CN100392209C - Salt rock deposit horizontal chamber type oil and gas storage and its construction method - Google Patents

Salt rock deposit horizontal chamber type oil and gas storage and its construction methodDownload PDFInfo

- Publication number

- CN100392209C CN100392209CCNB2005100124700ACN200510012470ACN100392209CCN 100392209 CCN100392209 CCN 100392209CCN B2005100124700 ACNB2005100124700 ACN B2005100124700ACN 200510012470 ACN200510012470 ACN 200510012470ACN 100392209 CCN100392209 CCN 100392209C

- Authority

- CN

- China

- Prior art keywords

- chamber

- storage

- oil

- horizontal

- gas storage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000003860storageMethods0.000titleclaimsabstractdescription89

- 150000003839saltsChemical class0.000titleclaimsabstractdescription66

- 239000011435rockSubstances0.000titleclaimsabstractdescription59

- 238000010276constructionMethods0.000titleclaimsabstractdescription30

- 238000005553drillingMethods0.000claimsabstractdescription14

- 239000012267brineSubstances0.000claimsabstractdescription11

- HPALAKNZSZLMCH-UHFFFAOYSA-Msodium;chloride;hydrateChemical compoundO.[Na+].[Cl-]HPALAKNZSZLMCH-UHFFFAOYSA-M0.000claimsabstractdescription11

- 238000004090dissolutionMethods0.000claimsabstractdescription7

- 239000010410layerSubstances0.000claimsdescription22

- 239000000243solutionSubstances0.000claimsdescription17

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription10

- 239000002356single layerSubstances0.000claimsdescription8

- 238000002347injectionMethods0.000claimsdescription7

- 239000007924injectionSubstances0.000claimsdescription7

- 238000003032molecular dockingMethods0.000claimsdescription7

- 238000007789sealingMethods0.000claimsdescription5

- 238000009933burialMethods0.000claimsdescription4

- 239000007864aqueous solutionSubstances0.000claimsdescription2

- 230000014759maintenance of locationEffects0.000claimsdescription2

- 239000003921oilSubstances0.000abstractdescription40

- 238000005516engineering processMethods0.000abstractdescription7

- 239000010779crude oilSubstances0.000abstractdescription3

- 239000002699waste materialSubstances0.000abstractdescription3

- 210000001503jointAnatomy0.000abstractdescription2

- 239000007789gasSubstances0.000description30

- 239000011229interlayerSubstances0.000description11

- 238000000034methodMethods0.000description6

- 230000015572biosynthetic processEffects0.000description5

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneChemical compoundCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000description4

- 238000004364calculation methodMethods0.000description2

- 238000010586diagramMethods0.000description2

- 238000005065miningMethods0.000description2

- 239000003345natural gasSubstances0.000description2

- 230000005540biological transmissionEffects0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000011978dissolution methodMethods0.000description1

- 230000000694effectsEffects0.000description1

- 238000003912environmental pollutionMethods0.000description1

- 239000003673groundwaterSubstances0.000description1

- 238000003895groundwater pollutionMethods0.000description1

- 238000003306harvestingMethods0.000description1

- 229910052500inorganic mineralInorganic materials0.000description1

- 230000007774longtermEffects0.000description1

- 239000011707mineralSubstances0.000description1

- 238000000518rheometryMethods0.000description1

- 239000000126substanceSubstances0.000description1

Images

Landscapes

- Earth Drilling (AREA)

- Lining And Supports For Tunnels (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于油气储存的工业范畴,是一种在盐岩矿床内利用定向钻井及控制溶解技术,建造油气储库以及一种水平式油气储库的建造方法。The invention belongs to the industrial category of oil and gas storage, and relates to a construction method of oil and gas storage and a horizontal oil and gas storage using directional drilling and controlled dissolution technology in salt rock deposits.

背景技术Background technique

盐岩矿床是由易溶于水的盐类物质沉积而成的矿床,由于盐岩具有结构致密、流变及损伤自愈合性强的物理力学特性,盐岩矿床被视为油气储库建造的理想场所。在国外,采后盐岩溶腔用来储存石油天然气已有几十年的历史;为加快我国的地下石油战略储备,配合西气东输工程的下游储气库建设,国内也于近几年开始了对盐岩矿床油气储库建造方法的研究。由于形成历史及地质作用的不同,盐岩矿床通常可分为展布小而厚度巨大(数百米)的盐丘型矿床和展布大而厚度小(几十米)的层状矿床两大类。在国外,盐岩矿床油气储库的形状多为立式柱状,即为垂直硐室型油气储库,建造方法采用传统的单井油垫建槽水溶建腔的工艺。由于该方法建槽速度慢,开采成本高,因此,这种传统的盐矿开采建库工艺己被采用的越来越少。同时,该方法仅适用于巨厚盐丘型盐岩,在层状盐岩矿床中受到很大限制。然而,由于沉积地质成因的普遍性,层状盐岩矿床较巨厚盐丘更为常见,我国盐岩矿床的特征更是如此,具有“分层多、单层厚度薄、软弱夹层多”的特点。在层状盐岩矿床中建造垂直硐室型油气储库,势必穿越较多的软弱夹层,夹层的渗漏和夹层给储库稳定性造成的影响几乎是无法克服的障碍。另外,采用油垫控制建造油气储库,不仅要浪费大量的原油,而且对卤水也造成一定的污染,被污染的卤水排弃在野外,更会造成地表、地下水及环境污染。Salt rock deposits are deposited from water-soluble salt substances. Due to the physical and mechanical characteristics of salt rock with compact structure, rheology and strong damage self-healing, salt rock deposits are regarded as the construction of oil and gas reservoirs. ideal place. In foreign countries, post-harvest salt rock caverns have been used to store oil and natural gas for decades; in order to speed up my country's underground strategic oil reserves and cooperate with the construction of downstream gas storages for the West-to-East Gas Transmission Project, China has also started to use them in recent years. Research on the construction method of oil and gas storage in salt rock deposit. Due to the difference in formation history and geological processes, salt rock deposits can usually be divided into two types: salt dome deposits with small distribution and huge thickness (hundreds of meters) and layered deposits with large distribution and small thickness (tens of meters). kind. In foreign countries, the shape of oil and gas reservoirs in salt rock deposits is mostly vertical columns, that is, vertical chamber oil and gas reservoirs, and the construction method adopts the traditional process of single well oil pad to build tanks and water solution to build cavities. Due to the slow construction speed and high mining cost of this method, this traditional salt mine storage construction technology has been adopted less and less. At the same time, this method is only applicable to extremely thick salt dome-type salt rocks, and is greatly limited in layered salt rock deposits. However, due to the universality of sedimentary geological origin, layered salt rock deposits are more common than thick salt domes, especially the characteristics of salt rock deposits in my country, which have the characteristics of "multiple layers, thin single layer thickness, and many weak interlayers" features. To build a vertical chamber type oil and gas storage in a layered salt rock deposit, it is necessary to pass through many weak interlayers. The leakage of interlayers and the impact of interlayers on the stability of the reservoir are almost insurmountable obstacles. In addition, the use of oil pads to control the construction of oil and gas storage depots not only wastes a lot of crude oil, but also causes some pollution to brine. The polluted brine is discharged in the wild, which will cause surface, groundwater and environmental pollution.

发明内容Contents of the invention

本发明的目的在于克服现有垂直硐室型油气储库在层状盐岩体中的限制与不足,为在层状盐岩体、以及盐丘型矿床中建造油气储库,提供一种库容大、运行稳定、安全可靠的盐岩矿床水平硐室型油气储库及其建造方法。The purpose of the present invention is to overcome the limitations and deficiencies of the existing vertical chamber type oil and gas storage in layered salt rock bodies, and provide a storage capacity for building oil and gas storage in layered salt rock bodies and salt dome type deposits Large, stable operation, safe and reliable salt rock deposit horizontal chamber type oil and gas storage and its construction method.

本发明是通过以下技术方案来实现其目的的。The present invention realizes its purpose through the following technical solutions.

一种盐岩矿床水平硐室型油气储库,其特征在于:所述的油气储库呈硐室状,硐室截面形状近似圆形,硐室沿矿层水平展布,水平硐室的展布方位、长度、硐室腔体直径根据盐岩矿层的赋存特征及厚度而定。A salt rock deposit horizontal chamber type oil and gas storage, characterized in that: the oil and gas storage is in the shape of a chamber, the shape of the cross section of the chamber is approximately circular, the chambers are horizontally distributed along the ore bed, and the distribution of the horizontal chambers is The orientation, length, and diameter of the cavity are determined according to the occurrence characteristics and thickness of the salt rock layer.

所述的油气储库,在同一层至少排列2个水平硐室,形成单层储库群。In the oil and gas storage, at least two horizontal chambers are arranged on the same layer to form a single-layer storage group.

所述的油气储库,至少在两层中每层排列至少2个水平硐室,形成多层储库群。In the oil and gas storage, at least two horizontal chambers are arranged on each of at least two layers to form a multi-layer storage group.

所述的油气储库群,各个硐室的水平、垂直间距,根据盐岩矿层的地质条件及力学稳定性计算来确定。The horizontal and vertical spacing of each chamber in the oil and gas reservoir group is determined according to the geological conditions and mechanical stability of the salt rock deposit.

所述的油气储库群,各个硐室的水平间距,按公式:L≥3D计算,式中:L为两个硐室间的稳定性间距,D为硐室直径。The horizontal spacing of each chamber in the oil and gas storage group is calculated according to the formula: L≥3D, where: L is the stable distance between two chambers, and D is the diameter of the chamber.

一种盐岩矿床水平硐室型油气储库的建造方法,其具体步骤是:A method for constructing a horizontal chamber type oil and gas storage in a salt rock deposit, the specific steps of which are:

I.根据地质资料,在确定矿层的物理力学特性及埋藏特征后,确定水平硐室储库的尺寸参数,并进行相应布井;I. According to geological data, after determining the physical and mechanical properties and burial characteristics of the ore bed, determine the size parameters of the horizontal chamber storage, and carry out corresponding well layout;

II.依据定向钻井技术规范,进行垂直实施井、目标井的钻进与固井;II. Carry out drilling and cementing of vertical implementation wells and target wells according to the technical specifications of directional drilling;

III.在实施井的适当深度处,根据计算所得造斜半径,进行造斜并进入目标盐岩矿层;III. At the proper depth of the well, according to the calculated deflection radius, build up and enter the target salt rock layer;

IV.在目标盐岩矿层内,进行水平定向钻井,并与垂直目标井对接连通;IV. In the target salt rock layer, carry out horizontal directional drilling, and connect with the vertical target well;

V.对接连通后,依据腔体的目标直径,通过调节溶液的温度、浓度、水流速度等参数,适时调换注水与出卤井,进行水平腔体的控制溶解建造;V. After docking and connection, according to the target diameter of the cavity, by adjusting the temperature, concentration, water flow velocity and other parameters of the solution, the water injection and brine wells are replaced in due course, and the controlled dissolution construction of the horizontal cavity is carried out;

VI.为加快溶解建库速度,溶解水溶液的温度要求在40~100℃之间,浓度不得超过200g/l;在建库初期(腔体直径D≤15m期间),溶液流速应大于1.2m/h(注水量大于200m3/h),当腔体直径D>15m后,溶液流速应大于0.6m/h(注水量大于400m3/h),以保证储库的快速均匀溶解建造;VI. In order to speed up the speed of dissolving and building the warehouse, the temperature of the dissolved aqueous solution should be between 40 and 100°C, and the concentration should not exceed 200g/l; in the initial stage of building the warehouse (during the period when the diameter of the cavity is D≤15m), the solution flow rate should be greater than 1.2m/l h (the water injection volume is greater than 200m3 /h), when the cavity diameter D > 15m, the solution flow rate should be greater than 0.6m/h (water injection volume is greater than 400m3 /h), so as to ensure the rapid and uniform dissolution of the reservoir;

VII.储库腔体建造完成后,根据相应的储库建造规范及要求,进行储库井身及腔体密封耐压测试,保证储库的密封性,并验证储库腔体的运行极限压力;VII. After the construction of the storage chamber is completed, according to the corresponding storage construction specifications and requirements, the sealing pressure test of the storage well body and the cavity is carried out to ensure the tightness of the storage and verify the operating limit pressure of the storage cavity ;

VIII.在满足硐室规定间距的条件下,重复上述步骤II~VII,进行新的水平储库的建造施工,直至所有井全部完成,在该盐岩矿床内形成大型储库群。VIII. Under the condition that the specified distance between the chambers is met, repeat the above steps II to VII to carry out the construction of a new horizontal storage until all the wells are completed, and a large storage group is formed in the salt rock deposit.

本发明与现有技术相比具有以下优点和效果:Compared with the prior art, the present invention has the following advantages and effects:

1、运行稳定、安全可靠。由于本发明采用水平布置油气储库,硐室直径小于矿床单层厚度,垂直跨度小,从而避免了储库硐室穿越软弱夹层,最终避免了硐室的渗漏,并保证了硐室的长期稳定性。1. The operation is stable, safe and reliable. Because the present invention adopts the horizontal arrangement of oil and gas storage, the diameter of the chamber is smaller than the thickness of the single layer of the ore bed, and the vertical span is small, thereby avoiding the storage chamber from passing through the weak interlayer, finally avoiding the leakage of the chamber, and ensuring the long-term service life of the chamber stability.

2、建库快、污染少、成本低。由于本发明利用定向钻进对接连通井技术,同时利用溶解溶液的温度、浓度、压力、流速控制技术,以及注水井与出卤井调换技术,进行腔体的控制溶解建造,不仅速度快,而且避免了原来油垫建腔对原油的浪费和卤水的污染,是一种稳定、安全、经济的油气储库及建造方法。2. Fast storage, less pollution and low cost. Since the present invention utilizes the technology of directional drilling butt joint connection wells, the temperature, concentration, pressure and flow rate control technology of the dissolved solution, and the replacement technology of the water injection well and the brine well to carry out the controlled dissolution construction of the cavity, the speed is not only fast, but also It avoids the waste of crude oil and the pollution of brine in the original oil pad construction cavity, and is a stable, safe and economical oil and gas storage and construction method.

3、库容大。因为硐室轴向的延展沿盐岩层的水平方向,可以布置的很长,达500米以上。这样单硐室的容积可以达到100万方以上,这是垂直硐室储库所无法做到的。3. Large storage capacity. Because the axial extension of the chamber is along the horizontal direction of the salt rock layer, it can be arranged very long, reaching more than 500 meters. In this way, the volume of a single chamber can reach more than 1 million square meters, which is impossible for vertical chamber storage.

本发明适用于石油、天然气地下储库在盐岩矿床中的建造,尤其适用于层状盐岩矿床。The invention is suitable for the construction of oil and natural gas underground storage in salt rock deposits, especially for layered salt rock deposits.

下面结合附图,通过实施例对本发明作进一步的说明。Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

附图说明Description of drawings

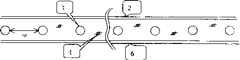

图1为采用定向对接连通控制溶解方法建造盐岩矿床水平硐室型油气储库的示意图;Fig. 1 is a schematic diagram of building a salt rock deposit horizontal chamber type oil and gas storage by using the directional docking connection control dissolution method;

图2为在单一盐岩矿层内水平硐室型储库群的排列示意图;Fig. 2 is a schematic diagram of the arrangement of horizontal chamber type storage reservoirs in a single salt rock mine layer;

具体实施方式Detailed ways

实施例1Example 1

如图1、2所示,一种盐岩矿床水平硐室型油气储库3,呈硐室状,硐室沿矿层走向方向水平展布,硐室截面形状近似圆形,硐室直径介于矿层厚度的1/2~2/3,硐室长度为直径的10倍以上。As shown in Figures 1 and 2, a horizontal chamber-type oil and

本实施例的盐岩矿单层厚度为80m,设计硐室直径为50m,水平方向长度为500m。The single layer thickness of the salt rock mine in this embodiment is 80m, the designed chamber diameter is 50m, and the length in the horizontal direction is 500m.

单一水平硐室的容量有限,要满足一定容量的要求,必须建造硐室储库群(参看图2)。单一硐室储库按照一定间距在岩层中排列,即可形成油气储库群。在同一岩层至少排列2个水平硐室,形成单层储库群。The capacity of a single level chamber is limited, to meet the requirements of a certain capacity, it is necessary to build chamber storage groups (see Figure 2). The single-chamber reservoirs are arranged in the rock formation at a certain interval to form a group of oil and gas reservoirs. At least two horizontal chambers are arranged in the same rock formation to form a single-layer reservoir group.

根据力学稳定性计算,对于直径为D的单一硐室,硐室间的稳定间距为3D,本实施例设计硐室直径D为50m,那么间距L为150m。如在60km2的矿区内,可布置上百孔硐室,其排列形式如图2。According to the calculation of mechanical stability, for a single chamber with a diameter of D, the stable interval between chambers is 3D. In this embodiment, the diameter D of the chamber is designed to be 50m, so the distance L is 150m. For example, in a mining area of60km2 , hundreds of chambers can be arranged, as shown in Figure 2.

盐岩矿床水平硐室型油气储库的建造方法的步骤:The steps of the construction method of the horizontal chamber type oil and gas storage of the salt rock deposit:

I.根据地质资料,在确定矿层的物理力学特性及埋藏特征后,确定水平硐室储库的尺寸参数,并进行相应布井;I. According to geological data, after determining the physical and mechanical properties and burial characteristics of the ore bed, determine the size parameters of the horizontal chamber storage, and carry out corresponding well layout;

II.选择合理间距(500~1000m),依据定向钻井技术规范,进行垂直实施井1、目标井5的钻井与固井;II. Select a reasonable spacing (500-1000m), and perform vertical drilling and cementing of well 1 and target well 5 according to the directional drilling technical specifications;

III.在实施井1穿过泥岩夹层2后,依据计算曲率半径进行造斜,并水平进入目标盐岩矿层4,进行与目标井5的定向对接连通;III. After the implementation well 1 passes through the

IV.在目标盐岩矿层内,进行水平井的定向钻进,并与垂直目标井5对接连通;IV. In the target salt rock mineral layer, carry out directional drilling of the horizontal well, and connect with the vertical target well 5;

V.对接连通后,依据腔体的目标直径,取:溶液的温度为40℃,出卤井溶液浓度低于200g/l,溶液流速在建库初期大于1.2m/h,当腔体直径D>15m后,溶液流速不小于0.6m/h,每隔半月调换一次注水与出卤井,进行水平腔体的控制溶解建造,直至硐室形状达到近似圆形,硐室截面直径D=50m(该盐岩层厚度80m),并保留硐室最高点至顶板非盐夹层2之间距离为20m,硐室最低点至底板非盐夹层6之间距离为10m的厚度;V. After docking and connection, according to the target diameter of the cavity, take: the temperature of the solution is 40°C, the concentration of the brine well solution is lower than 200g/l, and the solution flow rate is greater than 1.2m/h at the initial stage of building the reservoir. When the cavity diameter is D After >15m, the solution flow rate is not less than 0.6m/h, and the water injection and brine wells are replaced every half a month, and the horizontal cavity is controlled and dissolved until the shape of the cavity reaches a nearly circular shape, and the cross-sectional diameter of the cavity is D = 50m ( The thickness of the salt rock layer is 80m), and the distance between the highest point of the chamber and the

VI.储库建造完成后,根据相应的储库建造规范及要求,进行储库并身及腔体密封耐压测试,保证储库的密封性,并验证储库腔体的运行极限压力;VI. After the storage building is completed, according to the corresponding storage building specifications and requirements, carry out the storage tank body and cavity sealing pressure test to ensure the tightness of the storage tank and verify the operating limit pressure of the storage cavity;

VII.在满足硐室规定间距的条件下,重复上述步骤II~VI,进行新的水平储库的建造施工,直至所有井全部完成,在该盐岩矿床内形成大型储库群。VII. Under the condition that the specified distance between the chambers is met, repeat the above steps II-VI to carry out the construction of a new horizontal storage until all the wells are completed, and a large storage group is formed in the salt rock deposit.

实施例2Example 2

如图1、2所示,一种盐岩矿床水平硐室型油气储库3,呈硐室状,硐室截面形状近似圆形,硐室沿矿层水平展布,水平硐室的展布方位、长度、硐室腔体半径根据盐岩矿层的赋存特征及厚度而定。As shown in Figures 1 and 2, a horizontal chamber-type oil and

本实施例的盐岩矿单层厚度为60m,设计硐室直径为30m,水平方向长度为300m。The single layer thickness of the salt rock mine in this embodiment is 60m, the designed chamber diameter is 30m, and the length in the horizontal direction is 300m.

单一水平硐室的容量有限,要满足一定容量的要求,必须建造硐室储库群(参看图2)。单一硐室储库按照一定间距在岩层中排列,即可形成油气储库群。在同一岩层至少排列2个水平硐室,形成单层储库群。The capacity of a single level chamber is limited, to meet the requirements of a certain capacity, it is necessary to build chamber storage groups (see Figure 2). The single-chamber reservoirs are arranged in the rock formation at a certain interval to form a group of oil and gas reservoirs. At least two horizontal chambers are arranged in the same rock formation to form a single-layer reservoir group.

根据力学稳定性计算,对于直径为D的单一硐室,硐室间的稳定间距为3D,本实施例设计硐室直径D为30m,那么间距L为90m。According to the calculation of mechanical stability, for a single chamber with a diameter of D, the stable distance between chambers is 3D. In this embodiment, the chamber diameter D is designed to be 30m, and the distance L is 90m.

盐岩矿床水平硐室型油气储库的建造方法的步骤:The steps of the construction method of the horizontal chamber type oil and gas storage of the salt rock deposit:

I.根据地质资料,在确定矿层的物理力学特性及埋藏特征后,确定水平硐室储库的尺寸参数,并进行相应布井;I. According to geological data, after determining the physical and mechanical properties and burial characteristics of the ore bed, determine the size parameters of the horizontal chamber storage, and carry out corresponding well layout;

II.选择合理间距(300~600m),依据定向钻井技术规范,进行垂直实施井1、目标井5的钻进与固井;II. Select a reasonable spacing (300-600m), and carry out the drilling and cementing of the vertical implementation well 1 and the target well 5 according to the directional drilling technical specifications;

III.在实施井1穿过泥岩夹层2后,依据计算曲率半径进行造斜,并水平进入目标盐岩矿层4,进行与目标井5的定向对接连通;III. After the implementation well 1 passes through the

IV.对接连通后,依据腔体的目标直径,取:溶液的温度为100℃,出卤井溶液浓度低于200g/l,溶液流速在建库初期大于1.2m/h,当腔体直径D>10m后,溶液流速不小于0.6m/h,每隔半月调换一次注水与出卤井,进行水平腔体的控制溶解建造,直至硐室形状达到近似圆形,硐室截面直径D=30m(该盐岩层厚度60m),并保留硐室最高点至顶板非盐夹层2之间距离为20m,硐室最低点至底板非盐夹层6之间距离为10m的厚度;IV. After docking and connection, according to the target diameter of the cavity, take: the temperature of the solution is 100°C, the concentration of the brine well solution is lower than 200g/l, and the flow rate of the solution is greater than 1.2m/h at the initial stage of building the reservoir. When the cavity diameter is D After >10m, the solution flow rate is not less than 0.6m/h, and the water injection and brine wells are replaced every half a month, and the horizontal cavity is controlled and dissolved until the shape of the cavity is approximately circular, and the cross-sectional diameter of the cavity is D = 30m ( The thickness of the salt rock layer is 60m), and the distance between the highest point of the chamber and the

V.储库建造完成后,根据相应的储库建造规范及要求,进行储库井身及腔体密封耐压测试,保证储库的密封性,并验证储库腔体的运行极限压力;V. After the storage building is completed, according to the corresponding storage building specifications and requirements, carry out the storage well body and cavity sealing pressure test to ensure the sealing of the storage, and verify the operating limit pressure of the storage cavity;

VI.在满足硐室规定间距的条件下,重复上述步骤II~V,进行新的水平储库的建造施工,直至所有井全部完成,在该盐岩矿床内形成大型储库群。VI. Under the condition that the specified distance between the chambers is met, repeat the above steps II to V, and carry out the construction of a new horizontal storage until all the wells are completed, and a large storage group is formed in the salt rock deposit.

Claims (5)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNB2005100124700ACN100392209C (en) | 2005-04-20 | 2005-04-20 | Salt rock deposit horizontal chamber type oil and gas storage and its construction method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNB2005100124700ACN100392209C (en) | 2005-04-20 | 2005-04-20 | Salt rock deposit horizontal chamber type oil and gas storage and its construction method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1676880A CN1676880A (en) | 2005-10-05 |

| CN100392209Ctrue CN100392209C (en) | 2008-06-04 |

Family

ID=35049590

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB2005100124700AExpired - Fee RelatedCN100392209C (en) | 2005-04-20 | 2005-04-20 | Salt rock deposit horizontal chamber type oil and gas storage and its construction method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN100392209C (en) |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101315025B (en)* | 2008-06-05 | 2011-09-21 | 太原理工大学 | A method for constructing a salt rock karst cavity gas storage |

| CN102102536B (en)* | 2010-12-15 | 2013-02-13 | 中国神华能源股份有限公司 | Method for storing gas by using abandoned tunnel |

| CN102587982B (en)* | 2012-03-12 | 2013-01-23 | 中国石油大学(华东) | Underground salt cavern gas storage groups and method for constructing same |

| CN102828777B (en)* | 2012-09-19 | 2015-07-29 | 重庆大学 | Double-vertical shaft horizontal butt joint salt cavern deposit construction method |

| CN102828778B (en)* | 2012-09-24 | 2014-11-05 | 重庆大学 | Complex salt rock underground and water dissolution joint cavity construction method |

| CN103850711B (en)* | 2012-11-29 | 2016-08-10 | 中国石油天然气集团公司 | Salt hole air reserved storeroom twin-well banking process |

| CN103291331B (en)* | 2013-06-14 | 2015-09-16 | 中国电建集团成都勘测设计研究院有限公司 | Underground cavern group layout method |

| CN103266902B (en)* | 2013-06-14 | 2015-06-17 | 中国电建集团成都勘测设计研究院有限公司 | Layout design method of underground cavern group |

| CN103291332B (en)* | 2013-06-14 | 2015-04-15 | 中国电建集团成都勘测设计研究院有限公司 | Large-scale underground cavern group arrangement method |

| CN104612691B (en)* | 2014-11-27 | 2017-02-22 | 中盐勘察设计院有限公司 | Single borehole multilateral directional butted well salt mining method |

| CN105257338B (en)* | 2015-10-10 | 2017-10-17 | 中国石油天然气股份有限公司 | Vertical segmented cavity dissolving method for salt cavern of gas storage |

| CN106481360B (en)* | 2016-05-11 | 2018-11-20 | 江苏井神盐化股份有限公司 | A kind of twin-well asymmetry adopts halogen and quickly builds salt cave Tank Process |

| CN108087024A (en)* | 2017-12-13 | 2018-05-29 | 中盐勘察设计院有限公司 | A kind of method of construction of tunnel type salt cave storage cavern |

| CN108590760B (en)* | 2018-04-30 | 2019-04-19 | 西安科技大学 | Energy deep well underground storage and transportation system and construction method thereof |

| CN108561184B (en)* | 2018-04-30 | 2019-04-19 | 西安科技大学 | A kind of energy storage group built under mine and its construction method |

| CN109751022B (en)* | 2019-01-29 | 2019-08-27 | 江苏苏盐井神股份有限公司 | A kind of note gas production method of connected well salt hole air reserved storeroom |

| CN111236904B (en)* | 2020-01-19 | 2021-03-23 | 中国地质科学院勘探技术研究所 | Geothermal exploitation method for double horizontal wells in butt joint communication to extract heat by water separation |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB958745A (en)* | 1961-12-04 | 1964-05-27 | Continental Oil Co | Methods of constructing subterranean storage cavities |

| GB1267681A (en)* | 1969-05-01 | 1972-03-22 | Exxon Research Engineering Co | Underground storage for liquefied gas, particularly liquefied natural gas |

| EP0075973A1 (en)* | 1981-09-18 | 1983-04-06 | BBC Brown Boveri AG | Storage cavern for air under constant pressure with a hydraulic pressure compensation for a gas turbine power plant |

| US5431482A (en)* | 1993-10-13 | 1995-07-11 | Sandia Corporation | Horizontal natural gas storage caverns and methods for producing same |

| WO2000031376A2 (en)* | 1998-11-20 | 2000-06-02 | Cdx Gas, Llc | Method and system for accessing subterranean deposits from the surface |

| JP2001082694A (en)* | 1999-09-16 | 2001-03-30 | Shimizu Corp | High pressure gas storage facility in rock |

| DE10117617A1 (en)* | 2001-04-07 | 2002-10-10 | Ruhrgas Ag | System for storing fluid in underground hollow chamber comprises storage chamber for displacement fluid formed as underground hollow chamber |

- 2005

- 2005-04-20CNCNB2005100124700Apatent/CN100392209C/ennot_activeExpired - Fee Related

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB958745A (en)* | 1961-12-04 | 1964-05-27 | Continental Oil Co | Methods of constructing subterranean storage cavities |

| GB1267681A (en)* | 1969-05-01 | 1972-03-22 | Exxon Research Engineering Co | Underground storage for liquefied gas, particularly liquefied natural gas |

| EP0075973A1 (en)* | 1981-09-18 | 1983-04-06 | BBC Brown Boveri AG | Storage cavern for air under constant pressure with a hydraulic pressure compensation for a gas turbine power plant |

| US5431482A (en)* | 1993-10-13 | 1995-07-11 | Sandia Corporation | Horizontal natural gas storage caverns and methods for producing same |

| WO2000031376A2 (en)* | 1998-11-20 | 2000-06-02 | Cdx Gas, Llc | Method and system for accessing subterranean deposits from the surface |

| JP2001082694A (en)* | 1999-09-16 | 2001-03-30 | Shimizu Corp | High pressure gas storage facility in rock |

| DE10117617A1 (en)* | 2001-04-07 | 2002-10-10 | Ruhrgas Ag | System for storing fluid in underground hollow chamber comprises storage chamber for displacement fluid formed as underground hollow chamber |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1676880A (en) | 2005-10-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100392209C (en) | Salt rock deposit horizontal chamber type oil and gas storage and its construction method | |

| CN102587980B (en) | Multiple-interlayer salt cavern gas storage and building method of multiple-interlayer salt cavern gas storage | |

| CN101315025B (en) | A method for constructing a salt rock karst cavity gas storage | |

| CN102828777B (en) | Double-vertical shaft horizontal butt joint salt cavern deposit construction method | |

| CN105041289B (en) | Method for forming multiple seams by temporarily blocking seam and forcibly turning plane | |

| CN101881151B (en) | Rapid solution construction method for rock salt cavity | |

| CN104727795B (en) | The low very thin layering water jet exploitation anti-reflection method of permeability soft seam | |

| CN107830907B (en) | A dynamic design method for water curtain system structure of underground water-sealed cavern | |

| CN109187321B (en) | Large-size salt level communication well group water-soluble cavity-making simulation experiment method | |

| CN104790918B (en) | Method for mining coal bed gas from cluster well and horizontal well combined ground under complex terrain condition | |

| CN116557067B (en) | Pressure balance compensation device and method for gas production process of communicated well salt cavern gas storage | |

| CN107035343A (en) | A kind of rock salt cavern method of construction and its application based on to the well exploitation old well of formula | |

| CN115234302A (en) | Method for building gas storage cavity through layered rock salt twin-well convection | |

| CN117605533B (en) | A method for regulating and expanding the intermittent period of gas storage in an L-shaped cavity gas storage reservoir with connected wells | |

| CN102828778B (en) | Complex salt rock underground and water dissolution joint cavity construction method | |

| CN107859506B (en) | Method for determining gas injection parameters of carbon dioxide flooding layered gas injection well | |

| CN117108258A (en) | Accurate advanced gas treatment method for large area of underground thick coal seam of coal mine | |

| CN115324646A (en) | Horizontal salt cavity construction method for thin salt layer reservoir construction | |

| CN103742119B (en) | The water-soluble high-pressure bittern feed system making chamber experiment of a kind of rock salt bank | |

| CN116044506A (en) | Layered rapid cavity-making method for salt cavern storage | |

| CN105134151A (en) | Hot nitrogen energy increase, viscosity reduction and production increase technology | |

| CN117868755B (en) | Marine natural gas hydrate reservoir combined production device and combined production method | |

| CN110230897B (en) | Dry heat single pump geothermal system and construction method thereof | |

| CN117514351A (en) | A method of arranging hydrogen storage using abandoned mine coal pillars | |

| CN115688396B (en) | Extraction-injection ratio determination method for in-situ leaching uranium mining well site extraction-injection mode |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20080604 Termination date:20100420 |