CN100552879C - Stage driving method, stage device, exposure apparatus, and device manufacturing method - Google Patents

Stage driving method, stage device, exposure apparatus, and device manufacturing methodDownload PDFInfo

- Publication number

- CN100552879C CN100552879CCNB2005800022692ACN200580002269ACN100552879CCN 100552879 CCN100552879 CCN 100552879CCN B2005800022692 ACNB2005800022692 ACN B2005800022692ACN 200580002269 ACN200580002269 ACN 200580002269ACN 100552879 CCN100552879 CCN 100552879C

- Authority

- CN

- China

- Prior art keywords

- stage

- wafer

- liquid

- state

- area

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

- Exposure And Positioning Against Photoresist Photosensitive Materials (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明是关于载台驱动方法及载台装置、曝光装置、及元件制造方法,更详细的说,是关于将能在包含有液体局部供应的二维面内的第一区域的区域移动的两个载台驱动的载台驱动方法及适于实施该载台驱动方法的载台装置,在投影光学系统与基板之间供应液体且通过投影光学系统与该液体使基板曝光的曝光装置,以及使用该曝光装置的元件制造方法。The present invention relates to a method for driving a stage, a stage device, an exposure device, and a device manufacturing method. A stage driving method for driving a stage and a stage device suitable for carrying out the stage driving method, an exposure device for supplying a liquid between a projection optical system and a substrate and exposing a substrate through the projection optical system and the liquid, and using The element manufacturing method of this exposure apparatus.

背景技术Background technique

已知,在供制造半导体元件(集成电路等)、液晶显示元件等电子元件的光刻步骤,主要使用步进重复(step and repeat)方式的缩小投影曝光装置(所谓步进机),或步进扫描(step and scan)方式的投影曝光装置(所谓扫描步进机(也称为扫描机)),将掩膜或标线片(以下,统称为“标线片”)的图案像通过投影光学系统,转印于涂布有光刻胶(感光剂)的晶片或玻璃板等的感旋光性基板(以下,称为“基板”或“晶片”)上的多个各照射区域。It is known that in the photolithography steps for manufacturing electronic components such as semiconductor components (integrated circuits, etc.), liquid crystal display components, mainly use step and repeat (step and repeat) reduction projection exposure devices (so-called steppers), or steppers. Step and scan projection exposure device (so-called scanning stepper (also called scanner)), the pattern image of the mask or reticle (hereinafter collectively referred to as "reticle") is projected The optical system is transferred to a plurality of irradiated regions on a photosensitive substrate (hereinafter referred to as "substrate" or "wafer") coated with a photoresist (photosensitive agent) such as a wafer or a glass plate.

投影曝光装置所具备的投影光学系统的分辨率R,能以下式(1)的瑞利(Rayleigh)式表示:The resolution R of the projection optical system included in the projection exposure apparatus can be expressed by the Rayleigh formula of the following formula (1):

R=K1×λ/NA (1)R=K1 ×λ/NA (1)

在此,λ是曝光波长,NA是投影光学系统的数值孔径,K1是处理系数。由于式(1)所使用的曝光波长(曝光用光的波长)越短,且投影光学系统的数值孔径(NA)越大,分辨率R则越高。因此,随着集成电路的微细化,使用于投影曝光装置的曝光波长则年年越短波长化,目前以比KrF准分子激光(波长248nm)短波长的ArF准分子激光(波长193nm)为光源的曝光装置也实用化。又,投影光学系统的数值孔径也逐渐增大。Here, λ is the exposure wavelength, NA is the numerical aperture of the projection optical system, andK1 is the process coefficient. Since the exposure wavelength (wavelength of exposure light) used in formula (1) is shorter and the numerical aperture (NA) of the projection optical system is larger, the resolution R is higher. Therefore, with the miniaturization of integrated circuits, the exposure wavelength used in projection exposure equipment is becoming shorter and shorter every year. At present, ArF excimer laser light (wavelength 193nm) shorter than KrF excimer laser light (wavelength 248nm) is used as a light source. The exposure device is also practical. In addition, the numerical aperture of the projection optical system is gradually increasing.

进行曝光时,与分辨率同样,焦点深度(DOF)也很重要。焦点深度δ能以下式(2)表示:When making an exposure, the depth of focus (DOF) is as important as the resolution. The depth of focus δ can be expressed by the following formula (2):

δ=K2×λ/NA2(2)δ=K2 ×λ/NA2 (2)

在此,K2是处理系数。依据式(1)、式(2),为了要提高分辨率R,若使曝光波长缩短,使数值孔径NA变大(大NA化),则得知焦点深度δ会变小。在投影曝光装置,是将晶片的表面配合投影光学系统的像面来进行曝光,因此,较佳者为焦点深度δ应具某程度大。Here,K2 is the processing coefficient. According to equations (1) and (2), in order to increase the resolution R, if the exposure wavelength is shortened and the numerical aperture NA is increased (increased NA), it is known that the depth of focus δ becomes smaller. In the projection exposure apparatus, the surface of the wafer is exposed according to the image plane of the projection optical system. Therefore, it is preferable that the depth of focus δ should be large to some extent.

然而,通过上述曝光用光的短波长化及投影光学系统的大NA化,焦点深度δ是越来越变小。又,曝光波长将来会变成更短波长化已确定,假如保持此趋势,焦点深度δ则会变过小,而产生曝光动作时的焦点裕度不足之虞。However, the depth of focus δ is getting smaller and smaller due to the shortening of the wavelength of the exposure light described above and the increase in the NA of the projection optical system. In addition, it is confirmed that the exposure wavelength will become shorter in the future. If this trend is maintained, the depth of focus δ will become too small, and there may be a risk of insufficient focus margin during the exposure operation.

因此,当作实质上能使曝光波长缩短,且比空气中使焦点深度变大(宽广)的方法,最近利用液浸法的曝光装置则引起注目。利用该液浸法的曝光装置,已知悉:在投影光学系统的下面与晶片表面之间,以局部填满水或有机溶剂等的液体的状态,进行曝光的(例如,参照下述专利文献1)。此专利文献1所记载的曝光装置,是利用在液体中的曝光用光的波长,会成为空气中的1/n倍(n是液体的折射率,通常1.2~1.6程度),来提高分辨率,并且比起不使用液浸法能获得与该分辨率相同分辨率的投影光学系统(假设此种投影光学系统的制造是可能的),能使焦点深度扩大为n倍,即比空气中能使焦点深度实质上扩大n倍。Therefore, recently, an exposure apparatus using a liquid immersion method has attracted attention as a method that can substantially shorten the exposure wavelength and make the depth of focus larger (wider) than in air. Utilize the exposure apparatus of this liquid immersion method, known: between the lower surface of projection optical system and wafer surface, with the state that partly fills liquids such as water or organic solvent, expose (for example, refer to following patent document 1 ). The exposure device described in this

然而,专利文献1所记载的曝光装置,在晶片交换时,在晶片载台从投影光学系统正下方离开前的阶段,需要将液体暂时回收,使投影光学系统的下面与晶片表面之间,从湿状态变成干状态。但是,如此,若每于晶片交换时,需要进行液体的回收与供应,可确定液体的回收与供应所需的时间会变成曝光装置的产能降低的主要原因。However, in the exposure apparatus described in

又,如上述,将投影光学系统的像面侧的光路空间从湿状态变成干状态时,若持续干状态,则在构成投影光学系统最下端的光学构件(所谓前球,透镜或玻璃板等;以下,称为“前端透镜”)的表面,会有产生水纹(水痕)之虞。又,在该前端透镜附近若配置自动对焦机构的构成构件的光学构件(例如棱镜)的情形,在该自动对焦机构的构成构件的光学构件表面,会有产生水纹(水痕)之虞。此水纹的产生,则会成为投影光学系统的透过率降低或闪光(flare)的要因,进而或会成为使投影光学系统的其它结像性能恶化的要因。又,若在上述棱镜等产生水痕的情形,以自动对焦方式使晶片表面与投影光学系统的像面对准时的面对准精度则有降低之虞。又,水痕的产生若严重时,需要前端透镜或光学构件的更换,但其更换所需的时间会成为使曝光装置的运转率降低的要因。Also, as mentioned above, when the optical path space on the image plane side of the projection optical system is changed from a wet state to a dry state, if the dry state continues, the optical components (so-called front ball, lens or glass plate) constituting the lowest end of the projection optical system will be damaged. etc.; hereinafter, referred to as "front lens"), there is a risk of water streaks (water marks) on the surface. Also, if an optical member (for example, a prism) that is a constituent member of the autofocus mechanism is disposed near the front lens, watermarks (watermarks) may occur on the surface of the optical member that is a constituent member of the autofocus mechanism. The generation of the water streaks will cause the decrease of the transmittance of the projection optical system or the cause of flare, and may further cause the deterioration of other imaging performances of the projection optical system. In addition, if the above-mentioned prisms and the like generate water marks, the surface alignment accuracy when the wafer surface is aligned with the image plane of the projection optical system by the autofocus method may decrease. In addition, if the occurrence of water marks is severe, replacement of the front lens or the optical member is required, but the time required for the replacement becomes a factor that lowers the operating rate of the exposure apparatus.

又,在本说明书,使用水以外的液体时,将形成于前端透镜等的花纹也称为水纹(水痕)。In addition, in this specification, when a liquid other than water is used, the pattern formed on the front-end lens etc. is also called a water streak (water mark).

前述专利文献1为国际公开第99/49504号小册子。The

发明内容Contents of the invention

本发明,有鉴于上述情况,依第一观点,提出一种载台驱动方法,是在包含有液体局部供应的二维面内的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围区域内,独立驱动第一载台与第二载台,其中:In view of the above situation, the present invention proposes a stage driving method according to the first point of view, in which the first region in the two-dimensional plane containing the partial supply of liquid is aligned with the first axis direction located in the first region. Within the predetermined area of the second area on the side, the first stage and the second stage are independently driven, wherein:

当从该第一、第二载台中的一载台位于该第一区域的第一状态,迁移至另一载台位于该第一区域的第二状态时,使该第一载台与第二载台,维持于与该第一轴方向交叉的第二轴方向上呈近接状态及接触状态的任一状态,并将该第一、第二载台朝该第二轴方向同时驱动。When transferring from the first state where one of the first and second carriers is located in the first region to the second state where the other carrier is located in the first region, the first carrier and the second The stage is maintained in either a proximity state or a contact state in a second axial direction intersecting with the first axial direction, and the first and second stages are simultaneously driven in the second axial direction.

在此,所谓“第一载台与第二载台呈近接状态”,是指以从第一载台与第二载台之间不泄漏液体,或液体的泄漏少的程度,使第一载台与第二载台呈近接状态而言。但是,第一载台与第二载台的间隔的容许值,是因该两载台的材质或液体的种类等而不同。本说明书,是站在这种观点使用“第一载台与第二载台呈近接状态”的表现。Here, "the first stage and the second stage are in a close proximity state" means that the first stage is placed in a state where no liquid leaks from between the first stage and the second stage, or the leakage of liquid is small. The platform and the second carrier are in a close state. However, the allowable value of the distance between the first stage and the second stage differs depending on the material of the two stages, the type of liquid, and the like. In this specification, the expression "the first stage and the second stage are in a close proximity state" is used from this point of view.

依此,在包含将液体局部供应的二维面内的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围区域内,使第一载台与第二载台独立驱动时,在从一载台位于该第一区域的第一状态迁移至另一载台位于该第一区域的第二状态的情形,第一、第二载台,维持与第一轴方向交叉的第二轴方向彼此呈近接状态或接触状态,而朝第二轴方向同时驱动。藉此,以在第一、第二载台中的至少一载台上形成液浸区域的状态,边防止或抑制从第一、第二载台(两载台)的间隙泄漏液体,边能从第一状态迁移至第二状态。即,从一载台上保持液体的状态,经过在双方的载台上保持液体的状态,至另一载台上保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。因此,将从第一状态至第二状态的迁移能以短时间进行。Accordingly, within a predetermined area including the first area in the two-dimensional plane where the liquid is locally supplied, and the second area located on one side of the first axis in the direction of the first axis, the first stage and the second When the carrier is driven independently, when transferring from the first state where one carrier is located in the first region to the second state where the other carrier is located in the first region, the first and second carriers maintain the same position as the first carrier. The second axial directions intersecting the axial directions are in a close state or contact state with each other, and are simultaneously driven toward the second axial direction. Thereby, in the state where the liquid immersion region is formed on at least one of the first and second stages, while preventing or suppressing leakage of liquid from the gap between the first and second stages (both stages), the The first state transitions to the second state. That is, from the state of maintaining the liquid on one stage, through the state of maintaining the liquid on both stages, to the state of maintaining the liquid on the other stage, it is possible to make it possible without going through the steps of fully recovering and resupplying the liquid. migrate. Therefore, the transition from the first state to the second state can be performed in a short time.

本发明,依第二观点,提出一种载台驱动方法,是在包含有液体局部供应的二维面内的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围的区域内,驱动第一载台;在包含该第一区域、与位于该第一区域的该第一轴方向的另一侧的第三区域的既定范围的区域内,驱动第二载台,其中:According to the second point of view, the present invention proposes a method for driving a stage, which comprises a first region in a two-dimensional plane containing a local supply of liquid, and a second region located on one side of the first axis direction of the first region. In the area of the predetermined range of the first stage, drive the first stage; in the area of the predetermined range including the first area and the third area located on the other side of the first axis direction of the first area, drive the second stage. stage, where:

当从该第一、第二载台中的一载台位于该第一区域的第一状态,迁移至另一载台位于该第一区域的第二状态时,使该第一载台与第二载台,维持与该第一轴方向呈近接状态及接触状态的任一状态,并将该第一、第二载台朝该第一轴方向同时驱动。When transferring from the first state where one of the first and second carriers is located in the first region to the second state where the other carrier is located in the first region, the first carrier and the second The stage maintains any state of being in proximity or in contact with the first axis, and simultaneously drives the first and second stages toward the first axis.

依此,在包含将液体局部供应的二维面内的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围区域内,驱动第一载台,在包含该第一区域、与位于该第一区域的该第一轴方向的另一侧的第三区域的既定范围区域内,驱动第二载台时,从一载台位于第一区域的第一状态迁移至另一载台位于第一区域的第二状态时,第一载台与第二载台,维持与第一轴方向呈近接状态或接触状态的任一状态,而朝第一轴方向同时驱动。藉此,以在第一、第二载台中的至少一载台上形成液浸区域的状态,边防止或抑制从第一、第二载台的间隙泄漏液体,边能从第一状态迁移至第二状态。即,从一载台上保持液体的状态,经过在双方的载台上保持液体的状态,至另一载台上保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。因此,将从第一状态至第二状态的迁移能以短时间进行。Accordingly, the first stage is driven within a predetermined area including the first area in the two-dimensional plane where the liquid is locally supplied, and the second area located on one side of the first axis in the direction of the first axis. In the predetermined area of the first area and the third area located on the other side of the first axis direction of the first area, when the second stage is driven, from the first state where a stage is located in the first area When moving to the second state where another stage is located in the first area, the first stage and the second stage maintain any state of being close to or in contact with the first axis direction, and move toward the first axis direction at the same time. drive. Thereby, in the state where the liquid immersion region is formed on at least one of the first and second stages, while preventing or suppressing leakage of liquid from the gap between the first and second stages, it is possible to transfer from the first state to the second state. That is, from the state of maintaining the liquid on one stage, through the state of maintaining the liquid on both stages, to the state of maintaining the liquid on the other stage, it is possible to make it possible without going through the steps of fully recovering and resupplying the liquid. migrate. Therefore, the transition from the first state to the second state can be performed in a short time.

本发明,依第三观点,提供第一载台装置,具备:According to the third point of view, the present invention provides a first stage device, which has:

第一、第二载台,能在包含有液体局部供应的二维面内的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围区域内独立驱动;及The first and second stages can be independently driven within a predetermined area including a first area in a two-dimensional plane where the liquid is locally supplied, and a second area located on one side of the first axis in the direction of the first axis; and

控制装置,当从该第一、第二载台中的一载台位于该第一区域的第一状态,迁移至另一载台位于该第一区域的第二状态时,该第一载台与该第二载台,维持与该第一轴方向交叉的第二轴方向呈近接状态及接触状态的任一状态,以使该第一、第二载台朝该第二轴方向同时移动的方式,来控制该第一、第二载台。The control device, when transferring from the first state where one of the first and second carriers is located in the first area to the second state where the other carrier is located in the first area, the first carrier and the second carrier The second stage is maintained in any state of proximity or contact in a second axial direction intersecting with the first axial direction, so that the first and second stages move toward the second axial direction simultaneously. , to control the first and second carriers.

依此,从第一、第二载台中的一载台位于有液体局部供应的二维面内的第一区域的第一状态,迁移至另一载台位于该第一区域的第二状态时,通过控制装置,控制第一、第二载台,使第一、第二载台维持与第一轴方向交叉的第二轴方向彼此呈近接状态或接触状态,而朝第二轴方向同时移动。藉此,以在第一、第二载台中的至少一载台上形成液浸区域的状态,边防止或抑制从第一、第二载台(两载台)的间隙泄漏液体,边能从第一状态迁移至第二状态。即,从一载台上保持液体的状态,经过在双方的载台上保持液体的状态,至另一载台上保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。因此,将从第一状态至第二状态的迁移能以短时间进行。According to this, when one of the first and second stages is located in the first region in the two-dimensional plane with partial supply of liquid from the first state, to the second state in which the other stage is located in the first region , through the control device, the first and second stages are controlled, so that the first and second stages maintain a state of proximity or contact with each other in the second axis direction intersecting with the first axis direction, and move toward the second axis direction simultaneously . Thereby, in the state where the liquid immersion region is formed on at least one of the first and second stages, while preventing or suppressing leakage of liquid from the gap between the first and second stages (both stages), the The first state transitions to the second state. That is, from the state of maintaining the liquid on one stage, through the state of maintaining the liquid on both stages, to the state of maintaining the liquid on the other stage, it is possible to make it possible without going through the steps of fully recovering and resupplying the liquid. migrate. Therefore, the transition from the first state to the second state can be performed in a short time.

本发明,依第四观点,提供第二载台装置,具备:According to the fourth viewpoint, the present invention provides a second stage device, which has:

第一载台,能在包含有液体局部供应的二维面内的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围的区域内移动;The first carrier can move within a predetermined range including a first area in a two-dimensional plane where liquid is locally supplied, and a second area located on one side of the first axis in the direction of the first axis;

第二载台,能在包含该第一区域、与位于该第一区域的该第一轴方向的另一侧的第三区域的既定范围区域内移动;及The second stage can move within a predetermined area including the first area and a third area located on the other side of the first axis in the direction of the first axis; and

控制装置,使从该第一、第二载台中的一载台位于该第一区域的第一状态,迁移至另一载台位于该第一区域的第二状态时,将该第一、第二载台控制成,维持与该第一轴方向呈近接状态及接触状态的任一状态,以使该第一、第二载台朝该第一轴方向同时移动。The control device, when transferring from the first state where one of the first and second carriers is located in the first area to the second state where the other carrier is located in the first area, the first and second The two stages are controlled to maintain any state of close proximity or contact with the first axis, so that the first and second stages move toward the first axis simultaneously.

依此,从第一、第二载台中的一载台位于有液体局部供应的二维面内的第一区域的第一状态,迁移至另一载台位于该第一区域的第二状态时,通过控制装置,控制第一载台与第二载台,使第一、第二载台维持与第一轴方向呈近接状态及接触状态的任一状态,而朝第一轴方向同时移动。藉此,以在第一、第二载台中的至少一载台上形成液浸区域的状态,边防止或抑制从第一、第二载台的间隙泄漏液体,边能从第一状态迁移至第二状态。即,从一载台上保持液体的状态,经过在双方的载台上保持液体的状态,至另一载台上保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。因此,将从第一状态至第二状态的迁移能以短时间进行。According to this, when one of the first and second stages is located in the first region in the two-dimensional plane with partial supply of liquid from the first state, to the second state in which the other stage is located in the first region , through the control device, the first stage and the second stage are controlled, so that the first and second stages maintain any state of being close to or in contact with the first axis direction, and move toward the first axis direction simultaneously. Thereby, in the state where the liquid immersion region is formed on at least one of the first and second stages, while preventing or suppressing leakage of liquid from the gap between the first and second stages, it is possible to transfer from the first state to the second state. That is, from the state of maintaining the liquid on one stage, through the state of maintaining the liquid on both stages, to the state of maintaining the liquid on the other stage, it is possible to make it possible without going through the steps of fully recovering and resupplying the liquid. migrate. Therefore, the transition from the first state to the second state can be performed in a short time.

本发明,依第五观点,提供第一曝光装置,是在投影光学系统与基板之间供应液体,通过该投影光学系统与该液体,通过能量光束使该基板曝光,具备:According to the fifth viewpoint, the present invention provides a first exposure device, which supplies a liquid between the projection optical system and the substrate, and exposes the substrate with an energy beam through the projection optical system and the liquid, and has:

第一载台,能在包含待供应该液体的该投影光学系统正下方的第一区域、与位于该投影光学系统的第一轴方向一侧的第二区域的既定范围区域内移动;The first stage can move within a predetermined area including a first area directly below the projection optical system to which the liquid is to be supplied, and a second area located on one side of the projection optical system in the direction of the first axis;

第二载台,能在包含该第一区域、与位于该投影光学系统的第一轴方向的另一侧的第三区域的区域内移动;The second stage can move within the area including the first area and the third area located on the other side of the projection optical system in the direction of the first axis;

载台驱动系统,使该第一、第二载台驱动,并且使从一载台位于该第一区域的第一状态迁移至另一载台位于该第一区域的第二状态时,使该第一载台与第二载台,维持与该第一轴方向呈近接状态及接触状态的任一状态,并将该第一、第二载台朝该第一轴方向同时驱动;The carrier driving system drives the first and second carriers, and when transferring from the first state where one carrier is located in the first area to the second state where the other carrier is located in the first area, the The first stage and the second stage maintain any state of being close to or in contact with the first axis, and simultaneously drive the first and second stages toward the first axis;

第一标记检测系统,配置于该第二区域上方,供检测存在于该第一载台上的标记;及a first mark detection system configured above the second area for detecting marks present on the first stage; and

第二标记检测系统,配置于该第三区域上方,供检测存在于该第二载台上的标记。The second mark detection system is configured above the third area for detecting marks existing on the second stage.

依此,使从一载台位于待供应液体的投影光学系统正下方的第一区域的第一状态迁移至另一载台位于第一区域的第二状态时,通过载台驱动系统,维持第一、第二载台与第一轴方向呈近接状态及接触状态,使该第一、第二载台朝第一轴方向同时驱动。因此,以在投影光学系统与其正下方的至少一载台上保持着液体的状态,边防止或抑制从第一、第二载台的间隙泄漏液体,边能从第一状态迁移至第二状态。即,从使用一载台进行通过投影光学系统与液体的基板的曝光动作后,至使用另一载台开始通过投影光学系统与液体的基板的曝光动作为止期间,从一载台与投影光学系统之间保持液体的状态,经过在双方的载台与投影光学系统之间保持液体的状态,至另一载台与投影光学系统之间保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。因此,将使用一载台的曝光动作结束后的使用另一载台的曝光动作,能以短时间开始。又,在投影光学系统的像面侧,因持续存在液体,故能有效地防止在投影光学系统的像面侧的光学构件产生前述的水纹(水痕)。又,因能分别一起进行对第一载台上的基板的曝光动作与以第二的标记检测系统的第二载台上的基板的标记检测动作(对准动作),及对第二载台上的基板的曝光动作与以第一的标记检测系统的第一载台上的基板的标记检测动作(对准动作),故相较于使用一个载台将基板交换、标记检测(对准)及曝光动作逐次进行的情形,能期待产能的提高。Accordingly, when transferring from the first state where one stage is located in the first area directly under the projection optical system to be supplied with liquid to the second state where the other stage is located in the first area, the stage driving system maintains the first state. 1. The second stage is in a close state and in contact with the first axis, so that the first and second stages are simultaneously driven toward the first axis. Therefore, with the projection optical system and at least one stage immediately below it holding the liquid, while preventing or suppressing liquid leakage from the gap between the first and second stages, the transition from the first state to the second state is possible. . That is, during the period from the exposure operation of the substrate passing through the projection optical system and the liquid using one stage to the start of the exposure operation of the substrate passing through the projection optical system and liquid using the other stage, from one stage and the projection optical system Maintain the state of liquid between the stage and the projection optical system on both sides, and maintain the state of liquid between the stage and the projection optical system on both sides. It is not necessary to recover the liquid and resupply it steps to make it migrate. Therefore, the exposure operation using the other stage can be started in a short time after the exposure operation using the other stage is completed. Furthermore, since the liquid continues to exist on the image plane side of the projection optical system, it is possible to effectively prevent the above-mentioned water streaks (water marks) from being generated on the optical members on the image plane side of the projection optical system. Moreover, since the exposure operation to the substrate on the first stage and the mark detection operation (alignment operation) on the substrate on the second stage by the second mark detection system can be performed separately, and the second stage The exposure operation of the substrate on the first mark detection system and the mark detection operation (alignment operation) of the substrate on the first stage of the first mark detection system, so compared with using one stage to exchange substrates and mark detection (alignment) And when the exposure operation is performed sequentially, an increase in productivity can be expected.

本发明,依第六观点,提供第二曝光装置,是在投影光学系统与基板之间供应液体,通过该投影光学系统与液体,通过能量光束使该基板曝光,具备:According to the sixth point of view, the present invention provides a second exposure device, which supplies liquid between the projection optical system and the substrate, and exposes the substrate with an energy beam through the projection optical system and the liquid, and has:

第一载台,能在包含供应该液体的该投影光学系统正下方的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围区域内移动,且能载置该基板;The first stage can move within a predetermined area including a first area directly below the projection optical system where the liquid is supplied, and a second area located on one side of the first axis direction of the first area, and can carry place the substrate;

第二载台,能在包含该第一区域、与位于该第一区域的第一轴方向的另一侧的第三区域的区域内移动,且用于既定的测量;及a second stage capable of moving within a region including the first region and a third region located on the other side of the first axis in the direction of the first axis, and used for predetermined measurements; and

载台驱动系统,使该第一、第二载台驱动,并且使从一载台位于该第一区域的第一状态迁移至另一载台位于该第一区域的第二状态时,使该第一载台与该第二载台,维持与该第一轴方向呈近接状态及接触状态的任一状态,并将该第一载台与第二载台朝该第一轴方向同时驱动。The carrier driving system drives the first and second carriers, and when transferring from the first state where one carrier is located in the first area to the second state where the other carrier is located in the first area, the The first stage and the second stage maintain any state of being close to or in contact with the first axis, and simultaneously drive the first stage and the second stage toward the first axis.

依此,从一载台位于待供应液体的投影光学系统正下方的第一区域的第一状态迁移至另一载台位于第一区域的第二状态时,通过载台驱动系统,第一、第二载台,维持与第一轴方向呈近接状态及接触状态的任一状态,使第一、第二载台向第一轴方向同时驱动。因此,以在投影光学系统与位于其正下方的至少一载台之间保持着液体的状态,边防止或抑制从第一载台与第二载台的间隙泄漏液体,边能从第一状态迁移至第二状态。即,对第一载台上的基板通过投影光学系统与液体进行基板的曝光动作后,至使用第二载台在投影光学系统正下方开始测量为止期间,从第一载台与投影光学系统之间保持液体的状态,经过在双方的载台与投影光学系统之间保持液体的状态,至第二载台与投影光学系统之间保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。又,对第二载台结束测量后,至对第一载台开始曝光为止,也同样。因此,将使用第一载台的曝光动作结束后的使用第二载台的测量动作,及使用第二载台的测量动作结束后的使用第一载台的曝光动作,能以短时间开始,能获得产能的提高。又,在投影光学系统的像面侧,因持续存在液体,故能有效地防止在投影光学系统的像面侧的光学构件产生前述的水纹(水痕)。又,将使用第一载台的基板的曝光动作与使用第二载台的基板的检测动作,依测量动作能一起进行。According to this, when transferring from the first state where one stage is located in the first area directly below the projection optical system to be supplied with liquid to the second state where the other stage is located in the first area, through the stage drive system, the first, The second stage is maintained in any state of proximity or contact with the first axial direction, and the first and second stages are simultaneously driven in the first axial direction. Therefore, in a state where the liquid is held between the projection optical system and at least one stage located directly below it, while preventing or suppressing leakage of the liquid from the gap between the first stage and the second stage, it is possible to obtain the liquid from the first state. Transition to the second state. That is, after the substrate on the first stage is exposed to the substrate through the projection optical system and the liquid, until the second stage is used to start measurement directly under the projection optical system, the distance between the first stage and the projection optical system is The state of liquid is maintained between the stage and the projection optical system of both sides, and the state of liquid is maintained between the second stage and the projection optical system. It is not necessary to go through the steps of full recovery and resupply of the liquid , enabling migration. The same applies to the period from the end of the measurement on the second stage to the start of exposure on the first stage. Therefore, the measurement operation using the second stage after the exposure operation using the first stage is completed, and the exposure operation using the first stage after the measurement operation using the second stage is completed can be started in a short time, Ability to increase productivity. Furthermore, since the liquid continues to exist on the image plane side of the projection optical system, it is possible to effectively prevent the above-mentioned water streaks (water marks) from being generated on the optical members on the image plane side of the projection optical system. In addition, the exposure operation of the substrate using the first stage and the detection operation of the substrate using the second stage can be performed together according to the measurement operation.

本发明,依第七观点,提供第三曝光装置,是在投影光学系统与基板之间供应液体,通过该投影光学系统与液体,使该基板曝光,具备:According to the seventh viewpoint, the present invention provides a third exposure device, which supplies liquid between the projection optical system and the substrate, and exposes the substrate through the projection optical system and the liquid, comprising:

第一载台,能在包含供应该液体的该投影光学系统正下方的第一区域、与位于该第一区域的第一轴方向一侧的第二区域的既定范围区域内移动;The first stage can move within a predetermined area including a first area directly below the projection optical system where the liquid is supplied, and a second area located on one side of the first axis in the direction of the first axis;

第二载台,能在包含该第一区域与该第二区域的区域内,与该第一载台独立移动;及a second carrier capable of moving independently of the first carrier within an area including the first area and the second area; and

载台驱动系统,使该第一、第二载台驱动,并且使从一载台位于该第一区域的第一状态迁移至另一载台位于该第一区域的第二状态时,使该第一载台与该第二载台,维持于与该第一轴方向交叉的第二轴方向上呈近接状态及接触状态的任一状态,并将该第一、第二载台朝该第二轴方向同时驱动。The carrier driving system drives the first and second carriers, and when transferring from the first state where one carrier is located in the first area to the second state where the other carrier is located in the first area, the The first stage and the second stage are maintained in any state of close proximity or contact state in the second axial direction intersecting with the first axial direction, and the first and second stages are moved toward the second axial direction. The two axes are driven simultaneously.

依此,从一载台位于待供应液体的投影光学系统正下方的第一区域的第一状态迁移至另一载台位于第一区域的第二状态时,通过载台驱动系统,第一、第二载台,维持与第二轴方向(与第一区域与第二区域所排列的第一方向的方向交叉)呈近接状态及接触状态的任一状态,使第一、第二载台向第二轴方向同时驱动。因此,以在投影光学系统与位于其正下方的至少一载台之间保持着液体的状态,边防止或抑制从第一载台与第二载台的间隙泄漏液体,边能从第一状态迁移至第二状态。即,在一载台侧通过投影光学系统与液体进行基板的曝光动作后,至在另一载台侧通过投影光学系统与液体开始基板的曝光动作为止期间,从一载台与投影光学系统之间保持液体的状态,经过在双方的载台与投影光学系统之间保持液体的状态,至另一载台与投影光学系统之间保持液体的状态,不必经过液体的全回收、再度供应的步骤,能使其迁移。因此,将使用一载台的曝光动作结束后的使用第二载台的测量动作,及使用第二载台的测量动作结束后的使用另一载台的曝光动作,能以短时间开始,能获得产能的提高。又,在投影光学系统的像面侧,因持续存在液体,故能有效地防止在投影光学系统的像面侧的光学构件产生前述的水纹(水痕)。According to this, when transferring from the first state where one stage is located in the first area directly below the projection optical system to be supplied with liquid to the second state where the other stage is located in the first area, through the stage drive system, the first, The second carrier maintains either the proximity state or the contact state with the second axis direction (the direction intersecting the first direction in which the first region and the second region are arranged), so that the first and second stages move toward each other. The direction of the second axis is driven simultaneously. Therefore, in a state where the liquid is held between the projection optical system and at least one stage located directly below it, while preventing or suppressing leakage of the liquid from the gap between the first stage and the second stage, it is possible to obtain the liquid from the first state. Transition to the second state. That is, after the exposure operation of the substrate is performed by the projection optical system and the liquid on the one stage side, until the exposure operation of the substrate is started by the projection optical system and the liquid on the other stage side, from one stage to the projection optical system Maintain the liquid state between the stage and the projection optical system on both sides, and keep the liquid state between the other stage and the projection optical system, without going through the steps of full recovery and resupply of the liquid , enabling migration. Therefore, the measurement operation using the second stage after the exposure operation using one stage is completed, and the exposure operation using the other stage after the measurement operation using the second stage is completed can be started in a short time. Gain increased productivity. Furthermore, since the liquid continues to exist on the image plane side of the projection optical system, it is possible to effectively prevent the above-mentioned water streaks (water marks) from being generated on the optical members on the image plane side of the projection optical system.

本发明,依第八观点,提供第四曝光装置,是在投影光学系统与基板之间供应液体,通过该投影光学系统与该液体,使该基板曝光,具备:According to the eighth viewpoint, the present invention provides a fourth exposure device, which supplies liquid between the projection optical system and the substrate, and exposes the substrate through the projection optical system and the liquid, comprising:

第一载台,能在包含待供应该液体的该投影光学系统正下方的第一区域、及与该第一区域不同区域的区域内移动;a first stage capable of moving within an area including a first area immediately below the projection optical system to which the liquid is to be supplied, and an area different from the first area;

第二载台,能在包含该第一区域、及与该第二区域不同区域的区域内,与该第一载台独立移动;a second carrier capable of moving independently of the first carrier in an area including the first area and an area different from the second area;

载台驱动系统,使该第一、第二载台驱动,并且使从一载台位于该第一区域的第一状态迁移至另一载台位于该第一区域的第二状态时,使该第一载台与该第二载台,维持与既定方向呈近接状态,并将该第一、第二载台朝该既定方向同时驱动;及The carrier driving system drives the first and second carriers, and when transferring from the first state where one carrier is located in the first area to the second state where the other carrier is located in the first area, the The first stage and the second stage are kept close to a predetermined direction, and the first and second stages are simultaneously driven toward the predetermined direction; and

抑制构件,设置于该第一载台及该第二载台的至少一方,从该第一状态迁移至该第二状态时其位于该两载台的间隙,藉此来防止该液体从该间隙泄漏。The restraining member is arranged on at least one of the first stage and the second stage, and it is located in the gap between the two stages when it moves from the first state to the second state, thereby preventing the liquid from passing through the gap. leakage.

依此,从能在包含投影光学系统正下方的第一区域、及与该第一区域不同区域的区域内移动的第一、第二载台的一载台,位于第一区域的第一状态,迁移至另一载台位于第一区域的第二状态时,通过使第一载台与第二载台与第一轴方向呈近接状态,并且使抑制构件(设置于第一、第二载台的至少一方,用以抑制液体的泄漏)以位于两载台的间隙的状态朝该既定方向同时驱动,从第一状态迁移至第二状态时,故能极力防止液体从两载台之间泄漏。According to this, the first state located in the first area from one of the first and second stages that can move in the area including the first area directly below the projection optical system and the area different from the first area When moving to the second state where another stage is located in the first area, the first stage and the second stage are placed in a close state to the first axis direction, and the restraining member (set on the first and second stages) At least one side of the stage, used to suppress the leakage of liquid) is simultaneously driven in the predetermined direction in the state of being located in the gap between the two stages, and when moving from the first state to the second state, it can prevent the liquid from flowing between the two stages as much as possible. leakage.

又,在光刻步骤,使用本发明的各第一~第四曝光装置,以该能量光束来使基板曝光,藉此,能将元件图案精度良好地转印在基板上,结果能提高高集成度的微元件的生产性。因此,本发明,进一步从另一观点来看,也可称元件制造方法,其包含使用本发明的第一~第四曝光装置的任一种,以该能量光束使基板曝光的光刻步骤。In addition, in the photolithography step, each of the first to fourth exposure devices of the present invention is used to expose the substrate with the energy beam, whereby the device pattern can be transferred onto the substrate with good accuracy, and as a result, high integration can be improved. Degree of productivity of micro components. Therefore, the present invention can also be referred to as a device manufacturing method from another viewpoint, including a photolithography step of exposing a substrate with the energy beam using any one of the first to fourth exposure apparatuses of the present invention.

附图说明Description of drawings

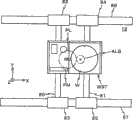

图1是表示第一实施形态的曝光装置的概略图。FIG. 1 is a schematic diagram showing an exposure apparatus according to a first embodiment.

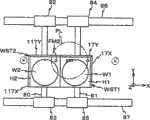

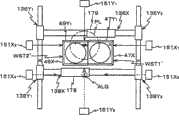

图2是表示第一实施形态的晶片载台装置的俯视图。Fig. 2 is a plan view showing the wafer stage device according to the first embodiment.

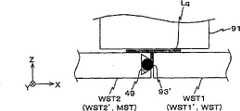

图3是表示图2的晶片载台WST1的立体图。FIG. 3 is a perspective view showing wafer stage WST1 of FIG. 2 .

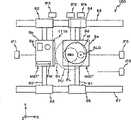

图4是表示液体供排机构的概略俯视图。Fig. 4 is a schematic plan view showing a liquid supply and discharge mechanism.

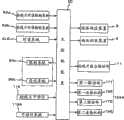

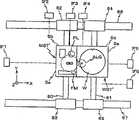

图5是表示第一实施形态的曝光装置的控制系统主要构成的方块图。Fig. 5 is a block diagram showing the main configuration of the control system of the exposure apparatus according to the first embodiment.

图6是用以说明并行处理动作的两个晶片载台的驱动方法的图(其1)。FIG. 6 is a diagram (Part 1) for explaining a method of driving two wafer stages in parallel processing operations.

图7是用以说明并行处理动作的两个晶片载台的驱动方法的图(其2)。FIG. 7 is a diagram (Part 2 ) for explaining a method of driving two wafer stages in a parallel processing operation.

图8是用以说明并行处理动作的两个晶片载台的驱动方法的图(其3)。FIG. 8 is a diagram (part 3 ) for explaining a method of driving two wafer stages in a parallel processing operation.

图9是用以说明并行处理动作的两个晶片载台的驱动方法的图(其4)。FIG. 9 is a diagram (part 4 ) for explaining a method of driving two wafer stages in a parallel processing operation.

图10是表示弹性密封构件的图。Fig. 10 is a diagram showing an elastic sealing member.

图11是表示第二实施形态的曝光装置的控制系统主要构成的方块图。Fig. 11 is a block diagram showing a main configuration of a control system of an exposure apparatus according to a second embodiment.

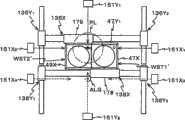

图12是表示第二实施形态的晶片载台装置的俯视图。Fig. 12 is a plan view showing a wafer stage device according to a second embodiment.

图13A是用以说明第二实施形态的并行处理动作的两个晶片载台的驱动方法的图(其1)。13A is a diagram (Part 1) for explaining a method of driving two wafer stages in a parallel processing operation according to the second embodiment.

图13B是用以说明第二实施形态的并行处理动作的两个晶片载台的驱动方法的图(其1)。Fig. 13B is a diagram (Part 1) for explaining a method of driving two wafer stages in a parallel processing operation according to the second embodiment.

图14A是用以说明第二实施形态的并行处理动作的两个晶片载台的驱动方法的图(其2)。Fig. 14A is a diagram (Part 2) for explaining a method of driving two wafer stages in a parallel processing operation according to the second embodiment.

图14B是用以说明第二实施形态的并行处理动作的两个晶片载台的驱动方法的图(其2)。Fig. 14B is a diagram (Part 2) for explaining a method of driving two wafer stages in a parallel processing operation according to the second embodiment.

图15A是用以说明第二实施形态的并行处理动作的两个晶片载台的驱动方法的图(其3)。Fig. 15A is a diagram (Part 3) for explaining a method of driving two wafer stages in a parallel processing operation according to the second embodiment.

图15B是用以说明第二实施形态的并行处理动作的两个晶片载台的驱动方法的图(其3)。Fig. 15B is a diagram (Part 3) for explaining the driving method of two wafer stages in the parallel processing operation of the second embodiment.

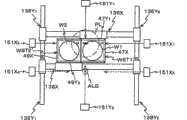

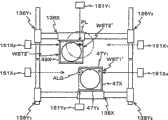

图16是表示第三实施形态的晶片载台装置的俯视图。Fig. 16 is a plan view showing a wafer stage device according to a third embodiment.

图17A是用以说明第三实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其1)。17A is a diagram (Part 1) for explaining a method of driving a wafer stage and a measurement stage in a parallel processing operation according to the third embodiment.

图17B是用以说明第三实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其1)。Fig. 17B is a diagram (Part 1) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation according to the third embodiment.

图18A是用以说明第三实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其2)。Fig. 18A is a diagram (part 2) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation according to the third embodiment.

图18B是用以说明第三实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其2)。18B is a diagram (Part 2) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation of the third embodiment.

图19A是用以说明抑制构件的变形例的图。FIG. 19A is a diagram for explaining a modified example of the restraining member.

图19B是用以说明抑制构件的变形例的图。FIG. 19B is a diagram for explaining a modified example of the suppressing member.

图19C是用以说明抑制构件的变形例的图。FIG. 19C is a diagram for explaining a modified example of the suppression member.

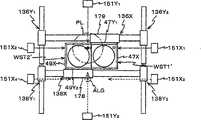

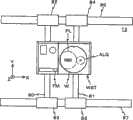

图20是表示第四实施形态的晶片载台装置的俯视图。Fig. 20 is a plan view showing a wafer stage device according to a fourth embodiment.

图21是表示晶片载台与测量载台近接状态的图。Fig. 21 is a diagram showing a state in which a wafer stage and a measurement stage approach each other.

图22A是用以说明第四实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其1)。Fig. 22A is a diagram (Part 1) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation according to the fourth embodiment.

图22B是用以说明第四实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其1)。Fig. 22B is a diagram (Part 1) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation according to the fourth embodiment.

图23A是用以说明第四实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其2)。Fig. 23A is a diagram (Part 2) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation according to the fourth embodiment.

图23B是用以说明第四实施形态的并行处理动作的晶片载台与测量载台的驱动方法的图(其2)。Fig. 23B is a diagram (Part 2) for explaining the method of driving the wafer stage and the measurement stage in the parallel processing operation according to the fourth embodiment.

图24是用以说明第四实施形态的变形例的图(其1)。Fig. 24 is a diagram (No. 1) for explaining a modified example of the fourth embodiment.

图25A是用以说明第四实施形态的变形例的图(其2)。Fig. 25A is a diagram (No. 2) for explaining a modified example of the fourth embodiment.

图25B是用以说明第四实施形态的变形例的图(其2)。Fig. 25B is a diagram (No. 2) for explaining a modified example of the fourth embodiment.

图26是用以说明本发明的元件制造方法的流程图。Fig. 26 is a flow chart for explaining the device manufacturing method of the present invention.

图27是表示图26的步骤204的具体例的流程图。FIG. 27 is a flowchart showing a specific example of step 204 in FIG. 26 .

主要元件符号说明:Description of main component symbols:

5:液体供应装置5: Liquid supply device

6:液体回收装置6: Liquid recovery device

10:照明系统10: Lighting system

11:标线片载台驱动部11: Reticle stage drive unit

12:基盘12: base plate

15:移动镜15: Moving Mirror

16、18:X轴干涉计16, 18: X-axis interferometer

17X、117X:X移动镜17X, 117X: X moving mirror

17Y、117Y:Y移动镜17Y, 117Y: Y moving mirror

20:主控制装置20: Master control device

21、22、27、28:供应管21, 22, 27, 28: supply pipe

21a、21b、21c、22a、22b、22c、27a、28a:供应嘴21a, 21b, 21c, 22a, 22b, 22c, 27a, 28a: supply nozzle

23、24、29、30:回收管23, 24, 29, 30: Recovery tube

23a、23b、24a、24b、29a、29b、30a、30b:回收嘴23a, 23b, 24a, 24b, 29a, 29b, 30a, 30b: Recovery nozzle

32:液体供排系统32: Liquid supply and drainage system

40:镜筒40: lens barrel

44、46、48:Y轴干涉计44, 46, 48: Y-axis interferometer

47X、49X:X移动镜47X, 49X: X moving mirror

47Y1、47Y2、49Y1、49Y2:Y移动镜47Y1 , 47Y2 , 49Y1 , 49Y2 : Y moving mirror

49、49’:槽49, 49': Groove

50、50’、50”:晶片载台装置50, 50’, 50”: wafer stage device

70:本体部70: Main body

72a~72d:辅助板72a~72d: auxiliary board

80~87:晶片载台驱动部80~87: Wafer stage drive unit

80、81、136Y1、136Y2、138Y1、138Y2、186、187、188、189:Y轴线性导件(Y轴线性发动机)80, 81, 136Y1 , 136Y2 , 138Y1 , 138Y2 , 186, 187, 188, 189: Y-axis linear guide (Y-axis linear engine)

82、83、84、85、86、87、136X、138X、180、181:X轴线性导件(X轴线性发动机)82, 83, 84, 85, 86, 87, 136X, 138X, 180, 181: X-axis linear guide (X-axis linear engine)

90a:照射系统90a: Irradiation system

90b:受光系统90b: Light receiving system

91:前端透镜91: front lens

93、93’、93”:密封构件、弹性密封构件93, 93’, 93”: sealing member, elastic sealing member

94:平板94: tablet

95:泼水被膜95: water splash film

100:曝光装置100: exposure device

111a:凸缘部111a: flange part

111b:段部111b: section

111c:突部111c: protrusion

116:标线片干涉计116: Reticle interferometer

118、118A:干涉计系统118, 118A: Interferometer system

124、124A:晶片载台驱动部124, 124A: wafer stage drive unit

151X1、151X2、151X3、151X4、151Y1、151Y2:干涉计151X1 , 151X2 , 151X3 , 151X4 , 151Y1 , 151Y2 : Interferometer

171:第一驱动部171: First drive unit

172:第二驱动部172: Second drive unit

178、179:X可动件178, 179: X movable parts

182、183、184、185:Y可动件182, 183, 184, 185: Y movable parts

195:第一连接机构195: First connection mechanism

196:第二连接机构196: Second connection mechanism

ALG1、ALG2:对准系统ALG1, ALG2: alignment system

B11X、B12X、B11Y、B12Y、B13Y:测轴B11X, B12X, B11Y, B12Y, B13Y: measuring axis

AX:光轴AX: optical axis

FM1、FM2:基准标记板FM1, FM2: Fiducial Marker Plate

H1、H2:晶片保持具H1, H2: wafer holder

IA:曝光区域IA: Exposure Area

IF1、IF5、IF6:X轴干涉计IF1, IF5, IF6: X-axis interferometer

IF2、IF3、IF4:Y轴干涉计IF2, IF3, IF4: Y-axis interferometer

IL:照明用光(曝光用光)IL: Light for illumination (light for exposure)

Lq:液体Lq: liquid

MST、MST’:测量载台MST, MST’: measurement stage

PL:投影光学系统PL: projection optics

PU:投影单元PU: projection unit

R:标线片R: Reticle

RAa、Rab:标线片对准检测系统RAa, Rab: Reticle Alignment Detection System

RST:标线片载台RST: Reticle Stage

Sb、Sc、Se:端面Sb, Sc, Se: end face

W1、W2:晶片W1, W2: chip

WST1、WST2、WST1’、WST2’、WST1”、WST2”:晶片载台WST1, WST2, WST1’, WST2’, WST1”, WST2”: wafer stage

具体实施方式Detailed ways

第一实施形态:The first form of implementation:

以下,依图1~图10说明本发明的第一实施形态。Hereinafter, a first embodiment of the present invention will be described with reference to FIGS. 1 to 10 .

在图1,表示第一实施形态的曝光装置100的概略构成。此曝光装置100,是步进扫描(step and scan)方式的投影曝光装置,即所谓扫描步进机(也称为扫描机)。此曝光装置100具备:照明系统10;标线片载台RST,用以保持当作掩膜使用的标线片R;投影单元PU;晶片载台装置50,具有当作第一、第二载台使用的晶片载台WST1、WST2;偏轴对准(off axisalignment)系统ALG1、ALG2,当作第一、第二标记检测系统;及这些构件的控制系统。在晶片载台WST1、WST2上,载置作为基板的晶片。在图1,在晶片载台WST1上载置晶片W1,在晶片载台WST2上载置晶片W2。FIG. 1 shows a schematic configuration of an

前述照明系统10,例如日本特开2001-313250号公报及对应于此的美国专利申请公开第2003/0025890号说明书所揭示,包含:光源、照度均匀化光学系统(含有光学积分器)、分束器、中继透镜、可变ND滤光片、标线片遮帘等(均未图标)。此照明系统10,将标线片遮帘所限制的标线片R上的狭缝状照明区域,通过照明用光(曝光用光)IL(作为能量光束)以大致均匀的照度照明。在此,照明用光IL,作为一例,使用ArF准分子激光(波长193nm)。又,光学积分器,能使用复眼透镜、杆式积分器(内面反射型积分器)或绕射光学元件等。其它,照明系统10,也可采用例如日本特开平6-349701号公报及对应于此的美国专利第5,534,970号等所揭示的构成。在本案所指定的指定国(或所选择的选择国)的国内法令所允许的范围,援用上述各公报及对应于此的美国专利申请公开说明书或美国专利的揭示,作为本说明书的记载的一部分。The

在前述标线片载台RST上,将形成电路图案等于其图案面(在图1是下面)的标线片R,例如通过真空吸附固定。标线片载台RST,例如通过包含线性发动机等的标线片载台驱动部11(在图1未图标,参照图5),能在垂直于照明系统10的光轴(一致于后述的投影光学系统PL的光轴AX)的XY平面内微驱动,并且能朝既定的扫描方向(在此,设为与图1纸面正交方向的Y轴方向)以所指定的扫描速度驱动。On the reticle stage RST, the reticle R on which the circuit pattern is formed equal to the pattern surface (lower side in FIG. 1 ) is fixed, for example, by vacuum suction. The reticle stage RST, for example, can be driven vertically to the optical axis of the illumination system 10 (consistent with the following description) by a reticle stage drive unit 11 (not shown in FIG. 1 , see FIG. 5 ) including a linear motor or the like. The optical axis AX) of the projection optical system PL is slightly driven in the XY plane, and can be driven at a predetermined scanning speed in a predetermined scanning direction (here, the Y-axis direction perpendicular to the paper surface of FIG. 1 ).

标线片载台RST的载台移动面内的位置,是通过标线片激光干涉计(以下称为“标线片干涉计”)116,通过移动镜15,例如以0.5~1nm程度的分解能持续检测。在此,实际上,虽在标线片载台RST上设置具有正交于Y轴方向的反射面的Y移动镜与具有正交于X轴方向的反射面的X移动镜,对应这些移动镜设置标线片Y干涉计与标线片X干涉计,但在图1以移动镜15、标线片干涉计116为代表这些元件来表示。又,也可例如将标线片载台RST的端面镜面加工来形成反射面(相当于上述的X移动镜、Y移动镜的反射面)。又,替代朝X轴方向延伸的反射面(使用于标线片载台RST的扫描方向(在本实施形态是Y轴方向)的位置检测),也可使用至少一个直角反射镜(corner cube mirror)(例如retroreflector)。在此,标线片Y干涉计与标线片X干涉计的一方,例如标线片Y干涉计,是具有2轴测长轴的2轴干涉计,根据此标线片Y干涉计的测量值,除了标线片载台RST的Y位置外,也能测量Z轴周围的旋转方向(θz方向)的旋转。The position in the stage movement plane of the reticle stage RST is determined by the reticle laser interferometer (hereinafter referred to as "reticle interferometer") 116 and the moving

标线片干涉计116的测量值,送至主控制装置20(在图1未图标,参照图5),主控制装置20,根据此标线片干涉计116的测量值算出标线片载台RST的X、Y、θz方向的位置,并且根据此算出结果控制标线片载台驱动部11,藉此来控制标线片载台RST的位置(及速度)。The measured value of the

在标线片R的上方,将使用曝光波长的光的TTR(Through The Reticle)对准系统所构成的一对标线片对准检测系统RAa、RAb沿X轴方向隔既定距离设置,用以通过投影光学系统PL将标线片R上的标线片标记与所对应的基准标记板上的基准标记同时观察。此等标线片对准检测系统RAa、RAb,使用例如与日本特开平7-176468号公报及对应于此的美国专利第5,646,413号等所揭示的同样的构成。在本案所指定的指定国(或所选择的选择国)的国内法令所允许的范围,援用上述公报及对应于此的美国专利的揭示,作为本说明书的记载的一部分。Above the reticle R, a pair of reticle alignment detection systems RAa and RAb composed of a TTR (Through The Reticle) alignment system using light at the exposure wavelength are set at a predetermined distance along the X-axis direction for The reticle marks on the reticle R and the fiducial marks on the corresponding fiducial mark plate are simultaneously observed by the projection optical system PL. These reticle alignment detection systems RAa and RAb use, for example, the same configuration as those disclosed in JP-A-7-176468 and US Pat. No. 5,646,413 corresponding thereto. To the extent permitted by the domestic laws and regulations of the designated country (or selected country) designated in this case, the disclosures of the above-mentioned publications and the corresponding US patents are cited as part of the description of this specification.

投影单元PU,配置于图1的标线片载台RST的下方。投影单元PU,包含:镜筒40;及投影光学系统PL,由在该镜筒40内以既定的位置关系保持的多个光学元件组成。投影光学系统PL,例如使用由具有Z轴方向的共同光轴AX的多个透镜(透镜元件)所构成的折射光学系统。此投影光学系统PL,例如在两侧远心具有既定的投影倍率(例如1/4倍、1/5倍或1/8倍)。因此,若以来自照明系统10的照明用光IL使标线片R的照明区域照明,由通过此标线片R的照明用光IL,通过投影单元PU(投影光学系统PL),将该照明区域内的标线片R的电路图案的缩小像(电路图案的一部分的缩小像)形成于在表面涂布有光刻胶(感光剂)的晶片上。Projection unit PU is disposed below reticle stage RST in FIG. 1 . Projection unit PU includes:

又,在本实施形态的曝光装置100,如后述由于是进行适用液浸法的曝光,故伴随数值孔径NA实质上增大,标线片侧的孔径也变大。因此,在仅以透镜构成的折射光学系统,要满足珀兹伐(Petzval)条件变成困难,而有使投影光学系统大型化的趋势。为了要避免这种投影光学系统的大型化,也可使用包含反射镜与透镜所构成的反射折射系统(catadioptric系统)。In addition, in the

又,本实施形态,在构成投影光学系统PL的最像面侧(晶片侧)的透镜(以下,称为“前端透镜”)91与晶片载台WST1或WST2上的晶片之间(或前端透镜91与晶片载台WST1或WST2之间),设置用以局部供应液体的液体供排系统32。在图1,表示构成此液体供排单元之嘴,来代表液体供排系统32。又,对液体供排系统32的构成等,将予后述。In addition, in this embodiment, between the lens (hereinafter referred to as "tip lens") 91 on the most image plane side (wafer side) constituting projection optical system PL and the wafer on wafer stage WST1 or WST2 (or the

前述晶片载台装置50具备:基盘12;晶片载台WST1、WST2,配置于该基盘12上面的上方;干涉计系统118(参照图5),包含用来测量所述晶片载台WST1、WST2的位置的干涉计的位置测量装置;及晶片载台驱动部124(参照图5),用以驱动晶片载台WST1、WST2。The aforementioned

在晶片载台WST1、WST2的底面,将未图标的非接触轴承,例如真空预压型空气静压轴承(以下,称为「气垫」)设置于多个位置,由从所述气垫朝基盘12上面所喷出的加压空气的静压,在基盘12上面的上方将晶片载台WST1、WST2通过数μm程度的间隙非接触地浮起支撑。又,晶片载台WST1、WST2,由晶片载台驱动部124,独立于X轴方向(图1纸面内的左右方向)及Y轴方向(与图1纸面正交的方向)能沿二维方向驱动。On the bottom surfaces of wafer stages WST1 and WST2, unillustrated non-contact bearings, such as vacuum preloaded aerostatic bearings (hereinafter referred to as "air cushions"), are provided at multiple positions, and The static pressure of the pressurized air blown from the upper surface floats and supports wafer stages WST1 , WST2 above the upper surface of

在基盘12上,如图2的俯视图所示,将一对X轴线性导件(朝X轴方向延伸的X固定件)86、87沿Y轴方向隔既定间隔配置。这些X轴线性导件86、87,例如由内设永久磁铁群组(沿X轴方向以既定间隔且交替配置的N极磁铁与S极磁铁的多组所构成)的磁极单元来构成。在这些X轴线性导件86、87上方,设置各两个滑件82、84及83、85,形成将所对应的X轴线性导件86、87从上方包围的状态且非接触。即,合计四个滑件82、84、83、85,具有截面倒U字形的形状,形成将X轴线性导件86、87从上方及侧方包围,对所对应的X轴线性导件86、87分别通过未图标的气垫例如以数μm程度的间隙浮起支撑。各滑件82、84、83、85,例如由分别内设沿X轴方向以既定间隔配置的电枢线圈的电枢单元来构成。即,在本实施形态,由电枢单元所构成的滑件82、84与磁极单元所构成的X轴线性导件86,分别构成动圈型的X轴线性发动机。同样地,由滑件83、85与X轴线性导件87,分别构成动圈(moving coil)型的X轴线性发动机。以下,对上述四个各X轴线性发动机,使用与构成各可动件的滑件82、84、83、85相同的符号,称为X轴线性发动机82、X轴线性发动机84、X轴线性发动机83、X轴线性发动机85。On the

上述四个X轴线性发动机中,构成两个X轴线性发动机82、83的滑件,分别固定于Y轴线性导件80(当作朝Y轴方向延伸的Y固定件)的长边方向的一端与另一端。又,构成另外的两个X轴线性发动机84、85的滑件,固定于Y轴线性导件81(当作朝Y轴方向延伸的Y固定件)的一端与另一端。因此,Y轴线性导件80、81,由各一对的X轴线性发动机82、83、84、85,使其沿X轴分别驱动。Among the above-mentioned four X-axis linear motors, the sliders constituting the two X-axis

前述各Y轴线性导件80、81,例如由分别内设沿Y轴方向以既定间隔配置的电枢线圈的电枢单元来构成。The aforementioned Y-axis

一Y轴线性导件81,以插入状态设置于形成在晶片载台WST1的开口。在此晶片载台WST1的上述开口的内部,设置具有永久磁铁群组(例如沿Y轴方向以既定间隔且交替配置的N极磁铁与S极磁铁的多组所构成)的磁极单元。由此磁极单元与Y轴线性导件81,构成将晶片载台WST1沿Y轴方向驱动的动磁型的Y轴线性发动机。同样地,另一Y轴线性导件80,以插入状态设置于形成在晶片载台WST2的开口。在此晶片载台WST2的上述开口的内部,设置与晶片载台WST1侧同样的磁极单元。由此磁极单元与Y轴线性导件80,构成将晶片载台WST2沿Y轴方向驱动的动磁(movingmagnet)型的Y轴线性发动机。在以下,对这些Y轴线性发动机,使用与构成各固定件的线性导件81、80相同的符号,称为Y轴线性发动机81、Y轴线性发动机80。A Y-axis

在本实施形态,包含X轴线性发动机82~85及Y轴线性发动机80、81,来构成图5所示的晶片载台驱动部124。构成此晶片载台驱动部124的上述各线性发动机,则由图5所示的主控制装置20控制。In this embodiment, the wafer

又,由使一对X轴线性发动机84、85(或82、83)分别所产生的推力稍微不同,能控制晶片载台WST1(或WST2)的偏摇(yawing)。Also, by making the thrusts generated by the pair of X-axis

在本实施形态,各晶片载台WST1、WST2,虽以单一的载台图标,但实际上,具备:载台本体,由Y轴线性发动机81、80分别驱动;晶片台,通过Z·调平驱动机构(例如音圈发动机)载置于该载台本体的上部,对载台本体相对地沿Z轴方向及X轴周围的旋转方向(θx方向)、Y轴周围的旋转方向(θy方向)微驱动。In this embodiment, although each wafer stage WST1, WST2 is shown as a single stage, in fact, it is equipped with: the stage body is driven by the Y-axis

在前述晶片载台WST1上(晶片台上),如图1所示,设置晶片保持具H1,由真空吸附等保持晶片W1。晶片保持具H1,如图3的立体图所示,具备:本体部70,俯视(从上方观察)大致呈正方形;四片辅助板72a~72d,以从上方重叠于本体部70的方式配置于晶片W1的载置区域周围。这些辅助板72a~72d的表面,形成与晶片W1的表面大致相同的高度。又,辅助板72a~72d,也可由一个构件构成。又,若能在投影光学系统PL的像面侧保持液体Lq,也可在晶片表面与辅助板表面之间有段差。On the aforementioned wafer stage WST1 (wafer stage), as shown in FIG. 1, a wafer holder H1 is provided, and the wafer W1 is held by vacuum suction or the like. The wafer holder H1, as shown in a perspective view of FIG. Around the mounting area of W1. The surfaces of these auxiliary plates 72a to 72d are formed at approximately the same height as the surface of the wafer W1. Also, the auxiliary plates 72a to 72d may be constituted by one member. Also, if the liquid Lq can be held on the image plane side of the projection optical system PL, there may be a level difference between the wafer surface and the auxiliary plate surface.

在晶片载台WST1的上面,将X移动镜17X(在X轴方向的一端(+X侧端)具有与X轴正交的反射面)朝Y轴方向延设,将Y移动镜17Y(在Y轴方向的一端(+Y侧端)具有与Y轴正交的反射面)朝X轴方向延设。对这些移动镜17X、17Y的各反射面,如图2所示,将来自构成后述的干涉计系统118(参照图5)的干涉计的干涉计光束(测长光束)投射,由以各干涉计接收该反射光,将从各移动镜反射面的基准位置(一般是在投影单元PU侧面,或对准系统ALG1的侧面配置固定反射镜,以此为基准面)的位移测量,藉此,测量晶片载台WST1的二维位置。较佳者为移动镜17X、17Y的上面也设为与晶片W1大致相同的高度。On the upper surface of wafer stage WST1, an X

在此,如图3所示,在各辅助板72a~72d与晶片W1之间,虽存在间隙D,但间隙D的尺寸,是以成为0.1~1mm的方式设定。又,在晶片W1,虽在其一部分存在缺口(V字形的缺口),但因此缺口的尺寸也是仅1mm程度,故省略图标。Here, as shown in FIG. 3 , there is a gap D between each of the auxiliary plates 72 a to 72 d and the wafer W1 , but the size of the gap D is set to be 0.1 to 1 mm. In addition, although there is a notch (V-shaped notch) in part of the wafer W1, the size of the notch is also only about 1 mm, so the illustration is omitted.

又,辅助板72a,在其一部分形成圆形开口,在其开口内,嵌入基准标记板FM1。基准标记板FM1,是使其表面与辅助板72a为大致同一面。在基准标记板FM1的表面,形成至少一对标线片对准用的第一基准标记,及如后述以对准系统ALG1所检测的第二基准标记(均未图标)等。Moreover, the auxiliary plate 72a has a circular opening formed in a part thereof, and the fiducial mark plate FM1 is fitted into the opening. The fiducial mark plate FM1 has a surface substantially flush with the auxiliary plate 72a. On the surface of fiducial mark plate FM1, at least a pair of first fiducial marks for reticle alignment, second fiducial marks (both not shown) and the like which are detected by alignment system ALG1 as described later are formed.

在前述晶片载台WST2上(晶片台上),如图1所示,设置晶片保持具H2,由真空吸附等保持晶片W2。此晶片保持具H2,是与前述的晶片保持具H1构成同样。因此,在形成于构成此晶片保持具H2的一个辅助板的一部分的圆形开口内,嵌入基准标记板FM2(在图1未图标,参照图2)。On the aforementioned wafer stage WST2 (wafer stage), as shown in FIG. 1, a wafer holder H2 is provided, and the wafer W2 is held by vacuum suction or the like. This wafer holder H2 has the same configuration as the aforementioned wafer holder H1. Therefore, a fiducial mark plate FM2 (not shown in FIG. 1 , see FIG. 2 ) is fitted into a circular opening formed in a part of one auxiliary plate constituting this wafer holder H2 .

又,在晶片载台WST2的上面,将X移动镜117X(在X轴方向的一端(-X侧端)具有与X轴正交的反射面)朝Y轴方向延设,将Y移动镜117Y(在Y轴方向的一端(+Y侧端)具有与Y轴正交的反射面)朝X轴方向延设。对这些移动镜117X、117Y的各反射面,如图2所示,将来自构成后述的干涉计系统118的干涉计的干涉计光束(测长光束)投射,由以各干涉计接收该反射光,将来自各移动镜反射面的基准位置的位移测量,藉此测量晶片载台WST2的二维位置。Further, on the upper surface of wafer stage WST2, an X

又,例如,可将晶片载台WST1、WST2的端面作镜面加工来形成移动镜(相当于前述的移动镜17X、17Y、117X、117Y的反射面)。Also, for example, the end surfaces of wafer stages WST1, WST2 may be mirror-finished to form moving mirrors (corresponding to the reflection surfaces of moving

又,在晶片载台WST1、WST2彼此对向侧的面,例如在晶片载台WST1的-X侧面,在其全面,如图10所示,贴附密封构件93。此密封构件93,例如使用由含氟橡胶等所构成的弹性密封构件。Further, on the surfaces of wafer stages WST1 and WST2 facing each other, for example, on the -X side of wafer stage WST1, a sealing

又,替代晶片载台WST1的-X侧面,也可将密封构件93贴附于晶片载台WST2的+X侧面,也可将密封构件93贴附于晶片载台WST1的-X侧面与晶片载台WST2的+X侧面双方。Also, instead of the -X side surface of wafer stage WST1, the sealing

回到图1,在分别隔相同距离于投影单元PU的+X侧、-X侧的位置,分别配置前述的偏轴对准系统(以下,略述为“对准系统”)ALG1、ALG2。这些对准系统ALG1、ALG2,实际上,是装设于用以保持投影单元PU的保持构件。这些对准系统ALG1、ALG2,例如使用影像处理方式的FIA(FieldImage Alignment)系统的感测器,该影像处理方式,是将对象标记的像(将不使晶片上的光刻胶感光的宽频(broad band)的检测光束照射于对象标记,由来自该对象标记的反射光结像于受光面)与未图标的指针(设置于对准系统ALG1、ALG2内的指针板上的指针图案)的像使用摄影元件(CCD等)来摄影后,将这些摄影信号输出。又,对准系统ALG1、ALG2,不限于FIA系统,将相干(coherent)的检测用光照射于对象标记,检测从该对象标记所产生的散射光或绕射光,或使从该对象标记所产生的两个绕射光(例如同次数的绕射光,或绕射于同方向的绕射光)干涉来检测的对准感测器,单独或适当组合使用当然可能。Referring back to FIG. 1 , the above-mentioned off-axis alignment systems (hereinafter, abbreviated as “alignment systems”) ALG1 and ALG2 are respectively disposed at positions on the +X side and −X side of the projection unit PU at the same distance. These alignment systems ALG1 and ALG2 are actually installed on a holding member for holding projection unit PU. These alignment systems ALG1 and ALG2 are, for example, sensors of the FIA (Field Image Alignment) system using an image processing method, which is an image of an object mark (a broadband ( The detection beam of the broad band) is irradiated on the object mark, and the reflected light from the object mark is imaged on the light receiving surface) and the image of the uniconted pointer (the pointer pattern set on the pointer plate in the alignment system ALG1, ALG2) After imaging is performed using an imaging element (CCD, etc.), these imaging signals are output. In addition, the alignment systems ALG1 and ALG2 are not limited to the FIA system, and irradiate the target mark with coherent detection light, detect scattered light or diffracted light generated from the target mark, or make the light generated from the target mark Two diffracted lights (for example, diffracted lights of the same order, or diffracted lights in the same direction) interfere to detect the alignment sensor, and it is of course possible to use them alone or in combination.

在本实施形态,对准系统ALG1,是使用于形成在晶片载台WST1上的晶片W1的对准标记及形成在基准标记板FM1上的基准标记的位置测量等。又,对准系统ALG2,是使用于形成在晶片载台WST2上的晶片W2的对准标记及形成在基准标记板FM2上的基准标记的位置测量等。In the present embodiment, alignment system ALG1 is used for position measurement of alignment marks formed on wafer W1 on wafer stage WST1 and fiducial marks formed on fiducial mark plate FM1 . Also, alignment system ALG2 is used for position measurement of alignment marks formed on wafer W2 on wafer stage WST2 and fiducial marks formed on fiducial mark plate FM2 , and the like.

来自这些对准系统ALG1、ALG2的资料,如图5所示,供应至主控制装置20。Data from these alignment systems ALG1 , ALG2 are supplied to the

其次,参照图2说明干涉计系统118的构成等。如图2所示,干涉计系统118,具有:三个Y轴干涉计46、48、44,分别具有测轴BI2Y、BI3Y、BI1Y,平行于通过投影光学系统PL的投影中心(光轴AX)、对准系统ALG1、ALG2的各检测中心的Y轴;及两个X轴干涉计16、18,分别具有测轴BI1X、BI2X,平行于连结投影光学系统PL的投影中心(光轴AX)及对准系统ALG1、ALG2的检测中心的X轴。Next, the configuration and the like of the

在此,当晶片载台WST1位于投影光学系统PL的光轴正下方的位置附近的区域(第一区域),对该晶片载台WST1上的晶片进行曝光时,由X轴干涉计18、Y轴干涉计46来管理晶片载台WST1的位置。以下,将由此X轴干涉计18、Y轴干涉计46各测长轴所规定的坐标系统称为第一曝光坐标系统。Here, when wafer stage WST1 is located in a region (first region) near the position immediately below the optical axis of projection optical system PL, and the wafer on wafer stage WST1 is exposed,

又,晶片载台WST2当投影光学系统PL位于第一区域,对该晶片载台WST2上的晶片进行曝光时,由X轴干涉计16、Y轴干涉计46来管理晶片载台WST2的位置。以下,将由此X轴干涉计16、Y轴干涉计46各别的测长轴所规定的坐标系统称为第二曝光坐标系统。In addition, when wafer stage WST2 is located in the first area and projection optical system PL is located in the first area to expose the wafer on wafer stage WST2, the position of wafer stage WST2 is controlled by

又,当晶片载台WST1,位于对准系统ALG1的检测中心正下方的位置附近的区域(第二区域),要进行形成于其晶片载台WST1上的晶片的对准标记的检测时,例如要进行后述的晶片对准时,由X轴干涉计18、Y轴干涉计48来管理晶片载台WST1的位置。以下,将由此X轴干涉计18、Y轴干涉计48各测长轴所规定的坐标系统称为第一对准坐标系统。Also, when wafer stage WST1 is located in a region (second region) near the position immediately below the detection center of alignment system ALG1, and the alignment mark of the wafer formed on the wafer stage WST1 is to be detected, for example The position of wafer stage WST1 is managed by

又,当晶片载台WST2,位于对准系统ALG2的检测中心正下方的位置附近的区域(第三区域),要进行形成于其晶片载台WST2上的晶片的对准标记的检测时,例如要进行后述的晶片对准时,由X轴干涉计16、Y轴干涉计44来管理晶片载台WST2的位置。以下,将由此X轴干涉计16、Y轴干涉计44各别的测长轴所规定的坐标系统称为第二对准坐标系统。In addition, when the wafer stage WST2 is located in the region (third region) near the position immediately below the detection center of the alignment system ALG2, and the alignment mark of the wafer formed on the wafer stage WST2 is to be detected, for example The position of wafer stage WST2 is controlled by

从上述的说明得知,在本实施形态,来自X轴干涉计18、16的干涉计光束,在晶片载台WST1、WST2的移动范围的全域持续分别照射于晶片载台WST1、WST2的移动镜17X、117X。因此,对X轴方向,使用投影光学系统PL曝光时,即使使用对准系统ALG1、ALG2时等任何情形,晶片载台WST1、WST2的位置,则由X轴干涉计18、16来管理。这些X轴干涉计18、16,是具有相对于Y轴方向及Z轴方向离开的至少三支光轴的多轴干涉计,各光轴的输出值能独立测量。因此,这些X轴干涉计18、16,除了晶片载台WST1、WST2的X轴方向的位置测量以外,也能测量Y轴周围的旋转量(横摇量(rolling))及Z轴周围的旋转量(偏摇量)。As can be seen from the above description, in this embodiment, the interferometer beams from the

又,上述Y轴干涉计46、48、44,例如是具有相对于Z轴方向离开的各二支光轴的二轴干涉计,各光轴的输出值能独立测量。因此,这些Y轴干涉计46、48、44,除了晶片载台WST1、WST2的Y轴方向的位置测量以外,也能测量X轴周围的旋转量(俯仰量(pitching))。In addition, the above-mentioned Y-

又,上述多轴干涉计,也可倾斜45°而设置于晶片载台WST1、WST2的反射面,对设置于将投影光学系统PL载置的架台(未图标)的反射面照射激光束,来检测相对于投影光学系统PL的光轴方向(Z轴方向)的相对位置数据。In addition, the above-mentioned multi-axis interferometer may be installed on the reflective surfaces of wafer stages WST1 and WST2 at an inclination of 45°, and the laser beam may be irradiated on the reflective surfaces provided on the gantry (not shown) on which the projection optical system PL is placed. Relative positional data with respect to the optical axis direction (Z-axis direction) of projection optical system PL is detected.

其次,依图4说明前述液体供排系统32。此液体供排系统32具备:液体供应装置5;液体回收装置6;供应管21、22、27、28,连接于液体供应装置5;及回收管23、24、29、30,连接于液体回收装置6。Next, the aforementioned liquid supply and

前述液体供应装置5包括:液体槽;加压泵;温度控制装置;及多个阀,用以控制对各供应管21、22、27、28的液体的供应、停止等。各阀,例如较佳者为使用流量控制阀,不仅液体的供应、停止,而且也能进行流量调整。前述温度控制装置,是用来将液体槽内的液体温度,调整为与收纳有例如投影单元PU等所构成的曝光装置本体的室(未图标)内的温度相同程度的温度。The aforementioned

前述供应管21,将其一端连接于液体供应装置5,将其它端分支为三个,在各分支端分别形成(或设置)由尖细嘴所构成的供应嘴21a、21b、21c。这些供应嘴21a、21b、21c的前端,位于前述的前端透镜91(参照图1)附近,沿X轴方向隔既定间隔且近接于曝光区域IA(与前述槽上的照明区域共同作用的像面上的区域)的+Y来配置。以供应嘴21a为中心,将供应嘴21b、21c配置于大致左右对称。One end of the

前述供应管22,将其一端连接于液体供应装置5,将其它端分支为三个,在各分支端分别形成(或设置)由尖细嘴构成的供应嘴22a、22b、22c。这些供应嘴22a、22b、22c的前端,位于前端透镜91附近,沿X轴方向隔既定间隔且近接于曝光区域IA的-Y来配置。在此情形,供应嘴22a、22b、22c,隔着曝光区域LA对向于供应嘴21a、21b、21c来配置。One end of the

前述供应管27,将其一端连接于液体供应装置5,将其它端形成(或设置)为由尖细嘴所构成的供应嘴27a。此供应嘴27a的前端,位于前端透镜91附近,近接于曝光区域IA的-X侧来配置。The

前述供应管28,将其一端连接于液体供应装置5,将其它端形成(或设置)为由尖细嘴所构成的供应嘴28a。此供应嘴28a的前端,位于前端透镜91附近,近接于曝光区域IA的+X侧,且隔着曝光区域IA对向于供应嘴27a来配置。The

又,不需要将用以供应液体的槽、加压泵、温度控制装置、阀等全部设于曝光装置100,至少将一部分能由设置曝光装置100的工厂等的设备来替代。In addition, it is not necessary to provide all the tanks, booster pumps, temperature control devices, valves, etc. for supplying the liquid in the

前述液体回收装置6包括:液体槽;吸引泵;及多个阀,用以控制分别通过各回收管23、24、29、30的液体的回收、停止等。各阀,较佳者为对应前述的液体供应装置5侧的阀,使用流量控制阀。The aforementioned

前述回收管23,将其一端连接于液体回收装置6,将其它端分支为二股,在各分支端分别形成(或设置)由尾宽嘴所构成的回收嘴23a、23b。在此情形,回收嘴23a、23b,是交替配置于供应嘴22a~22c之间。各回收嘴23a、23b的前端及各供应嘴22a、22b、22c的前端,大致沿着平行于X轴的同一直线上来配置。The

前述回收管24,将其一端连接于液体回收装置6,将其它端分支为二股,在各分支端分别形成(或设置)由尾宽嘴所构成的回收嘴24a、24b。在此情形,回收嘴24a、24b,是在供应嘴21a~21c之间,交替且隔着曝光区域IA分别对向于回收嘴23a、23b来配置。各回收嘴23a、23b的前端及各供应嘴21a、21b、21c的前端,大致沿着平行于X轴的同一直线上来配置。The

前述回收管29,将其一端连接于液体回收装置6,将其它端分支为二股,在各分支端分别形成(或设置)由尾宽嘴所构成的回收嘴29a、29b。这些回收嘴29a、29b,是隔着供应嘴28a配置。各回收嘴29a、29b及供应嘴28a的前端,大致沿着平行于Y轴的同一直线上来配置。The

前述回收管30,将其一端连接于液体回收装置6,将其它端分支为二股,在各分支端分别形成(或设置)由尾宽嘴所构成的回收嘴30a、30b。这些回收嘴30a、30b,是隔着供应嘴27a,且隔着曝光区域IA分别对向于回收嘴29a、29b来配置。各回收嘴30a、30b及供应嘴27a的前端,大致沿着平行于Y轴的同一直线上来配置。The above-mentioned

又,不需要将用以回收液体的槽、吸引泵、阀等全部设于曝光装置100,至少将一部分能由设置曝光装置100的工厂等的设备来替代。In addition, it is not necessary to provide all the tanks for recovering liquid, suction pumps, valves, etc. in the

在本实施形态,上述液体,是使用能通过ArF准分子激光(波长193nm)的超纯水(以下,除了特别需要时,简单称为“水”)。超纯水,能在半导体制造工厂容易大量获得,并且具有对涂布于晶片上的光刻胶(感光剂)或光学透镜等无不良影响的优点。又,超纯水对环境无不良影响,并且因杂质的含有量极低,故也能期待对晶片的表面及前端透镜91的表面的洗净作用。In this embodiment, the above-mentioned liquid is ultrapure water (hereinafter, simply referred to as "water" unless otherwise required) that can pass ArF excimer laser light (wavelength: 193 nm). Ultrapure water can be easily obtained in large quantities in semiconductor manufacturing plants, and has the advantage of not adversely affecting the photoresist (sensitizer) or optical lens coated on the wafer. In addition, ultrapure water has no adverse effect on the environment, and because the content of impurities is extremely low, it can also expect a cleaning effect on the surface of the wafer and the surface of the

对ArF准分子激光的水的折射率n,是大致1.44。在此水中,照明用光IL的波长,则使其短波长化为193nm×1/n=约134nm。The refractive index n of water for ArF excimer laser is about 1.44. In this water, the wavelength of the illumination light IL is shortened to 193 nm×1/n=approximately 134 nm.

前述液体供应装置5及液体回收装置6,分别具备控制器,各控制器,由主控制装置20来控制(参照图5)。例如,沿图4中的实线箭头A所示的方向(-Y方向)使晶片W1(或W2)移动时,液体供应装置5的控制器,依照主控制装置20的指示,以既定开度打开连接于供应管21的阀,使其它阀为全闭,通过设置于供应管21的供应嘴21a~21c朝-Y方向将水供应至前端透镜91与晶片W1(或W2)之间。又,此时,液体回收装置6的控制器,依照主控制装置20的指示,以既定开度打开连接于回收管23的阀,使其它阀为全闭,通过回收嘴23a、23b从前端透镜91与晶片W1(或W2)之间将水回收至液体回收装置6的内部。此时,主控制装置20,对液体供应装置5、液体回收装置6发出指令,使从供应嘴21a~21c朝-Y方向供应至前端透镜91与晶片W1(或W2)之间的水量,与通过回收嘴23a、23b回收的水量相等。因此,在前端透镜91与晶片W1(或W2)之间,保持一定量的水Lq(参照图1)。在此情形,保持于前端透镜91与晶片W1(或W2)之间的水Lq持续替换。The aforementioned

又,沿图4中的虚线箭头A’所示的方向(+Y方向)使晶片W1(或W2)移动时,液体供应装置5的控制器,依照主控制装置20的指示,以既定开度打开连接于供应管22的阀,使其它阀为全闭,通过设置于供应管22的供应嘴22a~22c朝+Y方向将水供应至前端透镜91与晶片W1(或W2)之间。又,此时,液体回收装置6的控制器,依照主控制装置20的指示,以既定开度打开连接于回收管24的阀,使其它阀为全闭,通过回收嘴24a、24b从前端透镜91与晶片W1(或W2)之间至液体回收装置6的内部回收水。此时,主控制装置20,对液体供应装置5、液体回收装置6发出指令,使从供应嘴22a~22c朝+Y方向供应至前端透镜91与晶片W1(或W2)之间的水量,与通过回收嘴24a、24b回收的水量相等。因此,在前端透镜91与晶片W1(或W2)之间,保持一定量的水Lq(参照图1)。在此情形,保持于前端透镜91与晶片W1(或W2)之间的水Lq持续替换。Also, when the wafer W1 (or W2) is moved in the direction (+Y direction) shown by the dotted arrow A' in FIG. The valve connected to the

如此,在本实施形态,因隔着曝光区域IA在Y轴方向一侧与另一侧,分别设置彼此成组的供应嘴群组与回收嘴群组,故即使要将晶片朝+Y方向或-Y方向的任一方移动时,在晶片W1(或W2)与前端透镜91之间使水稳定地持续填满。即,即使是正扫描及负扫描的任一情形,也能在前端透镜91与晶片之间稳定地保持水。In this way, in this embodiment, since the supply nozzle group and the recovery nozzle group are respectively provided in groups on one side and the other side of the Y-axis direction across the exposure area IA, even if the wafer is to be directed toward the +Y direction or -While moving in any one of the Y directions, the space between the wafer W1 (or W2 ) and the

又,因水会流动于晶片W1(或W2)上,故即使在晶片W1(或W2)上附着异物(包含来自光刻胶的飞散粒子)的情形,能将该异物用水冲洗。又,因供应由液体供应装置5已调整为既定温度的水,且此水是持续替换,故即使在曝光时照明用光IL照射于晶片W1(或W2)上,在晶片与流动于该晶片上的水之间进行热交换,能防止晶片表面的温度上升。又,在本实施形态,因水沿与移动晶片的方向相同方向流动,故不会使已吸收异物或热的液体滞留于前端透镜正下方的曝光区域而能将其回收。Also, since water flows on wafer W1 (or W2), even if foreign matter (including flying particles from photoresist) adheres to wafer W1 (or W2), the foreign matter can be washed away with water. In addition, since the water adjusted to a predetermined temperature by the

又,若要朝图4中实线箭头B所示的方向(+X方向)移动晶片W1(或W2)时,液体供应装置5的控制器,依照主控制装置20的指示,以既定开度打开连接于供应管27的阀,使其它阀为全闭,通过设置于供应管27的供应嘴27a朝+X方向将水供应至前端透镜91与晶片W1(或W2)之间。又,此时,液体回收装置6的控制器,依照主控制装置20的指示,以既定开度打开连接于回收管29的阀,使其它阀为全闭,通过回收嘴29a、29b将水从前端透镜91与晶片W1(或W2)之间回收至液体回收装置6的内部。此时,主控制装置20,对液体供应装置5、液体回收装置6发出指令,使从供应嘴27a供应至前端透镜91与晶片W1(或W2)之间的水量,与通过回收嘴29a、29b回收的水量相等。因此,在前端透镜91与晶片W1(或W2)之间,保持一定量的水Lq(参照图1)。在此情形,保持于前端透镜91与晶片W1(或W2)之间的水Lq持续替换。Also, if the wafer W1 (or W2) is to be moved in the direction (+X direction) shown by the solid line arrow B in FIG. The valve connected to the

又,若要朝图4中虚线箭头B’所示的方向(-X方向)移动晶片W1(或W2)时,液体供应装置5的控制器,依照主控制装置20的指示,以既定开度打开连接于供应管28的阀,使其它阀为全闭,通过设置于供应管28的供应嘴28a朝-X方向将水供应至前端透镜91与晶片W1(或W2)之间。又,此时,液体回收装置6的控制器,依照主控制装置20的指示,以既定开度打开连接于回收管30的阀,使其它阀为全闭,通过回收嘴30a、30b将水从前端透镜91与晶片W1(或W2)之间回收至液体回收装置6的内部。此时,主控制装置20,对液体供应装置5、液体回收装置6发出指令,使从供应嘴28a供应至前端透镜91与晶片W1(或W2)之间的水量,与通过回收嘴30a、309b回收的水量相等。因此,在前端透镜91与晶片W1(或W2)之间,保持一定量的水Lq(参照图1)。在此情形,保持于前端透镜91与晶片W1(或W2)之间的水Lq持续替换。Also, if the wafer W1 (or W2) is to be moved in the direction (-X direction) shown by the dotted arrow B' in FIG. The valve connected to the

藉此,与使晶片W1(或W2)朝Y轴方向移动的情形同样,即使要将晶片朝+X方向或-X方向的任一方移动时,将水稳定地填满于晶片与前端透镜91之间。因此,在所谓照射间步进时,即使其步进方向是任何方向,也能在晶片与前端透镜91之间稳定地持续保持水。Thereby, as in the case of moving the wafer W1 (or W2) in the Y-axis direction, even when the wafer is moved in either the +X direction or the −X direction, the wafer and the

又,以上,虽对在晶片与前端透镜91之间将水保持的情形说明,但如前述,因晶片表面与晶片保持具H1、H2的表面成为大致同一面,故即使晶片保持具H1(或H2)位于对应投影单元P正下方的曝光区域IA的位置的情形,与上述同样,水则保持于前端透镜91与晶片保持具H1(或H2),也即与前述的辅助板之间。又,步进时,若在晶片与前端透镜91之间能保持水的情形,也可停止水的供应与回收。Also, above, although the situation of holding water between the wafer and the

又,除了从X轴方向或Y轴方向进行水的供应及回收的嘴外,例如也可设置用以从斜方向进行水的供应及回收的嘴。In addition, instead of nozzles for supplying and recovering water from the X-axis direction or the Y-axis direction, for example, nozzles for supplying and recovering water from an oblique direction may be provided.

又,也可与晶片的移动方向无关,从供应嘴21a~21c、22a~22c、27a、28a持续供应液体Lq,从回收嘴23a、23b、24a、24b、29a、29b、30a、30b持续回收液体Lq。Also, regardless of the moving direction of the wafer, the liquid Lq may be continuously supplied from the

又,液体供排系统不限于上述图4的形态,只要能在投影光学系统PL的像面侧形成液浸区域,能适用各种形态。Also, the liquid supply and discharge system is not limited to the above-mentioned form shown in FIG. 4 , and various forms can be applied as long as a liquid immersion region can be formed on the image plane side of projection optical system PL.

本实施形态100,进一步在用以保持投影单元PU的未图标的保持构件,设置斜射入方式的多点焦点位置检测系统,是由照射系统90a(在图1未图标,参照图5)及受光系统90b(在图1未图标,参照图5)构成,与例如日本特开平6-283403号公报及对应于此的美国专利第5,448,332等所揭示的同样。照射系统90a,具有以图5的主控制装置20控制开关的光源,朝投影光学系统PL的结像面射出用以形成多数个针孔或狭缝的像的光束。此所射出的光束,通过设置于投影单元PU的镜筒的未图标的棱镜(照射系统90a内的光学系统的一部分)对光轴AX从斜方向照射于晶片表面。另一方面,在晶片表面被反射的这些光束的反射光束,以设置于投影单元PU的镜筒的未图标的另外的棱镜(受光系统90b内的光学系统的一部分)反射,由受光系统90b内的受光元件受光。In this

此焦点位置检测系统(90a、90b)的受光系统90b的输出的焦点偏移信号(散焦信号),是供应至主控制装置20。主控制装置20,在后述的扫描曝光时等,算出来自受光系统90b的焦点偏移信号(散焦信号),例如根据S曲线信号算出晶片表面的Z位置及θx、θy旋转,使所算出的晶片表面的Z位置及θx、θy旋转对所述的目标值的差变成零,即要使焦点偏移为零,由通过晶片载台驱动部124控制晶片载台WST1、WST2的Z轴方向的移动,及二维方向的倾斜(即,θx、θy方向的旋转),在照明用光IL的照射区域(与前述的照射区域共同的区域)内执行使投影光学系统PL的结像面与晶片的表面实质上一致的自动对焦(auto focus)及自动调平(auto levelling)。又,在本案所指定的指定国(或所选择的选择国)的国内法令所允许的范围,援用上述日本特开平6-283403号公报及对应的美国专利的揭示,作为本说明书的记载的一部分。The focus shift signal (defocus signal) output by the

又,焦点位置检测系统,也可通过液体检测晶片表面的位置资料,也可不通过液体检测。又,焦点位置检测系统,不限于在投影光学系统PL的像面侧检测晶片表面的位置资料,也可从投影光学系统PL离开处检测晶片表面的位置资料。In addition, the focus position detection system may also detect the position data on the surface of the wafer through liquid, or not through liquid detection. In addition, the focus position detection system is not limited to detecting the position data of the wafer surface on the image plane side of the projection optical system PL, and may detect the position data of the wafer surface from the point away from the projection optical system PL.

在图5,表示本实施形态的曝光装置100的控制系统的主要构成。此控制系统,以将装置全体综合控制的微电脑(或工作站)所构成的主控制装置20为中心来构成。FIG. 5 shows the main configuration of the control system of the

其次,说明本实施形态的曝光装置100曝光时的各部的动作。在此,如图2所示,说明在晶片载台WST1侧进行曝光的情形。Next, the operation of each part during exposure by the

此曝光动作的开始时,在主控制装置20,根据事前所进行的例如增强型总对准(EGA,Enhanced Global Alignment)等的晶片对准的结果等,边监视干涉计18、46的测量值,边控制X轴线性发动机84、85及Y轴线性发动机81,而将晶片载台WST1移动至用以晶片W1的第一照射区域的曝光用扫描开始位置(加速开始位置)。在此曝光次序,是在第一曝光坐标系统上进行晶片载台WST1的位置管理。At the start of this exposure operation, the

其次,在主控制装置20,开始相对于标线片R(标线片载台RST)与晶片W1(晶片载台WST1)的Y轴方向的相对扫描。此相对扫描时,主控制装置20,边监视前述的干涉计18、46及标线片干涉计116的测量值,边控制标线片载台驱动部11并且Y轴线性发动机81(及X轴线性发动机84、85)。Next, in

接着,当两载台RST、WST1加速至各目标扫描速度时,在主控制装置20,对未图标的光源(ArF准分子激光装置)发出指令,开始脉冲发光。然后,当两载台RST、WST1达到等速同步状态时,由来自照明系统10的照明用光IL(紫外脉冲光)使标线片R的图案区域开始照明,开始扫描曝光。虽在此扫描曝光开始之前,如上述,光源的脉冲发光已开始,但由主控制装置20,照明系统10内的可动标线片遮帘(未图标)的既定叶片同步于标线片载台RST而移动,藉此防止在扫描曝光的开始前对晶片W1进行不必要的曝光。Next, when the two stages RST and WST1 are accelerated to the respective target scanning speeds, the

然后,以照明用光IL依次照明标线片R的图案区域,由完成对图案区域全面的照明,结束晶片W1上的第一照射区域的扫描曝光。藉此,标线片R的图案通过投影光学系统PL缩小转印于晶片W1上的第一照射区域。Then, the pattern area of the reticle R is sequentially illuminated with the illumination light IL, and the scanning exposure of the first shot area on the wafer W1 is completed when the illumination of the entire pattern area is completed. Thereby, the pattern of the reticle R is reduced and transferred to the first shot area on the wafer W1 through the projection optical system PL.

在此情形,扫描曝光结束后,也由主控制装置20,使照明系统10内的可动标线片遮帘(未图标)同步于标线片载台RST而移动,藉此防止晶片W1的不必要的曝光。In this case, after the scanning exposure is finished, the

如上述,结束第一照射区域的扫描曝光后,由主控制装置20,通过X轴线性发动机84、85及Y轴线性发动机81使晶片载台WST1沿X、Y方向步进移动,移动至用以第二照射区域的曝光的加速开始位置(扫描开始位置)。此照射间步进时,主控制装置20,依干涉计18、46的测量值将晶片载台WST1的X、Y、θz方向的位置位移实时(real time)检测。并且,根据此测量结果,主控制装置20,控制晶片载台WST1的位置,使晶片载台WST1的XY位置位移成为既定状态。又,主控制装置20,根据晶片载台WST1的θz方向的资料,控制标线片载台RST(标线片微动载台)及晶片载台WST1的至少一旋转,使其晶片侧的旋转位移补偿。As mentioned above, after the scanning exposure of the first shot region is completed, the

接着,在照射间步进结束后,由主控制装置20,与上述同样,控制各部的动作,对晶片W1上的第二照射区域进行与上述同样的扫描曝光。Next, after the stepping between shots is completed, the

如上述,反复进行晶片W1上的照射区域的扫描曝光与供下次照射曝光的照射间步进动作,使标线片R的图案依序转印于晶片W1上的曝光对象的照射区域全部。As described above, the stepping operation between the scanning exposure of the shot area on wafer W1 and the irradiation for the next shot exposure is repeated, and the pattern of reticle R is sequentially transferred to all the shot areas of the exposure target on wafer W1.

又,上述的对晶片W1的步进扫描方式的曝光动作中,按照晶片W1的移动方向的变化,由主控制装置20,如前述,进行液体供排系统32的液体供应装置5及液体回收装置6的各阀的开关控制则是理所当然。因此,上述的对晶片W1的步进扫描方式的曝光动作中,在前端透镜91与晶片W1之间维持持续将一定量的水稳定地保持的状态。Moreover, in the exposure operation of the step-and-scan method to the wafer W1 described above, according to the change in the moving direction of the wafer W1, the

其次,对使用两个晶片载台WST1、WST2的并行处理动作,参照图2及图6~图9说明。又,以下的动作中,由主控制装置20,按照位于投影单元PU正下方的第一区域的晶片载台的移动方向,如前述进行液体供排系统32的液体供应装置5及液体回收装置6的各阀的开关控制,在投影光学系统PL的前端透镜91正下方持续填满水。但是,以下,为了要使说明容易了解,将关于液体供应装置5及液体回收装置6的控制的说明省略。Next, the parallel processing operation using two wafer stages WST1 and WST2 will be described with reference to FIG. 2 and FIGS. 6 to 9 . In addition, in the following operations, the

在图2表示:对晶片载台WST1上的晶片W1如前述以步进扫描方式进行曝光,与此并行,在晶片载台WST2侧,在对准系统ALG2的下方的第三区域进行对晶片W2的晶片对准的状态。2 shows that wafer W1 on wafer stage WST1 is exposed in a step-and-scan manner as described above, and in parallel with this, wafer W2 is exposed in the third area below alignment system ALG2 on the wafer stage WST2 side. The state of wafer alignment.

如上述,对晶片W1以步进扫描方式进行曝光期间,在晶片载台WST2侧,则进行如下所述的动作。As described above, while the wafer W1 is exposed by the step-and-scan method, the following operations are performed on the wafer stage WST2 side.

即,在上述的晶片对准前,在左侧装载位置,未图标的晶片搬送机构与晶片载台WST2之间进行晶片交换。在此,所谓左侧装载位置,是指设定为基准标记板FM2位于对准系统ALG2的正下方的位置而言。在此情形,在左侧装载位置,由对准系统ALG2检测基准标记板FM2上的第二基准标记以前,由主控制装置20执行Y轴干涉计44的重置(reset)。That is, before the wafer alignment described above, at the loading position on the left side, wafer exchange is performed between a wafer transfer mechanism (not shown) and wafer stage WST2. Here, the loading position on the left side refers to a position set such that fiducial mark plate FM2 is located directly below alignment system ALG2. In this case, at the left loading position, before the second fiducial mark on the fiducial mark plate FM2 is detected by the alignment system ALG2, the reset of the Y-

上述第二基准标记的检测时,主控制装置20,使用对准系统ALG2取进第二基准标记的影像,对其影像信号施加既定的处理,由解析其处理后的信号来检测以对准系统ALG2的指针中心为基准的第二基准标记的位置。又,主控制装置20,根据其第二基准标记的位置的检测结果与其检测时的干涉计16、44的测量结果,算出第二对准坐标系统上的第二基准标记的位置坐标。During the detection of the above-mentioned second fiducial mark, the

其次,主控制装置20,由边在前述第二对准坐标系统上管理晶片载台WST2的XY面内的位置,边使用对准系统ALG2来检测附设于晶片W2上的特定的多个照射区域(样本照射区域)的对准标记(样本标记)的位置资料(对对准系统ALG2的检测中心的位置资料),来求出第二对准坐标系统上的样本标记的位置资料。接着,主控制装置20,根据其检测结果与特定的照射区域的设计上的位置坐标,执行例如日本特开昭61-22249号公报及对应于此的美国专利第4,780,617号等所揭示的统计运算,来算出晶片W2上的多个照射区域的第二对准坐标系统上的位置坐标。即,如上述,进行EGA(增强型总对准)。并且,主控制装置20,由从晶片W2上的多个照射区域的第二对准坐标系统上的位置坐标将前述第二基准标记的位置坐标减算,使多个照射区域的位置坐标转换成以第二基准标记的位置为原点的位置坐标。又,在本案所指定的指定国(或所选择的选择国)的国内法令所允许的范围,援用上述公报及对应美国专利的揭示,作为本说明书的记载的一部分。Next, the

上述在两个晶片载台WST1、WST2上并行而进行的曝光次序与晶片交换/对准次序,通常,是晶片交换/对准次序最先结束。因此,已结束对准的晶片载台WST2,则在既定的待机位置呈等待状态。The exposure sequence and the wafer exchange/alignment sequence performed in parallel on the two wafer stages WST1 and WST2 are usually completed first by the wafer exchange/alignment sequence. Therefore, wafer stage WST2 whose alignment has been completed is in a waiting state at a predetermined waiting position.

并且,在晶片载台WST1侧,在对晶片W1的曝光结束的时点,主控制装置20,将晶片载台WST1、WST2朝图6所示的既定位置分别开始移动。Then, at the wafer stage WST1 side, when the exposure to the wafer W1 is completed, the

并且,将晶片载台WST1、WST2移动至图6所示的位置后,主控制装置20,则开始使晶片载台WST1与晶片载台WST2同时朝+X方向驱动的动作。又,在图6的状态,晶片载台WST1与晶片载台WST2是通过设置于晶片载台WST1的弹性密封构件93接触。Then, after wafer stages WST1 and WST2 are moved to the positions shown in FIG. 6 ,

如上述,由主控制装置20,使晶片载台WST1、WST2同时移动,在图6的状态,保持于投影单元PU的前端透镜91与晶片W1之间的水,则伴随晶片载台WST1、WST2朝+X侧移动,在晶片W1→晶片载台WST1(更具体而言是晶片保持具H1)→晶片载台WST2(更具体而言是晶片保持具H2)上依序移动。又,上述移动期间,晶片载台WST1、WST2则与图6的状态同样通过弹性密封构件93保持彼此接触的位置关系。在图7,表示:在上述移动的中途,水同时存在于晶片载台WST1、WST2(晶片保持具H1、H2)时的状态,即从晶片载台WST1上待将水交给晶片载台WST2上之前的状态。As mentioned above, wafer stages WST1 and WST2 are moved simultaneously by

从图7的状态,当进一步使晶片载台WST1、WST2朝+X方向同时驱动既定距离,则如图8所示,形成在晶片载台WST2上的包含基准标记板FM2的区域与前端透镜91之间保持水的状态。先行于此,主控制装置20,在使来自Y轴干涉计46的干涉计光束能照射于移动镜117Y的任一时点,执行Y轴干涉计46的重置。From the state of FIG. 7, when wafer stages WST1 and WST2 are further simultaneously driven for a predetermined distance in the +X direction, as shown in FIG. Keep water in between. Prior to this, the

接着,主控制装置20,朝图9所示的右侧装载位置开始晶片载台WST1的驱动。此右侧装载位置,设定为基准标记板FM1位在对准系统ALG1的正下方的位置。Next,

与朝上述右侧装载位置的晶片载台WST1的移动开始并行,主控制装置20,由一对标线片对准系统RAa、RAb(参照图1)使用照明用光IL进行基准标记板FM2上的一对第一基准标记与对应于其的标线片R上的标线片对准标记的晶片上投影像的相对位置检测。此时,基准标记板FM2上的一对第一基准标记与标线片对准标记的像的检测,是通过投影光学系统PL及水来进行。Parallel to the start of movement of wafer stage WST1 to the above-mentioned right loading position,

并且,主控制装置20,根据此所检测的相对位置资料,与对预先所求的第二基准标记的晶片W2上的各照射区域的位置资料,及既知的第一基准标记与第二基准标记的位置关系,算出标线片R的图案的投影位置(投影光学系统PL的投影中心)与晶片W2上的各照射区域的相对位置关系。并且,根据其算出结果,主控制装置20,与前述的晶片W1的情形同样,在第二曝光坐标系统上边管理晶片载台WST2的位置,边以步进扫描方式将标线片R的图案转印于晶片W2上的各照射区域。And, the