘合剂,这些聚合物选自诸如苯乙烯嵌段共聚物和氢化苯乙烯嵌段共聚物的嵌段共聚物、无定形聚α烯烃(APAO)、聚丙烯酸、聚乙烯醚、聚氨酯、聚乙烯基乙酸酯、硅酮或水凝胶压敏粘合剂的组。Suitably the pressure sensitive adhesive from which the adhesive body is formed is an adhesive based on polymers selected from block copolymers such as styrenic block copolymers and hydrogenated styrenic block copolymers, Group of amorphous polyalphaolefin (APAO), polyacrylic acid, polyvinyl ether, polyurethane, polyvinyl acetate, silicone or hydrogel pressure sensitive adhesives.

基于这些聚合物的压敏粘合剂是公知的,并且本领域技术人员知道如何制备基于这些聚合物的粘合剂。Pressure-sensitive adhesives based on these polymers are well known and the person skilled in the art knows how to prepare adhesives based on these polymers.

诸如苯乙烯嵌段共聚物和氢化苯乙烯嵌段共聚物的嵌段共聚物可适当地选自苯乙烯/乙烯-丁烯/苯乙烯(SEBS)、苯乙烯/异戊二烯/苯乙烯(SIS)和苯乙烯/乙烯-丙烯/苯乙烯(SEPS)。Block copolymers such as styrene block copolymers and hydrogenated styrene block copolymers may suitably be selected from styrene/ethylene-butylene/styrene (SEBS), styrene/isoprene/styrene ( SIS) and styrene/ethylene-propylene/styrene (SEPS).

粘合剂也可基于PDMS(聚二甲基硅氧烷),并可适当地为PDMS凝胶。The adhesive may also be based on PDMS (polydimethylsiloxane), and may suitably be a PDMS gel.

水凝胶粘合剂也可基于或包含amfifilic聚合物、聚乙烯吡咯烷酮、聚乙烯醇、聚环氧乙烷、明胶、天然树胶和纤维素衍生物或它们的任意组合。Hydrogel adhesives may also be based on or comprise amfifilic polymers, polyvinylpyrrolidone, polyvinyl alcohol, polyethylene oxide, gelatin, natural gums, and cellulose derivatives, or any combination thereof.

压敏粘合剂可根据这些原理并基于在Donatas Satas的手册:Handbook of pressure sensitive adhesive technology,Third edition中列出和公开的聚合物被配制。Pressure sensitive adhesives can be formulated according to these principles and based on the polymers listed and disclosed in Donatas Satas' Handbook: Handbook of pressure sensitive adhesive technology, Third edition.

在本发明的一个特定的实施例中,制成粘合剂体的压敏粘合剂包含水解胶体。包含水解胶体的压敏粘合剂可以是上述类型的压敏粘合剂中的任一种或本领域公知的任何其它压敏粘合剂。In a particular embodiment of the invention, the pressure-sensitive adhesive from which the adhesive body is made comprises hydrocolloids. The pressure sensitive adhesive comprising the hydrocolloid may be any of the types of pressure sensitive adhesives described above or any other pressure sensitive adhesive known in the art.

因此,美国专利No.3339549公开了诸如聚异丁烯的橡胶弹性体和诸如果胶、明胶和羧甲基纤维素的粉状混合物的一种或更多种水溶性或水可膨胀的水解胶体的混合。粘合剂块具有施加到一个表面上的不溶于水的膜。这种类型的成分可在商业上从E.R.Squibb & Sons Inc.按商标“Stomahesive”得到,并被用作气孔周围的皮肤阻挡剂以防止由气孔排出的腐蚀性流体损坏皮肤。Thus, US Patent No. 3339549 discloses the mixing of a rubber elastomer such as polyisobutylene and one or more water-soluble or water-swellable hydrocolloids of a powdered mixture such as pectin, gelatin and carboxymethylcellulose . The adhesive mass has a water-insoluble film applied to one surface. Compositions of this type are commercially available from E.R. Squibb & Sons Inc. under the trademark "Stomahesive" and are used as skin barriers around stomata to prevent damage to the skin by corrosive fluids expelled from the stomata.

在这种类型的粘合剂成分中,聚异丁烯负责提供粘合性能,并且分散的水解胶体粉末吸收流体并使得粘合剂还能够粘合到湿的皮肤上(湿粘性)。这些成分作为用于皮肤溃疡、烧伤和其它的外渗伤口的创伤敷料也得到越来越多的接受。In adhesive compositions of this type, polyisobutylene is responsible for providing the adhesive properties, and the dispersed hydrocolloid powder absorbs fluids and enables the adhesive to adhere also to wet skin (wet tack). These ingredients are also gaining acceptance as wound dressings for skin ulcers, burns and other exuding wounds.

在大量的实施例中,在大量的专利文献中公开的苯乙烯共聚物被加入。In a number of examples, styrene copolymers disclosed in a number of patent documents are incorporated.

因此,Sorensen等人的美国专利No.4231369公开了包含在其中分散了水溶性水解胶体树胶的苯乙烯共聚物和增粘剂的造口术皮肤阻挡剂。Thus, US Patent No. 4,231,369 to Sorensen et al. discloses an ostomy skin barrier comprising a styrene copolymer having dispersed therein a water-soluble hydrocolloid gum and a tackifier.

在美国专利No.4367732中,Poulsen等人公开了包含分散于包含苯乙烯共聚物、碳氢化合物增粘剂和增塑剂的连续相中的水溶性水解胶体、抗氧化剂和油质增充剂的造口术皮肤阻挡剂。In U.S. Patent No. 4,367,732, Poulsen et al. disclose a water-soluble hydrocolloid, an antioxidant, and an oleaginous extender dispersed in a continuous phase comprising a styrene copolymer, a hydrocarbon tackifier, and a plasticizer. ostomy skin barrier.

美国专利No.4551490(Doyle等人)公开了包含5~30%的一种或更多种聚异丁烯、3~20%的双嵌段(diblock)共聚物的含量低于20%的一种或更多种苯乙烯基团或嵌段共聚物、矿物油、一种或更多种水溶性水解胶体树胶和增粘剂的均匀混合物的医疗级压敏粘合剂成分。一种或更多种水可膨胀的粘性增强剂、抗氧化剂和各种其它任选的成分也可被包含于粘合剂成分内。U.S. Patent No. 4,551,490 (Doyle et al.) discloses one or more polyisobutylenes comprising 5 to 30%, 3 to 20% of a diblock copolymer, or A medical grade pressure sensitive adhesive composition of a homogeneous mixture of more styrenic group or block copolymers, mineral oil, one or more water soluble hydrocolloid gums and a tackifier. One or more water-swellable viscosity enhancers, antioxidants, and various other optional ingredients may also be included in the adhesive composition.

美国专利No.5492943公开了包含两种粘弹性粘合剂弹性体、具体而言为高分子量聚异丁烯和苯乙烯嵌段共聚物的混合物的压敏粘合剂成分,该混合物与增塑剂(优选为矿脂)和适当的增粘剂和抗氧化剂一起形成其中分散了诸如羧甲基纤维素钠和果胶的水解胶体的连续相。U.S. Patent No. 5,492,943 discloses pressure sensitive adhesive compositions comprising a blend of two viscoelastic adhesive elastomers, specifically high molecular weight polyisobutylene and a styrene block copolymer, in combination with a plasticizer ( Petrolatum, preferably) together with suitable viscosifiers and antioxidants form a continuous phase in which hydrocolloids such as sodium carboxymethylcellulose and pectin are dispersed.

在美国专利No.4867748中,Samuelsen公开了由与背衬膜组合的水解胶体粘合剂制成的密封垫的几何结构及其处理。In US Patent No. 4,867,748, Samuelsen discloses the geometry of gaskets made of hydrocolloid adhesives combined with backing films and their handling.

在美国专利No.5492943中公开的粘合剂成分被描述为用于将造口术用具粘合到皮肤上的晶片,并且通过包含具有更高含量的双嵌段共聚物的苯乙烯嵌段共聚物与已知的成分不同,从而完全避免使用低分子量聚异丁烯并优选地不包含明胶。The adhesive composition disclosed in U.S. Patent No. 5,492,943 is described as a wafer for bonding ostomy appliances to the skin, and is obtained by including styrene block copolymers with higher content of diblock copolymers The composition differs from known ingredients, thereby avoiding the use of low molecular weight polyisobutylene altogether and preferably containing no gelatin.

包含水解胶体的压敏粘合剂的特征在于具有分散于粘合剂相中的水解胶体的微粒相,它是粘合剂的特别合适的组。包含水解胶体的粘合剂可从皮肤吸收水分,避免皮肤的阻塞,同时维持其对皮肤的粘合性能。并且,包含水解胶体的粘合剂体可具有任意的厚度并仍具有不吸留的性能。水解胶体粘合剂由于热熔性可被处理并且很容易模压为特定的形状。Pressure sensitive adhesives comprising hydrocolloids, which are characterized by having a particulate phase of hydrocolloids dispersed in the adhesive phase, are a particularly suitable group of adhesives. Adhesives containing hydrocolloids absorb moisture from the skin, avoiding skin clogging while maintaining their adhesive properties to the skin. Also, the adhesive body comprising the hydrocolloid can be of any thickness and still have non-occlusive properties. Hydrocolloid adhesives can be processed and easily molded into specific shapes due to their hot melt properties.

这意味着,与易模压性组合的热熔性使得粘合剂体的厚度能够从包含微电子系统的粘合剂器件的边缘逐渐过渡到中心部分,从而提供平滑的没有不连贯的突出的外形。This means that hot melt properties combined with easy moldability enable the thickness of the adhesive body to gradually transition from the edges to the central portion of the adhesive device containing the microelectronic system, thereby providing a smooth profile with no discontinuous protrusions .

以下详细说明用于制造根据本发明的可用于粘合剂体的压敏粘合剂的配方。The formulation for producing the pressure-sensitive adhesive usable for the adhesive body according to the present invention is explained in detail below.

因此,典型的压敏粘合剂成分基于成分的总重量包含10~60wt.%的一种或更多种橡胶状弹性体成分、5~60%的一种或更多种吸收剂粒子、0~50%的增粘剂树脂、0~10%的增塑剂和0~60%的非极性油质增充剂的基本上均匀的混合物。Thus, a typical pressure sensitive adhesive composition comprises 10 to 60 wt.% of one or more rubbery elastomer components, 5 to 60% of one or more absorbent particles, 0 A substantially homogeneous mixture of -50% tackifier resin, 0-10% plasticizer, and 0-60% non-polar oily extender.

橡胶状弹性体基本成分可选自包含物理上交联的弹性体(适当地为包含聚苯乙烯嵌段的嵌段共聚物)、化学交联的天然或合成橡胶状弹性体或橡胶状均聚物的组。The rubbery elastomer base may be selected from the group consisting of physically crosslinked elastomers (suitably block copolymers comprising polystyrene blocks), chemically crosslinked natural or synthetic rubbery elastomers or rubbery homopolymers. group of things.

选自苯乙烯和一种或更多种丁二烯的嵌段共聚物的物理交联的弹性体可以是苯乙烯-丁二烯-苯乙烯嵌段共聚物、苯乙烯-异戊二烯共聚物,并优选是苯乙烯-异戊二烯-苯乙烯和苯乙烯-异戊二烯嵌段共聚物的混合物。Physically cross-linked elastomers selected from block copolymers of styrene and one or more butadiene can be styrene-butadiene-styrene block copolymers, styrene-isoprene copolymers and preferably a mixture of styrene-isoprene-styrene and styrene-isoprene block copolymers.

化学交联的橡胶状弹性体可以是例如丁基橡胶或天然橡胶。The chemically crosslinked rubbery elastomer can be, for example, butyl rubber or natural rubber.

橡胶状均聚物可以是诸如低密度聚乙烯或丙烯的低烯烃的聚合物、优选无规聚丙烯(APP)或聚异丁烯。The rubbery homopolymer may be a polymer of low olefins such as low density polyethylene or propylene, preferably atactic polypropylene (APP) or polyisobutylene.

根据本发明任选使用的增粘树脂优选是氢化增粘剂树脂,并且更优选选自包含环戊二烯、二环戊二烯、α蒎烯或β蒎烯的聚合物和共聚物的组。The tackifying resin optionally used according to the present invention is preferably a hydrogenated tackifying resin and is more preferably selected from the group of polymers and copolymers comprising cyclopentadiene, dicyclopentadiene, alpha-pinene or beta-pinene .

当物理交联的弹性体是苯乙烯-丁二烯-苯乙烯嵌段共聚物或苯乙烯-异戊二烯-苯乙烯嵌段共聚物时,粘合剂适当地包含0~10%的增塑剂(例如,citrofol BII,DOA)。When the physically crosslinked elastomer is a styrene-butadiene-styrene block copolymer or a styrene-isoprene-styrene block copolymer, the adhesive suitably contains 0 to 10% of Plasticizers (eg, citrofol BII, DOA).

膨胀水解胶体粒子优选包含一种或更多种水溶性或水膨胀水解胶体聚合物或树胶。The swollen hydrocolloid particles preferably comprise one or more water-soluble or water-swellable hydrocolloid polymers or gums.

适当的水解胶体包含可以为线性的或交联的合成聚合物,诸如从内酰胺或聚乙烯吡咯烷酮制备的水解胶体。可用于制备合成的水解胶体的其它单体包含丙烯酸盐、异丁烯酸盐和水溶性氨化物。Suitable hydrocolloids comprise synthetic polymers which may be linear or crosslinked, such as hydrocolloids prepared from lactams or polyvinylpyrrolidone. Other monomers that can be used to prepare synthetic hydrocolloids include acrylates, methacrylates, and water-soluble amides.

根据本发明,天然出现或合成制备的其它水解胶体聚合物是可用的。这些材料包含聚乙烯醇、聚氧化烯和诸如聚糖、树胶和改性的纤维素的天然出现或合成地改性的水解胶体。Other hydrocolloid polymers, naturally occurring or synthetically prepared, are useful in accordance with the present invention. These materials include polyvinyl alcohols, polyoxyalkylenes, and naturally occurring or synthetically modified hydrocolloids such as polysaccharides, gums, and modified celluloses.

代表性的聚糖包含淀粉、糖原、半纤维素、戊聚糖、纤维素、果胶、壳聚糖和壳多糖。代表性的树胶包含Arabic、Locust Bean、Guar、Agar、Carrageenan、Xanthan、Karaya、Alginates、Tragacanth、Ghatti和Furcelleran树胶。代表性的改性纤维素包含甲基纤维素、羟丙基甲基纤维素、羧甲基纤维素和羟丙基纤维素。Representative polysaccharides include starch, glycogen, hemicellulose, pentosan, cellulose, pectin, chitosan, and chitin. Representative gums include Arabic, Locust Bean, Guar, Agar, Carrageenan, Xanthan, Karaya, Alginates, Tragacanth, Ghatti, and Furcelleran gums. Representative modified celluloses include methylcellulose, hydroxypropylmethylcellulose, carboxymethylcellulose and hydroxypropylcellulose.

优选的水解胶体包含诸如淀粉、糖原、半纤维素、戊聚糖、明胶、纤维素、改性纤维素、果胶、壳聚糖和壳多糖的聚糖。改性的纤维素包含甲基纤维素、羟丙基甲基纤维素、羧甲基纤维素和羟丙基纤维素。最优选的水解胶体是选自包含聚乙烯醇、粉状果胶、明胶、甲基纤维素、羟丙基甲基纤维素、羧甲基纤维素、羟丙基纤维素和它们的混合物的组的水溶性或膨胀水解胶体。在一个优选实施例中,水解胶体是羧甲基纤维素(CMC)。Preferred hydrocolloids comprise polysaccharides such as starch, glycogen, hemicellulose, pentosan, gelatin, cellulose, modified cellulose, pectin, chitosan and chitin. Modified celluloses include methylcellulose, hydroxypropylmethylcellulose, carboxymethylcellulose and hydroxypropylcellulose. Most preferred hydrocolloids are selected from the group comprising polyvinyl alcohol, powdered pectin, gelatin, methylcellulose, hydroxypropylmethylcellulose, carboxymethylcellulose, hydroxypropylcellulose and mixtures thereof water-soluble or swelling hydrocolloids. In a preferred embodiment, the hydrocolloid is carboxymethylcellulose (CMC).

适当的膨胀胶体是基于交联的聚丙烯酸聚合物的小球形粒子。在美国专利No.4867748、EP 0122344和美国专利申请No.2004065232中可找到这些材料的例子。Suitable swelling colloids are based on small spherical particles of cross-linked polyacrylic acid polymers. Examples of these materials can be found in US Patent No. 4867748, EP 0122344 and US Patent Application No. 2004065232.

有时用于附着粘合剂器件的皮肤可以是潮湿的或者甚至是湿的。在这些情况下,普通的粘合剂不能提供粘合剂器件的足够强和永久的附着。在这些情况下有用的专用粘合剂是水凝胶粘合剂。这些粘合剂基于亲水聚合物和使得能够在粘合剂的完全的皮肤接触表面上平稳摄取水分的增充剂。存在成分范围广泛的这种亲水粘合剂。具有高含量的任选地被部分中和的酸基的亲水聚丙烯酸酯是该粘合剂组中的主要代表。这些粘合剂可以是固有的粘合剂,或者可在干燥条件下用增粘剂和增充剂被配制为希望的粘合剂性能。由于水的摄取将粘合剂转换成更加有塑性的状态,因此,当得到水分时,粘性将根据配方大大增加。替代性的粘合剂基于诸如聚乙烯吡咯烷酮、聚乙烯醇、聚环氧乙烷等的聚合物。两性聚合物或可通过基团聚合化学交联的聚合物可被添加以提高粘合剂的粘性,并且一般优选诸如聚乙二醇、聚丙二醇和丙三醇的增充剂。Sometimes the skin used to attach the adhesive device can be damp or even wet. In these cases, common adhesives do not provide a sufficiently strong and permanent attachment of the adhesive device. A specialized adhesive useful in these cases is a hydrogel adhesive. These adhesives are based on hydrophilic polymers and extenders that enable smooth water uptake on the complete skin-contacting surface of the adhesive. Such hydrophilic binders exist in a wide range of compositions. Hydrophilic polyacrylates with a high content of optionally partially neutralized acid groups are the main representatives of this group of adhesives. These adhesives may be inherent adhesives, or may be formulated dry with tackifiers and extenders to provide the desired adhesive properties. Since water uptake converts the adhesive into a more plastic state, the tack will increase greatly depending on the formulation when moisture is available. Alternative adhesives are based on polymers such as polyvinylpyrrolidone, polyvinyl alcohol, polyethylene oxide, and the like. Amphoteric polymers or polymers that can be chemically crosslinked by radical polymerization can be added to increase the tack of the adhesive, and extenders such as polyethylene glycol, polypropylene glycol, and glycerol are generally preferred.

基于聚二甲基硅氧烷(PDMS)的粘合剂成分从19世纪70年代为人们所认识。最近,新的子类的基于PDMS的压敏粘合剂即软硅酮粘合剂已被开发。软硅酮粘合剂(SSA)是基于交联的硅酮弹性体结构的两部分的不溶解粘合剂。交联是具有乙烯基的聚二甲基硅氧烷和氢功能硅氧烷之间的加成反应的结果。固化反应被铂络合物催化并可在室温下发生,或者可在高温(80℃~145℃)下被加速使得不形成副产物。这些粘合剂的特征在于较软并且符合皮肤的表面结构,由此迅速实现皮肤的湿润。由于粘性成分最少,因此材料不流动,并且当施加变形压力时仅出现较小的能量耗散。结果是迅速的剥离,这种剥离在较低的剥离力或剪切力下发生,这对于一些情况可能是有利的。Adhesive compositions based on polydimethylsiloxane (PDMS) have been known since the 1970s. Recently, a new subclass of PDMS-based pressure-sensitive adhesives, soft silicone adhesives, has been developed. Soft silicone adhesives (SSA) are two-part insoluble adhesives based on a cross-linked silicone elastomer structure. Crosslinking is the result of an addition reaction between polydimethylsiloxanes with vinyl groups and hydrofunctional siloxanes. The curing reaction is catalyzed by platinum complexes and can occur at room temperature, or can be accelerated at high temperatures (80°C to 145°C) so that by-products are not formed. These adhesives are characterized by being relatively soft and conforming to the surface structure of the skin, thereby quickly achieving moisturization of the skin. Due to the minimal viscous component, the material does not flow and only a small energy dissipation occurs when deformation pressure is applied. The result is rapid peeling, which occurs at lower peel or shear forces, which may be advantageous in some cases.

由于基于PDMS的压敏粘合剂可用自来水清洗并可被重新施加到皮肤上,因此,除了是优异的皮肤粘合剂以外,它们还具有可再使用的性能。Since PDMS-based pressure-sensitive adhesives can be washed with running water and reapplied to the skin, besides being excellent skin adhesives, they also have reusable properties.

用于制作本发明的粘合剂体的压敏粘合剂也可以是常被描述为粘性凝胶的PDMS凝胶。这些市售系统的例子是来自Dow CorningHealth Care US的Dow Corning 7-9800A&B或来自Wacker-ChemieGmbH,Burghausen,Germany的SilGel 612和来自NuSil Technology,Carpinteria,USA的MED-6340。The pressure sensitive adhesive used to make the adhesive body of the present invention may also be a PDMS gel, often described as a tacky gel. Examples of these commercially available systems are Dow Corning 7-9800A & B from Dow Corning Health Care US or SilGel 612 from Wacker-Chemie GmbH, Burghausen, Germany and MED-6340 from NuSil Technology, Carpinteria, USA.

上述压敏粘合剂可以以无泡沫型或以泡沫型被使用。当在制造过程中气泡被引入压敏粘合剂中时,重量轻的胞状结构被制造。这种压敏粘合剂比无泡沫型更柔软。(参见美国专利No.6326524和美国专利申请No.2004065232)。The above-mentioned pressure-sensitive adhesive may be used in a non-foamed type or in a foamed type. When air bubbles are introduced into the pressure-sensitive adhesive during the manufacturing process, a lightweight cell-like structure is created. This pressure sensitive adhesive is softer than the non-foam type. (See US Patent No. 6326524 and US Patent Application No. 2004065232).

一般地,本发明的粘合剂体具有希望的弹性、粘性、水分传送和/或吸收性能以及较高的舒适性和柔性。柔性提供能够符合身体部位的曲率同时即使在移动条件下也保持其粘合性能的合成。室温下的较高的初始粘性便于粘合剂器件的施加。In general, the adhesive bodies of the present invention have desirable elasticity, tack, moisture transport and/or absorption properties as well as high comfort and flexibility. Flex provides a composition that conforms to the curvature of the body part while maintaining its adhesive properties even under moving conditions. The higher initial tack at room temperature facilitates the application of the adhesive device.

本发明的粘合剂在上表面上具有任何性质的一个或更多个覆盖层、优选仅仅一个覆盖层,以防止对于亚麻布、衣服和其它环境的粘合。The adhesive of the present invention has one or more cover layers of any nature, preferably only one cover layer, on the upper surface to prevent adhesion to linen, clothing and other environments.

作为覆盖材料,优选使用热塑性聚合物膜形式的膜或编织或非编织层。覆盖层优选由弹性材料制成。覆盖层适当地能够传送水分,并可例如由聚合物和聚合物的任意叠层制成,这些聚合物诸如:例如聚乙烯、聚丙烯或聚丁烯的聚烯烃类、诸如尼龙的聚酰胺、聚氨酯、聚乙酸乙烯酯、聚氯乙烯、氟化聚乙烯化合物、聚偏二氯乙烯、聚乙烯醇、乙烯醋酸乙烯酯(ethylene vinyl acetate)、醋酸纤维素或其它的热塑性聚糖、诸如PEBAX的聚醚嵌段氨化物、诸如苯乙烯-异戊二烯-苯乙烯嵌段共聚物或乙烯丙烯酸盐嵌段共聚物的嵌段共聚物、诸如聚对苯二甲酸乙二醇酯(PET)或其衍生物的聚酯。覆盖层可适当地是由聚氨酯、聚乙烯或聚乙酸乙烯酯制成的薄泡沫层等。As covering material, preference is given to using films in the form of thermoplastic polymer films or woven or non-woven layers. The covering layer is preferably made of elastic material. The cover layer is suitably capable of transmitting moisture and may for example be made of polymers and any laminates of polymers such as: polyolefins such as polyethylene, polypropylene or polybutylene, polyamides such as nylon, Polyurethane, polyvinyl acetate, polyvinyl chloride, fluorinated polyvinyl compounds, polyvinylidene chloride, polyvinyl alcohol, ethylene vinyl acetate, cellulose acetate or other thermoplastic polysaccharides, such as PEBAX Polyether block amides, block copolymers such as styrene-isoprene-styrene block copolymers or ethylene acrylate block copolymers, such as polyethylene terephthalate (PET) or Its derivatives are polyesters. The covering layer may suitably be a thin foam layer or the like made of polyurethane, polyethylene or polyvinyl acetate.

覆盖层或膜保护集成的/嵌入的微电子部件以及粘合剂体免受环境影响。The cover layer or film protects the integrated/embedded microelectronic component and the adhesive body from the environment.

在本发明的一个特定的实施例中,天线可通过导电墨水或印刷金属被直接印刷到覆盖层上。In a particular embodiment of the invention, the antenna can be printed directly onto the cover layer by means of conductive ink or printed metal.

在施加到皮肤上之前,为了保证保持粘合剂的性能并且为了使得粘合剂表面在使用前才被铺开,保护性释放衬套覆盖压敏粘合剂体的皮肤接触侧。释放衬套适当地为硅化或氟化释放衬套,诸如硅化或氟化牛皮纸、聚乙烯、聚丙烯或聚对苯二甲酸乙二醇酯膜。适当地,释放衬套是硅化聚乙烯膜,诸如来自公司Huhtamaki的中密度聚乙烯。Prior to application to the skin, a protective release liner covers the skin contacting side of the pressure sensitive adhesive body to ensure that the properties of the adhesive are maintained and to allow the adhesive surface to be spread just prior to use. The release liner is suitably a siliconized or fluorinated release liner, such as siliconized or fluorinated kraft paper, polyethylene, polypropylene or polyethylene terephthalate film. Suitably the release liner is a siliconized polyethylene film, such as medium density polyethylene from the company Huhtamaki.

微电子系统包含大量的部件,这些部件可被组装到一个任选地封装的单元中,该单元被加入本发明的粘合剂器件内。微电子感测系统的部件也可以是位于粘合剂器件中的不同位置中的单个的任选地封装的部件的组件。本发明的该实施例包含粘合剂器件使微电子器件的所有的各单个部件位于不同位置的情况以及部件中的一个或更多个位于与位于同一位置的其它部件的位置不同的位置的情况。Microelectronic systems comprise a large number of components that can be assembled into an optionally encapsulated unit that is incorporated into the adhesive device of the present invention. The components of the microelectronic sensing system may also be an assembly of individual, optionally packaged components located in different locations within the adhesive device. This embodiment of the invention encompasses the case where the adhesive means has all of the individual components of the microelectronic device in different positions and the case where one or more of the components are in a different position than the other components that are co-located .

当微电子器件的部件位于粘合剂器件中的不同位置时,粘合剂器件还在集成到粘合剂体内的部件之间具有必要的机械或电气连接。The adhesive device also has the necessary mechanical or electrical connections between the components integrated into the adhesive body when the components of the microelectronic device are located at different locations in the adhesive device.

因此,根据本发明的一个实施例,整个微电子系统被集成到粘合剂体内,并在所有各边被粘合剂体完全覆盖。Thus, according to one embodiment of the invention, the entire microelectronic system is integrated into the adhesive body and is completely covered by the adhesive body on all sides.

根据本发明的另一实施例,整个微电子系统被包含于设置在面对覆盖层的粘合剂体的上表面中的凹槽内。According to another embodiment of the invention, the entire microelectronic system is contained within a recess provided in the upper surface of the adhesive body facing the cover layer.

根据本发明的另一实施例,整个微电子系统被包含于设置在粘合剂体的粘合剂底表面中的凹槽中。在本发明的另一实施例中,微电子系统被包含于粘合剂体中的通孔中并且从面对覆盖层的上表面以及从粘合剂底表面均可到达。According to another embodiment of the invention, the entire microelectronic system is contained in recesses provided in the adhesive bottom surface of the adhesive body. In another embodiment of the invention, the microelectronics are contained in through-holes in the adhesive body and are accessible both from the upper surface facing the cover layer and from the adhesive bottom surface.

在本发明的替代性的实施例中,微电子系统的一个或更多个部件被集成到粘合剂体内,并且在所有各边被粘合剂体覆盖,并且,微电子系统的其它部件位于粘合剂体的其它位置,微电子感测系统的部件相互具有必要的机械和电气连接。In an alternative embodiment of the invention, one or more components of the microelectronic system are integrated into the adhesive body and are covered on all sides by the adhesive body, and the other components of the microelectronic system are located Elsewhere in the adhesive body, the components of the microelectronic sensing system have the necessary mechanical and electrical connections to each other.

根据本发明的上述实施例,微电子系统的一个或更多个部件可被集成到粘合剂体内并在所有各边被粘合剂体覆盖,并且微电子系统的其余部分被包含于设置在面对覆盖层的粘合剂体的上表面中的一个或更多个凹槽(适当为一个凹槽)内。According to the above-described embodiments of the present invention, one or more components of the microelectronic system may be integrated into the adhesive body and covered on all sides by the adhesive body, and the rest of the microelectronic system is contained in a One or more grooves, suitably one groove, in the upper surface of the adhesive body facing the cover layer.

作为替代方案,微电子系统的一个或更多个部件被集成到粘合剂体内并在所有各边被粘合剂体覆盖,并且微电子系统的其余部分被包含于设置在粘合剂体的粘合剂底表面中的一个或更多个凹槽(适当地为一个凹槽)中。Alternatively, one or more components of the microelectronic system are integrated into the adhesive body and covered on all sides by the adhesive body, and the rest of the microelectronic system is contained in a One or more grooves, suitably a groove, in the bottom surface of the adhesive.

在另一替代性实施例中,微电子系统的一个或更多个部件被集成到粘合剂体内并被粘合剂体覆盖,并且微电子系统的其余部分被包含于粘合剂体中的一个或更多个通孔(适当地为一个通孔)中,并且从面对覆盖层的上表面和粘合剂底表面均可到达。In another alternative embodiment, one or more components of the microelectronic system are integrated into and covered by the adhesive body, and the remainder of the microelectronic system is contained within the adhesive body. One or more through holes, suitably a through hole, and are accessible from both the upper surface facing the cover layer and the bottom surface of the adhesive.

在另一替代性实施例中,微电子系统的一个或更多个部件被集成到粘合剂体内并被粘合剂体覆盖,同时,微电子系统的其它部件被包含于粘合剂体中的一个或更多个通孔(适当地为一个通孔)中,并且从面对覆盖层的上表面和粘合剂底表面均可到达,并且,微电子系统的其余部分被包含于设置在粘合剂体的上和/或底表面中的一个或更多个凹槽(适当地为一个凹槽)中。In another alternative embodiment, one or more components of the microelectronic system are integrated into and covered by the adhesive body while other components of the microelectronic system are contained within the adhesive body one or more through holes (suitably a through hole), and both are accessible from the upper surface facing the cover layer and the bottom surface of the adhesive, and the rest of the microelectronic system is contained in the In one or more grooves, suitably a groove, in the upper and/or bottom surface of the adhesive body.

在另一替代性实施例中,微电子系统的一个或更多个部件被包含于粘合剂体中的一个或更多个通孔(适当地为一个通孔)中,并且从面对覆盖层的上表面或粘合剂底表面均可到达,并且,微电子系统的其余部分被包含于设置在粘合剂体的上和/或底表面中的一个或更多个凹槽(适当地为一个凹槽)中。In another alternative embodiment, one or more components of the microelectronic system are contained in one or more through-holes (suitably a through-hole) in the adhesive body and are covered from face to face. Both the upper surface of the layer or the bottom surface of the adhesive are accessible, and the rest of the microelectronic system is contained in one or more grooves (suitably located in the upper and/or bottom surface of the adhesive body). for a groove).

在另一适当的实施例中,微电子系统的一个或更多个部件被包含于粘合剂体的上表面中的一个或更多个凹槽中(适当地在一个凹槽中),并且微电子系统的其余部分被包含于粘合剂体的底表面中的一个或更多个凹槽(适当地为一个凹槽)中。In another suitable embodiment, one or more components of the microelectronic system are contained in one or more grooves (suitably in a groove) in the upper surface of the adhesive body, and The remainder of the microelectronic system is contained in one or more grooves, suitably one groove, in the bottom surface of the adhesive body.

在微电子系统或其部件被放在粘合剂体的上表面中的情况下,它们适当地遵循轮廓与上表面一起形成,或者被成形为配合粘合剂体的上表面。可以通过适当的部件封装实现这一点。Where microelectronic systems or components thereof are placed in the upper surface of the adhesive body, they are suitably contoured with, or shaped to fit, the upper surface of the adhesive body. This can be achieved through appropriate component packaging.

如上所述,微电子系统的各单个部件、各单个部件的多个组或所有部件可在它们被嵌入粘合剂体之前被封装。当希望保护部件免受环境影响和/或保护环境免受部件影响的附加保护时,例如,当已存在于粘合剂体中或在制造过程中导致集成到粘合剂体中时,选择封装。微电子系统的封装的部件通过必要的电气和/或机械连接相互连接。As mentioned above, individual components, groups of individual components, or all components of the microelectronic system may be encapsulated before they are embedded in the adhesive body. Encapsulation is chosen when protection of the component from the environment and/or additional protection of the environment from the component is desired, for example when it is already present in the adhesive body or has resulted in integration into the adhesive body during the manufacturing process . The packaged components of the microelectronic system are interconnected by the necessary electrical and/or mechanical connections.

在一些情况下,由于粘合剂中的湿气和/或渗出物将引起腐蚀,因此要求保护微电子系统或其部件免受其影响,或者出于其它的原因需要屏蔽外部影响。在这些情况下,微电子系统或其部件被封装。In some cases, it is desirable to protect the microelectronic system or its components from corrosion since moisture and/or exudates in the adhesive will cause corrosion, or to shield it from external influences for other reasons. In these cases, microelectronic systems or components thereof are packaged.

大量的封装技术是已知的,并且包括涂敷、热熔封装、陶瓷封装和玻璃封装。用于封装电气部件的其它方法是本领域公知的。A number of encapsulation techniques are known and include coating, hot melt encapsulation, ceramic encapsulation and glass encapsulation. Other methods for packaging electrical components are known in the art.

微电子系统或其部件被适当地封装到聚合物膜、聚合物箔或聚合物涂层中,或者,微电子系统或其部件被模压到聚合物材料中或被封装到玻璃或陶瓷材料中。The microelectronic system or its components are suitably encapsulated in a polymer film, polymer foil or polymer coating, or the microelectronic system or its components are molded into a polymer material or encapsulated in a glass or ceramic material.

通过涂敷进行的封装一般包含用诸如环氧树脂、PDMS(硅酮)、丙烯酸盐、聚氨酯或UV硬化树脂的材料涂敷部件。Encapsulation by coating generally involves coating the part with a material such as epoxy, PDMS (silicone), acrylate, polyurethane or UV hardening resin.

由于硅酮表面容易从粘合剂体的粘合剂被释放,因此,当微电子部件要被放入粘合剂体中的通孔或凹槽中时,或者在希望使得容易去除或更换封装的微电子部件的情况下,特别优选诸如PDMS的硅酮中的封装。可很容易地从粘合剂释放的其它材料也可用于封装。Since the silicone surface is easily released from the adhesive of the adhesive body, it is useful when microelectronic components are to be placed into through holes or grooves in the adhesive body, or when it is desired to allow easy removal or replacement of the package. In the case of microelectronic components, encapsulation in silicone such as PDMS is particularly preferred. Other materials that are readily releasable from the adhesive can also be used for encapsulation.

热熔性封装一般包含通过注模在热塑性材料中加入微电子系统或其部件。使用的热塑性材料可选自苯乙烯嵌段共聚物、聚氨酯、ABS(丙烯腈-丁二烯-苯乙烯共聚物)、SAN(苯乙烯-丙烯腈共聚物)、聚氯乙烯、PDMS、POM(聚氧化甲烯)、聚苯乙烯、聚酯、聚丙烯酸盐、聚烯烃,例如聚乙烯或聚丙烯。Hot melt encapsulation generally involves incorporating microelectronic systems or components thereof in thermoplastic materials by injection molding. The thermoplastic material used can be selected from styrenic block copolymer, polyurethane, ABS (acrylonitrile-butadiene-styrene copolymer), SAN (styrene-acrylonitrile copolymer), polyvinyl chloride, PDMS, POM ( polyoxymethylene), polystyrene, polyester, polyacrylate, polyolefins such as polyethylene or polypropylene.

微电子系统的部件需要互连。各系统可包含需要在机械上或电学上被组装的一个或更多个离散的部件。可通过PCB(印刷电路板)、弹簧锁、薄的柔性PCB、胶水等建立机械或电学连接。The components of a microelectronic system need to be interconnected. Each system may contain one or more discrete components that need to be assembled mechanically or electrically. The mechanical or electrical connection can be established via PCB (Printed Circuit Board), snap locks, thin flex PCB, glue, etc.

在上述的一个实施例中,微电子感测系统的所有部分都在制造中被集成到粘合剂体内,这意味着具有微电子系统的粘合剂器件具有一次性的性质。In one embodiment described above, all parts of the microelectronic sensing system are integrated into the adhesive body during manufacture, which means that the adhesive device with the microelectronic system has a disposable nature.

根据本发明的粘合剂器件也可以以这种方式被构建,即,微电子系统的部件可在粘合剂器件的寿命期间被更换,或者可在新的粘合剂器件中被重新使用。The adhesive device according to the invention can also be constructed in such a way that components of the microelectronic system can be replaced during the lifetime of the adhesive device, or can be reused in a new adhesive device.

微电子系统的某些部件在制造中被集成到粘合剂体内,而剩余的部件在之后、紧挨着附着到皮肤上之前或附着到皮肤上之后被施加到本发明的粘合剂器件上。在粘合剂体的制造之后施加到粘合剂体上的部件一般是可互换的或可再用的。Certain components of the microelectronic system are integrated into the adhesive body during manufacture, while the remaining components are applied to the adhesive device of the present invention afterward, immediately before or after attachment to the skin . Components applied to the adhesive body after manufacture of the adhesive body are generally interchangeable or reusable.

可被更换的部件例如为能源,例如电池。A replaceable component is, for example, an energy source, such as a battery.

在本发明的特定实施例中,整个微电子系统是可互换的或可再用的,并且可在紧挨着附着之前或在被施加到皮肤上之后被施加到粘合剂器件上。In certain embodiments of the invention, the entire microelectronic system is interchangeable or reusable and can be applied to the adhesive device immediately before attachment or after application to the skin.

适当地,可互换部件或可再用部件如上面所述的那样被封装并形成配合粘合剂体中的凹槽或孔的封装件。Suitably, the interchangeable or reusable part is encapsulated as described above and forms an enclosure that fits into a recess or hole in the body of adhesive.

在可互换或可再用部件的情况下,它们必须具有一些类型的使用中对粘合剂体的安全附着手段。这些附着手段可由粘合剂提供,例如,由已存在于凹痕中的粘合剂体的压敏粘合剂提供,该凹痕是粘合剂体中的孔的空腔。In the case of interchangeable or reusable parts, they must have some type of secure attachment means to the adhesive body in use. These means of attachment may be provided by an adhesive, for example by a pressure sensitive adhesive of the adhesive body already present in the indentation, which is the cavity of the hole in the adhesive body.

在这种情况下,优选封装材料是不太强地粘合到粘合剂体的粘合剂上的材料,见上文。In this case, it is preferred that the encapsulating material is a material which does not adhere too strongly to the adhesive of the adhesive body, see above.

作为替代方案,封装的可互换或可再用部件的封装件通过对粘合剂体的机械耦合被附着到粘合剂体上。上述的包含可更换或可再用部件的封装的封装件可由此通过弹簧锁机构被配入粘合剂体中。Alternatively, the package of packaged interchangeable or reusable components is attached to the adhesive body by mechanical coupling to the adhesive body. A packaged package as described above containing replaceable or reusable components may thus be fitted into the adhesive body by a snap-lock mechanism.

封装用作微电子系统或其部件的外壳,并适当地由注模的聚合物材料形成,但大致上可以为任何材料和任何结构。The encapsulation serves as an enclosure for the microelectronic system or components thereof, and is suitably formed of injection molded polymer material, but may be of generally any material and of any construction.

封装的微电子部件的封装件可具有任意适当的形状,适当地为配合粘合剂体中的凹槽或通孔的三维形状。在一个实施例中,封装的电子部件将具有具有圆端的棒状胶囊的形状。The package of the encapsulated microelectronic component may have any suitable shape, suitably a three-dimensional shape that fits a groove or via in the adhesive body. In one embodiment, the packaged electronic component will have the shape of a stick capsule with rounded ends.

如上所述,本发明使用用于获取生理数据的侵入式以及非侵入式技术。在非侵入式测量的情况下,一个或更多个金属电极可被用于皮肤接点。但是,任何导电材料均可被用于皮肤接点,诸如导电的聚合物、导电的水凝胶和电解质。在侵入式测量的情况下,常规的针或显微针可被使用。当前这种侵入式技术已是公知的例如用于测量氧或血糖的技术。As noted above, the present invention uses invasive as well as non-invasive techniques for acquiring physiological data. In the case of non-invasive measurements, one or more metal electrodes can be used for the skin contact. However, any conductive material can be used for the skin contact, such as conductive polymers, conductive hydrogels, and electrolytes. In the case of invasive measurements, conventional needles or microneedles can be used. Such invasive techniques are currently known eg for measuring oxygen or blood sugar.

通过组合详细说明的部件,所有类别的微电子感测系统均可被设计和加入到本发明的粘合剂器件中。适于嵌入粘合剂器件中的系统的例子是适于测量生物传感器信号、EKG、EMG、EEG、血糖、脉搏、血压、pH值和氧的系统。By combining the components specified, all classes of microelectronic sensing systems can be designed and incorporated into the adhesive devices of the present invention. Examples of systems suitable for embedding in adhesive devices are systems suitable for measuring biosensor signals, EKG, EMG, EEG, blood glucose, pulse, blood pressure, pH and oxygen.

加入本发明的粘合剂器件中的微电子系统一般需要以下的部件:通信部件、CPU(中央处理单元)、电源、存储部件、换能器部件、互连,并任选地包含致动器部件。Microelectronic systems incorporated into adhesive devices of the present invention generally require the following components: communication components, CPU (Central Processing Unit), power supply, storage components, transducer components, interconnects, and optionally include actuators part.

CPU(中央处理单元)控制微电子系统的部件并与它们通信。CPU操纵应用软件、数据决策(诸如数据信号处理)、A/D转换、DSP(数字信号处理)、路由选择、定时、电力管理、休眠功能、中断的执行。The CPU (Central Processing Unit) controls and communicates with the components of the microelectronic system. The CPU handles execution of application software, data decision making (such as data signal processing), A/D conversion, DSP (digital signal processing), routing, timing, power management, sleep functions, interrupts.

CPU是微电子系统的控制其它部件并进行适当的数据分析的部件。一般地,需要的速度和数据分析越多,则需要的电力越多。因此,为了节省电力,休眠功能常被使用。在某些时间,或者如果某件事件发生(由功率非常低的监视子系统触发),那么CPU被唤醒,进行必要的计算,与相关的部件通信并返回休眠模式。根据本发明,可根据需要使用从非常基本的CPU到功能强大的微控制器。The CPU is the part of the microelectronic system that controls the other parts and performs appropriate data analysis. In general, the more speed and data analysis required, the more power is required. Therefore, in order to save power, the sleep function is often used. At certain times, or if some event occurs (triggered by a very low power monitoring subsystem), the CPU wakes up, performs the necessary calculations, communicates with the relevant components and returns to sleep mode. According to the invention, everything from a very basic CPU to a powerful microcontroller can be used as required.

通信部件控制送往和来自微电子系统的所有通信。适当地,微电子系统是使得能够与离开粘合剂器件某一距离的接收器单元无线通信的系统。但是,本发明不限于诸如RF无线通信的无线通信。其它的通信手段可以是音频或光学通信手段。部件包含必要的用于实现这种无线通信的电子部件,还包含天线以及必要的硬件和软件。The communications component controls all communications to and from the microelectronic system. Suitably, the microelectronic system is a system enabling wireless communication with a receiver unit at a distance from the adhesive device. However, the present invention is not limited to wireless communications such as RF wireless communications. Other means of communication may be audio or optical means of communication. The components contain the electronics necessary to enable this wireless communication, as well as the antenna and the necessary hardware and software.

天线可根据频率、功率和信号形式采取不同的形状和形式。一些天线用于在几厘米的范围上传送信息,另一些天线的范围为几米。天线的例子是:环绕小铁氧体磁芯(例如,直径小于4mm)的线圈、具有多圈的扁平线圈(直径一般为10mm或更大)、诸如单极或双极天线的单和双导线射电天线和集成到粘合剂中的天线。Antennas can take different shapes and forms depending on frequency, power and signal form. Some antennas are used to transmit information over a range of a few centimeters, others have a range of a few meters. Examples of antennas are: coils around small ferrite cores (e.g. less than 4mm in diameter), flat coils with multiple turns (typically 10mm in diameter or more), single and dual conductors such as monopole or dipole antennas Radio antennas and antennas integrated into adhesives.

只具有几圈和例如50mm的大直径的天线可被层叠并被集成到粘合剂体中或被印刷到或直接放在粘合剂器件的覆盖层上。天线一般由诸如铜或铝的金属制成,但也可以是导电墨水。Antennas with only a few turns and a large diameter of eg 50 mm can be laminated and integrated into the adhesive body or printed or placed directly on the cover layer of the adhesive device. Antennas are typically made of metals such as copper or aluminum, but can also be conductive ink.

电源包含功率调节电子部件、再充电电子部件和一般为内部或可互换电池的能源。但是,其它的为微电子系统得到电力的手段可被提出,诸如动能转换、燃料电池、同位素辐射、太阳能电池,或者通过射频(RF)链路。并且,天线可被用于将能量加载到微电子系统中。The power supply contains power conditioning electronics, recharging electronics, and an energy source, typically an internal or interchangeable battery. However, other means of obtaining power for microelectronic systems can be proposed, such as kinetic energy conversion, fuel cells, isotopic radiation, solar cells, or via radio frequency (RF) links. Also, the antenna can be used to load energy into the microelectronic system.

优选地,电源是电池,并且可以为一次性使用或可以为可充电的。Preferably, the power source is a battery and may be single use or may be rechargeable.

存储部件用于存储嵌入的系统软件和/或存储在器件的操作中获取的数据。存储部件可以是CPU的一部分、其自身的部件或可被去除和更换的诸如FLASH RAM的可互换存储器。The memory component is used to store embedded system software and/or store data acquired during operation of the device. The storage unit can be part of the CPU, its own unit or an interchangeable memory such as FLASH RAM that can be removed and replaced.

换能器部件是被设计为将能量从一种形式转换成另一种形式的部件。换能器一般为但不限于微电子系统的传感器或感测部分。换能器可由此能够转换例如物理输入,并且换能器将一般但不必将该能量转换成要被CPU等解释的电气形式。A transducer component is a component designed to convert energy from one form to another. A transducer is generally, but not limited to, a sensor or sensing portion of a microelectronic system. The transducer may thus be able to convert eg a physical input, and the transducer will typically but not necessarily convert this energy into an electrical form to be interpreted by a CPU or the like.

换能器可转换的物理输入的例子是加速度、化学品/气体、流量、湿度、惯性、电容、导电率、传导率、电流、阻抗、电感、pH值、电阻、电阻率、电压、光检测、光、磁性、压力、角度、线性位置、速度、温度、声音和机械力。Examples of physical inputs that a transducer can transduce are acceleration, chemical/gas, flow, humidity, inertia, capacitance, conductivity, conductivity, current, impedance, inductance, pH, resistance, resistivity, voltage, light detection , light, magnetism, pressure, angle, linear position, velocity, temperature, sound and mechanical force.

换能器的切实代表是检测部件。检测部件一般选自电极(极性、双极)、压力传感器、具有电极的针、加速计、光检测器、麦克风、离子敏感场效应晶体管(ISFET)、NTC(负温度系数)电阻器、带隙检测器、离子膜、酶反应器或电容器。A tangible representation of the transducer is the detection component. The detection components are generally selected from electrodes (polar, bipolar), pressure sensors, needles with electrodes, accelerometers, light detectors, microphones, ion sensitive field effect transistors (ISFETs), NTC (negative temperature coefficient) resistors, band Gap detectors, ionic membranes, enzyme reactors or capacitors.

在本发明的一个实施例中,换能器包含用于非侵入检测的检测器,诸如电极。In one embodiment of the invention, the transducer contains detectors, such as electrodes, for non-invasive detection.

在本发明的另一实施例中,换能器包含侵入式检测器,诸如包含电极的针。In another embodiment of the invention, the transducer comprises an intrusive detector, such as a needle comprising electrodes.

致动器与换能器相反。它以与换能器基本上相同的方式但以相反的次序将能量从一种形式转换成另一种形式。通常它将电信号转换成物理信号。致动器的切实代表是例如电极(例如用于神经系统或神经刺激)、泵、注射针、发光二极管(LED)或另一光源、扬声器、电流发生器或化学分析仪。致动器的可能的用途在某些事件中由CPU决定,以激活微电子系统中的警报,诸如扬声器或LED,或者指示电池电量低。Actuators are the opposite of transducers. It converts energy from one form to another in essentially the same way as a transducer, but in the reverse order. Usually it converts electrical signals into physical signals. Concrete representatives of actuators are eg electrodes (eg for nervous system or nerve stimulation), pumps, injection needles, light emitting diodes (LEDs) or another light source, loudspeakers, current generators or chemical analyzers. Possible uses of the actuator are determined by the CPU in certain events, to activate an alarm in the microelectronic system, such as a speaker or an LED, or to indicate a low battery.

因此,致动器可被用作系统中的对从诸如警报(可视的和可听的)、注射泵、阀等的换能器部件获得的输入做出反应的部件。它可以是一次使用、多次使用或连续使用的致动器。Thus, actuators may be used as components in the system that react to inputs obtained from transducer components such as alarms (visual and audible), syringe pumps, valves, and the like. It can be a single use, multiple use or continuous use actuator.

许多感测系统仅是传送关于哺乳动物的身体条件的信息的情报系统,并且在这种情况下不需要致动器。Many sensing systems are simply intelligence systems that convey information about the physical condition of the mammal, and in this case no actuators are required.

微电子系统将在用于给定应用的器件中可能仅需要部件中的一些的意义上被模块化构建。一些应用将利用很少的部件,并且一些应用可使用所有的部件。这些部件可被配入相同的物理ASIC(专用集成电路)、电气系统或子系统,诸如但不限于PCB(印刷电路板)、柔性PCB、厚膜、薄膜或陶瓷技术,或者,系统或其部件可被单独地封装。Microelectronic systems will be modularly built in the sense that only some of the components may be required in a device for a given application. Some applications will utilize few components, and some applications may use all components. These components can be fitted into the same physical ASIC (Application Specific Integrated Circuit), electrical system or subsystem, such as but not limited to PCB (Printed Circuit Board), flex PCB, thick film, thin film or ceramic technology, or, the system or its components can be packaged individually.

RFID(射频识别)标签在各种尺寸、范围和功能上是可在市场上得到的。当RFID读取器施加适当的场(例如,感应场)时,基本的RFID标签返回一个比特序列。该序列在使用之前被编程。RFID范围为从1cm到用于无源标签(不包含电源)的约2米到用于有源标签(包含电源)的超过100米。可用的更复杂的RFID标签具有可读取或存储数据的存储部件。RFID (Radio Frequency Identification) tags are commercially available in a variety of sizes, sizes and functions. Basic RFID tags return a sequence of bits when an RFID reader applies an appropriate field (eg, an inductive field). This sequence is programmed prior to use. RFID ranges from 1 cm to about 2 meters for passive tags (without power supply) to over 100 meters for active tags (with power supply included). More sophisticated RFID tags are available that have memory components that can read or store data.

RFID标签可作为独立的部分或与其它的微电子部件组合被加入粘合剂体中。可以在不明显增加系统的复杂性和价格的条件下很容易地使得复杂的微电子系统包含各种形式的RFID标签。在复杂的系统中,标签可被用作简单的跟踪部件以识别产品,诸如搁置寿命、寿命,但它也可被用于对传感器网络中的其它系统的识别。The RFID tag can be incorporated into the adhesive body as a stand-alone part or in combination with other microelectronic components. Complex microelectronic systems can easily be made to incorporate various forms of RFID tags without significantly increasing the complexity and cost of the system. In complex systems, the tag can be used as a simple tracking component to identify the product, such as shelf life, lifespan, but it can also be used for identification to other systems in a sensor network.

对于独立的方案,RFID标签基本上包含RF芯片和线圈。适当的形式的RFID标签是被封装到玻璃外壳内的RFID标签、被封装到塑料/环氧树脂(一般为药丸状)中的RFID标签、具有层叠在2个聚酰亚胺层之间的线圈和RF芯片的平面RFID标签、或在没有任何其它的保护/封装的情况下具有印刷在粘合剂体上或粘合剂体中的圈数很少的大型线圈天线并具有与天线互连的RF芯片的平面RFID标签。For stand-alone solutions, RFID tags basically contain an RF chip and a coil. Suitable forms of RFID tags are those encapsulated into glass housings, RFID tags encapsulated in plastic/epoxy (typically pill-shaped), have coils laminated between 2 polyimide layers and a planar RFID tag with an RF chip, or a large coil antenna with a small number of turns printed on or in an adhesive body with interconnects to the antenna without any other protection/encapsulation Flat RFID tags with RF chips.

这些系统可在粘合剂体的制造中被完全集成到粘合剂体内。These systems can be fully integrated into the adhesive body during its manufacture.

上述平面RFID标签可在制造过程中被夹在2层压敏粘合剂之间。由于RF芯片非常小(1mm×1mm)并且线圈较为柔软,因此不需要刚性的封装。玻璃封装的RFID标签具有非常好的耐化学性和较小的尺寸以保证没有不舒适感。封装在塑料或环氧树脂中的RFID标签可以为更复杂的设计,并且在本发明的粘合剂体的制造过程中或制造之后均可被添加。The planar RFID tags described above can be sandwiched between 2 layers of pressure sensitive adhesive during the manufacturing process. Since the RF chip is very small (1mm x 1mm) and the coil is relatively flexible, rigid packaging is not required. Glass-encapsulated RFID tags have very good chemical resistance and are small in size to ensure no discomfort. RFID tags encapsulated in plastic or epoxy can be of more complex designs and can be added during or after manufacture of the adhesive body of the present invention.

封装的RFID标签是一个或更多个粘合剂体中的可被再使用的部件。封装的RFID标签从一个粘合剂体被转移到另一个粘合剂体,并由此一次又一次被再使用,并且对于存储个人特定数据是十分理想的。An encapsulated RFID tag is a reusable component in one or more adhesive bodies. Encapsulated RFID tags are transferred from one adhesive body to another and thus reused again and again, and are ideal for storing person-specific data.

一般嵌入的微电子系统在其系统中包含某种类型的传感器,但这一点不是对于所有的应用都是必须的。Typically embedded microelectronic systems include some type of sensor in their system, but this is not necessary for all applications.

本发明的粘合剂器件也可以是放在体部的不同位置上的粘合剂传感器器件的网络的一部分。这些单个粘合剂器件的复杂性可根据位置和感测性能从较小的基本传感器系统变化到更复杂的系统。网络的一些粘合剂器件具有简化的功能,称为RFD(简化功能器件),而其它的器件是FFD(全功能器件)。The adhesive device of the present invention may also be part of a network of adhesive sensor devices placed at different locations on the body. The complexity of these individual adhesive devices can vary from smaller basic sensor systems to more complex systems depending on location and sensing performance. Some adhesive devices of the network have reduced functionality, called RFDs (Reduced Functional Devices), while others are FFDs (Full Functional Devices).

FFD器件可在任何拓扑技术中起作用,并且是网络的协调器,或者它可以是可与任何其它器件对话的协调器。RFD器件限于星形拓扑,它不能变为网络协调器,它仅与网络协调器对话并具有非常简单的实现方案。The FFD device can function in any topology and be the coordinator of the network, or it can be the coordinator that can talk to any other device. The RFD device is limited to a star topology, it cannot become a network coordinator, it only talks to the network coordinator and has a very simple implementation.